Professional Documents

Culture Documents

WRFC-H: Wireline-Retrievable Flow Control Valve For Gas Lift Applications

WRFC-H: Wireline-Retrievable Flow Control Valve For Gas Lift Applications

Uploaded by

ghyuihCopyright:

Available Formats

You might also like

- VC Series Zone Valves: Balanced 2-Way and 3-Way Hydronic ValvesDocument8 pagesVC Series Zone Valves: Balanced 2-Way and 3-Way Hydronic ValvesGiovanni Dala PaulaNo ratings yet

- IWCF Prep Refresher - Subsea Supplement - Well Control EquipmentDocument29 pagesIWCF Prep Refresher - Subsea Supplement - Well Control EquipmentAustine Ameh50% (2)

- Control Station Piping LayoutDocument9 pagesControl Station Piping LayoutKrunalpanchalNo ratings yet

- Subsea Bop PDFDocument48 pagesSubsea Bop PDFJorge VarelaNo ratings yet

- Hydraulic Calculation - PROPOSED BRILLIANT SKIN ESSENTIALS WAREHOUSE BUILDINGDocument9 pagesHydraulic Calculation - PROPOSED BRILLIANT SKIN ESSENTIALS WAREHOUSE BUILDINGRhowelle TibayNo ratings yet

- Hydraulic Components For Strip Guiding: Long Life-Time High Reliability Huge Performance RangeDocument8 pagesHydraulic Components For Strip Guiding: Long Life-Time High Reliability Huge Performance RangepekmezzNo ratings yet

- Safety Shutdown Valve SSV Control System BrochureDocument12 pagesSafety Shutdown Valve SSV Control System BrochureWellington Barbalho100% (1)

- Denison Hydraulics Pressure Controls - Flanged Type: Series R5with 3 PortsDocument17 pagesDenison Hydraulics Pressure Controls - Flanged Type: Series R5with 3 PortsYuriPasenkoNo ratings yet

- CG 2015132 02 - 2019 HccavDocument4 pagesCG 2015132 02 - 2019 HccavRangga AsengNo ratings yet

- Altitude Valve: For One-Way Flow With Delayed OpeningDocument4 pagesAltitude Valve: For One-Way Flow With Delayed Openingramon duldulaoNo ratings yet

- ARCA Fly ReglerInstr GBDocument6 pagesARCA Fly ReglerInstr GBChanNo ratings yet

- The V10k Vacuum Gas Feed System BrochureDocument4 pagesThe V10k Vacuum Gas Feed System BrochureReview DragonsNo ratings yet

- Armas 600 Series en S PDF - 19 10 2020 - 11 50 07Document40 pagesArmas 600 Series en S PDF - 19 10 2020 - 11 50 07aoajaaoajajNo ratings yet

- Aviation Fueling Brochure WEB 2017Document16 pagesAviation Fueling Brochure WEB 2017Ing. Gilberto Velásquez C.No ratings yet

- Shafer™ RV-Series Rotary Vane Valve ActuatorsDocument8 pagesShafer™ RV-Series Rotary Vane Valve ActuatorsarseneNo ratings yet

- Control Valve - WikipediaDocument4 pagesControl Valve - Wikipediaramthecharm_46098467No ratings yet

- SSV Control System SHUT DOWN VALVEDocument12 pagesSSV Control System SHUT DOWN VALVEglobal3tNo ratings yet

- Clorador v10kDocument8 pagesClorador v10kMarco Antonio VelazcoNo ratings yet

- Nimco Loads of ControlDocument2 pagesNimco Loads of Controllukasz20511No ratings yet

- PICV Guide SpecificationDocument7 pagesPICV Guide Specificationrio jeffryNo ratings yet

- Safety ValvesDocument12 pagesSafety ValvesMuhammad Ahmed KhanNo ratings yet

- Product Description - Wellhead Control Panel (WHCP) and HPUDocument5 pagesProduct Description - Wellhead Control Panel (WHCP) and HPUIsioma1No ratings yet

- Bab 9 Control Valve 2018Document55 pagesBab 9 Control Valve 2018Ramadian100% (1)

