Professional Documents

Culture Documents

Ford Caja Automatica PDF

Ford Caja Automatica PDF

Uploaded by

Luis AlcalaCopyright:

Available Formats

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- 2001 Honda Odyssey Transm. B7TA B7XADocument62 pages2001 Honda Odyssey Transm. B7TA B7XAAgustin Chaparro Tirado86% (14)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Trasmision Automatic A Buick-Oldmobile 4T65EDocument156 pagesTrasmision Automatic A Buick-Oldmobile 4T65E52600100% (26)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WFrom EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WRating: 4.5 out of 5 stars4.5/5 (6)

- Error CodesDocument58 pagesError CodesAnoir Akkari93% (57)

- MF 210 210 4 Tractor OPT SQ w5cw2nrr34Document54 pagesMF 210 210 4 Tractor OPT SQ w5cw2nrr34dinismiguelNo ratings yet

- Code False Akpp 5r55Document7 pagesCode False Akpp 5r55VobsStrongNo ratings yet

- 5R55S Cooler Thermal Bypass FixDocument4 pages5R55S Cooler Thermal Bypass FixDon Jenkins100% (2)

- JF015E Valve Body DiagnosticDocument2 pagesJF015E Valve Body Diagnosticสนั่น วิริยะเจริญกุล100% (2)

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildFrom EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildRating: 5 out of 5 stars5/5 (1)

- Discover 110 Cbs 125 CbsDocument44 pagesDiscover 110 Cbs 125 Cbsaayush shuklaNo ratings yet

- Manual 6l50Document84 pagesManual 6l50franceli ferreira reisNo ratings yet

- Transmission 4R70W Main Control Valve Body Disassembly and Assembly of SubassembliesDocument5 pagesTransmission 4R70W Main Control Valve Body Disassembly and Assembly of SubassembliesFDONo ratings yet

- A-761E Manual PDFDocument107 pagesA-761E Manual PDFsergNo ratings yet

- 02-2009 4t65e, F4a23-33, A246e Check Ball, Ax4s-Ax4n-4f50n Codes DTCDocument16 pages02-2009 4t65e, F4a23-33, A246e Check Ball, Ax4s-Ax4n-4f50n Codes DTCAleNo ratings yet

- 09 GM3C 4t40e 4t45eDocument8 pages09 GM3C 4t40e 4t45eJoe MontanaNo ratings yet

- 2020 Seminar TopicsDocument7 pages2020 Seminar Topicsarstjunk25% (4)

- Atsg 2005 BulletinDocument46 pagesAtsg 2005 Bulletinlolop434350% (4)

- Transmission Filter Catalog: Oe Quality Transmission FiltersDocument103 pagesTransmission Filter Catalog: Oe Quality Transmission FiltersRamon Pujol PerramonNo ratings yet

- U660e Zip inDocument11 pagesU660e Zip inGabriel Harper'100% (1)

- Air Check Book 39 50Document12 pagesAir Check Book 39 50Timur TOT100% (2)

- Ford 5R55S Partes CDocument8 pagesFord 5R55S Partes CJose Mejia CaveroNo ratings yet

- Welcome To Today's Presentation Sponsored byDocument47 pagesWelcome To Today's Presentation Sponsored byfadrique54No ratings yet

- Valve Body Exploded View: ChryslerDocument2 pagesValve Body Exploded View: ChryslerJUAN CAMPOSANONo ratings yet

- Auto Trans 4R70W PDFDocument57 pagesAuto Trans 4R70W PDFDavid Bravo100% (2)

- p1811-p0748 Impala PDFDocument5 pagesp1811-p0748 Impala PDFUlloaEliasNo ratings yet

- 6L45 6L90 VacTestDocument4 pages6L45 6L90 VacTestJehovana100% (1)

- 4f50n CompleteDocument58 pages4f50n CompleteCarlos Treviño100% (2)

- 5r55 Oil Control PDFDocument14 pages5r55 Oil Control PDFHumberto Lojan100% (2)

- GM 4L60E/4L65E/4L70E 078: SOLENOID TEST: (Engine Off)Document2 pagesGM 4L60E/4L65E/4L70E 078: SOLENOID TEST: (Engine Off)twinturbo2No ratings yet

