Professional Documents

Culture Documents

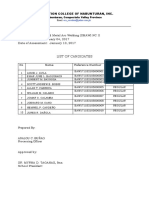

Pickling Procedure 20 - 08

Pickling Procedure 20 - 08

Uploaded by

Siriepathi SeetharamanCopyright:

Available Formats

You might also like

- Sponge Iron PlantDocument11 pagesSponge Iron PlantLi GaryNo ratings yet

- Asme CCase 1987-2Document2 pagesAsme CCase 1987-2ADAMJSRAONo ratings yet

- Generic Repair Procedure For Grinding and Build-UpDocument8 pagesGeneric Repair Procedure For Grinding and Build-UpRafiqKuNo ratings yet

- QA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsDocument1 pageQA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsvinothNo ratings yet

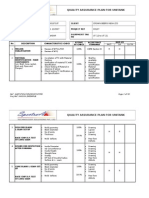

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanVicky Gautam100% (1)

- Pickling ProcedureDocument2 pagesPickling Proceduremahazari100% (6)

- Quality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Document10 pagesQuality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Narayana Mugalur100% (1)

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- TDC 1150Document3 pagesTDC 1150shazanNo ratings yet

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDocument8 pages44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- AST Nozzle Repair Req.Document10 pagesAST Nozzle Repair Req.Irvansyah RazadinNo ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Welding InspectionDocument7 pagesWelding Inspectionzahid_497100% (1)

- Pipe Bend ReportDocument1 pagePipe Bend ReportMohd Effiezool Yaser100% (1)

- How To Calculate Hydrostatic Test Height in TanksDocument4 pagesHow To Calculate Hydrostatic Test Height in TanksEric MagnayeNo ratings yet

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- ASME9 DrawingDocument1 pageASME9 DrawingÇağrı TansuğNo ratings yet

- TDC 003 - SS Pipes - r0Document1 pageTDC 003 - SS Pipes - r0samkarthik47No ratings yet

- Safe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallDocument1 pageSafe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallHarun Akkaya100% (1)

- TDC PP742 F2Document3 pagesTDC PP742 F2Arjun PrajapatiNo ratings yet

- Qap 8000ce Reactor - Repat - 1Document2 pagesQap 8000ce Reactor - Repat - 1AliasgarNo ratings yet

- API Repair ProcedureDocument1 pageAPI Repair ProcedurejacquesmayolNo ratings yet

- Job Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Weld Repair - PR - 0XXDocument10 pagesWeld Repair - PR - 0XXRAMAKRISHNANo ratings yet

- STD-InSP-0007 (Fitting Inspection Report)Document3 pagesSTD-InSP-0007 (Fitting Inspection Report)airbroomNo ratings yet

- Blasting & Painting Inspection Report Format For Bottom Plate 01Document7 pagesBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNo ratings yet

- Pneumatic Test Procedure For SeagullDocument4 pagesPneumatic Test Procedure For SeagullDarkvaderNo ratings yet

- NDT Map Itp Pressure VesselDocument4 pagesNDT Map Itp Pressure VesselSYED FADZIL SYED MOHAMEDNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- ITP-1612-F01 Rev. 2Document19 pagesITP-1612-F01 Rev. 2Erin JohnsonNo ratings yet

- Roundness Before Weld TK012-strike 1Document2 pagesRoundness Before Weld TK012-strike 1yuwantoniNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Pressure Vessel Dimension Inspection PDFDocument17 pagesPressure Vessel Dimension Inspection PDFEqubal KhanNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- 8 Material ControlDocument8 pages8 Material ControlPrakash RajNo ratings yet

- Visual Inspection of Weld Api 650Document2 pagesVisual Inspection of Weld Api 650amshivNo ratings yet

- SSPC sp1Document2 pagesSSPC sp1Malik AzeemNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Pressure Testing of Pressure VesselDocument3 pagesPressure Testing of Pressure VesselAriq FauzanNo ratings yet

