Professional Documents

Culture Documents

94-Tmss-02-R0-Drinking Water Cooler PDF

94-Tmss-02-R0-Drinking Water Cooler PDF

Uploaded by

Utkucan KILIÇOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

94-Tmss-02-R0-Drinking Water Cooler PDF

94-Tmss-02-R0-Drinking Water Cooler PDF

Uploaded by

Utkucan KILIÇCopyright:

Available Formats

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev.

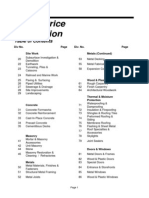

TABLE OF CONTENTS

1.0 SCOPE

2.0 CROSS-REFERENCES

3.0 APPLICABLE CODES AND STANDARDS

4.0 DEFINITIONS

5.0 DESIGN AND CONSTRUCTION REQUIREMENTS

5.1 General Requirements

5.2 Design Criteria

5.3 Ratings

5.4 Manufacture

6.0 TESTS

7.0 DATA SCHEDULE

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 2 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

1.0 SCOPE

This Transmission Material Standard Specification (TMSS) specifies the minimum technical

requirements for design, engineering, manufacture, inspection; testing and performance of

Drinking-Water Coolers intended to be used in the system of Saudi Electricity Company (SEC),

Saudi Arabia.

2.0 CROSS REFERENCES

This Material Standard Specification shall be read in conjunction with the latest revision of

SEC General Specification No. 01-TMSS-01, titled "General Requirements for All

Equipment/Materials" which shall be considered as an integral part of this TMSS.

This TMSS shall also be read in conjunction with SEC Purchase Order or Contract Schedules

for project, as applicable.

3.0 APPLICABLE CODES AND STANDARDS

The latest revision/amendments of the following Codes and Standards shall be applicable for

the equipment/material covered in this TMSS. In case of conflict, the vendor/manufacturer may

propose equipment/material conforming to one group of Industry Codes and Standards quoted

hereunder without jeopardizing the requirements of this TMSS.

3.1 SASO 415 Drinking Water Coolers-Arabic Version

3.2 ARI 1010 Self-Contained, Mechanically-Refrigerated Drinking-Water Coolers

3.3 ASHRAE 18 Methods of Testing for Rating Drinking-Water Coolers with Self-

Contained Mechanical Refrigeration Systems

3.4 UL 399 Standard for Safety Drinking Water Coolers

3.5 UL 1995 Standard for Safety Heating and Cooling Equipment

3.6 ASTM A240 Specification for Chromium and Chromium-Nickel Stainless Steel

Plate, Sheet, and Strip for Pressure Vessels and for General

Applications

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 3 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

4.0 DEFINITIONS

4.1 Remote-Type Drinking-Water Cooler

A water cooler which has the primary function of cooling potable water for delivery to

remotely-installed drinking fountains, etc. However, such remotely-installed dispensing

means are not considered part of this water cooler.

4.2 Individual (Unitary) Drinking-Water Cooler

A water cooler which has the primary function of cooling potable water and also

provides for dispensing such water by integral means.

4.2.1 Bubbler-Type Pressure Water Coolers

A pressure water cooler which utilizes a valve to control the flow of water as a

projected stream from a bubbler so that the water may be consumed without

utilizing glasses or cups.

4.2.2 Hot and Cold-Type Water Coolers

A pressure water cooler which, in addition to the primary function of cooling

and dispensing potable cold water, includes means for heating and dispensing

potable hot water.

4.2.3 Bottle-Type Water Coolers

A water cooler which employs a bottle or reservoir for storing the supply of

water to be cooled and which utilizes a faucet or similar means for filling

glasses, cups or other containers.

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 4 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

5.0 DESIGN AND CONSTRUCTION REQUIREMENTS

5.1 General Requirements

5.1.1 Design and Manufacture

Drinking-water coolers shall be of manufacturer's standard designed and

manufactured equipment with factory-installed accessories for a complete and

fully automatic operational system.

5.1.2 Type

Water cooler shall be designed either remote-type cooler or individual (unitary)

cooler. Unitary cooler shall either be of bubbler-type or hot and cold-type or

bottle-type.

5.1.3 Product Listing

All water coolers referred to in this specification shall be listed under ETL in

accordance with UL 1995 and UL 399 for Remote Type and Unitary Drinking-

Water Coolers respectively. All coolers shall carry UL stamp of approval.

5.1.4 Refrigerant

The unit shall be fully charged with "ozone safe" refrigerant R134a.

5.1.5 Miscellaneous:

a. All cooler enclosures shall be properly bonded to the grounding system.

b. Each compressor shall be provided with vibration isolation.

c. All coolers, except for bottle-type, shall be provided with a minimum

inlet water pressure of 276 kPa for satisfactory performance.

5.2 Design Criteria

All coolers shall be designed to operate satisfactorily at high ambient conditions as high

as 50°C and to produce a maximum chilled water temperature of 10°C.

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 5 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

5.3 Ratings

5.3.1 Published Ratings

Ratings of any representative production water cooler shall have a capacity not

less 95% of its published capacity rating in accordance with ARI 1010.