- Fundamentals of Final Control ElementsDocument57 pagesFundamentals of Final Control ElementshazemNo ratings yet

- CATAìLOGO VAìLVULA DE GLOBODocument8 pagesCATAìLOGO VAìLVULA DE GLOBODanny Guarderas RNo ratings yet

- Dualrange Control For Fine Throttling Service: Dualrange Weir Type Bonnet AssembliesDocument5 pagesDualrange Control For Fine Throttling Service: Dualrange Weir Type Bonnet Assembliesvarun sharmaNo ratings yet

- Surface Hydraulic Control System PsDocument1 pageSurface Hydraulic Control System PsabdouNo ratings yet

- F 9197Document4 pagesF 9197lipetrol007No ratings yet

- CLA-VAl Float ValveDocument4 pagesCLA-VAl Float ValveEntor EntorNo ratings yet

- Control ValveDocument35 pagesControl Valveshivani DubeyNo ratings yet

- RexrothDocument14 pagesRexrothWilson Cendales100% (1)

- Flow Control Valves DVE: Up To 350 Bar Up To 160 L/minDocument5 pagesFlow Control Valves DVE: Up To 350 Bar Up To 160 L/minVijay BhureNo ratings yet

- Float Valve: (Sizes 1/2"-6" / 15 - 150 MM)Document4 pagesFloat Valve: (Sizes 1/2"-6" / 15 - 150 MM)TeoxNo ratings yet

- Wellhead Control Panel1Document2 pagesWellhead Control Panel1kmsrini@yahoo.com100% (1)

- Safety ValvesDocument13 pagesSafety ValvesAntonio DiabanzaNo ratings yet

- Surface Well Testing SWTDocument3 pagesSurface Well Testing SWTHussein AbdallahNo ratings yet

- V10K Gas ChlorinatorDocument8 pagesV10K Gas ChlorinatorleonardseniorNo ratings yet

- Control Valve Main ObjectivesDocument55 pagesControl Valve Main Objectivesعبدالحميد عبدالغفار الدرديريNo ratings yet

- Series 825Y: Reduced Pressure Zone AssembliesDocument2 pagesSeries 825Y: Reduced Pressure Zone Assembliesmiljan trifkovicNo ratings yet

- V2000 Gas Feed Models PDFDocument8 pagesV2000 Gas Feed Models PDFRandy LangleyNo ratings yet

- Evopicv Tech Manual en 5a62d7d99eDocument80 pagesEvopicv Tech Manual en 5a62d7d99eAmando GonzalesNo ratings yet

- Capital Controls® Series Wp70Cv3 Gas FeedersDocument8 pagesCapital Controls® Series Wp70Cv3 Gas FeedersLoan NguyênNo ratings yet

- 7 - Andre VolschenkDocument24 pages7 - Andre VolschenkPieter Vd MerweNo ratings yet

- Picv New2Document12 pagesPicv New2arojit deyNo ratings yet

- Aquestia OCV AVIATIONDocument16 pagesAquestia OCV AVIATIONSony Nd AshaNo ratings yet

- VFD Versus Control Valve For Pump Flow ControlsDocument6 pagesVFD Versus Control Valve For Pump Flow ControlsCarlos WayNo ratings yet

- Remote Hydraulically Operated Monitor 03 RCHM299: System Package Valve Box / Hydraulic SourceDocument1 pageRemote Hydraulically Operated Monitor 03 RCHM299: System Package Valve Box / Hydraulic SourceKrishna N HNo ratings yet

- Safety ValvesDocument22 pagesSafety ValvesJabbarKaddemNo ratings yet

- Drilling Chokes BrochureDocument12 pagesDrilling Chokes BrochureAshok SureshNo ratings yet

- Av-Tek VRX Plunger REV-GDocument12 pagesAv-Tek VRX Plunger REV-GwaqasNo ratings yet