- Application: 1997 Isuzu Hombre S 1997 Isuzu Hombre SDocument53 pagesApplication: 1997 Isuzu Hombre S 1997 Isuzu Hombre SWin Cardona100% (1)

- 5R55W-S Repair DiagnosisDocument70 pages5R55W-S Repair Diagnosisaxallindo100% (2)

- TH350 GDDocument1 pageTH350 GDJose CencičNo ratings yet

- 5L40 eDocument1 page5L40 ePedroMecanico100% (1)

- AX4N Vs AX4S OPERACIÓN DE SOLENOIDESDocument7 pagesAX4N Vs AX4S OPERACIÓN DE SOLENOIDESTransmisiones Automáticas Chepe100% (2)

- 4R100 NonPTO VBDocument2 pages4R100 NonPTO VBGina LópezNo ratings yet

- Gears RE5R05A PDFDocument8 pagesGears RE5R05A PDFossoskiNo ratings yet

- 700R4 Pin TravelDocument2 pages700R4 Pin Travelstansracing100% (1)

- 2006 Seminar Sonnax PDFDocument18 pages2006 Seminar Sonnax PDFHumberto LojanNo ratings yet

- Fig 1: 2.0L Turbo, A/T CircuitDocument1 pageFig 1: 2.0L Turbo, A/T Circuitbyungchul kimNo ratings yet

- 5R55N Seminar InfoDocument18 pages5R55N Seminar InfocarlosNo ratings yet

- 2007 ATRA Seminar Manual ContentsDocument272 pages2007 ATRA Seminar Manual Contentschoco84100% (1)

- A Look at The : FeaturesDocument10 pagesA Look at The : FeaturesDavid Lacunes100% (3)

- ATRA Test Preparation Guide PDFDocument82 pagesATRA Test Preparation Guide PDFsuattosun100% (1)

- 4R70WDocument10 pages4R70WVictor Feder100% (1)

- Jatco Tranny Part 3 of 3 2007-04-40Document5 pagesJatco Tranny Part 3 of 3 2007-04-40cec985458100% (1)

- Atra SeminarsDocument2,631 pagesAtra SeminarsSarah Davis100% (8)

- Transmission Code GuideDocument1 pageTransmission Code Guideautof100% (1)

- 4l60 1 PDFDocument55 pages4l60 1 PDFwantier100% (2)

- 2014 AT Catalog Combined PDFDocument828 pages2014 AT Catalog Combined PDFted100% (1)

- 6T70Document6 pages6T70Manuales Transmisiones AutomaticasNo ratings yet

- RE5R05ADocument196 pagesRE5R05Avmv68No ratings yet

- VBL ZF6HP19 26 32Document1 pageVBL ZF6HP19 26 32PedroMecanico100% (1)

- Sonnax HP 4L60E Catalog v1Document12 pagesSonnax HP 4L60E Catalog v1Brad Franc100% (2)

- 4r44e 5r55e ZipDocument1 page4r44e 5r55e ZipAlejandro VargasNo ratings yet

- Technical Service Information: FORD 5R55N, 5R55W/SDocument8 pagesTechnical Service Information: FORD 5R55N, 5R55W/SJose garcua vargas 2006401321No ratings yet

- 2ML70Document4 pages2ML70Dezső Lőcsei50% (2)

- 4T40E / 4T45E: Multiple Codes, Slips, FailsafeDocument4 pages4T40E / 4T45E: Multiple Codes, Slips, FailsafeCo Kl100% (1)

- NB 31AS 6L80 Installation ManualDocument8 pagesNB 31AS 6L80 Installation ManualjhosepnegroNo ratings yet

- Install 6f50nDocument4 pagesInstall 6f50nmedicaluvNo ratings yet

- Attention: 6L80 & 6L90 Installation GuideDocument4 pagesAttention: 6L80 & 6L90 Installation GuideUlloaEliasNo ratings yet

- Fluid Check Ig Cd4eDocument5 pagesFluid Check Ig Cd4enameNo ratings yet

- Human Factors Products CFO Jan 2022Document24 pagesHuman Factors Products CFO Jan 2022Luis AlcalaNo ratings yet

