Professional Documents

Culture Documents

Design Mix Concrete For Paver Blocks

Design Mix Concrete For Paver Blocks

Uploaded by

Nipan DekaCopyright:

Available Formats

You might also like

- PQC Mix DesignDocument60 pagesPQC Mix DesignAshok amlapure70% (10)

- COBIT 2019 - RACI by Role - April 2020Document295 pagesCOBIT 2019 - RACI by Role - April 2020gaston6711100% (1)

- Concrete Mix Design M-30 (Paver Block) Grade: Name of Work Client Authority Engineer ContractorDocument23 pagesConcrete Mix Design M-30 (Paver Block) Grade: Name of Work Client Authority Engineer ContractorAshok amlapure75% (4)

- Cement Consumption DSR 2018Document40 pagesCement Consumption DSR 2018Thilak Balakrishnan100% (8)

- The Sanlam Brand: Connecting Hearts and Minds MeaningfullyDocument26 pagesThe Sanlam Brand: Connecting Hearts and Minds MeaningfullyXolani Radebe RadebeNo ratings yet

- Is 10262-2019 PDFDocument44 pagesIs 10262-2019 PDFMaulik Panseriya100% (1)

- Original Ground Level-Ogl CompactionDocument3 pagesOriginal Ground Level-Ogl CompactionCheng Engi100% (2)

- Mix Design For Dry Lean ConcreteDocument3 pagesMix Design For Dry Lean ConcreteKunal Paul100% (2)

- Morth 1700 Structural ConcreteDocument23 pagesMorth 1700 Structural ConcreteRamesh88% (40)

- What Is PQC PDFDocument19 pagesWhat Is PQC PDFLASA VADODARANo ratings yet

- Is 458-1988Document46 pagesIs 458-1988Rajashekhar Katta100% (2)

- Is 10262 1982Document23 pagesIs 10262 1982rathirajaNo ratings yet

- IS 1199 Part6-2018 PDFDocument18 pagesIS 1199 Part6-2018 PDFਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟ100% (14)

- Concrete Mix Design M40 Grade (PQC) PDFDocument41 pagesConcrete Mix Design M40 Grade (PQC) PDFJalgaon60% (5)

- Mix Design c40Document13 pagesMix Design c40Jaime Manalili LandinginNo ratings yet

- History of PavingDocument42 pagesHistory of PavingNipan DekaNo ratings yet

- GM 1927 01 Project PlanDocument1 pageGM 1927 01 Project Planmark100% (2)

- Info On Paver BlocksDocument6 pagesInfo On Paver BlocksGaneshNo ratings yet

- Mix Design For M35 Grade of ConcreteDocument4 pagesMix Design For M35 Grade of ConcretePaulos Wodajenehe TessemaNo ratings yet

- Interlocking Paver Block Mix Design-5.8.2020Document5 pagesInterlocking Paver Block Mix Design-5.8.2020Ganesh100% (1)

- Concrete Mix Design M25 PDFDocument8 pagesConcrete Mix Design M25 PDFJEFFY JACOBNo ratings yet

- IS 1199 - (RA 2018) Methods of Sampling and Analysis of ConcreteDocument46 pagesIS 1199 - (RA 2018) Methods of Sampling and Analysis of Concretebala subramanyam100% (3)

- Calibration of Pouring CylinderDocument16 pagesCalibration of Pouring CylinderAnonymous drBWfwhNo ratings yet

- Determination - of - Concrete - Yield and DensifyingDocument7 pagesDetermination - of - Concrete - Yield and Densifyingexam robot100% (1)

- Design Mix M 30 PPC - CP2659-41Document2 pagesDesign Mix M 30 PPC - CP2659-41Sathish AnandakumarNo ratings yet

- M 30 Concrete Mix Design FinalDocument10 pagesM 30 Concrete Mix Design FinalRakesh ReddyNo ratings yet

- Laboratory Test Report: MIX DESIGN of M20 CONCRETE (Pakur Variety)Document8 pagesLaboratory Test Report: MIX DESIGN of M20 CONCRETE (Pakur Variety)SubhadipNo ratings yet

- Bitumen VG 30 & VG 40 Mix DesignDocument5 pagesBitumen VG 30 & VG 40 Mix DesignPoirei Zildjian0% (1)