5.3.2 Standard Ratings

Ratings shall be verified by tests in accordance with ASHRAE 18.

5.4 Manufacture

5.4.1 Remote-Type Drinking-Water Cooler

a. General

Remote drinking-water coolers shall be of manufacturer's standard

designed and manufactured equipment consisting of refrigeration unit,

chilled water reservoir, recirculating pump, make-up water filtration,

built-in sterilizer, phosphate feeder and complete controls for fully

automatic operational system.

i. The cooler shall be self-contained mechanically-refrigerated

system, factory-assembled, prewired, prepiped and precharged

with refrigerant and compressor oil; and ready for field

connections to drinking fountains, all housed as one package.

ii. The unit shall be constructed of a rugged, rust-proofed and

enameled steel (18 gauge) cabinet mounted on a heavy angle iron

frame. Housing panels shall be easily removable for complete

access to all components without tools.

iii. The unit shall be configured to provide inlet/outlet piping

connections for make-up water, chilled water discharge and

chilled water return.

iv. The unit shall be provided with inlet/outlet air openings (hooked

up to ductwork) for condenser cooling i.e. by introducing fresh air

then venting out the hot air off the condenser through ductwork

to the atmosphere.

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 6 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

b. Refrigeration Unit

i. The unit shall consist of high efficient, lifetime lubricated

hermetic compressor, refrigerant receiver and air-cooled

condenser with capability to remove heat load at high ambient

conditions.

ii. The condenser shall be supplied with thermostat, low/high

pressurestat, pump down solenoid valves, expansion valve,

refrigeration gauges, oil pressure switch, sight glass and

dehydrator.

iii. Condenser coil shall be constructed of aluminum fin bonded to

seamless copper tube and shall be epoxy-sprayed for corrosion

protection.

c. Chilled Water Reservoir

i. The cooling tank shall be constructed of 316L stainless steel

tested at 1724 kPa and designed for 862 kPa working pressure.

Tank plate wall thickness shall be as per manufacturer's standard.

ii. The tank shall be equipped with immersion type cooling coils

constructed of 316L stainless steel seamless pipe having a

minimum wall thickness of 1.524 mm. Shell and tube evaporators

or open tanks with float valves are not acceptable.

iii. The storage tank shall be supplied with air vent, drain connection

and insulated with closed cell thermo-elastomer with U-factor of

0.048 W/m2°C.

d. Recirculating Pump

i. The pump shall be stainless steel centrifugal type designed for

862 kPa working pressure mounted on rubber pad over a stainless

steel condensation tray, with drain.

ii. The pump shall be supplied with manual on/off switch.

iii. All piping and fitting shall be hard-drawn seamless type K copper

and insulated with closed-cell thermo-elastomer with U-factor of

0.048 W/m2°C.

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 7 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

iv. Piping shall be equipped with temperature sensor on discharge

side of the pump, unions, service valves, manual bypass valve and

drain.

e. Make-Up Water Filtration

i. General

Water filters shall be provided to the water treatment module

performing in accordance with U.S. Public Health Standards.

Filter capacity shall be as per manufacturer's standard correspond

to unit requirement. Vendor to provide at least two (2) spare

filters of each type for every cooler's required capacity.

• Filter assembly shall be provided with unions and shut-off

valves at the inlet and outlet for quicker disconnection

from plumbing or recharging. Backwash and manual

bypass valves shall also be supplied.

• Filter housing shall be equipped with cock or cleanout

port for water draining.

• Filter housing shall be provided with removable top for

sediment filter replacement or carbon recharging without

using any tool and without disconnecting the plumbing.

ii. Combined Sediment/Activated Carbon Water Filters

• Filter shall be dual media installed inside a single housing

for removal of sediment, taste, odors and other harmful

chemicals.

• Filter housing shall be constructed of a polished 316L

stainless steel (12 gauge) designed for a working pressure

of 862 kPa. No plastic part will be acceptable.

iii. Prefilters and Activated Carbon Water Filters

• Prefilters

Prefilter shall be a natural fiber filter sheets for removal

of suspended matter down to 5 microns. Non-

biodegradable elements are not acceptable.

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 8 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

Filter housing shall be as mentioned in item 5.4.1 (e.ii)

above.

• Activated Carbon Filters

* Filter elements shall be composed of granular

activated carbon where all taste, odors and other

organic chemicals are removed.

* Filter housing shall be fiberglass reinforced

polyester resin , one-piece, totally seamless

construction with no welded seams, cemented

joints or special tank lining which can corrode,

electrolyze, give way and leak. Inside finish shall

smooth to avoid dirt retention

* Filter housing shall be designed to operate at

maximum pressure of 862 kPa and shall be

equipped with air vent.

f. Built-In Ultraviolet (UV) Sterilizer

i. UV sterilizer shall be fabricated of 316L stainless steel and shall

be rated for treatment of water-borne bacteria, algae, spores,

viruses and cysts. Capacity shall be as per manufacturer's

standard correspond to unit requirement.

ii. Sterilizer shall be horizontally mounted with a removable quartz

sleeves for maintenance.

iii. Sterilizer shall have water flow regulator to ensure an exposure of

at least 30,000 microwatt-sec/cm2 .

g. Phosphate Feeder

i. Phosphate feeder shall be constructed of a transparent plastic

body designed for 862 kPa working pressure complete with shut-

off valves and drain valve.

ii. The feeder shall be rated to provide solution flowrate sufficient

enough to protect plumbing in inhibiting lime scale formation,

preventing corrosion or rusting, etc. Capacity shall be as per

manufacturer's standard correspond to unit requirement.

