Professional Documents

Culture Documents

Brake System PDF

Brake System PDF

Uploaded by

Albert BriceñoCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Customer PDFDocument2 pagesCustomer PDFSuraj BhandariNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Gehl SL 4640 4840 5640 6640 Parts ManualDocument2 pagesGehl SL 4640 4840 5640 6640 Parts ManualautobritaiNo ratings yet

- Preparation 2zr-Fe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

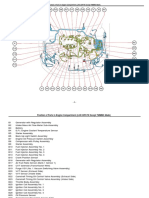

- B23 B22 B25 B26 B17 B27 B28 B20 B19 B4 B2 B31: Position of Parts in Engine Compartment (LHD 2ZR-FE Except TMMMS Made)Document4 pagesB23 B22 B25 B26 B17 B27 B28 B20 B19 B4 B2 B31: Position of Parts in Engine Compartment (LHD 2ZR-FE Except TMMMS Made)Albert BriceñoNo ratings yet

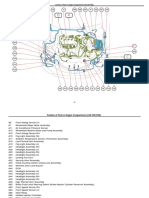

- B22 B25 B23 B26 B27 B28 B20 B66 B21 B31 B29 B67: Position of Parts in Engine Compartment (LHD 2ZR-FE TMMMS Made)Document4 pagesB22 B25 B23 B26 B27 B28 B20 B66 B21 B31 B29 B67: Position of Parts in Engine Compartment (LHD 2ZR-FE TMMMS Made)Albert BriceñoNo ratings yet

- D1 A32 A66 A65 A40 A62 A7 A64 A34: Position of Parts in Engine Compartment (LHD 3ZR-FBE)Document4 pagesD1 A32 A66 A65 A40 A62 A7 A64 A34: Position of Parts in Engine Compartment (LHD 3ZR-FBE)Albert BriceñoNo ratings yet

- Position of Parts in Engine Compartment (RHD 2ZR-FE)Document5 pagesPosition of Parts in Engine Compartment (RHD 2ZR-FE)Albert BriceñoNo ratings yet

- Preparation 2zr-Fbe Engine Mechanical Equipment PDFDocument1 pagePreparation 2zr-Fbe Engine Mechanical Equipment PDFAlbert BriceñoNo ratings yet

- B23 B22 B25 B26 B17 B27 B28 B20 B19 B21 B4 B72 B73 B2 B31: Position of Parts in Engine Compartment (LHD 3ZR-FBE)Document4 pagesB23 B22 B25 B26 B17 B27 B28 B20 B19 B21 B4 B72 B73 B2 B31: Position of Parts in Engine Compartment (LHD 3ZR-FBE)Albert BriceñoNo ratings yet

- Preparation 2zr-Fbe Engine Mechanical Recommended ToolsDocument2 pagesPreparation 2zr-Fbe Engine Mechanical Recommended ToolsAlbert BriceñoNo ratings yet

- Preparation 1zr-Fe Engine Mechanical Recommended Tools PDFDocument2 pagesPreparation 1zr-Fe Engine Mechanical Recommended Tools PDFAlbert BriceñoNo ratings yet

- Preparation 1zr-Fe Engine Mechanical SSMDocument1 pagePreparation 1zr-Fe Engine Mechanical SSMAlbert BriceñoNo ratings yet

- Preparation 2zr-Fe Engine Control Equipment PDFDocument1 pagePreparation 2zr-Fe Engine Control Equipment PDFAlbert BriceñoNo ratings yet

- Preparation 1zr-Fae Engine Mechanical SSTDocument4 pagesPreparation 1zr-Fae Engine Mechanical SSTAlbert BriceñoNo ratings yet

- Preparation 2zr-Fbe Engine Mechanical SSMDocument1 pagePreparation 2zr-Fbe Engine Mechanical SSMAlbert BriceñoNo ratings yet

- Preparation 3zr-Fbe Engine Control Recommended ToolsDocument1 pagePreparation 3zr-Fbe Engine Control Recommended ToolsAlbert BriceñoNo ratings yet

- Preparation 1zr-Fe Engine Mechanical Equipment PDFDocument1 pagePreparation 1zr-Fe Engine Mechanical Equipment PDFAlbert BriceñoNo ratings yet

- Preparation 2zr-Fe Engine Control Equipment PDFDocument1 pagePreparation 2zr-Fe Engine Control Equipment PDFAlbert BriceñoNo ratings yet

- Preparation 2zr-Fbe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fbe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

- GENERAL INFORMATION Vehicle Data - Ram Pickup PDFDocument14 pagesGENERAL INFORMATION Vehicle Data - Ram Pickup PDFcharlesNo ratings yet

- Specifications M4900SUD 4Wd Rops Model M4900 2WD 4WD, ROPS and CabDocument3 pagesSpecifications M4900SUD 4Wd Rops Model M4900 2WD 4WD, ROPS and Cabمہرؤآنہ آبہرآهہيہمہNo ratings yet

- 7010 7011 7012hgc5bc E-En-Sg Rough-Terrain-F1.8-5ut F1.8-3.5ut4 Brochure Low-ResDocument8 pages7010 7011 7012hgc5bc E-En-Sg Rough-Terrain-F1.8-5ut F1.8-3.5ut4 Brochure Low-ResKobusNo ratings yet

- Ford Cortina GT MK 1 - NBDocument6 pagesFord Cortina GT MK 1 - NBabelcardenNo ratings yet

- Penawaran PT Atn Besquip (John Deere 2653b)Document1 pagePenawaran PT Atn Besquip (John Deere 2653b)Muhammad IqbalNo ratings yet

- Comperative Analysis On Sales &: Marketing in Automobile IndustryDocument94 pagesComperative Analysis On Sales &: Marketing in Automobile Industryshakti shankerNo ratings yet

- Catálogo Kit Retenes-Guardapolvos Horquilla: TLF. 952 09 10 31 FAX. 951 99 17 39 MOVIL: 677 77 24 71 Web. E-MailDocument14 pagesCatálogo Kit Retenes-Guardapolvos Horquilla: TLF. 952 09 10 31 FAX. 951 99 17 39 MOVIL: 677 77 24 71 Web. E-MailRamiro CastellanosNo ratings yet

- 98 ZJDocument393 pages98 ZJcarminezarrellaNo ratings yet

- Automobile CSVDocument8 pagesAutomobile CSVdhaval kulkarniNo ratings yet

- Lista Gran Mayor y Detales 19-02-2022Document621 pagesLista Gran Mayor y Detales 19-02-2022Carlos LiendoNo ratings yet

- RG Body PDFDocument1,396 pagesRG Body PDFNolberto CastilloNo ratings yet

- HImachal Taxi RatesDocument5 pagesHImachal Taxi RatesKshitiz SharmaNo ratings yet

- Kicker Mopar Application ChartDocument6 pagesKicker Mopar Application ChartStephane GlaudeNo ratings yet

- 4017RS Telehndler Spec Sheet LAEngDocument2 pages4017RS Telehndler Spec Sheet LAEngmetroroadNo ratings yet

- FMVSS 203Document2 pagesFMVSS 203Tomáš RybaNo ratings yet

- Charudatta Ughade SIP Final ProjectDocument64 pagesCharudatta Ughade SIP Final Projectkasimmalnas.ipsNo ratings yet

- Reading Practice 6Document2 pagesReading Practice 6Doaa AhmedNo ratings yet

- GS-2669DC GS-3369DC GS-4069DC: Serial Number RangeDocument164 pagesGS-2669DC GS-3369DC GS-4069DC: Serial Number Rangesolidsnake019No ratings yet

- 2017 Hawk Complete Catalog Med Res PDFDocument516 pages2017 Hawk Complete Catalog Med Res PDFDavid ChowNo ratings yet

- Parts Manual (EN) : Read The Operators Manual Before Using The MachineDocument22 pagesParts Manual (EN) : Read The Operators Manual Before Using The MachineVüsal 1No ratings yet

- Case Study3Document2 pagesCase Study3only_rushi4everNo ratings yet

- FSAE EV - Virtual SDPS PresentationDocument23 pagesFSAE EV - Virtual SDPS PresentationStewart PrinceNo ratings yet

- Documento de Osvaldo NavarroDocument92 pagesDocumento de Osvaldo Navarroa cNo ratings yet

- Multicab BusinessDocument6 pagesMulticab BusinessMichelle GoNo ratings yet

- 2034Document1 page2034Seshagiri DeenadayaluNo ratings yet

- Specialized - Sell Sheet - Turbo Levo SL CompDocument1 pageSpecialized - Sell Sheet - Turbo Levo SL CompMTB-VCONo ratings yet

- Nissan Almera P1251 Engine Trouble Code - Nissan Almera P1251 OBD-II Diagnostic Powertrain (P) Trouble Code For Nissan Almera PDFDocument2 pagesNissan Almera P1251 Engine Trouble Code - Nissan Almera P1251 OBD-II Diagnostic Powertrain (P) Trouble Code For Nissan Almera PDFJoaquin Enrique Rivas HungNo ratings yet

- NPR-HD Diesel SpecsDocument1 pageNPR-HD Diesel SpecsHuawei Serie PNo ratings yet

Brake System PDF

Brake System PDF

Uploaded by

Albert BriceñoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brake System PDF

Brake System PDF

Uploaded by

Albert BriceñoCopyright:

Available Formats

206-03-1 Front Disc Brake 206-03-1

REMOVAL AND INSTALLATION

Disc Brake System — Exploded View

4.0L SOHC and 4.6L (3V)

NOTE: LH shown, RH similar.