- Is 1542 1992Document8 pagesIs 1542 1992kc_nk100% (1)

- Ceramic Tiles - Methods of Test, Sampling and Basis For AcceptanceDocument52 pagesCeramic Tiles - Methods of Test, Sampling and Basis For Acceptancekaran singhNo ratings yet

- RMC Plant Calibration ReportDocument5 pagesRMC Plant Calibration ReportSurendra kumar50% (2)

- Designed Concrete MixDocument6 pagesDesigned Concrete MixniceseshaNo ratings yet

- Is 1199 Part 2 2018Document5 pagesIs 1199 Part 2 2018Sanchit Gupta0% (1)

- IS 516-1959 (Reaffirmed 2018)Document27 pagesIS 516-1959 (Reaffirmed 2018)Sai Pavan100% (1)

- Cement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementDocument4 pagesCement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementChalamaiah VM100% (1)

- Methodology For DBMDocument10 pagesMethodology For DBMvivekNo ratings yet

- Brick Test ReportDocument1 pageBrick Test Reportsudugouda67% (3)

- 6-Methodologyfor Plum ConcreteDocument2 pages6-Methodologyfor Plum ConcreteAshok kumar100% (1)

- DLC Design Mix Stipulation1Document8 pagesDLC Design Mix Stipulation1abhishek negiNo ratings yet

- Wet Mix Macadam (WMM) Technical Specifications As Per MORTH and Indian StandardDocument40 pagesWet Mix Macadam (WMM) Technical Specifications As Per MORTH and Indian StandardRAMPALLI GATTAIAH0% (1)

- M30 Grade Concrete Mix Design With Fly Ash - IS10262Document5 pagesM30 Grade Concrete Mix Design With Fly Ash - IS10262scribdfree anytimeNo ratings yet

- Mix Design M - 40 GradeDocument3 pagesMix Design M - 40 GradeAashu chaudharyNo ratings yet

- Mix Design M40Document3 pagesMix Design M40D21No ratings yet

- Concrete Mix Design G20Document4 pagesConcrete Mix Design G20Syerifaizal Hj. MustaphaNo ratings yet

- Parameters For Mix Design M40Document2 pagesParameters For Mix Design M40Sethu MadhavNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix DesignUma MaheshwaraNo ratings yet

- Mix Design MDocument3 pagesMix Design MPrabhakar Kumar BarnwalNo ratings yet

- Sp. Gravity: of Water Cement RatioDocument2 pagesSp. Gravity: of Water Cement RatioarjunNo ratings yet

- Concrete Mix Design ProcedureDocument7 pagesConcrete Mix Design ProcedureJaime Manalili Landingin0% (1)

- IS Code Method of Mix Design Using SuperplasticizerDocument29 pagesIS Code Method of Mix Design Using SuperplasticizerJameel KhanNo ratings yet

- Civil EngineerDocument26 pagesCivil Engineerchrreddy3No ratings yet

- M 15 Mix Designs As Per IS-10262-2009Document25 pagesM 15 Mix Designs As Per IS-10262-2009Prasad MsrkNo ratings yet

- Mix Design M40 Grade Designed As Per IS 10262:2009 & IS 456:2000Document6 pagesMix Design M40 Grade Designed As Per IS 10262:2009 & IS 456:2000Sanjoy RoyNo ratings yet

- Calculations of Mix Design For M30 Grade ConcreteDocument2 pagesCalculations of Mix Design For M30 Grade Concretenutan acharya100% (2)

- Annex 4.1 - Technical Specifications - Civil WorksDocument6 pagesAnnex 4.1 - Technical Specifications - Civil WorksMW ALSABRINo ratings yet

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignPratyush Kumar DoraNo ratings yet

- Design Mix Concrete/ RMC Proportioning - M 40: Annex ADocument9 pagesDesign Mix Concrete/ RMC Proportioning - M 40: Annex AWilliam ReedNo ratings yet

- M 20 Mix Design Sample ReportDocument3 pagesM 20 Mix Design Sample ReportRakesh ReddyNo ratings yet

- Mix Design M-40 GradeDocument2 pagesMix Design M-40 GradePruthvi TejaNo ratings yet