- 6-12-0002 Rev 8 Supplementary Specification For Carbon Steel VesselsDocument7 pages6-12-0002 Rev 8 Supplementary Specification For Carbon Steel Vesselsravi2007No ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- Std-Insp-0002 (Incoming Material Inspection Procedure)Document3 pagesStd-Insp-0002 (Incoming Material Inspection Procedure)airbroomNo ratings yet

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocument7 pagesA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNo ratings yet

- Visual and Dimension Inspection Tolerance RevDocument8 pagesVisual and Dimension Inspection Tolerance RevJorgeNo ratings yet

- Shop Fabrication Procedure (Supply of Tank Option#3) PDFDocument7 pagesShop Fabrication Procedure (Supply of Tank Option#3) PDFGATOTNo ratings yet

- Vessel Cleaning ProcedureDocument6 pagesVessel Cleaning ProcedureZool HilmiNo ratings yet

- Material With Electrod SelectionDocument1 pageMaterial With Electrod SelectionMahmud HasanNo ratings yet

- Weld Repair Rev. 1Document3 pagesWeld Repair Rev. 1vinas kusdinarNo ratings yet

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 pageJNK Heaters Co - LTD: Ferrite Test ReportUzorNo ratings yet

- Job Procedure For Puncture/Floatation/Rain Water Accumulation TestDocument4 pagesJob Procedure For Puncture/Floatation/Rain Water Accumulation Testfaisal jasim100% (1)

- Ferr It Scope Procedure 1Document7 pagesFerr It Scope Procedure 1Abd Rahman AliasNo ratings yet

- Test Pack Clearance FormatDocument2 pagesTest Pack Clearance FormatKarthikNo ratings yet

- Cleaning PresentationDocument26 pagesCleaning PresentationhiNo ratings yet

- Penguard Express ZP AGDocument9 pagesPenguard Express ZP AGengramir07No ratings yet

- CP09 TDS 34002 Marathon 1000 XHBDocument5 pagesCP09 TDS 34002 Marathon 1000 XHBherdiansyahNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetCyril J PadiyathNo ratings yet

- International Paint - Corrossion Knowledge Sharing - Rizal PDFDocument87 pagesInternational Paint - Corrossion Knowledge Sharing - Rizal PDFIndra100% (1)

- Pmi 027Document2 pagesPmi 027Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 001Document2 pagesPmi Test Report - 001Siriepathi SeetharamanNo ratings yet

- QSC - 001Document2 pagesQSC - 001Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 051Document2 pagesPmi Test Report - 051Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 053Document2 pagesPmi Test Report - 053Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 018Document2 pagesPmi Test Report - 018Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 038Document2 pagesPmi Test Report - 038Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 050Document2 pagesPmi Test Report - 050Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 023Document2 pagesPmi Test Report - 023Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 008Document2 pagesPmi Test Report - 008Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 019Document2 pagesPmi Test Report - 019Siriepathi SeetharamanNo ratings yet

- Mrir 010Document5 pagesMrir 010Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 003Document2 pagesPmi Test Report - 003Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 007Document2 pagesPmi Test Report - 007Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 002Document2 pagesPmi Test Report - 002Siriepathi SeetharamanNo ratings yet

- Mrir 002Document1 pageMrir 002Siriepathi SeetharamanNo ratings yet

- Mrir 009Document4 pagesMrir 009Siriepathi SeetharamanNo ratings yet

- Grab E-Receipt Oct26.2Document2 pagesGrab E-Receipt Oct26.2Siriepathi SeetharamanNo ratings yet

- RT - 015Document1 pageRT - 015Siriepathi SeetharamanNo ratings yet

- Dcsm-Tep-1182968-Mec-D06-0009 Rev Z04 4 of 11Document1 pageDcsm-Tep-1182968-Mec-D06-0009 Rev Z04 4 of 11Siriepathi SeetharamanNo ratings yet

