Professional Documents

Culture Documents

High-Temperature Braze Applications: Ready To Meet Your Needs

High-Temperature Braze Applications: Ready To Meet Your Needs

Uploaded by

john davidsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High-Temperature Braze Applications: Ready To Meet Your Needs

High-Temperature Braze Applications: Ready To Meet Your Needs

Uploaded by

john davidsCopyright:

Available Formats

High-Temperature Braze Applications

Brazing is often used when a metallurgical bond is required,

but where welding temperatures may cause

distortion of the parts or a change in the alloy’s

morphology. The temperatures used in brazing melt

the filler powder and draw it into the base alloys to be

joined via capillary action. A wide variety of brazing

applications exist in aircraft engines, land-based turbines,

chemical equipment, medical devices, and food handling

components, among others. CPP provides clean, spherical,

gas atomized powders in a wide range of standard alloys for Being the

use in these markets. The powders are provided with very only major

consistent chemistries and particle sizes to provide uniform powder metals

products and production flow rates. Many of the more manufacturer with

common alloys used are listed in this sheet. Should another production facilities in both

alloy be required, the Research & Development staff has North America and Europe

extensive experience and facilities to provide what is enables CPP to supply customers in a

required for your application. timely and cost-effective manner. Currently in

place are one 450 kg and two 1000 kg furnaces in

Ready to Meet Your Needs Bridgeville, PA, USA, a 1200 kg furnace in Woonsocket, RI,

A pioneer in the development and production of metal USA, and twin 5500 kg furnaces in Torshalla, Sweden. This is

powders, CPP offers a tremendous variety of alloys covering one of the largest capacities for gas atomized powder

nearly every application. Great pride is taken in our ability available from any manufacturer. Extensive research and

to control the alloy’s chemistry and particle size to meet development capabilities are available for developing new

stringent customer requirements. Superb consistency is alloys to meet our customers’ needs including a 150 kg

provided within and between production lots. furnace in Reading, PA, USA. Facilities include cover gas,

vacuum, and air induction melt furnaces which are capable

of using a variety of gasses for atomization, depending upon

Standard Packaging the alloy being produced. Certifications include ISO 9001,

PE Bottles 5 kg 10 lbs AS 9100, and NADCAP.

PE Pails 25 kg 50 lbs Producing metal powders for over 40 years, CPP has

Other packages available upon request. hundreds of years of combined experience and is committed

to continuous manufacturing improvement. Strategic

relationships are often initiated with customers to develop

and supply new powder metal alloys in the exact

specification which best suits the requirements of their

application.

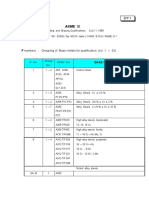

High-Temperature Braze Powders

Chemical Composition (Typical Values in wt.%)