- TRIG0082 - 1007-Modified Cover PDFDocument80 pagesTRIG0082 - 1007-Modified Cover PDFLuis AlcalaNo ratings yet

- 5R55N / 5R55S / 5R55W: RWD 5 SpeedDocument10 pages5R55N / 5R55S / 5R55W: RWD 5 SpeedLuis AlcalaNo ratings yet

- LR Remote Assurance Brochure PDFDocument8 pagesLR Remote Assurance Brochure PDFLuis AlcalaNo ratings yet

- 213 34172 Global Marine Fuel Trends 2030Document60 pages213 34172 Global Marine Fuel Trends 2030Luis AlcalaNo ratings yet

- Classification and StatutoryDocument2 pagesClassification and StatutoryLuis AlcalaNo ratings yet

- E7052 Dual Clutch Automatic Transmission (TCT TransmissionDocument6 pagesE7052 Dual Clutch Automatic Transmission (TCT Transmissionomid yadegariNo ratings yet

- E60H E75B 75B: Owner'S ManualDocument116 pagesE60H E75B 75B: Owner'S Manualjorge alonsoNo ratings yet

- Manual Definitivo NSF250RDocument203 pagesManual Definitivo NSF250RGustavo FajardoNo ratings yet

- Operator's ManualDocument108 pagesOperator's ManualFelix Marcelo100% (1)

- The Seamless Gear Shifting Control For Pure Electric Vehicle With 2-Speed Inverse-AMTDocument5 pagesThe Seamless Gear Shifting Control For Pure Electric Vehicle With 2-Speed Inverse-AMTmihai_1957No ratings yet

- Includes US and Canadian Models: BF40D50D - AH-OM表紙31ZZ4610 背幅7mmDocument139 pagesIncludes US and Canadian Models: BF40D50D - AH-OM表紙31ZZ4610 背幅7mmbugmeyoucan100% (1)

- Engine Bja Bah Bpa BLH Ccra Cfza Repair Manual EngDocument175 pagesEngine Bja Bah Bpa BLH Ccra Cfza Repair Manual EngLuis Alberto Garcia Villanueva100% (1)

- F500 RS2Document14 pagesF500 RS2margargi100% (2)

- Infodiag 210Document25 pagesInfodiag 210ArturHeiseNo ratings yet

- Tipping Gears Operators ManualDocument23 pagesTipping Gears Operators ManualLovenessmalabaNo ratings yet

- Gearbox 02T PDFDocument100 pagesGearbox 02T PDFAttila Modi100% (1)

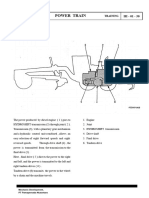

- 03 Power TrainDocument30 pages03 Power TrainSantosa NagoyaNo ratings yet

- Idaho Motorcycle Manual - Idaho Motorcycle HandbookDocument72 pagesIdaho Motorcycle Manual - Idaho Motorcycle HandbookpermittestNo ratings yet

- Smart Ebike ManualDocument80 pagesSmart Ebike Manualivanpuzic85No ratings yet

- Gearbox 0ajDocument214 pagesGearbox 0ajNick PNo ratings yet

- Catalogues$Ci Tata Superace 1ton RHD b3Document200 pagesCatalogues$Ci Tata Superace 1ton RHD b3Diane Owen100% (5)

- License GuideDocument28 pagesLicense GuideErning PuspitaNo ratings yet

- 82 Fuller RTO 6613 Transmission Service ManualDocument114 pages82 Fuller RTO 6613 Transmission Service Manualfdpc1987No ratings yet

- SoftwareDocument39 pagesSoftwarepetsamo_m100% (5)

- RA4a-EL 1993 Automatic TransmissionDocument62 pagesRA4a-EL 1993 Automatic Transmissionโจ้ สแปร์แร็คNo ratings yet

- BMW 02 - F10 PowertrainDocument34 pagesBMW 02 - F10 PowertrainSalisbur100% (2)

- Application: 1997 Golf, GTI, Jetta & Passat 01M 1998 Jetta, Golf, GTI 01MDocument17 pagesApplication: 1997 Golf, GTI, Jetta & Passat 01M 1998 Jetta, Golf, GTI 01MflintexpertNo ratings yet