- HD-2-FM ServiceDocument8 pagesHD-2-FM Servicebabis lionakisNo ratings yet

- Ug VX Valves WebDocument2 pagesUg VX Valves Webczdcxdtr2rNo ratings yet

- PB4310Document2 pagesPB4310parrastevens930No ratings yet

- Air Admittance Valves (Ventapipe) : SectionDocument5 pagesAir Admittance Valves (Ventapipe) : SectionDinesh GuptaNo ratings yet

- Second-Stage Nozzle Control: GeneralDocument4 pagesSecond-Stage Nozzle Control: GeneralSara VaccaNo ratings yet

- US4977928 Patent Load SensingDocument5 pagesUS4977928 Patent Load SensingAmeerNo ratings yet

- Control Valves: Rejath Jacob ThomasDocument77 pagesControl Valves: Rejath Jacob Thomasshakti sindhuNo ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Schaum S Outline Fluid Mechanics and HydraulicsDocument388 pagesSchaum S Outline Fluid Mechanics and HydraulicsNelson Fernandez RoblesNo ratings yet

- CS 563 Hydraulic PDFDocument2 pagesCS 563 Hydraulic PDFanggieNo ratings yet

- Materials Indent For Purchase: SR, No. Description Make Unit Qty Cat No. Price Remark CPVC PipeDocument5 pagesMaterials Indent For Purchase: SR, No. Description Make Unit Qty Cat No. Price Remark CPVC PipeAzad AnsariNo ratings yet

- Valvula Check AlarmDocument20 pagesValvula Check AlarmCarlos Amaya CuevaNo ratings yet

- S12 Water Flushing Circuit PDFDocument34 pagesS12 Water Flushing Circuit PDFRicardo Ramirez EstrelloNo ratings yet

- Plumbing System AnalysisDocument3 pagesPlumbing System AnalysisAvery DuckworthNo ratings yet

- Hydraulic System Veth-Compact-Jet Thruster (11 KW / 100 Ltrs. Steering Power Pack)Document1 pageHydraulic System Veth-Compact-Jet Thruster (11 KW / 100 Ltrs. Steering Power Pack)Costel Ava ConstantinNo ratings yet

- Ex ArisuDocument12 pagesEx ArisuJeiner Leyva BernalNo ratings yet

- Hydraulic Cylinder Seal KitsDocument3 pagesHydraulic Cylinder Seal KitsSami KahtaniNo ratings yet

- Module 2 of PlumbingDocument12 pagesModule 2 of PlumbingDJNo ratings yet

- Green Mark - Sanitary AppDocument10 pagesGreen Mark - Sanitary Appoj_ordeNo ratings yet

- CA Spare Parts List For From ShumattDocument7 pagesCA Spare Parts List For From ShumattMasauso LunguNo ratings yet

- Section 35 - Hydraulic System - Chapter 2Document52 pagesSection 35 - Hydraulic System - Chapter 2Cristian Sterie100% (1)

- 3.1 Design BriefDocument5 pages3.1 Design BriefRaj KamalNo ratings yet

- 4U3S Water SupplyDocument15 pages4U3S Water SupplyKhin Thu Zar HtayNo ratings yet

- CUP 04 BOIN USA 02 WebDocument2 pagesCUP 04 BOIN USA 02 WebMajid abdulNo ratings yet

- Aurora Bombas CI Tipo Turbina VerticalDocument32 pagesAurora Bombas CI Tipo Turbina VerticalEsteban Calderón NavarroNo ratings yet

- 1-Piping Manual-Pdms12Document413 pages1-Piping Manual-Pdms12MOHSEN2005IBNo ratings yet

- AXERA 5-140 4408: Section 6Document20 pagesAXERA 5-140 4408: Section 6YuriPasenkoNo ratings yet

- Section04 Relief ValvesDocument30 pagesSection04 Relief ValvesHENRY LLOFREL CORREA LOPEZNo ratings yet

- Pressure Relief AplicationsDocument3 pagesPressure Relief AplicationsAndres PerezNo ratings yet

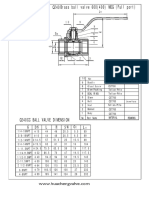

- Ball Valve Data Sheet Q240Document1 pageBall Valve Data Sheet Q240faruk hossain100% (2)