- Test Data For Material: Specific Gravity: Written by Administrator Sunday, 25 October 2009 17:20Document6 pagesTest Data For Material: Specific Gravity: Written by Administrator Sunday, 25 October 2009 17:20Akash PaulNo ratings yet

- Concrete Mix DesignDocument92 pagesConcrete Mix Designtanveer100% (1)

- M30 Normal - Mix Design With Trial SheetDocument4 pagesM30 Normal - Mix Design With Trial Sheetabir senguptaNo ratings yet

- Strength of ConcreteDocument3 pagesStrength of ConcretelombangrurusNo ratings yet

- Concrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDocument5 pagesConcrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDattatreya DattuNo ratings yet

- Aiwtdsociety - Application FormDocument8 pagesAiwtdsociety - Application FormNipan DekaNo ratings yet

- Offer of Hexagonal ShapeCharcoal Briquette Production Line 20191024Document4 pagesOffer of Hexagonal ShapeCharcoal Briquette Production Line 20191024Nipan DekaNo ratings yet

- Part-Ii: Bamboo Briquette Charcoal Making From Bamboo WasteDocument7 pagesPart-Ii: Bamboo Briquette Charcoal Making From Bamboo WasteNipan DekaNo ratings yet

- Maoist Documents: Strategy & Tactics of The Indian Revolution Central Committee (P) CPI (Maoist)Document85 pagesMaoist Documents: Strategy & Tactics of The Indian Revolution Central Committee (P) CPI (Maoist)Nipan DekaNo ratings yet

- Interlocking Concrete Paver BlocksDocument13 pagesInterlocking Concrete Paver BlocksNipan DekaNo ratings yet

- Fully Automatic Colour Paver MachinesDocument3 pagesFully Automatic Colour Paver MachinesNipan DekaNo ratings yet

- Toothpick Production LineDocument3 pagesToothpick Production LineNipan DekaNo ratings yet

- Cement Concrete Tiles and Paving BlocksDocument8 pagesCement Concrete Tiles and Paving BlocksNipan DekaNo ratings yet

- Author's Purpose Mini PassagesDocument5 pagesAuthor's Purpose Mini Passages18118No ratings yet

- DP FourSeals ENGDocument60 pagesDP FourSeals ENGgeorgia83609No ratings yet

- Declaration of Conformity For Restriction of Hazardous Substances (Rohs)Document1 pageDeclaration of Conformity For Restriction of Hazardous Substances (Rohs)Yogesh KatyarmalNo ratings yet

- Chapter 2 - Equivalence Above Word LevelDocument23 pagesChapter 2 - Equivalence Above Word LevelNoo NooNo ratings yet

- UPNMG Press Statement-Unemployed Nurses and MidwivesDocument1 pageUPNMG Press Statement-Unemployed Nurses and MidwivesClavia NyaabaNo ratings yet

- Adu Gloria WorkDocument68 pagesAdu Gloria WorkAiman UsmanNo ratings yet

- PT RatioDocument5 pagesPT RatioMazidul Islam MahfujNo ratings yet

- Construction PlanningDocument198 pagesConstruction PlanningHajarath Prasad AbburuNo ratings yet

- Make Up TT23Document1 pageMake Up TT23ShreyasNo ratings yet

- Rheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteDocument3 pagesRheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteFrancois-No ratings yet

- Classroom Program 10B 2023 2024Document2 pagesClassroom Program 10B 2023 2024jester18 bordersyoNo ratings yet

- NHPC Dulhasti 1Document2 pagesNHPC Dulhasti 1Sherry SherNo ratings yet

- Internship 2021Document25 pagesInternship 2021PRAGYA CHANSORIYANo ratings yet

- Year 9 Naplan Non CalcDocument12 pagesYear 9 Naplan Non CalcSophieNoorSalibiNo ratings yet

- Chapter 2 SOURCES & FOUNDATIONS OF HUMAN RIGHTS LAWDocument6 pagesChapter 2 SOURCES & FOUNDATIONS OF HUMAN RIGHTS LAWI Lobeu My CaratNo ratings yet

- Am at Photogr 21 February 2015Document92 pagesAm at Photogr 21 February 2015TraficantdePufarineNo ratings yet

- Air Equipment Compressors Compressor 250 300CFM D XAS 125DD Operation ManualDocument34 pagesAir Equipment Compressors Compressor 250 300CFM D XAS 125DD Operation ManualFloyd MG100% (1)