Item Part Number Description Item Part Number Description

1 — Brake caliper guide pin bolts 3 2001 Brake pads kit

(2 required) (part of 2B134, 4 — Spring clips (4 required) (part

also part of 2001) of 2001)

2 2C357 RH/ Brake caliper 5 W710233 Brake caliper anchor plate

2C358 LH bolts (2 required)

(Continued) (Continued)

Copyright 2006, Ford Motor Company

Last updated: 6/19/2006 2007 Mustang, Mustang GT 8/2006

206-03-2 Front Disc Brake 206-03-2

REMOVAL AND INSTALLATION (Continued)

Item Part Number Description Item Part Number Description

6 2B134 Brake caliper anchor plate 13 — Brake tube fittings

7 — Guide pins (part of 2B134) 14 N802191 Brake flexible hose bracket

8 1125 Brake disc bolts

9 W500020 Brake disc shield bolts (3 15 2078 RH/ Brake flexible hose

required) 2B557 LH

10 2K004 Brake disc shield 16 — Bleeder screw cap (part of

2208)

11 W712275 Brake caliper flow bolt

17 2208 Bleeder screw

12 W712362 Copper washers (2 required)

(Continued)

2007 Mustang, Mustang GT 8/2006

206-03-3 Front Disc Brake 206-03-3

REMOVAL AND INSTALLATION (Continued)

5.4L

NOTE: RH shown, LH similar

Item Part Number Description Item Part Number Description

1 383609 Retaining nut 7 — Brake pad mounting pin (2

2 1125 Brake disc required) (part of 2B164)

3 2B220 RH/ Brake caliper 8 — Spring retainer clip (part of

2B221 LH 2K583)

4 W500020 Brake disc shield bolt (3 9 N802191 Brake hose-to-strut bolt

required) 10 W710233 Brake caliper bolt (2

5 2K004 Brake disc shield required)

6 2001 Brake pad (2 required) 11 — Brake tube fitting

(Continued)

(Continued)

2007 Mustang, Mustang GT 8/2006

206-03-4 Front Disc Brake 206-03-4

REMOVAL AND INSTALLATION (Continued)

Item Part Number Description 1. NOTE: A revised part, with the same base part

12 N802191 Brake hose bracket-to-body number, has been released for the RH brake

bolt hose. When installing a new RH brake hose,

13 2078 RH/ Brake flexible hose position the anti-rotation tab on the mounting

2B557 LH bracket toward the front of the vehicle and

14 W712362 Copper washer (2 required) install the bolt with the head toward the rear of

the vehicle.

15 W712275 Brake caliper flow bolt

For additional information, refer to the

procedures in this section.

2007 Mustang, Mustang GT 8/2006

206-09-1 Vehicle Dynamic Systems 206-09-1

REMOVAL AND INSTALLATION

Anti-Lock Brake System (ABS)

Module

Item Part Number Description

1 — Anti-lock brake system (ABS)

module electrical connector

(part of 14A005)

2 ZD061 ABS module screws (4

required)

3 2C219 ABS module

Copyright 2006, Ford Motor Company

Last updated: 6/19/2006 2007 Mustang, Mustang GT 8/2006

206-09-2 Vehicle Dynamic Systems 206-09-2

REMOVAL AND INSTALLATION (Continued)

Removal and Installation 4. Remove the 4 screws and the ABS module.

• To install, tighten to 3 Nm (27 lb-in) in the

CAUTION: Electronic modules are sequence shown.

sensitive to electrical charges. The anti-lock

brake system (ABS) module can be damaged if

exposed to these charges.

1. Disconnect the battery ground cable. For

additional information, refer to Section 414-01.

2. Remove the air cleaner assembly. For additional

information, refer to Section 303-12.

3. Disconnect the ABS module electrical

connector.

5. To install, reverse the removal procedure.

2007 Mustang, Mustang GT 8/2006

206-09-1 Vehicle Dynamic Systems 206-09-1

DIAGNOSIS AND TESTING

Anti-Lock Control The ABS module is self-monitoring. When the

ignition switch is turned to the run position, the

Special Tool(s) ABS module does a preliminary electrical check

Vehicle Communication Module and, at approximately 12 km/h (8 mph), the pump

(VCM) and Integrated motor is turned on for approximately one

Diagnostic System (IDS) half-second. Any malfunction of the ABS causes

software with appropriate the ABS to shut OFF and the yellow ABS warning

hardware, or equivalent scan

indicator to illuminate, however normal power

tool

assisted braking remains.

The traction control system controls wheelspin by

73III Digital Multi-meter modulating engine torque and by applying and

105-R0057 or equivalent releasing the appropriate rear brake to restore

traction when driving on slippery or loose surfaces.

The traction control system can be disabled by

pressing the traction control switch and is indicated

by an indicator lamp in the traction control switch.

The traction control will reset and return to normal

Flex Probe Kit traction assist when the ignition switch is cycled or

418-F090 (105-R025B) or

equivalent when the traction control switch is pressed and

released a second time.

Inspection and Verification

1. Verify the customer concern.

2. Verify the stoplamps operate correctly by

Principles of Operation applying and releasing the brake pedal with the

The anti-lock brake system (ABS) module receives ignition switch in the OFF position. If the

wheel speed readings from each wheel speed sensor stoplamps do not operate correctly, refer to

and processes this information to determine if an Section 417-01. If the stoplamps operate

ABS event is necessary. The wheel speed sensor correctly, proceed to the next step.

electrically senses each tooth of the wheel speed 3. Visually inspect for obvious signs of

sensor indicators as it passes through the wheel mechanical or electrical damage:

speed sensor’s magnetic field.

Visual Inspection Chart

The ABS module continuously monitors and

compares the rotational speed of each wheel and, Mechanical Electrical

when it detects an impending wheel lock, modulates • Brake fluid level • Bussed electrical center

hydraulic brake pressure to the appropriate brake • Tire inflation (BEC) fuse(s):

caliper. This is accomplished by the ABS module • Wheel and tire sizes — 8 (40A)

triggering the hydraulic control unit (HCU) to open • Steering components — 65 (30A)

and suspension • Smart junction box

and close the appropriate solenoid valves. Once the

components (SJB) fuse 18 (10A)

affected wheel returns to normal speed, the ABS • Base brake system • Circuitry

module returns the solenoid valves to their normal • Wheel speed sensor ring • Brake fluid level switch

position and normal (base) braking resumes. • HCU • Stoplamp switch

• Wheel speed sensor

• Anti-lock brake system

(ABS) module

• Traction control switch

4. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

Copyright 2006, Ford Motor Company

Last updated: 6/19/2006 2007 Mustang, Mustang GT 8/2006

206-09-2 Vehicle Dynamic Systems 206-09-2

DIAGNOSIS AND TESTING (Continued)

5. NOTE: Make sure to use the latest scan tool • refer to Section 418-00 to diagnose no

software release. response from the powertrain control module

If the cause is not visually evident, connect the (PCM).

scan tool to the data link connector (DLC). 8. Carry out the network test.

6. NOTE: The vehicle communication module • If the scan tool responds with no

(VCM) LED prove out confirms power and communication for one or more modules,

ground from the DLC are provided to the refer to Section 418-00.

VCM. • If the network test passes, retrieve and

If the scan tool does not communicate with the record continuous memory diagnostic

VCM: trouble codes (DTCs).

• check the VCM connection to the vehicle. 9. Clear the continuous DTCs and carry out the

• check the scan tool connection to the VCM. self-test diagnostics for the anti-lock brake

system (ABS) module.

• refer to Section 418-00, No Power To The

Scan Tool, to diagnose no communication 10. If the DTCs retrieved are related to the concern,

with the scan tool. go to the Anti-Lock Brake System (ABS)

Module Diagnostic Trouble Code (DTC) Chart.

7. If the scan tool does not communicate with the For all other DTCs, refer to Section 419-10.

vehicle:

11. If no DTCs related to the concern are retrieved,

• verify the ignition key is in the ON position. GO to Symptom Chart.

• verify the scan tool operation with a known

good vehicle.

Anti-Lock Brake System (ABS) Module Diagnostic Trouble Code (DTC) Chart

DTC Description Source Action

B1317 Battery Voltage High ABS Module GO to Pinpoint Test A.

B1318 Battery Voltage Low ABS Module GO to Pinpoint Test A.

B1342 ECU is Faulted ABS Module NOTE: If other DTCs are present, repair

them before installing a new module.

CLEAR the DTCs. RETRIEVE the

DTCs. If DTC B1342 is retrieved again,

INSTALL a new ABS module. REFER

to Anti-Lock Brake System (ABS)

Module in this section. REPEAT the

self-test.

C1093 Traction Control Disable Switch Circuit Instrument GO to Pinpoint Test H.

Failure Cluster

C1095 ABS Hydraulic Pump Motor Circuit ABS Module GO to Pinpoint Test B.

Failure

C1096 ABS Hydraulic Pump Motor Circuit ABS Module GO to Pinpoint Test B.