- Swagelok Valves CatDocument38 pagesSwagelok Valves CatBITS AEROSPACE MECHATRONICSNo ratings yet

- ENCH 425: Transport Processes IDocument13 pagesENCH 425: Transport Processes IAlex DoanNo ratings yet

- Cat - Dcs.sis - Controllerloader 924ghDocument15 pagesCat - Dcs.sis - Controllerloader 924ghmahmod alrousanNo ratings yet

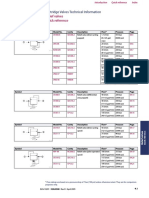

- Content: General Technical InformationDocument26 pagesContent: General Technical InformationVito LaudicinaNo ratings yet

- Check Valve VickersDocument15 pagesCheck Valve Vickersعلي عائشة100% (1)

- 1 .Reverse Osmosis System (RO) Bahan Baku 500ppmDocument2 pages1 .Reverse Osmosis System (RO) Bahan Baku 500ppmboynaduaNo ratings yet

WRFC-H: Wireline-Retrievable Flow Control Valve For Gas Lift Applications

WRFC-H: Wireline-Retrievable Flow Control Valve For Gas Lift Applications

Uploaded by

ghyuihOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WRFC-H: Wireline-Retrievable Flow Control Valve For Gas Lift Applications

WRFC-H: Wireline-Retrievable Flow Control Valve For Gas Lift Applications

Uploaded by

ghyuihCopyright:

Available Formats

WRFC-H

Wireline-retrievable flow control valve for gas lift applications

APPLICATIONS The WRFC-H wireline-retrievable flow control

■■ Natural in-situ gas lift intelligent valve is designed for gas lift applications. It

completions provides surface-actuated remote control

when hydraulic pressure is applied to a control

■■ Specialized gas lift completions

line that connects the surface operating sys-

BENEFITS tem to the mandrel operating section.

■■ Maximize production by

The actuation module adjusts the WRFC

■■ artificially lifting an oil producing zone

variable window control valve. The variable

by controlling gas from a gas-bearing

window control valve can be configured with

formation or gas cap, eliminating the

up to six positions, including a median setting

need for traditional gas lift injection

selected to meet the anticipated requirements

■■ eliminating loss to thief zones and for a specific reservoir. From the median set-

cross-contamination of reservoirs ting, two individual adjustments can be made

to increase or decrease flow from a zone or

■■ Economical repair or replacement of

injection into a zone. In either configuration,

parts exposed to turbulent flow

optional reverse-flow check valves prevent

FEATURES crossflow between reservoirs and unwanted

■■ Ability to be retrieved by standard annular flow to the surface.

slickline methods

The valve is housed in a Schlumberger side-

■■ Optional reverse-flow check valves to

pocket mandrel located adjacent to the tubing

prevent crossflow

bore in the eccentric pocket of the mandrel.

■■ Incremental adjustment of variable The WRFC valve has a customizable maximum

window choke flow area and controls flow rates of up to

10,000 bbl/d of solids-free liquid or 30 MMscf/d

■■ Customizable, four choking positions

of dry gas. The valve mandrel is available in a

plus fully closed and fully open positions

variety of sizes and materials.

■■ Dependable mechanical closure spring

Operation

■■ Compatibility with oil- and water-base

The WRFC-H valve uses proven surface-

control line fluids

controlled safety valve hydraulics to adjust the

■■ Gas qualification valve so that production is optimized without

costly well intervention. Hydraulic pressure

is supplied to the WRFC-H valve through a

0.25-in-OD hydraulic control line connected

into the mandrel.

The actuator in the mandrel couples with the

flow control valve to shift the variable window

orifice to one of six sequential positions, one of

which is sealed closed. Fluid flow is controlled

from 0% to 100% in 20% increments, or flow

control can be customized for individual ap-

plications. The flow rate of each control valve

WRFC-H wireline-retrievable flow control valve.

is tailored to the individual zone.