- LOPC-mech Seal FailureDocument26 pagesLOPC-mech Seal FailureSanjeevi Kumar SpNo ratings yet

- Genetic Mutation LAB SHEET REVISEDDocument2 pagesGenetic Mutation LAB SHEET REVISEDyusufoyololaNo ratings yet

- Statement of Claim Form PDFDocument3 pagesStatement of Claim Form PDFWalla MahmoudNo ratings yet

- Conceptual, FEED, Detailed Eng - Phases (An Overview)Document7 pagesConceptual, FEED, Detailed Eng - Phases (An Overview)nazeer_mohdNo ratings yet

- Syllabus For Applied ElectronicsDocument28 pagesSyllabus For Applied ElectronicsvinayakbondNo ratings yet

- Backtracking - Set 2 (Rat in A Maze) - GeeksforGeeksDocument7 pagesBacktracking - Set 2 (Rat in A Maze) - GeeksforGeeksAtul GargNo ratings yet

- Object-Oriented Systems Analysis and DesignDocument8 pagesObject-Oriented Systems Analysis and DesignAmar KulkarniNo ratings yet

- Current Issues in AIS655Document5 pagesCurrent Issues in AIS655AmmarNo ratings yet

- Elizabeth Winifred Brewster,: CanadianDocument4 pagesElizabeth Winifred Brewster,: CanadianVinnoDarmawanNo ratings yet

- Ingeteam Catalogo Cms Mayo2019 Eng MailDocument7 pagesIngeteam Catalogo Cms Mayo2019 Eng MailChrist Rodney MAKANANo ratings yet

Design Mix Concrete For Paver Blocks

Design Mix Concrete For Paver Blocks

Uploaded by

Nipan DekaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Mix Concrete For Paver Blocks

Design Mix Concrete For Paver Blocks

Uploaded by

Nipan DekaCopyright:

Available Formats

Design Mix Concrete for Paver Blocks:

The minimum cement content for compacted concrete of pavers shall not be less

than 380 Kg / cum.

The cement used in the manufacture of high quality pre-cast concrete paving blocks shall be

conforming to IS 12269 (53 grade ordinary Portland cement) or IS 8112(43 grade ordinary

Portland cement).

The maximum water cement ratio for pavers concrete shall not be more than

0.40

The fine and coarse aggregates shall consist of naturally occurring crushed or

uncrushed materials, which apart from the grading requirements comply with IS

383-1970. The fine aggregates used shall contain a minimum of 25% natural

silicon sand. Lime stone aggregates shall not be used. Aggregates shall contain no

more than 3% by weight of clay & shall be free from deleterious salt sand

contaminants. Zone iv sand shall not be acceptable. Course aggregate shall be 10

mm and below.

The pigment shall be used only on wearing and top surface and through out the

paver block. The pigment used shall not be more than 10% of weight of cement

used in the wearing course layer. However, use of pigment shall in no way alter the

required strength of the paver block.Pigment used for colouring paver blocks shall

have durable colour. It shall not contain matters detrimental to concrete. The

pigment shall not contain Zinc compound. Lead pigment shall not be used.

The compressive strength requirement of concrete paver block shall be

minimum 47.2 MPa (N / sqmm) for 28 days (Testing as per IS;15658) after

applying the correction factor as per IS-15658; 2006. No lower tolerance limit in

compressive strength shall be allowed.

Compressive Strength

Minimum 47.2 MPa (N/Sqmm) (for 80mm)

Abrasion Resistance

Maximum 2.0 mm

Water Absorption

Maximum 5.80%

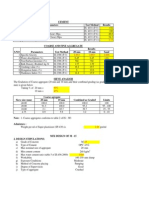

Parameters for mix design M-40

Grade Designation = M-40

Type of cement = O.P.C-43 grade

Admixture = Fosroc ( Conplast SP 430 G8M )

Fine Aggregate = Zone-II

Sp. Gravity Cement = 3.15

Fine Aggregate = 2.61

Coarse Aggregate (20mm) = 2.65

Coarse Aggregate (10mm) = 2.66

Minimum Cement (Taking higher Value) = 400 kg /m3

Maximum water cement ratio (Taking higher Value) = 0.45

Mix Calculation: –

1. Target Mean Strength = 40 + (5 X 1.65) = 48.25 Mpa (Taking higher Value)

2. Selection of water cement ratio:-

Assume water cement ratio = 0.4

3. Calculation of cement content: –

Assume cement content 400 kg / m3

(As per contract Minimum cement content 400 kg / m3)

4. Calculation of water: –

400 X 0.4 = 160 kg Which is less than 186 kg (As per Table No. 4, IS: 10262)

Hence o.k.