- RT - 016Document1 pageRT - 016Siriepathi SeetharamanNo ratings yet

- RT - 019Document1 pageRT - 019Siriepathi SeetharamanNo ratings yet

- Grab HelpCenter 18082022Document5 pagesGrab HelpCenter 18082022Siriepathi SeetharamanNo ratings yet

- RT - 004Document1 pageRT - 004Siriepathi SeetharamanNo ratings yet

- GRAB Transaction Receipt - 11 Oct To 30 OctDocument3 pagesGRAB Transaction Receipt - 11 Oct To 30 OctSiriepathi SeetharamanNo ratings yet

- RT - 020Document1 pageRT - 020Siriepathi SeetharamanNo ratings yet

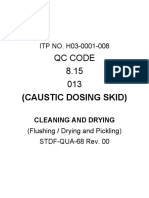

- MDR Separator Piping - FlushingDocument1 pageMDR Separator Piping - FlushingSiriepathi SeetharamanNo ratings yet

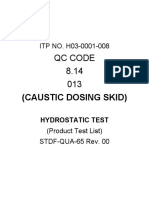

- MDR Separator Piping - HydrotestDocument1 pageMDR Separator Piping - HydrotestSiriepathi SeetharamanNo ratings yet

- Top HolidayDocument5 pagesTop HolidaySiriepathi SeetharamanNo ratings yet

- Grab HelpCenterDocument3 pagesGrab HelpCenterSiriepathi SeetharamanNo ratings yet

- Cytec Solutions 2013 8Document1 pageCytec Solutions 2013 8aktivrudarpNo ratings yet

- Keckley: Drawing No. AL 77020Document1 pageKeckley: Drawing No. AL 77020Luis Alberto Serrano MesaNo ratings yet

- Wrought Aluminium and Aluminium Alloys - Extruded Round Tube and Hollow Sections For General Engineering Purposes - SpecificationDocument10 pagesWrought Aluminium and Aluminium Alloys - Extruded Round Tube and Hollow Sections For General Engineering Purposes - Specificationmanasmech002No ratings yet

- Optimize Your Polymer Extrusion Process by Eliminating InstabilitiesDocument1 pageOptimize Your Polymer Extrusion Process by Eliminating InstabilitiesMekonnen BirhaneNo ratings yet

- IstanbulDocument8 pagesIstanbulAli YacineNo ratings yet

- Catalog FEEL by THM AgencyDocument68 pagesCatalog FEEL by THM Agencykartika lestariNo ratings yet

- Assignment On Bulk-Forming ProcessesDocument4 pagesAssignment On Bulk-Forming ProcessesMohammed ArishNo ratings yet

- Welding, Cutting, and BrazingDocument42 pagesWelding, Cutting, and BrazingRosiana AgustinNo ratings yet

- TM 9-242 Ordnance ToolsDocument427 pagesTM 9-242 Ordnance ToolsedrestNo ratings yet

- Production Technology (CD)Document7 pagesProduction Technology (CD)ParasNo ratings yet

- 0001y01091 en PDFDocument1 page0001y01091 en PDFvivekpattniNo ratings yet

- Highlights-ASME Guides Preheat-PWHT-VIII PDFDocument5 pagesHighlights-ASME Guides Preheat-PWHT-VIII PDFEr Manish JadaunNo ratings yet

- Milling FormulasDocument4 pagesMilling FormulasspedrerosNo ratings yet

- Taller Calculo de Parametros de CorteDocument4 pagesTaller Calculo de Parametros de CorteWendy Paola Rodriguez PerezNo ratings yet

- Pernos NelsonDocument4 pagesPernos NelsonJuan Manuel BazánNo ratings yet

- Metaline XL Series & Resistance Test, 100 XTM & Resistance TestDocument57 pagesMetaline XL Series & Resistance Test, 100 XTM & Resistance TestRiszki PangestuNo ratings yet