WRFC-H

The WRFC-H flow control valve meters either swage, a special guide-orienting sleeve A coiled tubing adapter and kickover tool can

fluids injected into the reservoir or those pro- positively aligns a kickover tool for installation be used for valve replacement in highly devi-

duced from it. In either configuration, optional or retrieval of side-pocket accessories and ated or horizontal wells.

reverse-flow check valves prevent crossflow provides the stop necessary for actuating the

between reservoirs and to the surface. kickover tool. The side-pocket mandrel is manufactured to

meet the expected downhole environment.

The flow control valve can be installed or re- A finger on the kickover tool fits into a vertical Metallurgic properties are closely controlled

trieved by standard slickline or coiled tubing. A slot in the orienting sleeve and positions the through rigid specifications and quality as-

window between the power supply pocket and tool so that the side-pocket device is aligned surance programs, all meeting NACE MR0175

the flow control valve pocket allows the valve with the pocket. This sleeve verifies positive specifications.

to be connected to the power supply actuator. alignment regardless of the degree of well

deviation. A tool discriminator above the man- As a contingency, conventional orifice or

To facilitate retrieval operations, the WRFC-H drel pocket guides side-pocket devices into dummy valves can be installed in the mandrel

mandrel incorporates several unique features. the pocket and automatically deflects tools pocket. These devices do not change the

Below the threads in the mandrel’s upper with larger diameters into the tubing bore. inside diameter of the mandrel.

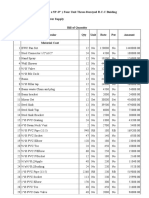

WRFC-H Flow Control Valve Specifications

Size, in 3½ 4½ 5½ 7

Max. OD, in [mm] 5.889 [149.581] 7.646 [194.208] 8.260 [209.804] 9.390 [238.506]

Min. ID, in [mm] 2.740 [69.596] 3.823 [97.104] 4.670 [118.618] 5.900 [149.860]

Drift ID, in [mm] 2.625 [66.675] 3.718 [94.437] 4.545 [115.443] 5.750 [146.050]

Eccentricity, in [mm] 0.977 [24.816] 1.172 [29.769] 1.075 [27.305] 0.914 [23.216]

Overall length, in [mm] 142 [3,607] 138 [3,505] 142 [3,607] 150 [3,810]

Max. gas flow rate, MMscf/d 30 30 30 30

Max. liquid flow rate, bbl/d [m3/d] 10,000 [1,590] 10,000 [1,590] 10,000 [1,590] 10,000 [1,590]

WRFC-H System Specifications

Max. number of tool positions six (open, closed, and four choking positions)

Max. flow area, in2 0.75 (customizable)

Actuator principles Single hydraulic line to surface with reservoir-pressure-assisted mechanical counteraction or balanced dual hydraulic lines to surface

Control line bypasses 3½-in and 5½-in valves: five control lines; 4½-in valve: four control lines; 7-in valve: one control line

Control line fitting type Inverted dual ferrule connector

Materials

Material specification NACE MR0175

Seal material Viton, hydrogenated nitrile butadiene rubber (HNBR)

Control line fluid compatibility Oil- or water-base

Operating Data

Working pressures, psi [kPa] 3½-in valve: 5,000 [34,474]; 4½-in valve: 6,500 [44,816]; 5½-in valve: 7,500 [51,711]; 7-in valve: 5,400 [37,232]

Operating temperature rating, 75–200 [23–93]

degF [degC]

slb.com/fcv

*Mark of Schlumberger

Other company, product, and service names are the properties of their respective owners.