- Cross Reference File For 595 Software CodesDocument31 pagesCross Reference File For 595 Software CodesKristen HolmesNo ratings yet

- 09 2016 PDFDocument60 pages09 2016 PDFbyungchul kimNo ratings yet

- 797F Power Train Systems Operation - KENR8370-00Document72 pages797F Power Train Systems Operation - KENR8370-00marcol705100% (1)

- IVECO Power DailyDocument8 pagesIVECO Power Dailywilliamb285No ratings yet

Ford Caja Automatica PDF

Ford Caja Automatica PDF

Uploaded by

Luis AlcalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ford Caja Automatica PDF

Ford Caja Automatica PDF

Uploaded by

Luis AlcalaCopyright:

Available Formats

A T T E N T I O N

YOUR WARRANTY DEPENDS ON YOUR ADHERENCE TO THESE GUIDELINES

5R55S & 5R55W INSTALLATION GUIDE

Ford Automatic Transmission

READ THIS ENTIRE DOCUMENT BEFORE BEGINNING

TRANSMISSION INSTALLATION

CONTENTS PRE-INSTALLATION

• Pre-Installation Tips This is an electronically-controlled transmission with a

complex shift adapt system. The following information

• Fluid Check Procedures

is VERY IMPORTANT to understand and perform

• Test Drive Cycle Procedures correctly. Failure to do so may cause damage to your new

transmission and/or be the main cause of transmission

• Installation Checklist performance problems.

• General Installation Tips Prior to the installation of the replacement transmission,

• Troubleshooting Guide scan vehicle for engine and transmission codes, record all

codes, and resolve all engine codes prior to transmission

replacement.

Inspect the transmission wiring harness for damaged

wires or connectors. Verify proper function of the entire

electrical system including the battery, alternator, mass air

flow sensor, throttle position sensor, and, most importantly,

the vehicle grounds.

Completely clean, hot flush, and flow test the entire

transmission cooling system. If the cooling is damaged,

plugged, or glycol/water contaminated, it must be

replaced. Failure to do so is the leading cause of

transmission failure after replacement.

Revision 9.6.16 5R55S & 5R55W Installation Guide Page 1 of 4

FLUID CHECK PROCEDURE

Due to its lack of dipstick, checking the fluid level on vehicles equipped with this transmission can be very time-

consuming and confusing. There is a simple way to fill the transmission before it is installed in your vehicle.

Once the transmission is on the jack and ready for installation, fill it using the following procedure. Use only the supplied

synthetic or OEM approved fluid.

STEP 1 STEP 2

Install a funnel into the center speed sensor hole on top of Install the transmission in the vehicle.

the transmission.

Remove the 5/16” hex plug (if equipped, this is the fill

Pour in 8 quarts of ATF. plug).

Install speed sensors. Attach a scan tool, start the vehicle and run the engine

until the TFT sensor reading is at least 80 degrees F.

Move the gearshift lever through each gear range,

stopping for 5 seconds in each and returning to the park

position.

Verify the transmission is in the park position and raise the

vehicle on a lift keeping the vehicle level.

STEP 3

Remove the T30 torx plug from the center of the drain STEP 4

plug. If no fluid comes out of the hole, fluid will need to be

added. Fill fluid through the fill plug (if equipped) or use

DO NOT REMOVE THE 7/8” DRAIN PLUG. special tool 307-437.

If fluid does come out of the hole, allow the fluid to drain

until it comes to a drip.

Once fluid comes to a drip the fluid is at the correct level,

reinstall the T30 torx plug and proceed to the drive cycle

test procedure.

Page 2 of 4 5R55S & 5R55W Installation Guide Revision 9.6.16

TEST DRIVE CYCLE PROCEDURE CHECKLIST

The transmission drive cycle test must be followed exactly. • Compare replacement transmission and torque

Transmission failure must occur four times consecutively converter before installation

for shift error DTC code to be set, and five times

• Scan vehicle computer, record and resolve all

consecutively for continuous torque converter clutch code

codes before removing transmission

set.