Open

C1115 ABS Power Relay Output Short Circuit ABS Module CLEAR all DTCs. DRIVE the vehicle. If

to Battery DTC C1115 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

C1145 Wheel Speed Sensor RF Input Circuit ABS Module GO to Pinpoint Test C.

Failure

2007 Mustang, Mustang GT 8/2006

206-09-3 Vehicle Dynamic Systems 206-09-3

DIAGNOSIS AND TESTING (Continued)

Anti-Lock Brake System (ABS) Module Diagnostic Trouble Code (DTC) Chart (Continued)

DTC Description Source Action

C1155 Wheel Speed Sensor LF Input Circuit ABS Module GO to Pinpoint Test C.

Failure

C1165 Wheel Speed Sensor RR Input Circuit ABS Module GO to Pinpoint Test C.

Failure

C1175 Wheel Speed Sensor LR Input Circuit ABS Module GO to Pinpoint Test C.

Failure

C1185 ABS Power Relay Output Circuit Failure ABS Module CLEAR all DTCs. If DTC C1185 is

retrieved again, INSTALL a new ABS

module. REFER to Anti-Lock Brake

System (ABS) Module in this section.

CARRY OUT the self-test with the brake

pedal not applied.

C1194 ABS Outlet Valve Coil LF Circuit ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Failure DTC C1194 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

C1198 ABS Inlet Valve Coil LF Circuit Failure ABS Module CLEAR all DTCs. DRIVE the vehicle. If

DTC C1198 is retrieved again, INSTALL

a new ABS module. INSTALL a new

ABS module. REFER to Anti-Lock

Brake System (ABS) Module in this

section. CARRY OUT the self-test with

the brake pedal not applied.

C1210 ABS Outlet Valve Coil RF Circuit ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Failure DTC C1210 is retrieved again, INSTALL

a new ABS module. INSTALL a new

ABS module. REFER to Anti-Lock

Brake System (ABS) Module in this

section. CARRY OUT the self-test with

the brake pedal not applied.

C1214 ABS Inlet Valve Coil RF Circuit Failure ABS Module CLEAR all DTCs. DRIVE the vehicle. If

DTC C1214 is retrieved again, INSTALL

a new ABS module. INSTALL a new

ABS module. REFER to Anti-Lock

Brake System (ABS) Module in this

section. CARRY OUT the self-test with

the brake pedal not applied.

C1222 Wheel Speed Mismatch ABS Module GO to Pinpoint Test D.

C1233 Wheel Speed LF Input Signal Missing ABS Module GO to Pinpoint Test D.

C1234 Wheel Speed RF Input Signal Missing ABS Module GO to Pinpoint Test D.

C1235 Wheel Speed RR Input Signal Missing ABS Module GO to Pinpoint Test D.

C1236 Wheel Speed LR Input Signal Missing ABS Module GO to Pinpoint Test D.

2007 Mustang, Mustang GT 8/2006

206-09-4 Vehicle Dynamic Systems 206-09-4

DIAGNOSIS AND TESTING (Continued)

Anti-Lock Brake System (ABS) Module Diagnostic Trouble Code (DTC) Chart (Continued)

DTC Description Source Action

C1242 ABS Outlet Valve Coil LR Circuit ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Failure DTC C1242 is retrieved again, INSTALL

a new ABS module. INSTALL a new

ABS module. REFER to Anti-Lock

Brake System (ABS) Module in this

section. CARRY OUT the self-test with

the brake pedal not applied.

C1246 ABS Outlet Valve Coil RR Circuit ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Failure DTC C1246 is retrieved again, INSTALL

a new ABS module. INSTALL a new

ABS module. REFER to Anti-Lock

Brake System (ABS) Module in this

section. CARRY OUT the self-test with

the brake pedal not applied.

C1250 ABS Inlet Valve Coil LR Circuit Failure ABS Module CLEAR all DTCs. DRIVE the vehicle. If

DTC C1250 is retrieved again, INSTALL

a new ABS module. INSTALL a new

ABS module. REFER to Anti-Lock

Brake System (ABS) Module in this

section. CARRY OUT the self-test with

the brake pedal not applied.

C1254 ABS Inlet Valve Coil RR Circuit Failure ABS Module CLEAR all DTCs. DRIVE the vehicle. If

DTC C1254 is retrieved again, INSTALL

a new ABS module. INSTALL a new

ABS module. REFER to Anti-Lock

Brake System (ABS) Module in this

section. CARRY OUT the self-test with

the brake pedal not applied.

C1329 ABS Valve Outlet Coil Over RF ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Temperature DTC C1329 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

C1330 ABS Valve Outlet Coil Over LR ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Temperature DTC C1330 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

C1331 ABS Valve Outlet Coil Over RR ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Temperature DTC C1331 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

2007 Mustang, Mustang GT 8/2006

206-09-5 Vehicle Dynamic Systems 206-09-5

DIAGNOSIS AND TESTING (Continued)

Anti-Lock Brake System (ABS) Module Diagnostic Trouble Code (DTC) Chart (Continued)

DTC Description Source Action

C1332 ABS Valve Outlet Coil Over LF ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Temperature DTC C1332 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

C1333 ABS Valve Inlet Coil Over RF ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Temperature DTC C1333 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

C1334 ABS Valve Inlet Coil Over LR ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Temperature DTC C1334 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

C1335 ABS Valve Inlet Coil Over RR ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Temperature DTC C1335 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

C1336 ABS Valve Inlet Coil Over LF ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Temperature DTC C1336 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

C1404 Traction Control Valve Rear Circuit ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Failure DTC C1404 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

C1446 Brake Switch Circuit Failure ABS Module GO to Pinpoint Test F.

C1527 ABS TC Valve Inlet Coil Over ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Temperature DTC C1527 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

2007 Mustang, Mustang GT 8/2006

206-09-6 Vehicle Dynamic Systems 206-09-6

DIAGNOSIS AND TESTING (Continued)

Anti-Lock Brake System (ABS) Module Diagnostic Trouble Code (DTC) Chart (Continued)

DTC Description Source Action

C1531 ABS TC Valve Outlet Coil Over ABS Module CLEAR all DTCs. DRIVE the vehicle. If

Temperature DTC C1531 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

C1730 Reference Voltage Out of Range (+5 V) ABS Module If any other DTC(s) are present,

DIAGNOSE those DTC(s) first. CLEAR

all DTCs. DRIVE the vehicle. If the

DTC is still present, INSTALL a new

ABS module. REFER to Anti-Lock

Brake System (ABS) Module in this

section. CARRY OUT the self-test with

the brake pedal not applied.

C1958 ABS TC Valve Outlet Coil Failure ABS Module CLEAR all DTCs. DRIVE the vehicle. If

DTC C1958 is retrieved again, INSTALL

a new ABS module. REFER to

Anti-Lock Brake System (ABS) Module

in this section. CARRY OUT the

self-test with the brake pedal not

applied.

U0073 CAN Bus Off — Transmit Error ABS Module REFER to Section 418-00.

U1900 CAN Communication Bus Fault — ABS Module REFER to Section 418-00.

Receive Error

U2011 Module Transmitted Invalid Data ABS Module VERIFY powertrain control module

(PCM) configuration. If PCM is not

correctly configured, CONFIGURE the

PCM. If the PCM is correctly configured,

REFER to Section 418-00.

Symptom Chart

Symptom Chart

Condition Possible Sources Action

• No communication with the • Circuitry • Refer to Section 418-00 to

anti-lock brake system (ABS) • ABS module diagnose the no

module communications problem.

• No communication with the • Circuitry • Refer to Section 418-00 to

instrument cluster • Instrument cluster diagnose the no

communication problem.

• The red brake warning • Circuitry • Refer to Section 413-01 to

indicator does not self-check • Instrument cluster continue diagnosis of the red

brake warning indicator.

• The red brake warning • Base brake system • Refer to Section 413-01 to

indicator stays on when the • Circuitry continue diagnosis of the red

ignition is in RUN • Low brake fluid warning brake warning indicator.

switch

• Parking brake switch

• Anti-lock brake system (ABS)

module

• Instrument cluster

2007 Mustang, Mustang GT 8/2006

206-09-7 Vehicle Dynamic Systems 206-09-7

DIAGNOSIS AND TESTING (Continued)

Symptom Chart (Continued)

Condition Possible Sources Action

• The yellow anti-lock brake • Circuitry • Refer to Section 413-01 to

system (ABS) warning • Instrument cluster continue diagnosis of the

indicator does not self-check yellow brake warning

indicator.

• Spongy/soft/low brake pedal • Air in brake hydraulic system • GO to Pinpoint Test F.

with no warning indicator • Base brake system

• Hydraulic control unit (HCU)

• Poor vehicle tracking during • Tire pressure • Refer to Section 206-00 to

anti-lock function • Air in the brake system continue diagnosis of the

• Base brake system brake system.

• Hydraulic control unit (HCU) • GO to Pinpoint Test G.

• The traction control is • Circuitry • Install a new ABS module.

inoperative • Traction control switch Refer to Anti-Lock Brake

• Anti-lock brake system (ABS) System (ABS) Module in this

module section.