Copyright © 2010 Schlumberger. All rights reserved. 09-CO-0263

You might also like

- VC Series Zone Valves: Balanced 2-Way and 3-Way Hydronic ValvesDocument8 pagesVC Series Zone Valves: Balanced 2-Way and 3-Way Hydronic ValvesGiovanni Dala PaulaNo ratings yet

- IWCF Prep Refresher - Subsea Supplement - Well Control EquipmentDocument29 pagesIWCF Prep Refresher - Subsea Supplement - Well Control EquipmentAustine Ameh50% (2)

- Control Station Piping LayoutDocument9 pagesControl Station Piping LayoutKrunalpanchalNo ratings yet

- Subsea Bop PDFDocument48 pagesSubsea Bop PDFJorge VarelaNo ratings yet

- Hydraulic Calculation - PROPOSED BRILLIANT SKIN ESSENTIALS WAREHOUSE BUILDINGDocument9 pagesHydraulic Calculation - PROPOSED BRILLIANT SKIN ESSENTIALS WAREHOUSE BUILDINGRhowelle TibayNo ratings yet

- Hydraulic Components For Strip Guiding: Long Life-Time High Reliability Huge Performance RangeDocument8 pagesHydraulic Components For Strip Guiding: Long Life-Time High Reliability Huge Performance RangepekmezzNo ratings yet

- Safety Shutdown Valve SSV Control System BrochureDocument12 pagesSafety Shutdown Valve SSV Control System BrochureWellington Barbalho100% (1)

- Denison Hydraulics Pressure Controls - Flanged Type: Series R5with 3 PortsDocument17 pagesDenison Hydraulics Pressure Controls - Flanged Type: Series R5with 3 PortsYuriPasenkoNo ratings yet

- CG 2015132 02 - 2019 HccavDocument4 pagesCG 2015132 02 - 2019 HccavRangga AsengNo ratings yet

- Altitude Valve: For One-Way Flow With Delayed OpeningDocument4 pagesAltitude Valve: For One-Way Flow With Delayed Openingramon duldulaoNo ratings yet

- ARCA Fly ReglerInstr GBDocument6 pagesARCA Fly ReglerInstr GBChanNo ratings yet

- The V10k Vacuum Gas Feed System BrochureDocument4 pagesThe V10k Vacuum Gas Feed System BrochureReview DragonsNo ratings yet

- Armas 600 Series en S PDF - 19 10 2020 - 11 50 07Document40 pagesArmas 600 Series en S PDF - 19 10 2020 - 11 50 07aoajaaoajajNo ratings yet

- Aviation Fueling Brochure WEB 2017Document16 pagesAviation Fueling Brochure WEB 2017Ing. Gilberto Velásquez C.No ratings yet

- Shafer™ RV-Series Rotary Vane Valve ActuatorsDocument8 pagesShafer™ RV-Series Rotary Vane Valve ActuatorsarseneNo ratings yet

- Control Valve - WikipediaDocument4 pagesControl Valve - Wikipediaramthecharm_46098467No ratings yet

- SSV Control System SHUT DOWN VALVEDocument12 pagesSSV Control System SHUT DOWN VALVEglobal3tNo ratings yet

- Clorador v10kDocument8 pagesClorador v10kMarco Antonio VelazcoNo ratings yet

- Nimco Loads of ControlDocument2 pagesNimco Loads of Controllukasz20511No ratings yet

- PICV Guide SpecificationDocument7 pagesPICV Guide Specificationrio jeffryNo ratings yet

- Safety ValvesDocument12 pagesSafety ValvesMuhammad Ahmed KhanNo ratings yet

- Product Description - Wellhead Control Panel (WHCP) and HPUDocument5 pagesProduct Description - Wellhead Control Panel (WHCP) and HPUIsioma1No ratings yet

- Bab 9 Control Valve 2018Document55 pagesBab 9 Control Valve 2018Ramadian100% (1)

- Fundamentals of Final Control ElementsDocument57 pagesFundamentals of Final Control ElementshazemNo ratings yet

- CATAìLOGO VAìLVULA DE GLOBODocument8 pagesCATAìLOGO VAìLVULA DE GLOBODanny Guarderas RNo ratings yet

- Dualrange Control For Fine Throttling Service: Dualrange Weir Type Bonnet AssembliesDocument5 pagesDualrange Control For Fine Throttling Service: Dualrange Weir Type Bonnet Assembliesvarun sharmaNo ratings yet

- Surface Hydraulic Control System PsDocument1 pageSurface Hydraulic Control System PsabdouNo ratings yet