Micro-Melt® Alloy AWS X-Ref EN 1044

Ni Co Cr Si B Fe C Mo Al Others

A4775 AMS 4775 Bal — 14 4.5 3 4.5 0.75 — — — BNi-1 125 NI 101

A4776 AMS 4776 Bal — 14 4.5 3 3 — — — — BNi-1a L.C. NI 1A1

A4777 AMS 4777 Bal — 7 4.2 3 3 — — — — BNi-2 L.M. NI 102

A4778 AMS 4778 Bal — — 4.5 3 — — — — — BNi-3 130 NI 103

A4779 AMS 4779 Bal — — 3.5 2 — — — — — BNi-4 135 NI 104

A4782 AMS 4782 Bal — 19 10 — — — — — — BNi-5 30 NI 105

A4783 AMS 4783 17 Bal 19 8 0.8 — 0.4 — — W: 4 BCo-1 210 Co 101

G173 D-15 Bal 10 15 — 2.3 — — — 3.5 Ta: 3.5 — — —

G99 B50TF99 Bal — 19.5 10 — — — — — Mn: 9.5 — 35 —

G142 B50TF142 Bal — 17 9 0.1 — — — — — — 3003 —

BRB BRB Bal 9 14 — 2.5 — — — 4 — — — —

A914 A914 Bal 20 — 4.3 3 — — — — — — — —

G207 BNi-9 Bal — 15 — 3.5 — — — — — BNi-9 150 —

B-20 B-20 Bal — — 2.5 1.4 — — — — — — #25 —

B-27 B-27 Bal — — 3.5 1.3 — 0.05 — — — — — —

B-33 B-33 Bal — 4.5 3.3 1.5 1.5 0.2 — — — — — —

B-40 B-40 Bal — 9 3.1 1.7 2.9 0.3 — — — — #42 —

B-50 B-50 Bal — 12.5 3.8 2.5 4.3 0.6 — — — — #52 —

B-56 B-56 Bal — 13 3.7 3 4 0.7 — — — — #56 —

B-60 B-60 Bal — 14.5 4.3 3.2 4.3 0.8 — — — — #62 —

B-60C B-60C Bal — 15 4.3 3.4 4.2 0.7 2.5 — Cu: 2.5 — #69 —

CuNiSnP — 4.2 — — — — — — — — Cu: Bal, Sn: 15.5, P: 5.3 — — —

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically for material

described herein are made solely for the purpose of illustration to enable the reader to make his or her own evaluation and are not intended as warranties, either express

or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as they become available.

Registered trademarks are the property of CRS Holdings, Inc.

Please contact us with your requests for alloys not listed. We have many more alloys available that

space limitations prevent us from listing.

www.cartech.com 1-800-992-6825

Main Office Woonsocket, RI USA Torshalla, Sweden Dusseldorf, Germany Singapore Shanghai PRC

Manufacturing & Sales Manufacturing Manufacturing and Sales Sales Sales Sales and Distribution

600 Mayer Street +46-16-34-9800 +49-211-175 2083-0 +65-6738-2401 +8621-2411-3500

Reading, PA USA

Bridgeville, PA 15017 USA CPPAB@Cartech.com CPPGMBH@Cartech.com

Research and Development

CPPBVL@Cartech.com

© CRS Holdings, Inc. All Rights reserved. 07-12 1K T35A

You might also like

- Specification Tuyauterie q3622011 02 220 Pe SPC 00001 - BDocument96 pagesSpecification Tuyauterie q3622011 02 220 Pe SPC 00001 - BLAKHTIRINo ratings yet

- nextLI Blue Economy ResearchDocument73 pagesnextLI Blue Economy ResearchNewsday100% (1)

- Grade7 ScienceDocument450 pagesGrade7 ScienceJannet Yang100% (4)

- The Elements of Boat Strength: For Builders, Designers, and OwnersFrom EverandThe Elements of Boat Strength: For Builders, Designers, and OwnersRating: 5 out of 5 stars5/5 (8)

- Asme Sec 9 PDFDocument144 pagesAsme Sec 9 PDFसंजय घिल्डियालNo ratings yet

- A105 A216 ComparisonDocument10 pagesA105 A216 Comparisonprihartono_diasNo ratings yet

- ASME Boiler and Pressure Vessel Codes (BPVC)Document57 pagesASME Boiler and Pressure Vessel Codes (BPVC)catdoNo ratings yet

- P Numbers: Grouping of Base Metals For Qualification (No. 1Document5 pagesP Numbers: Grouping of Base Metals For Qualification (No. 1Lim DongseopNo ratings yet

- Asme Sec Ix-2013 165Document1 pageAsme Sec Ix-2013 165Durgarao VasaNo ratings yet

- Guidelines On Use of Admixtures in ConcreteDocument8 pagesGuidelines On Use of Admixtures in Concreteviharikapavuluri1290No ratings yet

- Special Report Avoid Common Mistakes With VesselsDocument21 pagesSpecial Report Avoid Common Mistakes With VesselsAnonymous oVRvsdWzfB0% (1)

- Sfa-5 8 PDFDocument24 pagesSfa-5 8 PDFgst ajahNo ratings yet

- Arc Welding Requirments: General: 1.1 PurposeDocument47 pagesArc Welding Requirments: General: 1.1 PurposeAriel FerrerNo ratings yet