• Hot flush or replace the transmission cooler and

Perform a KAM (Keep Alive Memory) Reset. A scan tool

lines

will be required to perform this procedure.

• Inspect flex plate closely for cracks or damage

1. Record and then erase Quick Test codes.

• Inspect crank pilot bearing for wear and apply

2. Warm engine to normal operating temperature.

grease to aid with installation

3. Make sure transmission fluid level is correct.

• Verify both dowel pins are present, clean, and in

4. With transmission in D position, moderately accelerate good condition

from stop to 50 mph (80 km/h). This allows the

• Verify torque converter is properly and completely

transmission to shift into 5th gear. Hold speed and

installed

throttle open and steady for a minimum of 15 seconds.

• Check torque converter bolts for proper length

5. With the transmission in 5th gear and maintaining a

steady speed and throttle opening, lightly apply and • Inspect mounts, carrier bearing, driveshaft, yoke,

release brake to operate brake lights. Then hold speed and U-joints

and throttle steady for a minimum of 5 seconds.

• Inspect and install PRNDL Neutral Safety Switch

6. Brake to a stop and remain stopped for a minimum of

20 seconds. • Fill transmission with supplied synthetic or OEM

approved fluid

7. Repeat steps 4 through 6 at least 5 times.

8. Carry out Quick Test and record continuous DTCs.

9. Install vehicle back on a hoist and reconfirm the

transmission fluid level. TROUBLESHOOTING GUIDE

10. Verify that there are no leaks present. Vent Tube Replacement

It is now safe to release the vehicle. You will have to remove the external vent assembly from

the original transmission and install it on the replacement

transmission.

1. Remove the front by squeezing the inner tabs.

2. Remove the middle fitting, if present, by using a pair of

locking pliers to twist the fitting while pulling out.

3. Remove the rear fitting by squeezing and twisting the

tabs. Be careful to not bend the fitting to the side.

4. Install tube assembly by inserting the rear fitting,

middle fitting, and front fitting, in that order.

5. If a replacement is needed, use the following part

numbers:

• For 5R55S and 5R55W units: OEM# 6L2Z-7034-CA

* For 5R55N units: OEM# 4W4Z-7034-AB

8-Lug Torque Converter Alignment

Some 5R55 units use an 8-lug torque converter. In order

to properly align the flex plate adapter, you will need to

use a specific tool. Failure to properly align the flex plate

adapter can result in vibration, leaks, or failure of the

torque converter, pump, and bushings.

Revision 9.6.16 5R55S & 5R55W Installation Guide Page 3 of 4

5R55S & 5R55W INSTALLATION GUIDE

Ford Automatic Transmission

5R55 S/W Harsh Engagement Into Reverse

STEP 1 STEP 2

Make sure the alignment marks are aligned. If the Verify the shifter linkage is lined up properly through each

adjustment is even slightly off, the computer will read a range. If not, place the shifter in the manual low position

reverse signal and boost line pressure before the manual on the column. Pop the shifter cable off the manual arm on

valve is moved into the reverse position. the transmission. With a pick, pull the lock tab toward the

outside to release the lock and slide the tab up. Move the

lock and center it onto the manual arm ball. Snap the lock

onto the ball and slide the lock tab down. Move the shifter

handle into the neutral position and verify alignment.

STEP 3

If alignment cannot be achieved, verify that the shifter

cable bracket is not bent or out of position. Check the

witness marks where the bolts go through the bracket and STEP 4

line the bracket up to that.

If the alignment still cannot be achieved, inspection of

the column itself may be needed. There should be no slop

felt while moving the shifter handle. If there is, either the

shifter cable is stretched or the shifter mechanism is worn

out. At this time, you cannot purchase any of the shifter

mechanism parts separately; you have to buy a column kit.