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 9 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

iii. Vendor to provide phosphate for least one (1) year of continuous

operation.

h. Controls and Monitor Panel

The cooler shall be provided with an integral control panel suitable for

thermostat control (adjustable range from 4.45° to 32°C ±0.83°C),

freezestat and factory-set thermostatic expansion valve.

Control panel shall have standard features to perform the following

functions:

i. Purity Meter

To monitor water quality, signaling when filter or UV sterilizer

requires maintenance.

ii. UV Sterilizer Monitor Light

To indicate UV energy status, signaling when sterilizer needs

servicing.

iii. Differential Pressure Switch

To show when filter element needs changing and set for

maximum pressure drop of 69 kPa.

iv. Digital Thermometer

To display discharge water temperatures both in °F and °C.

v. Cooler Capacity

The following information, as shown in Tables 1 and 2, is only to

provide the basic cooler capacity based on 32°C ambient, 27°C

inlet and 7.22°C outlet, connections, approximate dimensions,

etc. for sizing purposes and shall not preclude other sizes which

satisfy all the requirements of this specification:

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 10 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

Table 1 - Cooler Capacity and Dimensions

1

Cooling Storage Person Served Chilled Dimensions

Cap., Capacity, liters at 1 liter./day Water L x W x H, mm

watts Conn., mm

293 7.57 50 10 750x175x600

341 18.93 130 10 750x300x600

495 37.85 200 15 800x475x1350

938 53.00 300 15 875x550x1350

1172 94.63 400 20 1000x675x1350

1758 151.40 600 20 1075x675x1750

2344 189.25 800 20 1075x675x2000

4103 227.10 1400 20 1125x750x2000

4982 378.50 1700 25 2625x750x1500

8206 605.6 2800 25 2925x875x1750

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 11 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

Table 2 - Cooler Electrical and Piping Allowance Data

2

Cooling Power Supply Compressor Pump Piping Allowance

Cap., watts V/Ph/Hz Motor, watts Motor/Cap.,

meter IPS size,mm

watts/lps

293 127/1/60 125 None 3.05 6

341 127 or 208/1/60 150 None 6.10 6

495 127 or 208/1/60 187 30 / 0.189 18.30 15

938 127 or 208/1/60 250 30 / 0.189 21.30 15

1172 127 or 208/1/60 373 150 / 0.378 30.50 15

1758 127 or 208/1/60 560 250 / 0.505 45.70 15

2344 127 or 208/1/60 746 250 / 0.505 58.00 20

4103 208 or 380/3/60 1119 250 / 0.505 91.50 20

4982 208 or 380/3/60 1492 373 / 0.95 106.70 25

8206 208 or 380/3/60 2238 373 / 0.95 176.80 25

1

Values are applicable for typical office building only. For buildings with heavy usage such as

clinics, schools, etc., reduce the indicated values by 50% to allow for 2 liters/day per person.

For high ambient areas with temperatures regularly above 38°C or with incoming water

temperature from 27°C to 38°C, multiply people served by 0.75. If make-up water exceeds

38°C, consult for manufacturer's recommendation.

2

Values include extra capacity to handle heat loss of insulated piping in the circulating loop up

to the length shown. For piping in excess of this allowance, reduce population served by 1.0

people per 0.305 meter of additional piping and the required power for pumping shall also be

resized accordingly.

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 12 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

5.4.2 Individual Drinking-Water Coolers

a. General

Individual drinking-water cooler shall be of manufacturer's standard

designed and manufactured equipment consisting of refrigeration system,

cooling tank and coil, thermostat, etc. complete for fully automatic

operational system.

i. The unit shall be free-standing with removable panel for easy

access for servicing and replacement.

ii. The unit shall have a power supply of 127 volt/1-phase /60 Hz

with a 1.80-meter heavy-duty 3-wire electrical cord and plug. All

connections shall be enclosed in a moisture resistant box to

prevent short circuiting in the event of water leaks or spillage.

iii. The unit, except for bottle-type cooler, shall be provided with

non-clogging stainless steel drain and quick disconnect water

connections for easy removal of the entire cooling package.

b. Bubbler-Type Water Cooler

i. Cabinet

Cabinet and top shall be constructed of #304 stainless steel, gauge

18 with satin finish and anti-splash ridge.

ii. Bubbler

Shall be push-button bubbler constructed of solid brass, chrome

plated, anti-squirt design with built-in automatic stream regulator

to assure constant stream height under varying line pressures from

138 kPa to 862 kPa.

Stream regulation shall be easily adjustable with screw driver by

simply removing the push-button cap.

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 13 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

iii. Tank and Evaporator

The cooling tank and immersion cooling coil shall be constructed

of 316L stainless steel, with a minimum storage capacity of 7.57

liters and designed for 862 kPa working pressure. Shell and tube

evaporators or open tanks with float valves are not acceptable.