- Query4 PDFDocument1 pageQuery4 PDFAlessandro1975No ratings yet

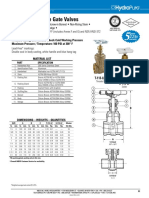

- Lead-Free Bronze Gate Valves: T-113-LF S-113-LFDocument1 pageLead-Free Bronze Gate Valves: T-113-LF S-113-LFAlessandro1975No ratings yet

- Fmav53d Si UnitsDocument2 pagesFmav53d Si UnitsAmr ATTIANo ratings yet

- MSA Ball Valves enDocument20 pagesMSA Ball Valves enBiswajit DeyNo ratings yet

- MSA Ball Valves PDFDocument20 pagesMSA Ball Valves PDFAli FardidNo ratings yet

- SBR C AnalysisDocument7 pagesSBR C AnalysisJayraj DaymaNo ratings yet

- Especificacion de Materiales Y Tabla de Compatibilidad Base Comercial SAE AstmDocument4 pagesEspecificacion de Materiales Y Tabla de Compatibilidad Base Comercial SAE AstmFrancisco VillaNo ratings yet

- Fca 501Document3 pagesFca 501Al JameelNo ratings yet

- PIPING PIPELINE Design BasisDocument25 pagesPIPING PIPELINE Design BasisAlitNo ratings yet

- BabbittDocument3 pagesBabbittEyner David Cubides ContrerasNo ratings yet

- Marvel-Schebler BulletinsDocument71 pagesMarvel-Schebler BulletinsAnderson RamalhoNo ratings yet

- Valvula Compuerta Una y MediaDocument1 pageValvula Compuerta Una y MediaRobertoNo ratings yet

- Valvula Compuerta Nibco T-113-LfDocument1 pageValvula Compuerta Nibco T-113-LfRobertoNo ratings yet

- DSM-0274.0 Bronze AlloysDocument5 pagesDSM-0274.0 Bronze AlloyskerbaubiruNo ratings yet

- Figure # 204A: Product FeaturesDocument1 pageFigure # 204A: Product FeaturesEsteban CastellanoNo ratings yet

- BPDocument36 pagesBPThiruvenkatasamy Elangovan100% (2)

- d101463x012 PDFDocument16 pagesd101463x012 PDFJesus GBNo ratings yet

- Bohler Welding Thermalpower - ENGDocument24 pagesBohler Welding Thermalpower - ENGghostinshellNo ratings yet

- Cross Reference of Astm Material Specifications Covering Cast and Equivalent Forged ValvesDocument1 pageCross Reference of Astm Material Specifications Covering Cast and Equivalent Forged ValvesmuhammedemraanNo ratings yet

- 06chapters13 15Document19 pages06chapters13 15Achmad Arifudin HidayatullohNo ratings yet

- Specifications Lignes Ba1 Bb1 Bb3 Bd2 Bg1 Bl5Document40 pagesSpecifications Lignes Ba1 Bb1 Bb3 Bd2 Bg1 Bl5LAKHTIRINo ratings yet

- Floating Ball Valves: GloriousDocument12 pagesFloating Ball Valves: GloriousDharmendra JadejaNo ratings yet

- Equivalent Material Cross Valve CastDocument2 pagesEquivalent Material Cross Valve CastsviswaNo ratings yet

- File No. 1Document11 pagesFile No. 1Ali RasheedNo ratings yet

- Ca-24 Codo Acero 90°Document2 pagesCa-24 Codo Acero 90°Luis Felipe Sanchez BernalNo ratings yet

- Bohler - Welding ConsumableDocument44 pagesBohler - Welding Consumablehareesh13hNo ratings yet

- Ewp000 P30 J00 501 - 1H PDFDocument61 pagesEwp000 P30 J00 501 - 1H PDFOk Oh100% (2)

- Bronze Stock ListDocument14 pagesBronze Stock ListFred Duarte Caldeira100% (1)