- TDS KH-8011S en 21Document2 pagesTDS KH-8011S en 21Carlos Lizarraga FloresNo ratings yet

- Spm-2000 II Eng Technical InformationDocument13 pagesSpm-2000 II Eng Technical Informationadrian9500No ratings yet

- Reference Number 2017Document493 pagesReference Number 2017Villamor NiezNo ratings yet

- Exothermic Welconnection Strip-Tape ConectionDocument9 pagesExothermic Welconnection Strip-Tape ConectionBenny HillNo ratings yet

- Threaded Rod: Plain, Zinc, Galvanized & Stainless SteelDocument7 pagesThreaded Rod: Plain, Zinc, Galvanized & Stainless Steelsidharth saraswatNo ratings yet

- Electronic PackagingDocument54 pagesElectronic PackagingAdelle Lyn Carlos100% (1)

- Final Main Starting PapersDocument6 pagesFinal Main Starting PapersAhmad HussainNo ratings yet

- Troubleshooting in Film CoatingDocument31 pagesTroubleshooting in Film Coatingfaysal_neo100% (1)

- Welder'S Qualification Test Certificate: The Welding Inspection CommunityDocument2 pagesWelder'S Qualification Test Certificate: The Welding Inspection CommunityRahulNo ratings yet

- H040800-01 Assembly BPV TWCV Installation ToolDocument1 pageH040800-01 Assembly BPV TWCV Installation ToolJitendra BhosaleNo ratings yet

- 2100 Lzi Primer PDFDocument1 page2100 Lzi Primer PDFphillipskincaidNo ratings yet

- Membrane Applications in Water Treatment: Snehal Dawkhar Mtech IIIDocument22 pagesMembrane Applications in Water Treatment: Snehal Dawkhar Mtech IIISnehal Dawkhar patilNo ratings yet

- Tiếng Anh chuyên nghiệp cho Thiết kế và Sản xuất Khuôn mẫuDocument170 pagesTiếng Anh chuyên nghiệp cho Thiết kế và Sản xuất Khuôn mẫuHoa HồngNo ratings yet

Pickling Procedure 20 - 08

Pickling Procedure 20 - 08

Uploaded by

Siriepathi SeetharamanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pickling Procedure 20 - 08

Pickling Procedure 20 - 08

Uploaded by

Siriepathi SeetharamanCopyright:

Available Formats

Tangguh Expansion Project – LNG EPC

Supplier – Pickling and Cleaning Procedure for Stainless Steel

PICKLING AND CLEANING PROCEDURE FOR STAINLESS STEEL

1. PURPOSE

This procedure to covers recommendations and precaustions for cleaning of new stainless steel

A316/316L parts, assemblies, equipment, and installed system.

This procedure will give guidance to remove surface contaminants that may impair the normal

corrosion resistance, or result a later contamination of the Stainless steel, or cause product

contamination.

Stainless pickling gel is used for cleaning of objects in dilute acids solution which for Stainless steel

are for:

• Remove oxide layers, discoloration and chromium depleted surface area.

• Restore the corrosion properties of external surface.

• Remove residual slag of the weld capping.

2. REFERENCES

ASTM A380, Standar Practise for Cleaning, Descaling, and Passivation of Stainless Steel

Parts, Equipment, and System. January 2000

BP GIS 36-102 Guidance on Industry Standard for Hardness Testing, Post Weld Heat

Treatment, Stress Relief, and Pickling for Pressure Vessels, Piping, and Other Components

3. PROCEDURE

3.1 Preparation and pickling method:

• All visible oil, grease, soil, and other soluble contaminants that would prevent pickling acid

from contacting the surface of base material or weld metal shall be removed by solvents

removal or cleaner. The method of use is with wipe repeatedly the surface of steel by rags or

brushes wetted with solvent then use clean solvent and clean rags or brushes for final

spaying,

•,The weld surface should be acceptable as per ANSI B31.3 for “Normal Fluid Services” prior to

pickling applied on the weld surfaces 1

• Shake the plastic bottle well before use. No stirring is required. The metal surface

temperature before application shall be between 5 °C to 50°C.