The storage tank shall be supplied with air vent, drain connection

and insulated with poured urethane.

The tank shall be housed in an insulated, rust-proof and vapor-

proof stainless steel container.

iv. Refrigeration System

The system shall be provided with a 249-watt high efficiency

hermetically sealed compressor having a minimum cooling

capacity of 38 liters/hour, aluminum finned, copper air-cooled

condenser epoxy-sprayed to prevent corrosion. Oversized

condenser shall be designed to operate at high ambient

conditions.

v. Built-in Water Filter Purifier

Filter shall be a combined sediment/activated carbon type as

described in item 5.4.1 (e.ii) above.

Filter capacity shall be rated at 7.57 liters/min. Vendor to provide

a least five (5) dozens spare filters.

vi. Chilled Water Controls

The cooler shall be provided with adjustable and corrosion-proof

thermostat and thermal overload relay.

c. Hot and Cold-Type Water Cooler

i. Same construction and features as in bubbler-type water cooler

but with additional insulated hot water dispenser that can deliver

up to 40 cups of 88°C water per hour.

ii. Hot water (HW) dispenser shall be installed inside the cooler

cabinet with 1.25-liter copper tank, heating element, expansion

chamber, self-closing valve, air vent and drain.

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 14 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

iii. HW dispenser shall be equipped with snap-action thermostat

adjustable from 71°C to 93°C.

iv. HW dispenser shall be provided with push lever with auto return

to "off", solid brass-chrome plated goose neck glass filler and

stream straightener for non-splash action.

d. Bottle-Type Water Cooler

i. Bottle-type water cooler shall be designed to dispense hot and cold

water, with 20-liter plastic water bottle. Vendor to provide at least

two (2) bottles packed in an individual dustproof carton.

ii. The cooler shall have a fully drainable stainless steel 3.5 liter

cooling reservoir, sandalwood acrylic finish with woodgrain vinyl

front panel.

iii. The cooler shall be equipped with food grade silicone gasket

around the bottle to keep out of contaminants.

iv. The cooler shall be equipped with a removable stainless steel

overflow tray.

v. The unit shall have sealed static-cooled condenser, 50-watt

compressor motor and heater. Controls shall be as per

manufacturer standards.

vi. The unit shall be capable of dispensing 4 liters/hour cold water

and up to 40 cups of hot water per hour.

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 15 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

5.4.3 Nameplate

a. Each equipment shall be equipped with a permanently marked stainless

steel nameplate in English to include the following minimum

information:

i. Manufacturer's Name

ii. Model Number

iii. Serial Number

iv. Year of Manufacture

v. Cooling Capacity, watts or liters/hour

vi. Unit Input Power, watts

vii. Power Supply, V/Ph/ Hz

viii. Full Load Current, Amps

ix. Locked Rotor Current, Amps

x. Unit Gross Weight, kg.

xi. 94-TMSS-02 Rev. 0

b. The nameplate shall be fastened to the equipment by stainless steel

screws or rivets.

6.0 TESTS

All water coolers shall be tested in compliance with the applicable requirements of UL 399, UL

1995 and the following performance tests as prescribed in ARI 1010 on any representative

sample:

6.1 Maximum Operating Condition Tests

6.2 Insulation Effectiveness Test

6.3 High Voltage and Low Voltage Tests

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 16 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

DWG*: 94TMSS02.01.00

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 17 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

DWG*: 94TMSS02.02.00

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 18 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

DWG*: 94TMSS02.03.00

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 19 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

7.0 DATA SCHEDULE

DRINKING-WATER COOLERS

SEC Inquiry No. Date:

SEC Purchase Order No. Date:

or Contract No.

SEC PTS No./Project Title with J.O. No.

REFERENCE

SECTION NO. DESCRIPTION 'A' 'B' 'C'

5.2 DESIGN CRITERIA

Design Ambient Temperature (°C)

Inlet Water Press. to the Cooler (kPa) (as applicable)

5.3 RATINGS

Cooler Mfg./Model Number

Unit Power Input (watts)

Min. Circuit Current (Amps)

Power Supply

Voltage (V)

Frequency (Hz)

Phase (Ph)

Control Voltage (V)

Frequency (Hz)

Phase (Ph)

'A' - SEC SPECIFIED DATA/PARAMETERS

'B' - BIDDER/SUPPLIER/VENDOR/CONTRACTOR PROPOSED

DATA/PARAMETERS

'C' - REMARKS SUPPORTING THE PROPOSED DEVIATION IN COLUMN 'B'

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 20 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

7.0 DATA SCHEDULE

DRINKING-WATER COOLERS

REFERENCE

SECTION NO. DESCRIPTION 'A' 'B' 'C'

5.3 (Continued)

Cooling Capacity (watts or liters/hr)

Make-Up Water Temperature (°C)

Water Discharge Temperature (°C)

Compressor

Manufacturer/Model No.