- Ad 69-24-03Document3 pagesAd 69-24-03Bruno BrazNo ratings yet

- Bavaria Flux BF 5.1Document3 pagesBavaria Flux BF 5.1Filipe CordeiroNo ratings yet

- Pressure Seal Check ValvesDocument18 pagesPressure Seal Check ValvesthomasnafNo ratings yet

- Welding Electrodes For Petrochemical IndustryG PDFDocument44 pagesWelding Electrodes For Petrochemical IndustryG PDFerogonNo ratings yet

- KP 431042323 KuatDocument4 pagesKP 431042323 KuatNoviita LupheLyNo ratings yet

- Alloy Reference LibraryDocument1 pageAlloy Reference LibraryDeepakNo ratings yet

- HotRolledConcreteReinforcingBars GRADES460B B500B B500C PDFDocument4 pagesHotRolledConcreteReinforcingBars GRADES460B B500B B500C PDFanwarNo ratings yet

- BS499 PDFDocument36 pagesBS499 PDFnisha_khanNo ratings yet

- Alloy Selection For Service in Caustic Soda: A Guide To The Use of Nickel-Containing AlloysDocument20 pagesAlloy Selection For Service in Caustic Soda: A Guide To The Use of Nickel-Containing AlloysMohammad FouladiNo ratings yet

- Code Alloys by UNS NumberDocument18 pagesCode Alloys by UNS NumberManivannanMudhaliarNo ratings yet

- ASME IX OrganizationDocument14 pagesASME IX OrganizationemrullahNo ratings yet

- BWSSB 07-03-2018 SorDocument184 pagesBWSSB 07-03-2018 Sorkathir1965No ratings yet

- Copper Alloys in Ingot and Other Remelt Forms: Standard Specification ForDocument14 pagesCopper Alloys in Ingot and Other Remelt Forms: Standard Specification Foranurag yadavNo ratings yet

- Characterization of Flyash and Bottom Ash and Their Utilization in Cement and ConcreteDocument48 pagesCharacterization of Flyash and Bottom Ash and Their Utilization in Cement and ConcreteDr_S_HarshNo ratings yet

- .. STDocs Tender TND 088754 172251Document243 pages.. STDocs Tender TND 088754 172251Bimal DeyNo ratings yet

- Paint Annexure 01a & 02aDocument3 pagesPaint Annexure 01a & 02aVikash SinghNo ratings yet

- Pillared Metal-Organic Frameworks: Properties and ApplicationsFrom EverandPillared Metal-Organic Frameworks: Properties and ApplicationsNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IIFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffNo ratings yet

- Modern Heterogeneous Oxidation Catalysis: Design, Reactions and CharacterizationFrom EverandModern Heterogeneous Oxidation Catalysis: Design, Reactions and CharacterizationNoritaka MizunoNo ratings yet

- Advances in Ceramic Armor, Bioceramics, and Porous MaterialsFrom EverandAdvances in Ceramic Armor, Bioceramics, and Porous MaterialsJerry C. LaSalviaNo ratings yet

- Recent Advances in Cast SX Superalloys: Jacqueline Wahl and Ken HarrisDocument34 pagesRecent Advances in Cast SX Superalloys: Jacqueline Wahl and Ken Harrisjohn davidsNo ratings yet

- Second Generation Columnar Grain Nickel-Base SuperalloyDocument10 pagesSecond Generation Columnar Grain Nickel-Base Superalloyjohn davidsNo ratings yet

- Strategic Metals Use in The Gas Turbine Industry - Challenges and OpportunitiesDocument21 pagesStrategic Metals Use in The Gas Turbine Industry - Challenges and Opportunitiesjohn davidsNo ratings yet

- Braze Materials Guide: Sulzer MetcoDocument16 pagesBraze Materials Guide: Sulzer Metcojohn davidsNo ratings yet

- 101-0020 USB-RS485 Converter Manual R2Document8 pages101-0020 USB-RS485 Converter Manual R2Juan Pablo Villazon RichterNo ratings yet

- Synopsys Design Vision TutorialDocument23 pagesSynopsys Design Vision TutorialferrariNo ratings yet