5. Calculation for C.A. & F.A.: – As per IS : 10262 , Cl. No. 3.5.1

V = [ W + (C/Sc) + (1/p) . (fa/Sfa) ] x (1/1000)

V = [ W + (C/Sc) + {1/(1-p)} . (ca/Sca) ] x (1/1000)

Where

V = absolute volume of fresh concrete, which is equal to gross volume (m3) minus the

volume of entrapped air ,

W = mass of water ( kg ) per m3 of concrete ,

C = mass of cement ( kg ) per m3 of concrete ,

Sc = specific gravity of cement,

(p) = Ratio of fine aggregate to total aggregate by absolute volume ,

(fa) , (ca) = total mass of fine aggregate and coarse aggregate (kg) per m3 of

Concrete respectively, and

Sfa , Sca = specific gravities of saturated surface dry fine aggregate and Coarse aggregate

respectively.

As per Table No. 3 , IS-10262, for 20mm maximum size entrapped air is 2% .

Assume F.A. by % of volume of total aggregate = 36.5 %

0.98 = [ 160 + ( 400 / 3.15 ) + ( 1 / 0.365 ) ( Fa / 2.61 )] ( 1 /1000 )

=> Fa = 660.2 kg

Say Fa = 660 kg.

0.98 = [ 160 + ( 400 / 3.15 ) + ( 1 / 0.635 ) ( Ca / 2.655 )] ( 1 /1000 )

=> Ca = 1168.37 kg.

Say Ca = 1168 kg.

Considering 20 mm : 10mm = 0.6 : 0.4

20mm = 701 kg .

10mm = 467 kg .

Hence Mix details per m3

Cement = 400 kg

Water = 160 kg

Fine aggregate = 660 kg

Coarse aggregate 20 mm = 701 kg

Coarse aggregate 10 mm = 467 kg

Admixture = 0.6 % by weight of cement = 2.4 kg.

Recron 3S = 900 gm

Water: cement: F.A.: C.A. = 0.4: 1: 1.65: 2.92

M30 is 1:1:2

M35 is 1: .856 : 1.7

M40 is 1: .75 : 1.5

You might also like

- PQC Mix DesignDocument60 pagesPQC Mix DesignAshok amlapure70% (10)

- COBIT 2019 - RACI by Role - April 2020Document295 pagesCOBIT 2019 - RACI by Role - April 2020gaston6711100% (1)

- Concrete Mix Design M-30 (Paver Block) Grade: Name of Work Client Authority Engineer ContractorDocument23 pagesConcrete Mix Design M-30 (Paver Block) Grade: Name of Work Client Authority Engineer ContractorAshok amlapure75% (4)

- Cement Consumption DSR 2018Document40 pagesCement Consumption DSR 2018Thilak Balakrishnan100% (8)

- The Sanlam Brand: Connecting Hearts and Minds MeaningfullyDocument26 pagesThe Sanlam Brand: Connecting Hearts and Minds MeaningfullyXolani Radebe RadebeNo ratings yet

- Is 10262-2019 PDFDocument44 pagesIs 10262-2019 PDFMaulik Panseriya100% (1)

- Original Ground Level-Ogl CompactionDocument3 pagesOriginal Ground Level-Ogl CompactionCheng Engi100% (2)

- Mix Design For Dry Lean ConcreteDocument3 pagesMix Design For Dry Lean ConcreteKunal Paul100% (2)

- Morth 1700 Structural ConcreteDocument23 pagesMorth 1700 Structural ConcreteRamesh88% (40)

- What Is PQC PDFDocument19 pagesWhat Is PQC PDFLASA VADODARANo ratings yet

- Is 458-1988Document46 pagesIs 458-1988Rajashekhar Katta100% (2)