• The traction control system • Circuitry • GO to Pinpoint Test H.

cannot be disabled • Traction control switch

• Instrument cluster

• Anti-lock brake system (ABS)

module

• The traction control switch • Circuitry • GO to Pinpoint Test I.

indicator is never/always on • Traction control switch

• Anti-lock brake system (ABS)

module

• Instrument cluster

Pinpoint Tests Possible Causes

Pinpoint Test A: DTCs B1317 and B1318 — • Fuse(s)

Battery Voltage High/Low • Circuit open

Refer to Wiring Diagrams Cell 42, Vehicle • Charging system

Dynamic Systems for schematic and connector • Anti-lock brake system (ABS) module

information.

Normal Operation

The vehicle electrical system voltage supplied is

within the range of 10-16 volts. Above or below

that voltage range, the DTC B1317 (Battery Voltage

High) or the DTC B1318 (Battery Voltage Low)

will be set.

Fused ignition voltage is supplied to the anti-lock

brake system (ABS) module from smart junction

box (SJB) fuse 18 (10A) along circuit 1844

(LG/RD), bussed electrical center (BEC) fuse 65

(30A) along circuit 601 (LB/BK) and BEC fuse 8

(40A) along circuit 534 (YE/LG). Ground is

provided along circuit 1205 (BK). There are 2

ground circuits, both share the same circuit number

and wire color.

2007 Mustang, Mustang GT 8/2006

206-09-8 Vehicle Dynamic Systems 206-09-8

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: DTCs B1317 AND B1318 — BATTERY VOLTAGE HIGH/LOW

CAUTION: Use the Flex Probe Kit for all test connections to prevent damage to the

wiring terminals. Do not use standard multi-meter probes.

Test Step Result / Action to Take

A1 CHECK THE BATTERY VOLTAGE

• Measure the battery voltage between the positive and negative

battery terminals with: Yes

— the key ON and the engine OFF (KOEO). GO to A2.

— the engine running. No

• Is the battery voltage between 10 and 13 volts with KOEO, REFER to Section 414-00 to continue

and between 13 and 17 volts with the engine running? diagnosis of the charging system.

A2 CHECK VOLTAGE TO THE ABS MODULE

• Key in OFF position.

• Disconnect: ABS Module C135.

• Key in ON position.

• Measure the voltage between ground and:

— ABS module C135-2, circuit 601 (LB/PK), harness side.

— ABS module C135-32, circuit 1844 (LG/RD), harness side.

Yes

GO to A3.

No

VERIFY SJB fuse 18 (10A) is OK. If OK,

REPAIR circuit 1844 (LG/RD).

VERIFY BEC fuse 65 (30A) is OK. If OK,

REPAIR circuit 601 (LB/PK).

CLEAR the DTCs. CARRY OUT the

• Are the voltages greater than 10 volts? self-test with the brake pedal not applied.

A3 CHECK THE ABS MODULE GROUND

• Key in OFF position.

• Measure the resistance between ground and:

— ABS module C135-45, circuit 1205 (BK), harness side.

— ABS module C135-16, circuit 1205 (BK), harness side.

Yes

GO to A4.

No

REPAIR the affected circuit(s). REPEAT

• Are the resistances less than 5 ohms? the self-test.

(Continued)

2007 Mustang, Mustang GT 8/2006

206-09-9 Vehicle Dynamic Systems 206-09-9

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST A: DTCs B1317 AND B1318 — BATTERY VOLTAGE HIGH/LOW (Continued)

Test Step Result / Action to Take

A4 CHECK FOR CORRECT ABS MODULE OPERATION

• Disconnect: ABS Module C135. Yes

• Check for: INSTALL a new ABS module. REFER to

— corrosion. Anti-Lock Brake System (ABS) Module in

— spread terminals. this section. CLEAR the DTCs. REPEAT

— pushed-out pins. the self-test.

• Connect the ABS module connector and make sure it seats No

correctly. The system is operating correctly at this

• Operate the system and verify the concern is still present. time. The concern may have been caused

• Is the concern still present? by a loose or corroded connector. CLEAR

the DTCs. CARRY OUT the self-test with

the brake pedal not applied.

Pinpoint Test B: DTCs C1095 and C1096 — Fused battery voltage is supplied from the bussed

ABS Hydraulic Pump Motor Circuit electrical center (BEC) fuse 8 (40A) along circuit

Failure/Open 534 (YE/LG). Ground is provided along circuit

Refer to Wiring Diagrams Cell 42, Vehicle 1205 (BK).

Dynamic Systems for schematic and connector Possible Causes

information.

• Fuse

Normal Operation

• Circuit open

Anti-lock brake system (ABS) diagnostic trouble

code (DTC) C1095 sets only when the motor is • Hydraulic pump motor

initially commanded on for 100 ms (+/-6 ms) and • Anti-lock brake system (ABS) module

the ABS hydraulic pump motor is then commanded

off and the voltage back is read after 6 ms. If the

voltage indicates the motor is spinning at less than

500 rpm, there may be a locked motor. If this

condition is detected 4 times, then a locked motor

DTC C1095 is set. The pump motor is checked for

an open circuit 2 seconds after the most recent

successful pump motor off command. If the pump

motor feedback remains greater than 0.75 volt for

more than 50 ms (+/-6 ms) after these conditions

have been met, then DTC C1096 is set.

PINPOINT TEST B: DTCs C1095 AND C1096 — ABS HYDRAULIC PUMP MOTOR CIRCUIT

FAILURE/OPEN

CAUTION: Use the Flex Probe Kit for all test connections to prevent damage to the

wiring terminals. Do not use standard multi-meter probes.

Test Step Result / Action to Take

B1 CHECK THE ABS PUMP MOTOR

• Key in ON position. Yes

• Is the ABS pump motor running all the time? INSTALL a new ABS module and

hydraulic control unit (HCU). REFER to

Anti-Lock Brake System (ABS) Module

and Hydraulic Control Unit (HCU) in this

section. CLEAR the DTCs. REPEAT the

ABS self-test.

No

GO to B2.

(Continued)

2007 Mustang, Mustang GT 8/2006

206-09-10 Vehicle Dynamic Systems 206-09-10

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST B: DTCs C1095 AND C1096 — ABS HYDRAULIC PUMP MOTOR CIRCUIT

FAILURE/OPEN (Continued)

Test Step Result / Action to Take

B2 CHECK THE PUMP MOTOR OPERATION

• Trigger the ABS module pump motor ON active command. Yes

• Does the ABS pump motor run for approximately 2 CLEAR the DTCs. CHECK the yellow ABS

seconds? warning indicator while driving the vehicle

(brakes must not be applied) above 32

km/h (20 mph). If the yellow ABS warning

indicator illuminates, RETRIEVE the

DTCs. If DTC C1096 is retrieved, GO to

B5.

If DTC C1095 is retrieved, INSTALL a new

HCU. REFER to Hydraulic Control Unit

(HCU) in this section. CLEAR the DTCs.

REPEAT the self-test.

No

TRIGGER the ABS module pump motor

OFF active command. GO to B3.

B3 CHECK CIRCUIT 534 (YE/LG) FOR AN OPEN

• Disconnect: ABS Module C135.

• Measure the voltage between ABS module C135-31, circuit 534

(YE/LG), harness side and ground.

Yes

GO to B4.

No

VERIFY BEC fuse 8 (40A) is OK. If OK,

REPAIR circuit 534 (YE/LG). CLEAR the

• Is the voltage greater than 10 volts? DTCs. REPEAT the self-test.

B4 CHECK CIRCUIT 1205 (BK) FOR AN OPEN

• Key in OFF position.

• Measure the resistance between ground and:

— ABS module C135-45, circuit 1205 (BK), harness side.

— ABS module C135-16, circuit 1205 (BK), harness side.

Yes

REPAIR the affected circuit(s). CLEAR the

DTCs. REPEAT the self-test.

No

INSTALL a new HCU. REFER to Hydraulic

Control Unit (HCU) in this section. CLEAR

• Are the resistances greater than 10,000 ohms? the DTCs. REPEAT the self-test.

(Continued)

2007 Mustang, Mustang GT 8/2006

206-09-11 Vehicle Dynamic Systems 206-09-11

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST B: DTCs C1095 AND C1096 — ABS HYDRAULIC PUMP MOTOR CIRCUIT

FAILURE/OPEN (Continued)

Test Step Result / Action to Take

B5 CHECK FOR CORRECT ABS MODULE OPERATION

• Disconnect: ABS Module C135. Yes

• Check for: INSTALL a new ABS module. REFER to

— corrosion. Anti-Lock Brake System (ABS) Module in

— spread terminals. this section. CLEAR the DTCs. REPEAT

— pushed-out pins. the self-test.

• Connect the ABS module connector and make sure it seats No

correctly. The system is operating correctly at this

• Operate the system and verify the concern is still present. time. The concern may have been caused

• Is the concern still present? by a loose or corroded connector. CLEAR

the DTCs. REPEAT the self-test.

Pinpoint Test C: DTCs C1145, C1155, C1165 Voltage and ground signals are supplied to the

and C1175 — Wheel Speed Sensor Input wheel speed sensors from the ABS module.