Page 4 of 4 5R55S & 5R55W Installation Guide Revision 9.6.16

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- 2001 Honda Odyssey Transm. B7TA B7XADocument62 pages2001 Honda Odyssey Transm. B7TA B7XAAgustin Chaparro Tirado86% (14)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Trasmision Automatic A Buick-Oldmobile 4T65EDocument156 pagesTrasmision Automatic A Buick-Oldmobile 4T65E52600100% (26)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WFrom EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WRating: 4.5 out of 5 stars4.5/5 (6)

- Error CodesDocument58 pagesError CodesAnoir Akkari93% (57)

- MF 210 210 4 Tractor OPT SQ w5cw2nrr34Document54 pagesMF 210 210 4 Tractor OPT SQ w5cw2nrr34dinismiguelNo ratings yet

- Code False Akpp 5r55Document7 pagesCode False Akpp 5r55VobsStrongNo ratings yet

- 5R55S Cooler Thermal Bypass FixDocument4 pages5R55S Cooler Thermal Bypass FixDon Jenkins100% (2)

- JF015E Valve Body DiagnosticDocument2 pagesJF015E Valve Body Diagnosticสนั่น วิริยะเจริญกุล100% (2)

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildFrom EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildRating: 5 out of 5 stars5/5 (1)

- Discover 110 Cbs 125 CbsDocument44 pagesDiscover 110 Cbs 125 Cbsaayush shuklaNo ratings yet

- Manual 6l50Document84 pagesManual 6l50franceli ferreira reisNo ratings yet

- Transmission 4R70W Main Control Valve Body Disassembly and Assembly of SubassembliesDocument5 pagesTransmission 4R70W Main Control Valve Body Disassembly and Assembly of SubassembliesFDONo ratings yet

- A-761E Manual PDFDocument107 pagesA-761E Manual PDFsergNo ratings yet

- 02-2009 4t65e, F4a23-33, A246e Check Ball, Ax4s-Ax4n-4f50n Codes DTCDocument16 pages02-2009 4t65e, F4a23-33, A246e Check Ball, Ax4s-Ax4n-4f50n Codes DTCAleNo ratings yet

- 09 GM3C 4t40e 4t45eDocument8 pages09 GM3C 4t40e 4t45eJoe MontanaNo ratings yet

- 2020 Seminar TopicsDocument7 pages2020 Seminar Topicsarstjunk25% (4)

- Atsg 2005 BulletinDocument46 pagesAtsg 2005 Bulletinlolop434350% (4)

- Transmission Filter Catalog: Oe Quality Transmission FiltersDocument103 pagesTransmission Filter Catalog: Oe Quality Transmission FiltersRamon Pujol PerramonNo ratings yet

- U660e Zip inDocument11 pagesU660e Zip inGabriel Harper'100% (1)

- Air Check Book 39 50Document12 pagesAir Check Book 39 50Timur TOT100% (2)

- Ford 5R55S Partes CDocument8 pagesFord 5R55S Partes CJose Mejia CaveroNo ratings yet

- Welcome To Today's Presentation Sponsored byDocument47 pagesWelcome To Today's Presentation Sponsored byfadrique54No ratings yet

- Valve Body Exploded View: ChryslerDocument2 pagesValve Body Exploded View: ChryslerJUAN CAMPOSANONo ratings yet

- Auto Trans 4R70W PDFDocument57 pagesAuto Trans 4R70W PDFDavid Bravo100% (2)

- p1811-p0748 Impala PDFDocument5 pagesp1811-p0748 Impala PDFUlloaEliasNo ratings yet

- 6L45 6L90 VacTestDocument4 pages6L45 6L90 VacTestJehovana100% (1)

- 4f50n CompleteDocument58 pages4f50n CompleteCarlos Treviño100% (2)

- 5r55 Oil Control PDFDocument14 pages5r55 Oil Control PDFHumberto Lojan100% (2)

- GM 4L60E/4L65E/4L70E 078: SOLENOID TEST: (Engine Off)Document2 pagesGM 4L60E/4L65E/4L70E 078: SOLENOID TEST: (Engine Off)twinturbo2No ratings yet

- Application: 1997 Isuzu Hombre S 1997 Isuzu Hombre SDocument53 pagesApplication: 1997 Isuzu Hombre S 1997 Isuzu Hombre SWin Cardona100% (1)

- 5R55W-S Repair DiagnosisDocument70 pages5R55W-S Repair Diagnosisaxallindo100% (2)

- TH350 GDDocument1 pageTH350 GDJose CencičNo ratings yet

- 5L40 eDocument1 page5L40 ePedroMecanico100% (1)