- Is 10262 1982Document23 pagesIs 10262 1982rathirajaNo ratings yet

- IS 1199 Part6-2018 PDFDocument18 pagesIS 1199 Part6-2018 PDFਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟ100% (14)

- Concrete Mix Design M40 Grade (PQC) PDFDocument41 pagesConcrete Mix Design M40 Grade (PQC) PDFJalgaon60% (5)

- Mix Design c40Document13 pagesMix Design c40Jaime Manalili LandinginNo ratings yet

- History of PavingDocument42 pagesHistory of PavingNipan DekaNo ratings yet

- GM 1927 01 Project PlanDocument1 pageGM 1927 01 Project Planmark100% (2)

- Info On Paver BlocksDocument6 pagesInfo On Paver BlocksGaneshNo ratings yet

- Mix Design For M35 Grade of ConcreteDocument4 pagesMix Design For M35 Grade of ConcretePaulos Wodajenehe TessemaNo ratings yet

- Interlocking Paver Block Mix Design-5.8.2020Document5 pagesInterlocking Paver Block Mix Design-5.8.2020Ganesh100% (1)

- Concrete Mix Design M25 PDFDocument8 pagesConcrete Mix Design M25 PDFJEFFY JACOBNo ratings yet

- IS 1199 - (RA 2018) Methods of Sampling and Analysis of ConcreteDocument46 pagesIS 1199 - (RA 2018) Methods of Sampling and Analysis of Concretebala subramanyam100% (3)

- Calibration of Pouring CylinderDocument16 pagesCalibration of Pouring CylinderAnonymous drBWfwhNo ratings yet

- Determination - of - Concrete - Yield and DensifyingDocument7 pagesDetermination - of - Concrete - Yield and Densifyingexam robot100% (1)

- Design Mix M 30 PPC - CP2659-41Document2 pagesDesign Mix M 30 PPC - CP2659-41Sathish AnandakumarNo ratings yet

- M 30 Concrete Mix Design FinalDocument10 pagesM 30 Concrete Mix Design FinalRakesh ReddyNo ratings yet

- Laboratory Test Report: MIX DESIGN of M20 CONCRETE (Pakur Variety)Document8 pagesLaboratory Test Report: MIX DESIGN of M20 CONCRETE (Pakur Variety)SubhadipNo ratings yet

- Bitumen VG 30 & VG 40 Mix DesignDocument5 pagesBitumen VG 30 & VG 40 Mix DesignPoirei Zildjian0% (1)

- Is 1542 1992Document8 pagesIs 1542 1992kc_nk100% (1)

- Ceramic Tiles - Methods of Test, Sampling and Basis For AcceptanceDocument52 pagesCeramic Tiles - Methods of Test, Sampling and Basis For Acceptancekaran singhNo ratings yet

- RMC Plant Calibration ReportDocument5 pagesRMC Plant Calibration ReportSurendra kumar50% (2)

- Designed Concrete MixDocument6 pagesDesigned Concrete MixniceseshaNo ratings yet

- Is 1199 Part 2 2018Document5 pagesIs 1199 Part 2 2018Sanchit Gupta0% (1)

- IS 516-1959 (Reaffirmed 2018)Document27 pagesIS 516-1959 (Reaffirmed 2018)Sai Pavan100% (1)

- Cement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementDocument4 pagesCement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementChalamaiah VM100% (1)

- Methodology For DBMDocument10 pagesMethodology For DBMvivekNo ratings yet

- Brick Test ReportDocument1 pageBrick Test Reportsudugouda67% (3)

- 6-Methodologyfor Plum ConcreteDocument2 pages6-Methodologyfor Plum ConcreteAshok kumar100% (1)

- DLC Design Mix Stipulation1Document8 pagesDLC Design Mix Stipulation1abhishek negiNo ratings yet

- Wet Mix Macadam (WMM) Technical Specifications As Per MORTH and Indian StandardDocument40 pagesWet Mix Macadam (WMM) Technical Specifications As Per MORTH and Indian StandardRAMPALLI GATTAIAH0% (1)

- M30 Grade Concrete Mix Design With Fly Ash - IS10262Document5 pagesM30 Grade Concrete Mix Design With Fly Ash - IS10262scribdfree anytimeNo ratings yet

- Mix Design M - 40 GradeDocument3 pagesMix Design M - 40 GradeAashu chaudharyNo ratings yet