• Apply a relatively thick layer of Stain Clean using the brush, spread evenly on surface of steel

Time of pickling with gel take approximately 10 minutes at ambient temperature.

• Chemical composition of gel consist of:

Nitric Acid, HNO3 (10 – 30) %

Hydrofluoric Acid, HF (1-3%)

• Rinse carefully with large amounts of clean water while clean by hand brush repeatedly.

3.2 Water Quality

The water which be used to rinse shall be demineralized water form water treatment as per

TEP-1182968 Page 1 of 2 Rev:01

BP Internal

Tangguh Expansion Project – LNG EPC

Supplier – Pickling and Cleaning Procedure for Stainless Steel

manufacture’s recommendation and controlled by CONTRACTOR inspector. The cleanliness of

water shall be limited to maximum 30 ppm for chloride level, and with pH between 6 to 8. 1

4. INSPECTION AND EXAMINATION

4.1 Inspection

Inspection after completion of the pickling will be done by QC Inspector. The inspection report

must be issued to CLIENT for approval. Type of inspection to be done are:

• Visual inspection

4.2 Examination

Examination to ensure surface pH balance is using pH Paper, 1 spot on each spool.

• pH Paper Test (pH value : 6 – 8), to be intact on the surface area of the piece and other 1

area that most probably missed to be rinsed.

After inspection and examination finished and accepted, pipe spool shall be ensure not to direct

touch with Carbon steel / ground to prevent contamination, by plastic wrapping and stored on

pallet or stool at dedicated area.

5. EQUIPMENT

Following equipment and materials are minimum requirement to be used during pickling activities:

• Equipment:

a. Brush (non-ferrous) 1

b. Cloth / rags

c. Rubber Chemical gloves, Mask, rubber boots, Plastic apron, as additional from minimum

standard PPE.

d. Thermocouple with magnetic / laser / any, to measure metal surface.

• Chemical

a. Stainless steel pickling gel : Nabakem, MSDS Attached

b. Solvent : 3M Stainless Steel Cleaner, MSDS Attached 1

TEP-1182968 Page 2 of 2 Rev:01

BP Internal

You might also like

- Sponge Iron PlantDocument11 pagesSponge Iron PlantLi GaryNo ratings yet

- Asme CCase 1987-2Document2 pagesAsme CCase 1987-2ADAMJSRAONo ratings yet

- Generic Repair Procedure For Grinding and Build-UpDocument8 pagesGeneric Repair Procedure For Grinding and Build-UpRafiqKuNo ratings yet

- QA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsDocument1 pageQA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsvinothNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanVicky Gautam100% (1)

- Pickling ProcedureDocument2 pagesPickling Proceduremahazari100% (6)

- Quality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Document10 pagesQuality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Narayana Mugalur100% (1)

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- TDC 1150Document3 pagesTDC 1150shazanNo ratings yet

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDocument8 pages44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- AST Nozzle Repair Req.Document10 pagesAST Nozzle Repair Req.Irvansyah RazadinNo ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Welding InspectionDocument7 pagesWelding Inspectionzahid_497100% (1)

- Pipe Bend ReportDocument1 pagePipe Bend ReportMohd Effiezool Yaser100% (1)

- How To Calculate Hydrostatic Test Height in TanksDocument4 pagesHow To Calculate Hydrostatic Test Height in TanksEric MagnayeNo ratings yet

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- ASME9 DrawingDocument1 pageASME9 DrawingÇağrı TansuğNo ratings yet

- TDC 003 - SS Pipes - r0Document1 pageTDC 003 - SS Pipes - r0samkarthik47No ratings yet

- Safe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallDocument1 pageSafe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallHarun Akkaya100% (1)