Circuit Failure

Possible Causes

Refer to Wiring Diagrams Cell 42, Vehicle

Dynamic Systems for schematic and connector • Circuit open

information. • Circuit shorted

Normal Operation • Wheel speed sensor

The active wheel speed sensors generate a square • Anti-lock brake system (ABS) module

wave signal that is sent to the anti-lock brake

system (ABS) module. The wheel speed sensor

circuitry connects to the ABS module through 2

wires and a connector at each wheel speed sensor.

When the ignition is turned to the run position, the

ABS module carries out a self-test by sending a

reference voltage to all of the wheel speed sensors

and their circuitry to determine if they are

functional.

PINPOINT TEST C: DTCs C1145, C1155, C1165 AND C1175 — WHEEL SPEED SENSOR INPUT CIRCUIT

FAILURE

CAUTION: Use the Flex Probe Kit for all test connections to prevent damage to the

wiring terminals. Do not use standard multi-meter probes.

Test Step Result / Action to Take

C1 CHECK THE WHEEL SPEED SENSOR CIRCUITS FOR A SHORT

TO VOLTAGE

NOTE: Both circuits must be checked for each DTC.

• Key in OFF position.

• Disconnect: ABS Module C135.

• Disconnect: Suspect Wheel Speed Sensor.

• Key in ON position.

• For DTC C1145, measure the voltage between:

— ABS module C135-26, circuit 514 (YE/RD), harness side

and ground.

— ABS module C135-27, circuit 516 (YE/BK), harness side

and ground.

• For DTC C1155, measure the voltage between:

— ABS module C135-13, circuit 522 (TN/BK), harness side

and ground.

— ABS module C135-12, circuit 521 (TN/OG), harness side

and ground.

• For DTC C1165, measure the voltage between:

— ABS module C135-44, circuit 524 (PK/BK), harness side

and ground.

— ABS module C135-43, circuit 523 (RD/PK), harness side

and ground.

(Continued)

2007 Mustang, Mustang GT 8/2006

206-09-12 Vehicle Dynamic Systems 206-09-12

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST C: DTCs C1145, C1155, C1165 AND C1175 — WHEEL SPEED SENSOR INPUT CIRCUIT

FAILURE (Continued)

Test Step Result / Action to Take

C1 CHECK THE WHEEL SPEED SENSOR CIRCUITS FOR A SHORT

TO VOLTAGE (Continued)

• For DTC C1175, measure the voltage between:

— ABS module C135-42, circuit 518 (LG/RD), harness side Yes

and ground. REPAIR the affected circuit(s). CLEAR the

— ABS module C135-41, circuit 519 (LG/BK), harness side DTCs. REPEAT the self-test.

and ground. No

• Is voltage present? GO to C2.

C2 CHECK THE WHEEL SPEED SENSOR CIRCUITS FOR A SHORT

TO GROUND

NOTE: Both circuits must be checked for each DTC.

• Key in OFF position.

• For DTC C1145, measure the resistance between:

— ABS module C135-26, circuit 514 (YE/RD), harness side

and ground.

— ABS module C135-27, circuit 516 (YE/BK), harness side

and ground.

• For DTC C1155, measure the resistance between:

— ABS module C135-13, circuit 522 (TN/BK), harness side

and ground.

— ABS module C135-12, circuit 521 (TN/OG), harness side

and ground.

• For DTC C1165, measure the resistance between:

— ABS module C135-44, circuit 524 (PK/BK), harness side

and ground.

— ABS module C135-43, circuit 523 (RD/PK), harness side

and ground.

• For DTC C1175, measure the resistance between:

— ABS module C135-42, circuit 518 (LG/RD), harness side Yes

and ground. GO to C3.

— ABS module C135-41, circuit 519 (LG/BK), harness side No

and ground. REPAIR the affected circuit(s). CLEAR the

• Are the resistances greater than 10,000 ohms? DTCs. REPEAT the self-test.

C3 CHECK THE WHEEL SPEED SENSOR CIRCUITS FOR AN OPEN

NOTE: Both circuits must be checked for each DTC.

• For DTC C1145, measure the resistance between:

— ABS module C135-26, circuit 514 (YE/RD), harness side

and RH front wheel speed sensor C160-1, circuit 514

(YE/RD), harness side.

— ABS module C135-27, circuit 516 (YE/BK), harness side

and RH front wheel speed sensor C160-2, circuit 516

(YE/BK), harness side.

• For DTC C1155, measure the resistance between:

— ABS module C135-13, circuit 522 (TN/BK), harness side

and LH front wheel speed sensor C150-2, circuit 522

(TN/BK), harness side.

— ABS module C135-12, circuit 521 (TN/OG), harness side

and LH front wheel speed sensor C150-1, circuit 521

(TN/OG), harness side.

• For DTC C1165, measure the resistance between:

— ABS module C135-44, circuit 524 (PK/BK), harness side

and RH rear wheel speed sensor C3117-2, circuit 524

(PK/BK), harness side.

— ABS module C135-43, circuit 523 (RD/PK), harness side

and RH rear wheel speed sensor C3117-1, circuit 523

(RD/PK), harness side.

• For DTC C1175, measure the resistance between:

— ABS module C135-42, circuit 518 (LG/RD), harness side

and LH rear wheel speed sensor C3116-1, circuit 518

(LG/RD), harness side. Yes

— ABS module C135-41, circuit 519 (LG/BK), harness side GO to C4.

and LH rear wheel speed sensor C3116-2, circuit 519 No

(LG/BK), harness side. REPAIR the affected circuit(s). CLEAR the

• Are the resistances less than 5 ohms? DTCs. REPEAT the self-test.

(Continued)

2007 Mustang, Mustang GT 8/2006

206-09-13 Vehicle Dynamic Systems 206-09-13

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST C: DTCs C1145, C1155, C1165 AND C1175 — WHEEL SPEED SENSOR INPUT CIRCUIT

FAILURE (Continued)

Test Step Result / Action to Take

C4 CHECK FOR SHORTED WHEEL SPEED SENSOR CIRCUITS

• Measure the resistance between the suspect wheel speed

sensor pins, harness side with the meter in the 10 mega ohm

range.

Yes

REPAIR the affected circuit(s). CLEAR the

DTCs. REPEAT the self-test.

No

• Is there any continuity? GO to C5.

C5 CHECK THE ABS MODULE OUTPUT

• Connect: ABS Module C135.

• Key in ON position.

• Measure the voltage between the suspect wheel speed sensor

pins, harness side.

Yes

INSTALL a new wheel speed sensor.

REFER to Wheel Speed Sensor — Front

or Wheel Speed Sensor — Rear in this

section. CLEAR the DTCs. REPEAT the

self-test.

No

• Is the voltage greater than 10 volts? GO to C6.

C6 CHECK FOR CORRECT ABS MODULE OPERATION

• Disconnect: ABS Module C135. Yes

• Check for: INSTALL a new ABS module. REFER to

— corrosion. Anti-Lock Brake System (ABS) Module in

— spread terminals. this section. CLEAR the DTCs. REPEAT

— pushed-out pins. the self-test.

• Connect the ABS module connector and make sure it seats No

correctly. The system is operating correctly at this

• Operate the system and verify the concern is still present. time. The concern may have been caused

• Is the concern still present? by a loose or corroded connector. CLEAR

the DTCs. REPEAT the self-test.

Pinpoint Test D: DTCs C1222, C1233, C1234, Normal Operation

C1235 and C1236 — Wheel Speed Sensor The wheel speed sensor and sensor ring generate a

Input Signal Missing/Mismatch square wave signal to the anti-lock brake system

Refer to Wiring Diagrams Cell 42, Vehicle (ABS) module that is proportional to wheel speed.

Dynamic Systems for schematic and connector The ABS module compares wheel speed inputs

information. from all wheel speed sensors to determine an

impending wheel lockup. Incorrect tire size can set

these DTCs as well.

2007 Mustang, Mustang GT 8/2006

206-09-14 Vehicle Dynamic Systems 206-09-14

DIAGNOSIS AND TESTING (Continued)

Possible Causes

• Wheel speed sensor

• ABS module

PINPOINT TEST D: DTCs C1222, C1233, C1234, C1235 AND C1236 — WHEEL SPEED SENSOR INPUT

SIGNAL MISSING/MISMATCH

CAUTION: Use the Flex Probe Kit for all test connections to prevent damage to the

wiring terminals. Do not use standard multi-meter probes.

Test Step Result / Action to Take

D1 CHECK THE DTCs FROM THE SELF-TEST

• Retrieve the recorded results from the anti-lock brake system Yes

(ABS) module continuous and on-demand self tests. GO to Pinpoint Test C.

• Are DTCs C1145, C1155, C1165 or C1175 present? No

If DTC C1222 is present, GO to D3. All

others, GO to D2.

D2 CHECK THE WHEEL SPEED SENSOR OUTPUT

NOTE: The ignition switch must be in the OFF position until the

connections are made or a DTC will set and the ABS warning

indicator will illuminate, cutting voltage to the wheel speed sensors.

If this happens, turn the ignition switch to the OFF position and

make sure that no jumper connections are shorted to ground or

shorted together. Turn the ignition switch to the ON position and

wait for the ABS warning indicator to prove out.

• Disconnect: Suspect Wheel Speed Sensor.