- Bar Basics PDFDocument10 pagesBar Basics PDFsrikanth_krishnamu_3100% (1)

- VijayawadaDocument62 pagesVijayawadakeerthiNo ratings yet

- Crowley - The Crisis in FreemasonryDocument18 pagesCrowley - The Crisis in FreemasonryCelephaïs Press / Unspeakable Press (Leng)100% (4)

- 2 Alcon CR Certificat 2024 g1 020895 0393 Rev.00Document1 page2 Alcon CR Certificat 2024 g1 020895 0393 Rev.00Cyber ChronoNo ratings yet

- Quality in Practice - Building Trust Through Quality at GerbDocument6 pagesQuality in Practice - Building Trust Through Quality at Gerbsakshi1404No ratings yet

- Surgical Manual - PremiumDocument80 pagesSurgical Manual - PremiumJadranka DjorgievaNo ratings yet

- Fossil Fuels Oil and GasDocument12 pagesFossil Fuels Oil and GasCrystian Kobee EmpeynadoNo ratings yet

- Brainstorming 2Document14 pagesBrainstorming 2AmierahIzzatiAisyahNo ratings yet

- Guest FolioDocument2 pagesGuest FolioJulyca SimbajonNo ratings yet

- Pengaruh Pencampuran Semen Terhadap Kuat Geser Tanah Lempung Lampoh KeudeDocument12 pagesPengaruh Pencampuran Semen Terhadap Kuat Geser Tanah Lempung Lampoh KeudeyongkihndrwnNo ratings yet

- Cpale Syllabus 2022Document27 pagesCpale Syllabus 2022BlueBladeNo ratings yet

- PenjelasanDocument10 pagesPenjelasanFAH Adi SetiawanNo ratings yet

- Research Article: Linkage Between Economic Value Added and Market Value: An AnalysisDocument14 pagesResearch Article: Linkage Between Economic Value Added and Market Value: An Analysiseshu agNo ratings yet

- RealVNC Enterprise Edition 4Document2 pagesRealVNC Enterprise Edition 4fannybrawijayaNo ratings yet

- OS Forecast Kwartal Mei - Agst 2024Document22 pagesOS Forecast Kwartal Mei - Agst 2024Iqbal MontgomeryNo ratings yet

- What Is Bar Model, Sir?Document5 pagesWhat Is Bar Model, Sir?Denis TarorehNo ratings yet

- Paper 1 MCQDocument8 pagesPaper 1 MCQmarwaNo ratings yet

- Marketing Concepts BCG MatrixDocument31 pagesMarketing Concepts BCG MatrixarunspeakersNo ratings yet

- History of AnatomyDocument21 pagesHistory of AnatomyCatarina SimõesNo ratings yet

- English For Academic and Professional Purposes Nov. 30-Dec 4Document5 pagesEnglish For Academic and Professional Purposes Nov. 30-Dec 4Princess Lynn Aquino PaduaNo ratings yet

- PedodonticsDocument2 pagesPedodonticsjunquelalaNo ratings yet

- Maklumat Vaksinasi: Vaccination DetailsDocument2 pagesMaklumat Vaksinasi: Vaccination DetailsNORFADHLI ARIFNo ratings yet

- Parents ConsentDocument2 pagesParents ConsentkarlylNo ratings yet

- Internal Control PSA315Document8 pagesInternal Control PSA315John Lexter Macalber100% (1)

- Activities and Games Animals HabitatsDocument26 pagesActivities and Games Animals HabitatsPauline Mae Cañete100% (1)

- Tipe / Type Vega R New 2008 Nomor Identifikasi Kendaraan / MH34D70028j903504 No. Mesin / Engine No. 4D7.903528 Nomor Plat / License No. KT 2701 KG 60Document7 pagesTipe / Type Vega R New 2008 Nomor Identifikasi Kendaraan / MH34D70028j903504 No. Mesin / Engine No. 4D7.903528 Nomor Plat / License No. KT 2701 KG 60DidinMuhtadinNo ratings yet