- TDC PP742 F2Document3 pagesTDC PP742 F2Arjun PrajapatiNo ratings yet

- Qap 8000ce Reactor - Repat - 1Document2 pagesQap 8000ce Reactor - Repat - 1AliasgarNo ratings yet

- API Repair ProcedureDocument1 pageAPI Repair ProcedurejacquesmayolNo ratings yet

- Job Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Weld Repair - PR - 0XXDocument10 pagesWeld Repair - PR - 0XXRAMAKRISHNANo ratings yet

- STD-InSP-0007 (Fitting Inspection Report)Document3 pagesSTD-InSP-0007 (Fitting Inspection Report)airbroomNo ratings yet

- Blasting & Painting Inspection Report Format For Bottom Plate 01Document7 pagesBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNo ratings yet

- Pneumatic Test Procedure For SeagullDocument4 pagesPneumatic Test Procedure For SeagullDarkvaderNo ratings yet

- NDT Map Itp Pressure VesselDocument4 pagesNDT Map Itp Pressure VesselSYED FADZIL SYED MOHAMEDNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- ITP-1612-F01 Rev. 2Document19 pagesITP-1612-F01 Rev. 2Erin JohnsonNo ratings yet

- Roundness Before Weld TK012-strike 1Document2 pagesRoundness Before Weld TK012-strike 1yuwantoniNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Pressure Vessel Dimension Inspection PDFDocument17 pagesPressure Vessel Dimension Inspection PDFEqubal KhanNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- 8 Material ControlDocument8 pages8 Material ControlPrakash RajNo ratings yet

- Visual Inspection of Weld Api 650Document2 pagesVisual Inspection of Weld Api 650amshivNo ratings yet

- SSPC sp1Document2 pagesSSPC sp1Malik AzeemNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Pressure Testing of Pressure VesselDocument3 pagesPressure Testing of Pressure VesselAriq FauzanNo ratings yet

- 6-12-0002 Rev 8 Supplementary Specification For Carbon Steel VesselsDocument7 pages6-12-0002 Rev 8 Supplementary Specification For Carbon Steel Vesselsravi2007No ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- Std-Insp-0002 (Incoming Material Inspection Procedure)Document3 pagesStd-Insp-0002 (Incoming Material Inspection Procedure)airbroomNo ratings yet

- A106 Seamless Carbon Steel Pipe: Hydrostatic TestingDocument7 pagesA106 Seamless Carbon Steel Pipe: Hydrostatic TestingTan Chee MingNo ratings yet

- Visual and Dimension Inspection Tolerance RevDocument8 pagesVisual and Dimension Inspection Tolerance RevJorgeNo ratings yet

- Shop Fabrication Procedure (Supply of Tank Option#3) PDFDocument7 pagesShop Fabrication Procedure (Supply of Tank Option#3) PDFGATOTNo ratings yet

- Vessel Cleaning ProcedureDocument6 pagesVessel Cleaning ProcedureZool HilmiNo ratings yet

- Material With Electrod SelectionDocument1 pageMaterial With Electrod SelectionMahmud HasanNo ratings yet

- Weld Repair Rev. 1Document3 pagesWeld Repair Rev. 1vinas kusdinarNo ratings yet

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 pageJNK Heaters Co - LTD: Ferrite Test ReportUzorNo ratings yet

- Job Procedure For Puncture/Floatation/Rain Water Accumulation TestDocument4 pagesJob Procedure For Puncture/Floatation/Rain Water Accumulation Testfaisal jasim100% (1)

- Ferr It Scope Procedure 1Document7 pagesFerr It Scope Procedure 1Abd Rahman AliasNo ratings yet

- Test Pack Clearance FormatDocument2 pagesTest Pack Clearance FormatKarthikNo ratings yet

- Cleaning PresentationDocument26 pagesCleaning PresentationhiNo ratings yet

- Penguard Express ZP AGDocument9 pagesPenguard Express ZP AGengramir07No ratings yet