• Connect a fused (5A) jumper wire between the suspect wheel

speed sensor, component side, and the wheel speed sensor,

harness side, as follows:

— For DTC C1233: LH front wheel speed sensor C150-1,

circuit 521 (TN/OG), harness side and LH front wheel speed

sensor C150 pin 1, circuit 521 (TN/OG), component side.

— For DTC C1234: RH front wheel speed sensor C160-1,

circuit 514 (YE/RD), harness side and RH front wheel speed

sensor C160 pin 1, circuit 514 (YE/RD), component side.

— For DTC C1235: RH rear wheel speed sensor C3117-1,

circuit 523 (RD/PK), harness side and RH rear wheel speed

sensor C3117 pin 1, circuit 523 (RD/PK), component side.

— For DTC C1236: LH rear wheel speed sensor C3116-1,

circuit 518 (LG/RD), harness side and LH rear wheel speed

sensor C3116 pin 1, circuit 518 (LG/RD), component side.

(Continued)

2007 Mustang, Mustang GT 8/2006

206-09-15 Vehicle Dynamic Systems 206-09-15

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST D: DTCs C1222, C1233, C1234, C1235 AND C1236 — WHEEL SPEED SENSOR INPUT

SIGNAL MISSING/MISMATCH (Continued)

Test Step Result / Action to Take

D2 CHECK THE WHEEL SPEED SENSOR OUTPUT (Continued)

• Connect a digital multi-meter between the suspect wheel speed

sensor, component side, and the wheel speed sensor, harness

side, as follows:

— For DTC C1233: LH front wheel speed sensor C150-2,

circuit 522 (TN/BK), harness side and LH front wheel speed

sensor C150 pin 2, circuit 522 (TN/BK), component side.

— For DTC C1234: RH front wheel speed sensor C160-2,

circuit 516 (YE/BK), harness side and RH front wheel speed

sensor C160 pin 2, circuit 516 (YE/BK), component side.

— For DTC C1235: RH rear wheel speed sensor C3117-2,

circuit 524 (PK/BK), harness side and RH rear wheel speed

sensor C3117 pin 2, circuit 524 (PK/BK), component side.

— For DTC C1236: LH rear wheel speed sensor C3116-2,

circuit 519 (LG/BK), harness side and LH rear wheel speed

sensor C3116 pin 2, circuit 519 (LG/BK), component side. Yes

• Key in ACCESSORY position. GO to D4.

• NOTE: The wheel must be moved very slowly to allow the meter No

to read the high and low current as the sensor tone ring INSTALL a new wheel speed sensor.

openings pass the sensor. REFER to Wheel Speed Sensor — Front

Measure the current while rotating the wheel slightly. or Wheel Speed Sensor — Rear in this

• Does the digital multi-meter switch between the low state section. CLEAR the DTC(s). REPEAT the

(5-8 mA) and the high state (11-18 mA)? self-test.

D3 CHECK FOR CORRECT ABS MODULE CONFIGURATION

OPERATION

NOTE: DTC C1222 indicates there is a problem with the Yes

configuration in the ABS module. GO to D4.

• Carry out the ABS module configuration. Verify the vehicle data No

matches the vehicle options. Refer to Section 418-01. The system is operating correctly at this

• Clear the DTCs and carry out the self-test. time. CLEAR the DTCs. REPEAT the

• Is DTC C1222 still present? self-test.

D4 CHECK FOR CORRECT ABS MODULE OPERATION

• Disconnect: ABS Module C135. Yes

• Check for: INSTALL a new ABS module. REFER to

— corrosion. Anti-Lock Brake System (ABS) Module in

— spread terminals. this section. CLEAR the DTCs. REPEAT

— pushed-out pins. the self-test.

• Connect the ABS module connector and make sure it seats No

correctly. The system is operating correctly at this

• Operate the system and verify the concern is still present. time. The concern may have been caused

• Is the concern still present? by a loose or corroded connector. CLEAR

the DTCs. REPEAT the self-test.

Pinpoint Test E: DTC C1446 — Brake Switch Possible Causes

Circuit Failure • Circuit shorted

Refer to Wiring Diagrams Cell 42, Vehicle • Brake pedal switch

Dynamic Systems for schematic and connector

information. • Brake fluid level sensor (master cylinder)

• Anti-lock brake system (ABS) module

Normal Operation

The anti-lock brake system (ABS) module receives

a voltage signal from the smart junction box (SJB)

along circuit 535 (LB/RD) through the brake pedal

switch. When the brake pedal is applied the voltage

signal is no longer referenced by the ABS module.

The SJB provides 5 volts to the brake fluid level

switch along circuit 547 (LG/YE). When the brake

fluid reaches a certain level, the switch closes and

the 5 volts are sent back to the SJB along circuit

512 (TN/LG).

2007 Mustang, Mustang GT 8/2006

206-09-16 Vehicle Dynamic Systems 206-09-16

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST E: DTC C1446 — BRAKE SWITCH CIRCUIT FAILURE

CAUTION: Use the Flex Probe Kit for all test connections to prevent damage to the

wiring terminals. Do not use standard multi-meter probes.

Test Step Result / Action to Take

E1 MONITOR THE SMART JUNCTION BOX (SJB) STOPLAMP

SWITCH PID

• Connect the scan tool. Yes

• Key in ON position. GO to E2.

• Press and release the brake pedal while monitoring the SJB No

stoplamp switch PID. For further diagnosis of the stoplamps,

• Do the stoplamps illuminate and does the PID agree? REFER to Section 417-01.

E2 MONITOR THE ANTI-LOCK BRAKE SYSTEM (ABS) MODULE

STOPLAMP SWITCH PID

• Press and release the brake pedal while monitoring the ABS Yes

module stoplamp switch PID and observing the stoplamps. GO to E3.

• Does the PID agree with the brake pedal position? No

REPAIR circuit 535 (LB/RD). CLEAR the

DTCs. REPEAT the self-test.

E3 CHECK THE BRAKE FLUID LEVEL SWITCH FOR A SHORT

• Key in OFF position. Yes

• Disconnect: Brake Fluid Level Switch C124. GO to E4.

• Key in ON position.

• Clear the DTCs. No

• Perform the smart junction box (SJB) self test. Retrieve and INSTALL a new brake fluid reservoir.

record any DTCs. REFER to section Section 206-06.

• Did DTC C1446 return? CLEAR the DTCs. REPEAT the self-test.

E4 CHECK CIRCUIT 512 (TN/LG) FOR A SHORT TO VOLTAGE

• Key in OFF position.

• Disconnect: Smart Junction Box (SJB) C2280c. Yes

• Key in ON position. REPAIR circuit 512 (TN/LG). CLEAR the

• Measure the voltage between brake fluid level switch C124-2, DTCs. REPEAT the self-test.

circuit 512 (TN/LG), harness side and ground. No

• Is any voltage present? GO to E5.

E5 CHECK THE ABS MODULE CONNECTOR

• Key in OFF position. Yes

• Disconnect: ABS Module C135. INSTALL a new ABS module. REFER to

• Check the ABS module connector for: Anti-Lock Brake System (ABS) Module in

— corrosion. this section. CLEAR the DTCs. REPEAT

— pushed-out pins. the self-test.

— spread terminals. No

• Connect: ABS Module C135. The system is operating correctly at this

• Make sure the ABS module connector seats correctly, then time. The concern may have been caused

operate the system and verify if the concern is still present. by a loose or corroded connector. CLEAR

• Is the concern still present? the DTCs. REPEAT the self-test with the

brake pedal not applied.

Pinpoint Test F: Spongy/Soft/Low Brake Possible Causes

Pedal with No Warning Indicator • Base brake system

Normal Operation • Hydraulic control unit (HCU)

The brake pedal should be firm when applied.

PINPOINT TEST F: SPONGY/SOFT/LOW BRAKE PEDAL WITH NO WARNING INDICATOR

Test Step Result / Action to Take

F1 CHECK THE BASE BRAKE COMPONENTS

• Visually inspect the brake hoses and tubes from the hydraulic Yes

control unit (HCU) to the brake calipers. REPAIR or INSTALL new components as

• Visually inspect the calipers and brake components. necessary. TEST the system for normal

• Are any of these components damaged? operation.

No

GO to F2.

(Continued)

2007 Mustang, Mustang GT 8/2006

206-09-17 Vehicle Dynamic Systems 206-09-17

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST F: SPONGY/SOFT/LOW BRAKE PEDAL WITH NO WARNING INDICATOR (Continued)

Test Step Result / Action to Take

F2 CHECK FOR A LEAKING DUMP VALVE

• Key in OFF position.

• Remove the rubber boots from the 2 HCU low pressure

accumulators (LPA) and insert a clean steel implement (e.g.

paper clip or a small screwdriver) into each LPA.

• Key in ON position.

• NOTE: A leaking dump valve is similar to the master cylinder Yes

bypass condition. It is important that the pedal be quickly and INSTALL a new HCU. REFER to Hydraulic

forcefully applied to rule out master cylinder bypass as a Control Unit (HCU) in this section.

condition. No

Have an assistant press hard on the brake pedal while REMOVE the steel implements. INSTALL

observing the steel implements. the rubber boots on each LPA. REFER to

• Do either of the implements move out 6.35 mm (0.25 in) or Section 206-00 to continue diagnosis of

more? the base brake system.