Motor Power (watts)

Power Supply

Voltage (V)

Frequency (Hz)

Phase (Ph)

Comp. Motor FLA/LRA (Amps)

Compressor Motor Speed (RPM)

Condenser Fan and Motor (as applicable)

Manufacturer/Model Number

Motor Power, (watts)

Power Supply

Voltage (V)

Frequency (Hz)

Phase (Ph)

Fan Motor FLA/LRA (Amps)

Fan Speed (RPM)

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 21 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

7.0 DATA SCHEDULE

DRINKING-WATER COOLERS

REFERENCE

SECTION NO. DESCRIPTION 'A' 'B' 'C'

5.3 (Continued)

Chilled Water Reservoir

Capacity (liters)

Working Pressure (kPa)

Recirculating Pump (as applicable)

Manufacturer/Model Number

Capacity (liters/min)

Head (kPa)

Motor Power (watts)

Power Supply

Voltage (V)

Frequency (Hz)

Phase (Ph)

Pump Motor FLA/LRA (Amps)

Pump Speed (RPM)

Make-Up Water Filtration (as applicable)

Combined Sediment/Activated Carbon Filter

Manufacturer/Model Number

Capacity (liters/min)

Quantity

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 22 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

7.0 DATA SCHEDULE

DRINKING-WATER COOLERS

REFERENCE

SECTION NO. DESCRIPTION 'A' 'B' 'C'

5.3 (Continued)

Prefilter

Manufacturer/Model Number

Capacity (liters/min)

Quantity

Activated Carbon Filter

Manufacturer/Model Number

Capacity (liters/min)

Quantity

UV Sterilizer (as applicable)

Manufacturer/Model No.

Capacity (liters/min)

No. of Lamps

Watts

Power Supply

Voltage (V)

Frequency (Hz)

Phase (Ph)

Phosphate Feeder (as applicable)

Manufacturer/Model No.

Capacity (liters)

Solution Flowrate (liters/min)

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 23 OF 24

TRANSMISSION MATERIALS STANDARD SPECIFICATION 94-TMSS-02, Rev. 0

7.0 DATA SCHEDULE

DRINKING-WATER COOLERS

A. ADDITIONAL TECHNICAL INFORMATION OR FEATURES SPECIFIED BY

BY SEC:

B. ADDITIONAL SUPPLEMENTARY DATA OR FEATURES PROPOSED BY BIDDER/

VENDOR/SUPPLIER/CONTRACTOR :

C. OTHER PARTICULARS TO BE FILLED UP BY BIDDER/VENDOR/SUPPLIER/

CONTRACTOR :

Manufacturer Vendor/Supplier/

of Material/Equipment Contractor

Name of the Company

Location and Office Address

Name and Signature of

Authorized Representative

and Date

Official Seal/Stamp

of the Company

94TMSS02R0/MHS Date of Approval: June 23, 2008 PAGE NO. 24 OF 24

You might also like

- SGS - MS - Installation of LED FloodlightsDocument8 pagesSGS - MS - Installation of LED FloodlightsomarqasimNo ratings yet

- Tes-B-106-06-R0-Fk 5-1-12 Fixed Installation Total Flooding Clean-Agent Fire Extinguishing SystemDocument12 pagesTes-B-106-06-R0-Fk 5-1-12 Fixed Installation Total Flooding Clean-Agent Fire Extinguishing SystemUtkucan KILIÇNo ratings yet

- Tes H 107 01 R1 Painting PDFDocument58 pagesTes H 107 01 R1 Painting PDFUtkucan KILIÇNo ratings yet

- 11-TMSS-04-11kV, 13.8kV, 33kV & 34.5kV MEDIUM VOLTAGE POWERDocument17 pages11-TMSS-04-11kV, 13.8kV, 33kV & 34.5kV MEDIUM VOLTAGE POWERUtkucan KILIÇNo ratings yet

- 11-Tmss-06-R0-Distributed Temperature Sensing (DTS) System For Uig Power CableDocument17 pages11-Tmss-06-R0-Distributed Temperature Sensing (DTS) System For Uig Power CableUtkucan KILIÇ100% (1)

- Gas Safety (Installation and Use) Regulations 1998Document100 pagesGas Safety (Installation and Use) Regulations 1998Adsfgxdt DxafcvxgbNo ratings yet

- 94 TMSS 02 R0Document0 pages94 TMSS 02 R0hasanmnhNo ratings yet

- 90-Tmss-10-R0-Firewater Spronklers PDFDocument15 pages90-Tmss-10-R0-Firewater Spronklers PDFUtkucan KILIÇNo ratings yet

- 94-Tmss-01-R0-Automatic Electric Water Heater PDFDocument14 pages94-Tmss-01-R0-Automatic Electric Water Heater PDFUtkucan KILIÇNo ratings yet

- Civil and Structural Underground System, Site Finishing & Miscellaneous Construction StandardsDocument63 pagesCivil and Structural Underground System, Site Finishing & Miscellaneous Construction StandardsKoshi DragonNo ratings yet

- Sec19 - AppendixDocument12 pagesSec19 - AppendixYusufNo ratings yet

- Sec08 - Cable TrayDocument8 pagesSec08 - Cable TrayYusufNo ratings yet

- f502 - Project Historical ReportingDocument4 pagesf502 - Project Historical ReportingYusufNo ratings yet