- CP09 TDS 34002 Marathon 1000 XHBDocument5 pagesCP09 TDS 34002 Marathon 1000 XHBherdiansyahNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetCyril J PadiyathNo ratings yet

- International Paint - Corrossion Knowledge Sharing - Rizal PDFDocument87 pagesInternational Paint - Corrossion Knowledge Sharing - Rizal PDFIndra100% (1)

- Pmi 027Document2 pagesPmi 027Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 001Document2 pagesPmi Test Report - 001Siriepathi SeetharamanNo ratings yet

- QSC - 001Document2 pagesQSC - 001Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 051Document2 pagesPmi Test Report - 051Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 053Document2 pagesPmi Test Report - 053Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 018Document2 pagesPmi Test Report - 018Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 038Document2 pagesPmi Test Report - 038Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 050Document2 pagesPmi Test Report - 050Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 023Document2 pagesPmi Test Report - 023Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 008Document2 pagesPmi Test Report - 008Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 019Document2 pagesPmi Test Report - 019Siriepathi SeetharamanNo ratings yet

- Mrir 010Document5 pagesMrir 010Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 003Document2 pagesPmi Test Report - 003Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 007Document2 pagesPmi Test Report - 007Siriepathi SeetharamanNo ratings yet

- Pmi Test Report - 002Document2 pagesPmi Test Report - 002Siriepathi SeetharamanNo ratings yet

- Mrir 002Document1 pageMrir 002Siriepathi SeetharamanNo ratings yet

- Mrir 009Document4 pagesMrir 009Siriepathi SeetharamanNo ratings yet

- Grab E-Receipt Oct26.2Document2 pagesGrab E-Receipt Oct26.2Siriepathi SeetharamanNo ratings yet

- RT - 015Document1 pageRT - 015Siriepathi SeetharamanNo ratings yet

- Dcsm-Tep-1182968-Mec-D06-0009 Rev Z04 4 of 11Document1 pageDcsm-Tep-1182968-Mec-D06-0009 Rev Z04 4 of 11Siriepathi SeetharamanNo ratings yet

- RT - 016Document1 pageRT - 016Siriepathi SeetharamanNo ratings yet

- RT - 019Document1 pageRT - 019Siriepathi SeetharamanNo ratings yet

- Grab HelpCenter 18082022Document5 pagesGrab HelpCenter 18082022Siriepathi SeetharamanNo ratings yet

- RT - 004Document1 pageRT - 004Siriepathi SeetharamanNo ratings yet

- GRAB Transaction Receipt - 11 Oct To 30 OctDocument3 pagesGRAB Transaction Receipt - 11 Oct To 30 OctSiriepathi SeetharamanNo ratings yet

- RT - 020Document1 pageRT - 020Siriepathi SeetharamanNo ratings yet

- MDR Separator Piping - FlushingDocument1 pageMDR Separator Piping - FlushingSiriepathi SeetharamanNo ratings yet

- MDR Separator Piping - HydrotestDocument1 pageMDR Separator Piping - HydrotestSiriepathi SeetharamanNo ratings yet

- Top HolidayDocument5 pagesTop HolidaySiriepathi SeetharamanNo ratings yet

- Grab HelpCenterDocument3 pagesGrab HelpCenterSiriepathi SeetharamanNo ratings yet

- Cytec Solutions 2013 8Document1 pageCytec Solutions 2013 8aktivrudarpNo ratings yet

- Keckley: Drawing No. AL 77020Document1 pageKeckley: Drawing No. AL 77020Luis Alberto Serrano MesaNo ratings yet

- Wrought Aluminium and Aluminium Alloys - Extruded Round Tube and Hollow Sections For General Engineering Purposes - SpecificationDocument10 pagesWrought Aluminium and Aluminium Alloys - Extruded Round Tube and Hollow Sections For General Engineering Purposes - Specificationmanasmech002No ratings yet