Pinpoint Test G: Poor Vehicle Tracking Fused ignition voltage is supplied by the smart

During Anti-lock Function junction box (SJB) through circuit 1844 (LG/RD)

Normal Operation and fused battery voltage is supplied by the bussed

The operating voltage required to supply the electrical center (BEC) through circuit 601 (LB/PK)

anti-lock brake system (ABS) module, hydraulic and circuit 534 (YE/LG). Ground is provided

pump and isolation valves is in a range between 10 through circuit 1205 (BK).

and 16 volts. Possible Causes

• Base brake system

• Hydraulic control unit (HCU)

PINPOINT TEST G: POOR VEHICLE TRACKING DURING ANTI-LOCK FUNCTION

Test Step Result / Action to Take

G1 BLEED THE BRAKE SYSTEM

• Bleed the brake system using the scan tool. Refer to Section Yes

206-00. The brake system is operating correctly.

• Test drive the vehicle. The concern may have been caused by

• Does the vehicle track correctly? air in the hydraulic system or a sticky

valve.

No

GO to G2.

G2 CHECK THE ABS INLET VALVE (CLOSED POSITION)

• Key in ON position. Yes

• Rotate all the wheels to make sure they rotate freely (the TRIGGER the LF INLET OFF active

transmission must be in NEUTRAL). command. GO to G3.

• Trigger the ABS module LF INLET ON active command. No

• Apply moderate brake pedal effort. INSTALL a new HCU. REFER to Hydraulic

• Have an assistant attempt to rotate the LF wheel. Control Unit (HCU) in this section. TEST

• Does the LF wheel rotate? the system for normal operation.

(Continued)

2007 Mustang, Mustang GT 8/2006

206-09-18 Vehicle Dynamic Systems 206-09-18

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST G: POOR VEHICLE TRACKING DURING ANTI-LOCK FUNCTION (Continued)

Test Step Result / Action to Take

G3 CHECK THE ABS INLET VALVE (OPEN POSITION)

• Apply moderate brake pedal effort. Yes

• Have an assistant attempt to rotate the LF wheel. INSTALL a new HCU. REFER to Hydraulic

• Does the LF wheel rotate? Control Unit (HCU) in this section. TEST

the system for normal operation.

No

GO to G4.

G4 CHECK THE ABS OUTPUT VALVE (OPEN POSITION)

• Apply moderate brake pedal effort.

• Trigger ABS module LF INLET ON active command.

• Trigger ABS module ABS POWER ON active command (turns

on the pump motor) for 6 seconds. (The trigger must be pressed Yes

3 times. Each press runs the pump for 2 seconds.) TRIGGER all active commands OFF. GO

• Trigger the ABS module LF OUTLET ON active command, then to G5.

trigger the ABS module LF OUTLET OFF active command. No

Repeat 3 times. INSTALL a new HCU. REFER to Hydraulic

• Have an assistant attempt to rotate the LF wheel. Control Unit (HCU) in this section. TEST

• Does the LF wheel rotate? the system for normal operation.

G5 CHECK THE ABS INLET AND OUTLET VALVES (CLOSED

POSITION)

• Apply moderate brake pedal effort. Yes

• Have an assistant attempt to rotate the LF wheel. INSTALL a new HCU. REFER to Hydraulic

• Does the LF wheel rotate? Control Unit (HCU) in this section. TEST

the system for normal operation.

No

REPEAT this procedure (beginning with

Step H2) for the RF, LR and RR wheels

using the appropriate active commands. If

no failure occurs, the system is operating

normally.

Pinpoint Test H: DTC C1093 — Traction Possible Causes

Control Disable Switch Circuit Failure and/or • Circuit open

the Traction Control System Cannot be

Disabled • Circuit shorted

Refer to Wiring Diagrams Cell 60, Instrument • Traction control switch

Cluster for schematic and connector information. • Anti-lock brake system (ABS) module

Normal Operation • Instrument cluster

Engine torque modulation is achieved by regulating

fuel and spark to the cylinders. The traction control

system operates using the anti-lock brake system

(ABS) module to interact with the powertrain

control module (PCM) to reduce engine torque and

apply the brakes if the wheels lose traction and

begin to spin during acceleration.

The instrument cluster circuit 1412 (WH/PK)

monitors for a ground (change of state). When the

traction control switch is pressed, a momentary

ground occurs through circuit 1205 (BK). The

instrument cluster then sends a voltage to the

traction control switch through circuit 939 (VT)

illuminating the traction control switch and

disabling the system.

2007 Mustang, Mustang GT 8/2006

206-09-19 Vehicle Dynamic Systems 206-09-19

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST H: DTC C1093 — TRACTION CONTROL DISABLE SWITCH CIRCUIT FAILURE AND/OR

THE TRACTION CONTROL SYSTEM CANNOT BE DISABLED

CAUTION: Use the Flex Probe Kit for all test connections to prevent damage to the

wiring terminals. Do not use standard multi-meter probes.

Test Step Result / Action to Take

H1 MONITOR THE INSTRUMENT CLUSTER PID

• Key in ON position. Yes

• Monitor the instrument cluster traction control switch status PID GO to H6.

while pressing the traction control disable switch repeatedly. No

• Does the PID agree with the switch position? GO to H2.

H2 CHECK THE TRACTION CONTROL SWITCH INPUT

• Key in OFF position.

• Disconnect: Instrument Cluster C220.

• Measure the resistance between instrument cluster C220-20,

circuit 1412 (WH/PK), harness side and ground while pressing

and releasing the traction control switch.

Yes

GO to H3.

No

INSTALL a new traction control switch.

REFER to Traction Control Switch in this

• Is the resistance less than 5 ohms with the switch pressed section. CLEAR the DTCs. REPEAT the

and greater than 10,000 ohms with the switch released? self-test.

H3 CHECK CIRCUIT 1412 (WH/PK) FOR A SHORT TO GROUND

• Key in OFF position.

• Disconnect: Traction Control Switch C2039.

• Measure the resistance between traction control switch C2039-7,

circuit 1412 (WH/PK), harness side and ground.

Yes

REPAIR circuit 1412 (WH/PK). CLEAR the

DTCs. REPEAT the self-test.

No

• Is the resistance less than 5 ohms? GO to H4.

(Continued)

2007 Mustang, Mustang GT 8/2006

206-09-20 Vehicle Dynamic Systems 206-09-20

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST H: DTC C1093 — TRACTION CONTROL DISABLE SWITCH CIRCUIT FAILURE AND/OR

THE TRACTION CONTROL SYSTEM CANNOT BE DISABLED (Continued)

Test Step Result / Action to Take

H4 CHECK CIRCUIT 1412 (WH/PK) FOR AN OPEN

• Measure the resistance between instrument cluster C220-20,

circuit 1412 (WH/PK), harness side and traction control switch

C2039-7, circuit 1412 (WH/PK), harness side.

Yes

REPAIR circuit 1412 (WH/PK). CLEAR the

DTCs. REPEAT the self-test.

No

• Is the resistance greater than 10,000 ohms? GO to H5.

H5 CHECK CIRCUIT 1205 (BK) FOR AN OPEN

• Measure the resistance between traction control switch C2039-1,

circuit 1205 (BK), harness side and ground.

Yes

REPAIR circuit 1205 (BK). CLEAR the

DTCs. REPEAT the self-test.

No

INSTALL a new traction control switch.

REFER toTraction Control Switch in this

section. CLEAR the DTCs. REPEAT the

• Is the resistance greater than 10,000 ohms? self-test.

H6 CHECK FOR CORRECT INSTRUMENT CLUSTER OPERATION

• Disconnect: Instrument Cluster C220. Yes

• Check for: INSTALL a new instrument cluster.

— corrosion. REFER to Section 413-01. CLEAR the

— spread terminals. DTCs. REPEAT the self-test.

— pushed-out pins. No

• Connect the instrument cluster connector and make sure it seats The system is operating correctly at this

correctly. time. The concern may have been caused

• Operate the system and verify the concern is still present. by a loose or corroded connector. CLEAR

• Is the concern still present? the DTCs. REPEAT the self-test.

Pinpoint Test I: The Traction Control Switch Normal Operation

Indicator is Never/Always On The instrument cluster circuit 1412 (WH/PK)

Refer to Wiring Diagrams Cell 42, Vehicle monitors for a ground (change of state). When the

Dynamic Systems for schematic and connector traction control switch is pressed momentary ground

information. occurs through circuit 1205 (BK). The instrument

cluster then sends a voltage to the traction control

switch through circuit 939 (VT) illuminating the

traction control switch and disabling the system.

2007 Mustang, Mustang GT 8/2006

206-09-21 Vehicle Dynamic Systems 206-09-21

DIAGNOSIS AND TESTING (Continued)

Possible Causes

• Circuit open

• Circuit shorted

• Traction control switch

• Instrument cluster

PINPOINT TEST I: THE TRACTION CONTROL SWITCH INDICATOR IS NEVER/ALWAYS ON

CAUTION: Use the Flex Probe Kit for all test connections to prevent damage to the

wiring terminals. Do not use standard multi-meter probes.

Test Step Result / Action to Take

I1 VERIFY THE TRACTION CONTROL SYSTEM OPERATION

• Operate the system and verify the traction control system can be Yes

enabled and disabled. GO to I2.