- F 9197Document4 pagesF 9197lipetrol007No ratings yet

- CLA-VAl Float ValveDocument4 pagesCLA-VAl Float ValveEntor EntorNo ratings yet

- Control ValveDocument35 pagesControl Valveshivani DubeyNo ratings yet

- RexrothDocument14 pagesRexrothWilson Cendales100% (1)

- Flow Control Valves DVE: Up To 350 Bar Up To 160 L/minDocument5 pagesFlow Control Valves DVE: Up To 350 Bar Up To 160 L/minVijay BhureNo ratings yet

- Float Valve: (Sizes 1/2"-6" / 15 - 150 MM)Document4 pagesFloat Valve: (Sizes 1/2"-6" / 15 - 150 MM)TeoxNo ratings yet

- Wellhead Control Panel1Document2 pagesWellhead Control Panel1kmsrini@yahoo.com100% (1)

- Safety ValvesDocument13 pagesSafety ValvesAntonio DiabanzaNo ratings yet

- Surface Well Testing SWTDocument3 pagesSurface Well Testing SWTHussein AbdallahNo ratings yet

- V10K Gas ChlorinatorDocument8 pagesV10K Gas ChlorinatorleonardseniorNo ratings yet

- Control Valve Main ObjectivesDocument55 pagesControl Valve Main Objectivesعبدالحميد عبدالغفار الدرديريNo ratings yet

- Series 825Y: Reduced Pressure Zone AssembliesDocument2 pagesSeries 825Y: Reduced Pressure Zone Assembliesmiljan trifkovicNo ratings yet

- V2000 Gas Feed Models PDFDocument8 pagesV2000 Gas Feed Models PDFRandy LangleyNo ratings yet

- Evopicv Tech Manual en 5a62d7d99eDocument80 pagesEvopicv Tech Manual en 5a62d7d99eAmando GonzalesNo ratings yet

- Capital Controls® Series Wp70Cv3 Gas FeedersDocument8 pagesCapital Controls® Series Wp70Cv3 Gas FeedersLoan NguyênNo ratings yet

- 7 - Andre VolschenkDocument24 pages7 - Andre VolschenkPieter Vd MerweNo ratings yet

- Picv New2Document12 pagesPicv New2arojit deyNo ratings yet

- Aquestia OCV AVIATIONDocument16 pagesAquestia OCV AVIATIONSony Nd AshaNo ratings yet

- VFD Versus Control Valve For Pump Flow ControlsDocument6 pagesVFD Versus Control Valve For Pump Flow ControlsCarlos WayNo ratings yet

- Remote Hydraulically Operated Monitor 03 RCHM299: System Package Valve Box / Hydraulic SourceDocument1 pageRemote Hydraulically Operated Monitor 03 RCHM299: System Package Valve Box / Hydraulic SourceKrishna N HNo ratings yet

- Safety ValvesDocument22 pagesSafety ValvesJabbarKaddemNo ratings yet

- Drilling Chokes BrochureDocument12 pagesDrilling Chokes BrochureAshok SureshNo ratings yet

- Av-Tek VRX Plunger REV-GDocument12 pagesAv-Tek VRX Plunger REV-GwaqasNo ratings yet

- HD-2-FM ServiceDocument8 pagesHD-2-FM Servicebabis lionakisNo ratings yet

- Ug VX Valves WebDocument2 pagesUg VX Valves Webczdcxdtr2rNo ratings yet

- PB4310Document2 pagesPB4310parrastevens930No ratings yet

- Air Admittance Valves (Ventapipe) : SectionDocument5 pagesAir Admittance Valves (Ventapipe) : SectionDinesh GuptaNo ratings yet

- Second-Stage Nozzle Control: GeneralDocument4 pagesSecond-Stage Nozzle Control: GeneralSara VaccaNo ratings yet

- US4977928 Patent Load SensingDocument5 pagesUS4977928 Patent Load SensingAmeerNo ratings yet

- Control Valves: Rejath Jacob ThomasDocument77 pagesControl Valves: Rejath Jacob Thomasshakti sindhuNo ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Schaum S Outline Fluid Mechanics and HydraulicsDocument388 pagesSchaum S Outline Fluid Mechanics and HydraulicsNelson Fernandez RoblesNo ratings yet