- Optimize Your Polymer Extrusion Process by Eliminating InstabilitiesDocument1 pageOptimize Your Polymer Extrusion Process by Eliminating InstabilitiesMekonnen BirhaneNo ratings yet

- IstanbulDocument8 pagesIstanbulAli YacineNo ratings yet

- Catalog FEEL by THM AgencyDocument68 pagesCatalog FEEL by THM Agencykartika lestariNo ratings yet

- Assignment On Bulk-Forming ProcessesDocument4 pagesAssignment On Bulk-Forming ProcessesMohammed ArishNo ratings yet

- Welding, Cutting, and BrazingDocument42 pagesWelding, Cutting, and BrazingRosiana AgustinNo ratings yet

- TM 9-242 Ordnance ToolsDocument427 pagesTM 9-242 Ordnance ToolsedrestNo ratings yet

- Production Technology (CD)Document7 pagesProduction Technology (CD)ParasNo ratings yet

- 0001y01091 en PDFDocument1 page0001y01091 en PDFvivekpattniNo ratings yet

- Highlights-ASME Guides Preheat-PWHT-VIII PDFDocument5 pagesHighlights-ASME Guides Preheat-PWHT-VIII PDFEr Manish JadaunNo ratings yet

- Milling FormulasDocument4 pagesMilling FormulasspedrerosNo ratings yet

- Taller Calculo de Parametros de CorteDocument4 pagesTaller Calculo de Parametros de CorteWendy Paola Rodriguez PerezNo ratings yet

- Pernos NelsonDocument4 pagesPernos NelsonJuan Manuel BazánNo ratings yet

- Metaline XL Series & Resistance Test, 100 XTM & Resistance TestDocument57 pagesMetaline XL Series & Resistance Test, 100 XTM & Resistance TestRiszki PangestuNo ratings yet

- TDS KH-8011S en 21Document2 pagesTDS KH-8011S en 21Carlos Lizarraga FloresNo ratings yet

- Spm-2000 II Eng Technical InformationDocument13 pagesSpm-2000 II Eng Technical Informationadrian9500No ratings yet

- Reference Number 2017Document493 pagesReference Number 2017Villamor NiezNo ratings yet

- Exothermic Welconnection Strip-Tape ConectionDocument9 pagesExothermic Welconnection Strip-Tape ConectionBenny HillNo ratings yet

- Threaded Rod: Plain, Zinc, Galvanized & Stainless SteelDocument7 pagesThreaded Rod: Plain, Zinc, Galvanized & Stainless Steelsidharth saraswatNo ratings yet

- Electronic PackagingDocument54 pagesElectronic PackagingAdelle Lyn Carlos100% (1)

- Final Main Starting PapersDocument6 pagesFinal Main Starting PapersAhmad HussainNo ratings yet

- Troubleshooting in Film CoatingDocument31 pagesTroubleshooting in Film Coatingfaysal_neo100% (1)

- Welder'S Qualification Test Certificate: The Welding Inspection CommunityDocument2 pagesWelder'S Qualification Test Certificate: The Welding Inspection CommunityRahulNo ratings yet

- H040800-01 Assembly BPV TWCV Installation ToolDocument1 pageH040800-01 Assembly BPV TWCV Installation ToolJitendra BhosaleNo ratings yet

- 2100 Lzi Primer PDFDocument1 page2100 Lzi Primer PDFphillipskincaidNo ratings yet

- Membrane Applications in Water Treatment: Snehal Dawkhar Mtech IIIDocument22 pagesMembrane Applications in Water Treatment: Snehal Dawkhar Mtech IIISnehal Dawkhar patilNo ratings yet

- Tiếng Anh chuyên nghiệp cho Thiết kế và Sản xuất Khuôn mẫuDocument170 pagesTiếng Anh chuyên nghiệp cho Thiết kế và Sản xuất Khuôn mẫuHoa HồngNo ratings yet