- Mix Design M40Document3 pagesMix Design M40D21No ratings yet

- Concrete Mix Design G20Document4 pagesConcrete Mix Design G20Syerifaizal Hj. MustaphaNo ratings yet

- Parameters For Mix Design M40Document2 pagesParameters For Mix Design M40Sethu MadhavNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix DesignUma MaheshwaraNo ratings yet

- Mix Design MDocument3 pagesMix Design MPrabhakar Kumar BarnwalNo ratings yet

- Sp. Gravity: of Water Cement RatioDocument2 pagesSp. Gravity: of Water Cement RatioarjunNo ratings yet

- Concrete Mix Design ProcedureDocument7 pagesConcrete Mix Design ProcedureJaime Manalili Landingin0% (1)

- IS Code Method of Mix Design Using SuperplasticizerDocument29 pagesIS Code Method of Mix Design Using SuperplasticizerJameel KhanNo ratings yet

- Civil EngineerDocument26 pagesCivil Engineerchrreddy3No ratings yet

- M 15 Mix Designs As Per IS-10262-2009Document25 pagesM 15 Mix Designs As Per IS-10262-2009Prasad MsrkNo ratings yet

- Mix Design M40 Grade Designed As Per IS 10262:2009 & IS 456:2000Document6 pagesMix Design M40 Grade Designed As Per IS 10262:2009 & IS 456:2000Sanjoy RoyNo ratings yet

- Calculations of Mix Design For M30 Grade ConcreteDocument2 pagesCalculations of Mix Design For M30 Grade Concretenutan acharya100% (2)

- Annex 4.1 - Technical Specifications - Civil WorksDocument6 pagesAnnex 4.1 - Technical Specifications - Civil WorksMW ALSABRINo ratings yet

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignPratyush Kumar DoraNo ratings yet

- Design Mix Concrete/ RMC Proportioning - M 40: Annex ADocument9 pagesDesign Mix Concrete/ RMC Proportioning - M 40: Annex AWilliam ReedNo ratings yet

- M 20 Mix Design Sample ReportDocument3 pagesM 20 Mix Design Sample ReportRakesh ReddyNo ratings yet

- Mix Design M-40 GradeDocument2 pagesMix Design M-40 GradePruthvi TejaNo ratings yet

- Test Data For Material: Specific Gravity: Written by Administrator Sunday, 25 October 2009 17:20Document6 pagesTest Data For Material: Specific Gravity: Written by Administrator Sunday, 25 October 2009 17:20Akash PaulNo ratings yet

- Concrete Mix DesignDocument92 pagesConcrete Mix Designtanveer100% (1)

- M30 Normal - Mix Design With Trial SheetDocument4 pagesM30 Normal - Mix Design With Trial Sheetabir senguptaNo ratings yet

- Strength of ConcreteDocument3 pagesStrength of ConcretelombangrurusNo ratings yet

- Concrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDocument5 pagesConcrete Mix Design Example - M50 Grade Concrete: 2. Selection of Water Cement Ratio: 3. Calculation of Water ContentDattatreya DattuNo ratings yet

- Aiwtdsociety - Application FormDocument8 pagesAiwtdsociety - Application FormNipan DekaNo ratings yet

- Offer of Hexagonal ShapeCharcoal Briquette Production Line 20191024Document4 pagesOffer of Hexagonal ShapeCharcoal Briquette Production Line 20191024Nipan DekaNo ratings yet

- Part-Ii: Bamboo Briquette Charcoal Making From Bamboo WasteDocument7 pagesPart-Ii: Bamboo Briquette Charcoal Making From Bamboo WasteNipan DekaNo ratings yet

- Maoist Documents: Strategy & Tactics of The Indian Revolution Central Committee (P) CPI (Maoist)Document85 pagesMaoist Documents: Strategy & Tactics of The Indian Revolution Central Committee (P) CPI (Maoist)Nipan DekaNo ratings yet

- Interlocking Concrete Paver BlocksDocument13 pagesInterlocking Concrete Paver BlocksNipan DekaNo ratings yet

- Fully Automatic Colour Paver MachinesDocument3 pagesFully Automatic Colour Paver MachinesNipan DekaNo ratings yet

- Toothpick Production LineDocument3 pagesToothpick Production LineNipan DekaNo ratings yet