- Sec14 - Electrical System and Equipment ProtectionDocument18 pagesSec14 - Electrical System and Equipment ProtectionYusufNo ratings yet

- DRS 00 VBQ TR FWB 001 - 0Document334 pagesDRS 00 VBQ TR FWB 001 - 0Korcan ÜnalNo ratings yet

- Sec02 - SafetyDocument3 pagesSec02 - SafetyYusufNo ratings yet

- 48 TMSS 04 R0Document0 pages48 TMSS 04 R0renjithas2005100% (1)

- Sec15 - Special SystemsDocument51 pagesSec15 - Special SystemsYusufNo ratings yet

- Sec18 - ReferencesDocument2 pagesSec18 - ReferencesYusufNo ratings yet

- Sec01 - Corporate Electrical ProceduresDocument2 pagesSec01 - Corporate Electrical ProceduresYusufNo ratings yet

- 01 - Corporate Piping-Mechanical ProceduresDocument2 pages01 - Corporate Piping-Mechanical Proceduresmostafa aliNo ratings yet

- Sec17 - Codes and StandardsDocument6 pagesSec17 - Codes and StandardsYusufNo ratings yet

- Sec03 - Duties and ResponsibilitiesDocument11 pagesSec03 - Duties and ResponsibilitiesYusufNo ratings yet

- Tes-T-111-18-R0-Environmental Considerations For Cummunications Sites and Remote Communications TerminalsDocument6 pagesTes-T-111-18-R0-Environmental Considerations For Cummunications Sites and Remote Communications TerminalsUtkucan KILIÇNo ratings yet

- Cost Index ProcedureDocument2 pagesCost Index Procedurerasputin0780803494No ratings yet

- Attachment C - Form WR-51: Instructions For Use: Bechtel ConfidentialDocument2 pagesAttachment C - Form WR-51: Instructions For Use: Bechtel ConfidentialGordon LongforganNo ratings yet

- TEI-I-111.15: Transmission Engineering StandardDocument12 pagesTEI-I-111.15: Transmission Engineering StandardArnieNo ratings yet

- Method Statement - Bus DuctDocument2 pagesMethod Statement - Bus Ductsoubhagya100% (1)

- DACE Labour Norms Painting V2Document16 pagesDACE Labour Norms Painting V2Amir AbazaNo ratings yet

- Table of Content Unit Price - MaterialDocument3 pagesTable of Content Unit Price - Materialrasputin0780803494No ratings yet

- Engineering Consultancy Services: Tender Document FORDocument69 pagesEngineering Consultancy Services: Tender Document FORKalai SelvanNo ratings yet

- Guidelines For The Installation of Cable in Cable Trays PDFDocument7 pagesGuidelines For The Installation of Cable in Cable Trays PDFStefanos DiamantisNo ratings yet

- Estimating 101 NECA LABOR ADJUSTMENT CHARTDocument1 pageEstimating 101 NECA LABOR ADJUSTMENT CHARTRicky ChangNo ratings yet

- Sec06 - GroundingDocument6 pagesSec06 - GroundingYusufNo ratings yet

- Method Statement For Horizontal Tray Erection.Document5 pagesMethod Statement For Horizontal Tray Erection.soubhagyaNo ratings yet

- 31-SAMSS-004 Dec, 24Document45 pages31-SAMSS-004 Dec, 24Fayez Al-ahmadiNo ratings yet

- Engineering Standard: IPS-E-AR-160Document68 pagesEngineering Standard: IPS-E-AR-160thermosol5416No ratings yet

- Seeds-I: Revision No. 00Document22 pagesSeeds-I: Revision No. 00ArnieNo ratings yet

- 6-36kV Medium Voltage Underground Power CablesDocument48 pages6-36kV Medium Voltage Underground Power CablesHtun SoeNo ratings yet

- Sec11 - Electrical EquipmentDocument29 pagesSec11 - Electrical EquipmentYusufNo ratings yet

- Aa - Req - 000131 - Quality Requirements Third Party Design VerificationDocument11 pagesAa - Req - 000131 - Quality Requirements Third Party Design Verificationjonodo89No ratings yet

- 213-04a - CONTROL OF NON-CONFORMING PRODUCTDocument7 pages213-04a - CONTROL OF NON-CONFORMING PRODUCTyusuf.yuzuakNo ratings yet

- Ducts Acessaries 1Document15 pagesDucts Acessaries 1KUMAARRR100% (1)

- DACE Labour Norms E I V2Document29 pagesDACE Labour Norms E I V2Amir AbazaNo ratings yet

- 19 - ReferencesDocument2 pages19 - Referencesyusuf.yuzuakNo ratings yet

- Sec12 - Electric MotorsDocument12 pagesSec12 - Electric MotorsYusufNo ratings yet

- ME430 Tests-031Document9 pagesME430 Tests-031kakajssh yhsusuaiwNo ratings yet

- GeneratorDocument19 pagesGeneratoruddinnadeemNo ratings yet

- 220 3PS JQ07 00001Document41 pages220 3PS JQ07 00001Augusto Francisco Diaz LaraNo ratings yet