- AX4N Vs AX4S OPERACIÓN DE SOLENOIDESDocument7 pagesAX4N Vs AX4S OPERACIÓN DE SOLENOIDESTransmisiones Automáticas Chepe100% (2)

- 4R100 NonPTO VBDocument2 pages4R100 NonPTO VBGina LópezNo ratings yet

- Gears RE5R05A PDFDocument8 pagesGears RE5R05A PDFossoskiNo ratings yet

- 700R4 Pin TravelDocument2 pages700R4 Pin Travelstansracing100% (1)

- 2006 Seminar Sonnax PDFDocument18 pages2006 Seminar Sonnax PDFHumberto LojanNo ratings yet

- Fig 1: 2.0L Turbo, A/T CircuitDocument1 pageFig 1: 2.0L Turbo, A/T Circuitbyungchul kimNo ratings yet

- 5R55N Seminar InfoDocument18 pages5R55N Seminar InfocarlosNo ratings yet

- 2007 ATRA Seminar Manual ContentsDocument272 pages2007 ATRA Seminar Manual Contentschoco84100% (1)

- A Look at The : FeaturesDocument10 pagesA Look at The : FeaturesDavid Lacunes100% (3)

- ATRA Test Preparation Guide PDFDocument82 pagesATRA Test Preparation Guide PDFsuattosun100% (1)

- 4R70WDocument10 pages4R70WVictor Feder100% (1)

- Jatco Tranny Part 3 of 3 2007-04-40Document5 pagesJatco Tranny Part 3 of 3 2007-04-40cec985458100% (1)

- Atra SeminarsDocument2,631 pagesAtra SeminarsSarah Davis100% (8)

- Transmission Code GuideDocument1 pageTransmission Code Guideautof100% (1)

- 4l60 1 PDFDocument55 pages4l60 1 PDFwantier100% (2)

- 2014 AT Catalog Combined PDFDocument828 pages2014 AT Catalog Combined PDFted100% (1)

- 6T70Document6 pages6T70Manuales Transmisiones AutomaticasNo ratings yet

- RE5R05ADocument196 pagesRE5R05Avmv68No ratings yet

- VBL ZF6HP19 26 32Document1 pageVBL ZF6HP19 26 32PedroMecanico100% (1)

- Sonnax HP 4L60E Catalog v1Document12 pagesSonnax HP 4L60E Catalog v1Brad Franc100% (2)

- 4r44e 5r55e ZipDocument1 page4r44e 5r55e ZipAlejandro VargasNo ratings yet

- Technical Service Information: FORD 5R55N, 5R55W/SDocument8 pagesTechnical Service Information: FORD 5R55N, 5R55W/SJose garcua vargas 2006401321No ratings yet

- 2ML70Document4 pages2ML70Dezső Lőcsei50% (2)

- 4T40E / 4T45E: Multiple Codes, Slips, FailsafeDocument4 pages4T40E / 4T45E: Multiple Codes, Slips, FailsafeCo Kl100% (1)

- NB 31AS 6L80 Installation ManualDocument8 pagesNB 31AS 6L80 Installation ManualjhosepnegroNo ratings yet

- Install 6f50nDocument4 pagesInstall 6f50nmedicaluvNo ratings yet

- Attention: 6L80 & 6L90 Installation GuideDocument4 pagesAttention: 6L80 & 6L90 Installation GuideUlloaEliasNo ratings yet

- Fluid Check Ig Cd4eDocument5 pagesFluid Check Ig Cd4enameNo ratings yet

- Human Factors Products CFO Jan 2022Document24 pagesHuman Factors Products CFO Jan 2022Luis AlcalaNo ratings yet

- TRIG0082 - 1007-Modified Cover PDFDocument80 pagesTRIG0082 - 1007-Modified Cover PDFLuis AlcalaNo ratings yet

- 5R55N / 5R55S / 5R55W: RWD 5 SpeedDocument10 pages5R55N / 5R55S / 5R55W: RWD 5 SpeedLuis AlcalaNo ratings yet