- CS 563 Hydraulic PDFDocument2 pagesCS 563 Hydraulic PDFanggieNo ratings yet

- Materials Indent For Purchase: SR, No. Description Make Unit Qty Cat No. Price Remark CPVC PipeDocument5 pagesMaterials Indent For Purchase: SR, No. Description Make Unit Qty Cat No. Price Remark CPVC PipeAzad AnsariNo ratings yet

- Valvula Check AlarmDocument20 pagesValvula Check AlarmCarlos Amaya CuevaNo ratings yet

- S12 Water Flushing Circuit PDFDocument34 pagesS12 Water Flushing Circuit PDFRicardo Ramirez EstrelloNo ratings yet

- Plumbing System AnalysisDocument3 pagesPlumbing System AnalysisAvery DuckworthNo ratings yet

- Hydraulic System Veth-Compact-Jet Thruster (11 KW / 100 Ltrs. Steering Power Pack)Document1 pageHydraulic System Veth-Compact-Jet Thruster (11 KW / 100 Ltrs. Steering Power Pack)Costel Ava ConstantinNo ratings yet

- Ex ArisuDocument12 pagesEx ArisuJeiner Leyva BernalNo ratings yet

- Hydraulic Cylinder Seal KitsDocument3 pagesHydraulic Cylinder Seal KitsSami KahtaniNo ratings yet

- Module 2 of PlumbingDocument12 pagesModule 2 of PlumbingDJNo ratings yet

- Green Mark - Sanitary AppDocument10 pagesGreen Mark - Sanitary Appoj_ordeNo ratings yet

- CA Spare Parts List For From ShumattDocument7 pagesCA Spare Parts List For From ShumattMasauso LunguNo ratings yet

- Section 35 - Hydraulic System - Chapter 2Document52 pagesSection 35 - Hydraulic System - Chapter 2Cristian Sterie100% (1)

- 3.1 Design BriefDocument5 pages3.1 Design BriefRaj KamalNo ratings yet

- 4U3S Water SupplyDocument15 pages4U3S Water SupplyKhin Thu Zar HtayNo ratings yet

- CUP 04 BOIN USA 02 WebDocument2 pagesCUP 04 BOIN USA 02 WebMajid abdulNo ratings yet

- Aurora Bombas CI Tipo Turbina VerticalDocument32 pagesAurora Bombas CI Tipo Turbina VerticalEsteban Calderón NavarroNo ratings yet

- 1-Piping Manual-Pdms12Document413 pages1-Piping Manual-Pdms12MOHSEN2005IBNo ratings yet

- AXERA 5-140 4408: Section 6Document20 pagesAXERA 5-140 4408: Section 6YuriPasenkoNo ratings yet

- Section04 Relief ValvesDocument30 pagesSection04 Relief ValvesHENRY LLOFREL CORREA LOPEZNo ratings yet

- Pressure Relief AplicationsDocument3 pagesPressure Relief AplicationsAndres PerezNo ratings yet

- Ball Valve Data Sheet Q240Document1 pageBall Valve Data Sheet Q240faruk hossain100% (2)

- Swagelok Valves CatDocument38 pagesSwagelok Valves CatBITS AEROSPACE MECHATRONICSNo ratings yet

- ENCH 425: Transport Processes IDocument13 pagesENCH 425: Transport Processes IAlex DoanNo ratings yet

- Cat - Dcs.sis - Controllerloader 924ghDocument15 pagesCat - Dcs.sis - Controllerloader 924ghmahmod alrousanNo ratings yet

- Content: General Technical InformationDocument26 pagesContent: General Technical InformationVito LaudicinaNo ratings yet

- Check Valve VickersDocument15 pagesCheck Valve Vickersعلي عائشة100% (1)

- 1 .Reverse Osmosis System (RO) Bahan Baku 500ppmDocument2 pages1 .Reverse Osmosis System (RO) Bahan Baku 500ppmboynaduaNo ratings yet