- 16 PumpsDocument3 pages16 Pumpsmostafa aliNo ratings yet

- 23 - Crushers and PulverizersDocument10 pages23 - Crushers and Pulverizersyusuf.yuzuakNo ratings yet

- Downloaded From Manuals Search EngineDocument50 pagesDownloaded From Manuals Search Enginemzmakba1No ratings yet

- 219-04a - VENDOR OPERATING AND SERVICING DOCUMENTATION AND SPARESDocument6 pages219-04a - VENDOR OPERATING AND SERVICING DOCUMENTATION AND SPARESyusuf.yuzuakNo ratings yet

- TS-05 Codes and StandardsDocument7 pagesTS-05 Codes and StandardsPraveen KumarNo ratings yet

- Flexible ConnectionsDocument118 pagesFlexible ConnectionsMuzaffarNo ratings yet

- Okonite Engineering HandbookDocument65 pagesOkonite Engineering Handbooktomgilmartin100% (1)

- 73 TMSS 01 R0Document32 pages73 TMSS 01 R0Ibrahim AntarNo ratings yet

- Field Inspectionand Testing ofDocument27 pagesField Inspectionand Testing ofsarsan nedumkuzhi maniNo ratings yet

- DACE Labour Norms Piping Tables V2Document33 pagesDACE Labour Norms Piping Tables V2Amir AbazaNo ratings yet

- Saes A 109Document4 pagesSaes A 109malika_00No ratings yet

- Chillers SpecsDocument13 pagesChillers Specsahmed ragabNo ratings yet

- 19MV Guide Specification (202406)Document8 pages19MV Guide Specification (202406)Angga HardiyantomoNo ratings yet

- Sample Chiller SpecificationDocument5 pagesSample Chiller Specificationjlcheefei9258No ratings yet

- 19DV Guide Specifications, 350 To 800 Nominal Tons (1231 To 2814 Nominal KW) - Published Date 8.4.2020Document10 pages19DV Guide Specifications, 350 To 800 Nominal Tons (1231 To 2814 Nominal KW) - Published Date 8.4.2020anganNo ratings yet

- 1995 Standard For: Refrigerant-Cooled Liquid Coolers, Remote TypeDocument8 pages1995 Standard For: Refrigerant-Cooled Liquid Coolers, Remote TypeDanZel DanNo ratings yet

- Tes-B-106.04-R0-Deluge SystemDocument37 pagesTes-B-106.04-R0-Deluge SystemUtkucan KILIÇNo ratings yet

- Tes-T-111-12-R0-Outside Plant (Communications) Standarts and Practices For Facility Area Plan Design and Remote Distribution Area Plan DesignDocument34 pagesTes-T-111-12-R0-Outside Plant (Communications) Standarts and Practices For Facility Area Plan Design and Remote Distribution Area Plan DesignUtkucan KILIÇNo ratings yet

- Tes H 107 01 R0 Painting PDFDocument56 pagesTes H 107 01 R0 Painting PDFUtkucan KILIÇ100% (2)

- Tes-W-109.01-R0-General Welding CriteriaDocument23 pagesTes-W-109.01-R0-General Welding CriteriaUtkucan KILIÇNo ratings yet

- Tes-T-111-18-R0-Environmental Considerations For Cummunications Sites and Remote Communications TerminalsDocument6 pagesTes-T-111-18-R0-Environmental Considerations For Cummunications Sites and Remote Communications TerminalsUtkucan KILIÇNo ratings yet

- 94-Tmss-01-R0-Automatic Electric Water Heater PDFDocument14 pages94-Tmss-01-R0-Automatic Electric Water Heater PDFUtkucan KILIÇNo ratings yet

- 90-Tmss-10-R0-Firewater Spronklers PDFDocument15 pages90-Tmss-10-R0-Firewater Spronklers PDFUtkucan KILIÇNo ratings yet

- 90-Tmss-09-R0-Valve Inspection and Testing Requirements PDFDocument10 pages90-Tmss-09-R0-Valve Inspection and Testing Requirements PDFUtkucan KILIÇNo ratings yet

- 31-Tmss-01-R0-Relay Control PanelsDocument30 pages31-Tmss-01-R0-Relay Control PanelsUtkucan KILIÇNo ratings yet

- 11-TMSS-02-R1-POWER CABLE, XLPE INSULATED, COPPER CONDUCTOR, SINGLE CORE, 110kV, 115kV, 132kV PDFDocument35 pages11-TMSS-02-R1-POWER CABLE, XLPE INSULATED, COPPER CONDUCTOR, SINGLE CORE, 110kV, 115kV, 132kV PDFUtkucan KILIÇNo ratings yet

- Toilet Toilet Entrance: Plan AREA: 1,602.22 M2 258.11 M2 29.38 M2 TOTAL AREA: 1,889.71 M2Document1 pageToilet Toilet Entrance: Plan AREA: 1,602.22 M2 258.11 M2 29.38 M2 TOTAL AREA: 1,889.71 M2Utkucan KILIÇNo ratings yet