- Cement Concrete Tiles and Paving BlocksDocument8 pagesCement Concrete Tiles and Paving BlocksNipan DekaNo ratings yet

- Author's Purpose Mini PassagesDocument5 pagesAuthor's Purpose Mini Passages18118No ratings yet

- DP FourSeals ENGDocument60 pagesDP FourSeals ENGgeorgia83609No ratings yet

- Declaration of Conformity For Restriction of Hazardous Substances (Rohs)Document1 pageDeclaration of Conformity For Restriction of Hazardous Substances (Rohs)Yogesh KatyarmalNo ratings yet

- Chapter 2 - Equivalence Above Word LevelDocument23 pagesChapter 2 - Equivalence Above Word LevelNoo NooNo ratings yet

- UPNMG Press Statement-Unemployed Nurses and MidwivesDocument1 pageUPNMG Press Statement-Unemployed Nurses and MidwivesClavia NyaabaNo ratings yet

- Adu Gloria WorkDocument68 pagesAdu Gloria WorkAiman UsmanNo ratings yet

- PT RatioDocument5 pagesPT RatioMazidul Islam MahfujNo ratings yet

- Construction PlanningDocument198 pagesConstruction PlanningHajarath Prasad AbburuNo ratings yet

- Make Up TT23Document1 pageMake Up TT23ShreyasNo ratings yet

- Rheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteDocument3 pagesRheobuild 1100: A High Range Water Reducing Superplasticising Admixture For The Production of Rheoplastic ConcreteFrancois-No ratings yet

- Classroom Program 10B 2023 2024Document2 pagesClassroom Program 10B 2023 2024jester18 bordersyoNo ratings yet

- NHPC Dulhasti 1Document2 pagesNHPC Dulhasti 1Sherry SherNo ratings yet

- Internship 2021Document25 pagesInternship 2021PRAGYA CHANSORIYANo ratings yet

- Year 9 Naplan Non CalcDocument12 pagesYear 9 Naplan Non CalcSophieNoorSalibiNo ratings yet

- Chapter 2 SOURCES & FOUNDATIONS OF HUMAN RIGHTS LAWDocument6 pagesChapter 2 SOURCES & FOUNDATIONS OF HUMAN RIGHTS LAWI Lobeu My CaratNo ratings yet

- Am at Photogr 21 February 2015Document92 pagesAm at Photogr 21 February 2015TraficantdePufarineNo ratings yet

- Air Equipment Compressors Compressor 250 300CFM D XAS 125DD Operation ManualDocument34 pagesAir Equipment Compressors Compressor 250 300CFM D XAS 125DD Operation ManualFloyd MG100% (1)

- LOPC-mech Seal FailureDocument26 pagesLOPC-mech Seal FailureSanjeevi Kumar SpNo ratings yet

- Genetic Mutation LAB SHEET REVISEDDocument2 pagesGenetic Mutation LAB SHEET REVISEDyusufoyololaNo ratings yet

- Statement of Claim Form PDFDocument3 pagesStatement of Claim Form PDFWalla MahmoudNo ratings yet

- Conceptual, FEED, Detailed Eng - Phases (An Overview)Document7 pagesConceptual, FEED, Detailed Eng - Phases (An Overview)nazeer_mohdNo ratings yet

- Syllabus For Applied ElectronicsDocument28 pagesSyllabus For Applied ElectronicsvinayakbondNo ratings yet

- Backtracking - Set 2 (Rat in A Maze) - GeeksforGeeksDocument7 pagesBacktracking - Set 2 (Rat in A Maze) - GeeksforGeeksAtul GargNo ratings yet

- Object-Oriented Systems Analysis and DesignDocument8 pagesObject-Oriented Systems Analysis and DesignAmar KulkarniNo ratings yet

- Current Issues in AIS655Document5 pagesCurrent Issues in AIS655AmmarNo ratings yet

- Elizabeth Winifred Brewster,: CanadianDocument4 pagesElizabeth Winifred Brewster,: CanadianVinnoDarmawanNo ratings yet

- Ingeteam Catalogo Cms Mayo2019 Eng MailDocument7 pagesIngeteam Catalogo Cms Mayo2019 Eng MailChrist Rodney MAKANANo ratings yet