• Does the traction control system operate correctly? No

REFER to symptom chart to continue

diagnosis.

I2 CHECK CIRCUIT 939 (VT) FOR VOLTAGE

• Key in OFF position.

• Disconnect: Traction Control Switch C2039.

• Key in ON position.

• Measure the voltage between traction control switch C2039-4,

circuit 939 (VT), harness side and ground.

Yes

GO to I3.

No

• Is voltage present? GO to I4.

I3 CHECK CIRCUIT 939 (VT) FOR A SHORT TO VOLTAGE

• Key in OFF position.

• Disconnect: Instrument Cluster C220.

• Key in ON position.

• Measure the voltage between traction control switch C2039-4,

circuit 939 (VT), harness side and ground.

Yes

REPAIR circuit 939 (VT). TEST the

system for normal operation.

No

• Is voltage present? GO to I6.

(Continued)

2007 Mustang, Mustang GT 8/2006

206-09-22 Vehicle Dynamic Systems 206-09-22

DIAGNOSIS AND TESTING (Continued)

PINPOINT TEST I: THE TRACTION CONTROL SWITCH INDICATOR IS NEVER/ALWAYS ON (Continued)

Test Step Result / Action to Take

I4 CHECK CIRCUIT 939 (VT) FOR AN OPEN OR SHORT TO

GROUND

• Key in OFF position.

• Disconnect: Instrument Cluster C220.

• Measure the resistance between instrument cluster C220-21,

circuit 939 (VT), harness side and:

— traction control switch C2039-4, circuit 939 (VT), harness

side.

— ground.

Yes

REPAIR circuit 939 (VT). TEST the

• Is the resistance greater than 10,000 ohms between the system for normal operation.

instrument cluster and the traction control switch, and less No

than 5 ohms between the instrument cluster and ground? GO to I5.

I5 CHECK THE INSTRUMENT CLUSTER OPERATION

• Connect: Traction Control Switch C2039.

• Connect a fused (10A) jumper wire between instrument cluster

C220-21, circuit 939 (VT), harness side and instrument cluster

C220-3, circuit 1001 (WH/YE), harness side.

Yes

Remove the jumper wire. GO to I6.

No

Remove the jumper wire. INSTALL a new

traction control switch. REFER to Traction

Control Switch in this section. CLEAR the

• Does the traction control switch indicator illuminate? DTCs. REPEAT the self-test.

I6 CHECK FOR CORRECT INSTRUMENT CLUSTER OPERATION

• Disconnect: Instrument Cluster C220. Yes

• Check for: INSTALL a new instrument cluster.

— corrosion. REFER to Section 413-01. CLEAR the

— spread terminals. DTCs. REPEAT the self-test.

— pushed-out pins. No

• Connect the instrument cluster connector and make sure it seats The system is operating correctly at this

correctly. time. The concern may have been caused

• Operate the system and verify the concern is still present. by a loose or corroded connector. CLEAR

• Is the concern still present? the DTCs. REPEAT the self-test.

2007 Mustang, Mustang GT 8/2006

206-09-1 Vehicle Dynamic Systems 206-09-1

DESCRIPTION AND OPERATION

Anti-Lock Control • Rear wheel speed sensors

• Rear wheel speed sensor rings

Anti-Lock Brake System (ABS) with

Traction Control • Traction control switch

The anti-lock brake system (ABS) consists of the • Traction control switch indicator

following components: • Trac off indicator

• Hydraulic control unit (HCU) • Yellow ABS warning indicator

• ABS module

• Front wheel speed sensors

• Front wheel speed sensors rings

Copyright 2006, Ford Motor Company

Last updated: 6/19/2006 2007 Mustang, Mustang GT 8/2006

206-07-1 Power Brake Actuation 206-07-1

REMOVAL AND INSTALLATION

Brake Booster

Item Part Number Description Item Part Number Description

1 9C482 Brake booster vacuum hose 5 2N513 Brake booster rod pin

2 — Brake booster vacuum check 6 13480 Stop lamp switch

valve (part of 2B195) 7 9C872 Speed deactivation switch

3 2475 Redundant self-locking clip 8 W520112-S440 Brake booster nuts (4

cover required)

4 380699-S100 Self-locking clip 9 2B195 Brake booster

(Continued)

Copyright 2006, Ford Motor Company

Last updated: 6/19/2006 2007 Mustang, Mustang GT 8/2006

206-07-2 Power Brake Actuation 206-07-2

REMOVAL AND INSTALLATION (Continued)

Removal and Installation 4. NOTE: Do not apply the brake pedal during

the removal or installation of the speed

1. Remove the brake master cylinder. For deactivation switch.

additional information, refer to Section 206-06. Disconnect the electrical connector and remove

the speed deactivation switch.

2. Disconnect the brake booster vacuum hose from

the brake booster vacuum check valve. 5. Remove the redundant self-locking pin cover,

self-locking pin and the booster rod pin.

3. NOTE: Do not apply the brake pedal during

the removal or installation of the stop lamp 6. Remove the 4 brake booster nuts.

switch.

• To install, tighten to 25 Nm (18 lb-ft).

Disconnect the electrical connector and remove

the stop lamp switch. 7. Remove the brake booster assembly from the

vehicle.

8. To install, reverse the removal procedure.

2007 Mustang, Mustang GT 8/2006

206-07-1 Power Brake Actuation 206-07-1

DESCRIPTION AND OPERATION

Brake Booster • is divided into separate chambers by the

diaphragms.

The vacuum type power brake booster:

• will not operate if vacuum fails.

• is a dual diaphragm, vacuum assisted power brake

booster. • is installed as an assembly.

• reduces brake pedal force and travel distance. If the power assist fails, the brake system continues

to operate with increased brake pedal effort.

• is located on the LH side of the cowl in the

engine compartment, between the brake pedal and

the brake master cylinder.

Copyright 2006, Ford Motor Company

Last updated: 6/19/2006 2007 Mustang, Mustang GT 8/2006

206-03-1 Front Disc Brake 206-03-1

REMOVAL AND INSTALLATION

Brake Caliper — 4.0L SOHC and 4.6L 1. With the vehicle in NEUTRAL, position it on a

(3V) hoist. For additional information, refer to

Section 100-02.

Material

2. Remove the brake caliper flow bolt and discard

Item Specification the 2 copper washers.

High Performance DOT 3 ESA-M6C25-A or

Motor Vehicle Brake Fluid WSS-M6C62-A 3. CAUTION: Do not use the caliper

PM-1 or PM-1-C (US); sight hole to retract pistons as this can

CPM-1 or CPM-1-C

(Canada) damage the pistons and boots.

Remove and discard the 2 brake caliper guide

Removal pin bolts and remove the brake caliper.

WARNING: Use of any other than 4. Inspect the brake caliper.

approved DOT 3 motor vehicle brake fluid will • If leaks or damaged boots are found, install

cause permanent damage to brake components a new brake caliper.

and will render the brakes inoperative. Failure to

follow these instructions may result in personal Installation

injury.

1. Position the brake caliper and install 2 new

WARNING: Carefully read cautionary guide pin bolts.

information on product label. For EMERGENCY • Tighten to 34 Nm (25 lb-ft).

MEDICAL INFORMATION seek medical advice.

In the USA or Canada on Ford/Motorcraft 2. Using 2 new copper washers, position the brake

products call: 1-800-959-3673. For additional flexible hose on the brake caliper and install the

information, consult the product Material Safety brake caliper flow bolt.

Data Sheet (MSDS) if available. Failure to follow

these instructions may result in personal injury. • Tighten to 40 Nm (30 lb-ft).

3. Bleed the brakes. For additional information,

CAUTION: Brake fluid is harmful to

refer to Section 206-00.

painted and plastic surfaces. If brake fluid is

spilled onto a painted or plastic surface,

4. Test the brakes for normal operation.

immediately wash it with water.

Copyright 2006, Ford Motor Company

Last updated: 6/19/2006 2007 Mustang, Mustang GT 8/2006

206-03-1 Front Disc Brake 206-03-1

REMOVAL AND INSTALLATION

Brake Caliper — 5.4L 1. With the vehicle in NEUTRAL, position it on a

hoist. For additional information, refer to

Material Section 100-02.

Item Specification 2. Remove the brake pads. For additional

High Performance DOT 3 ESA-M6C25-A or information, refer to Brake Pads — 5.4L in this

Motor Vehicle Brake Fluid WSS-M6C62-A section.

PM-1 or PM-1-C (US);

CPM-1 or CPM-1-C 3. Remove the brake caliper flow bolt and discard

(Canada)

the 2 copper washers.

Removal and Installation • To install, tighten to 48 Nm (35 lb-ft).

WARNING: Use of any other than 4. CAUTION: Do not remove the bolts

approved DOT 3 motor vehicle brake fluid will securing the 2 caliper halves together. Do not

cause permanent damage to brake components attempt to separate the 2 caliper halves.

and will render the brakes inoperative. Failure to Remove the 2 brake caliper anchor plate bolts

follow these instructions may result in personal and the brake caliper.

injury.

• To install, tighten to 40 Nm (30 lb-ft).

WARNING: Carefully read cautionary

5. To install, reverse the removal procedure.