- Section 1-1 Plan AREA: 286.91 M2: Labor Type E Accommodation 48Pp - Potable Water Plan and Isometric ViewsDocument1 pageSection 1-1 Plan AREA: 286.91 M2: Labor Type E Accommodation 48Pp - Potable Water Plan and Isometric ViewsUtkucan KILIÇNo ratings yet

- Central Laundry - Potable Water Plan and Isometric Views: Onshore PlantDocument1 pageCentral Laundry - Potable Water Plan and Isometric Views: Onshore PlantUtkucan KILIÇNo ratings yet

- Kitchen 2000Pp Local Camp - Potable Water Plan and Isometric ViewsDocument1 pageKitchen 2000Pp Local Camp - Potable Water Plan and Isometric ViewsUtkucan KILIÇNo ratings yet

- Central Laundry - Potable Water Plan and Isometric Views: Onshore PlantDocument1 pageCentral Laundry - Potable Water Plan and Isometric Views: Onshore PlantUtkucan KILIÇNo ratings yet

- Ariston MicroGENUS 27 MFFI User ManualDocument20 pagesAriston MicroGENUS 27 MFFI User ManualRayNo ratings yet

- RENNER RS (F) 11,0 - 75,0 - Brochure - ENDocument12 pagesRENNER RS (F) 11,0 - 75,0 - Brochure - ENAriantoNo ratings yet

- Grundfos 28-80Document6 pagesGrundfos 28-80anNo ratings yet

- Catálogo CRISTANINI FD311Document20 pagesCatálogo CRISTANINI FD311CRISTANINI_CHILENo ratings yet

- Old CSI85/CSI85T ManualDocument55 pagesOld CSI85/CSI85T ManualIrregular Shed100% (1)

- Chemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateDocument2 pagesChemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateIbadurrahman KahfiNo ratings yet

- Two Story Apartment Water Distribution SystemDocument36 pagesTwo Story Apartment Water Distribution SystemzaccNo ratings yet

- Building Elements ChecklistDocument11 pagesBuilding Elements Checklista_j_sanyal259No ratings yet

- 2017 - Working - 25c-Outlet 55C - EVI Heat Pump Tech DataDocument1 page2017 - Working - 25c-Outlet 55C - EVI Heat Pump Tech DataSiktonNo ratings yet

- Bukh Diesel Engine Type BBD1105 & BBV1505 Operator's Maintenance ManualDocument40 pagesBukh Diesel Engine Type BBD1105 & BBV1505 Operator's Maintenance ManualmarcusNo ratings yet

- GE Profile Washer Owner's ManualDocument24 pagesGE Profile Washer Owner's ManualJeremy MooreNo ratings yet

- Tehnicke Podloge ARI-FABADocument14 pagesTehnicke Podloge ARI-FABAjack-bcNo ratings yet

- Specifications Turbomax 1Document2 pagesSpecifications Turbomax 1api-221502147No ratings yet

- HT Lab Manual (Experiment-8)Document12 pagesHT Lab Manual (Experiment-8)Aryaman KapoorNo ratings yet

- LG Washing Machine Top LoadDocument44 pagesLG Washing Machine Top LoadJoelMalangNo ratings yet

- Iflow Manual A2: Iflow Hydronic Air HandlerDocument37 pagesIflow Manual A2: Iflow Hydronic Air HandlerCTHNo ratings yet

- 5054 w09 QP 1Document20 pages5054 w09 QP 1Fra TeNo ratings yet

- Steam CleanerDocument6 pagesSteam CleanerVenu Kumar Reddy ChallaNo ratings yet

- (Group 2) Plater Heat ExchangerDocument9 pages(Group 2) Plater Heat ExchangerRiethanelia UsunNo ratings yet

- Coway Bedienungsanleitung chp250l 1497518818Document52 pagesCoway Bedienungsanleitung chp250l 1497518818lapintacdNo ratings yet

- HVAC Handbook Part 10 All Air Systems PDFDocument62 pagesHVAC Handbook Part 10 All Air Systems PDFTanveer100% (2)

- Hot Water Circulation Pump Sizing1Document1 pageHot Water Circulation Pump Sizing1imtiyaz94No ratings yet

- Hobart ft1000 PDFDocument12 pagesHobart ft1000 PDFhernan espitiaNo ratings yet

- Steam Generator Presentation ESC Pony Boilers ESC-Pony BoilersDocument38 pagesSteam Generator Presentation ESC Pony Boilers ESC-Pony BoilerspaulpopNo ratings yet

- SPDI Recent and Similar Board Questions MPLE 2022Document7 pagesSPDI Recent and Similar Board Questions MPLE 2022Jeinevie T. MaurilloNo ratings yet

- 6035 L2u205 PPT Outcome2Document24 pages6035 L2u205 PPT Outcome2Adrian JugariuNo ratings yet

- 2016 WiloUSA ListPricing BuildingServices 0216Document52 pages2016 WiloUSA ListPricing BuildingServices 0216Wissam JarmakNo ratings yet

- Att GUIDE 1 R1Document13 pagesAtt GUIDE 1 R1l_badellNo ratings yet

- Repair To Fan GeyserDocument10 pagesRepair To Fan GeyserkihtrakaNo ratings yet