- LR Remote Assurance Brochure PDFDocument8 pagesLR Remote Assurance Brochure PDFLuis AlcalaNo ratings yet

- 213 34172 Global Marine Fuel Trends 2030Document60 pages213 34172 Global Marine Fuel Trends 2030Luis AlcalaNo ratings yet

- Classification and StatutoryDocument2 pagesClassification and StatutoryLuis AlcalaNo ratings yet

- E7052 Dual Clutch Automatic Transmission (TCT TransmissionDocument6 pagesE7052 Dual Clutch Automatic Transmission (TCT Transmissionomid yadegariNo ratings yet

- E60H E75B 75B: Owner'S ManualDocument116 pagesE60H E75B 75B: Owner'S Manualjorge alonsoNo ratings yet

- Manual Definitivo NSF250RDocument203 pagesManual Definitivo NSF250RGustavo FajardoNo ratings yet

- Operator's ManualDocument108 pagesOperator's ManualFelix Marcelo100% (1)

- The Seamless Gear Shifting Control For Pure Electric Vehicle With 2-Speed Inverse-AMTDocument5 pagesThe Seamless Gear Shifting Control For Pure Electric Vehicle With 2-Speed Inverse-AMTmihai_1957No ratings yet

- Includes US and Canadian Models: BF40D50D - AH-OM表紙31ZZ4610 背幅7mmDocument139 pagesIncludes US and Canadian Models: BF40D50D - AH-OM表紙31ZZ4610 背幅7mmbugmeyoucan100% (1)

- Engine Bja Bah Bpa BLH Ccra Cfza Repair Manual EngDocument175 pagesEngine Bja Bah Bpa BLH Ccra Cfza Repair Manual EngLuis Alberto Garcia Villanueva100% (1)

- F500 RS2Document14 pagesF500 RS2margargi100% (2)

- Infodiag 210Document25 pagesInfodiag 210ArturHeiseNo ratings yet

- Tipping Gears Operators ManualDocument23 pagesTipping Gears Operators ManualLovenessmalabaNo ratings yet

- Gearbox 02T PDFDocument100 pagesGearbox 02T PDFAttila Modi100% (1)

- 03 Power TrainDocument30 pages03 Power TrainSantosa NagoyaNo ratings yet

- Idaho Motorcycle Manual - Idaho Motorcycle HandbookDocument72 pagesIdaho Motorcycle Manual - Idaho Motorcycle HandbookpermittestNo ratings yet

- Smart Ebike ManualDocument80 pagesSmart Ebike Manualivanpuzic85No ratings yet

- Gearbox 0ajDocument214 pagesGearbox 0ajNick PNo ratings yet

- Catalogues$Ci Tata Superace 1ton RHD b3Document200 pagesCatalogues$Ci Tata Superace 1ton RHD b3Diane Owen100% (5)

- License GuideDocument28 pagesLicense GuideErning PuspitaNo ratings yet

- 82 Fuller RTO 6613 Transmission Service ManualDocument114 pages82 Fuller RTO 6613 Transmission Service Manualfdpc1987No ratings yet

- SoftwareDocument39 pagesSoftwarepetsamo_m100% (5)

- RA4a-EL 1993 Automatic TransmissionDocument62 pagesRA4a-EL 1993 Automatic Transmissionโจ้ สแปร์แร็คNo ratings yet

- BMW 02 - F10 PowertrainDocument34 pagesBMW 02 - F10 PowertrainSalisbur100% (2)

- Application: 1997 Golf, GTI, Jetta & Passat 01M 1998 Jetta, Golf, GTI 01MDocument17 pagesApplication: 1997 Golf, GTI, Jetta & Passat 01M 1998 Jetta, Golf, GTI 01MflintexpertNo ratings yet

- Cross Reference File For 595 Software CodesDocument31 pagesCross Reference File For 595 Software CodesKristen HolmesNo ratings yet

- 09 2016 PDFDocument60 pages09 2016 PDFbyungchul kimNo ratings yet

- 797F Power Train Systems Operation - KENR8370-00Document72 pages797F Power Train Systems Operation - KENR8370-00marcol705100% (1)

- IVECO Power DailyDocument8 pagesIVECO Power Dailywilliamb285No ratings yet