Professional Documents

Culture Documents

Caterpillar Sqep Procedures: May 3, 2017 SQEP Process Owner

Caterpillar Sqep Procedures: May 3, 2017 SQEP Process Owner

Uploaded by

Durai NaiduOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caterpillar Sqep Procedures: May 3, 2017 SQEP Process Owner

Caterpillar Sqep Procedures: May 3, 2017 SQEP Process Owner

Uploaded by

Durai NaiduCopyright:

Available Formats

CATERPILLAR SQEP

PROCEDURES

May 3, 2017

SQEP Process Owner

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

1 SUPPLIER QUALITY EXCELLENCE PROCESS (SQEP) Procedures........................................................... 2

1.1 Caterpillar Inc. .................................................................................................... Error! Bookmark not defined.

1.2 Value of SQEP .................................................................................................................................................... 3

1.3 Roles & Responsibilities - Caterpillar ................................................................................................................ 4

1.4 Roles & Responsibilities - Suppliers .................................................................................................................. 5

2 INITIAL & RECERTIFICATION PROCESS ............................................................................... 7

2.1 Certification Decision ........................................................................................................................................ 7

2.2 Application of Certification ............................................................................................................................... 7

2.3 SQEP Certification Requirements ..................................................................................................................... 8

2.4 Duration of Certification ................................................................................................................................... 9

2.5 Cert Status Definitions ...................................................................................................................................... 9

3 DECERTIFICATION AND DECISION NOT TO RECERTIFY ................................................... 10

3.1 Decertification ................................................................................................................................................. 10

3.2 Decision Not to Recertify ................................................................................................................................ 11

4 Audit ............................................................................................... Error! Bookmark not defined.

4.1 Auditor Training Requirements........................................................................................................................ 12

4.2 SQEP Audit Safe Source Details ......................................................................................................................13

5 Process & Product Controls & Programs ............................................................................. 14

5.1 Control Plan ..................................................................................................................................................... 14

6 Metrics ........................................................................................... Error! Bookmark not defined.

6.1 Supplier Performance Metrics ......................................................................................................................... 18

6.2 Capacity Planning .............................................................................................................................................20

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 1 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

6.3 PPM Exception Table .......................................................................................................................................21

6.4 Product-Specific Metrics ................................................................................................................................. 25

6.5 Customer Site Specific Metrics ........................................................................................................................ 26

6.6 Continuous Improvements ............................................................................................................................. 27

7 Additional Information .................................................................. Error! Bookmark not defined.

7.1 Contacts & Approval process ...........................................................................................................................28

7.2 Communications & Additional Information ..................................................................................................... 29

8 BACK Up Information ............................................................................................................ 29

8.1 Global Quality Auditor Training .......................................................................... Error! Bookmark not defined.

8.2 Checklist of SQEP Requirements ......................................................................................................................30

1 SUPPLIER QUALITY EXCELLENCE

PROCESS (SQEP) Procedures

1.1 Overview

Date: 04/01/2017

Revised: V5

Owner: Toni Schmidt

Caterpillar recognizes Supplier quality excellence. Core Suppliers play an integral role in driving a zero-

defect mentality into the supply chain management processes and culture. SQEP collaboratively drives

initiatives that result in breakthrough quality improvements, Suppliers who are utilizing systems and

processes that produce results that meet or exceed expectations should be recognized.

The SUPPLIER QUALITY EXCELLENCE PROCESS (SQEP) provides the means for recognizing

Supplier quality excellence while clearly communicating expectations for a world-class supply base.

This process combines industry-proven quality systems and process management requirements

from ISO9001 with demonstrated results to ensure expected Supplier capability and performance.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 2 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Recognition levels of Bronze, Silver, Gold and Platinum (reflected in order of increasing difficulty)

distinguish outstanding Supplier quality performance.

This Caterpillar SUPPLIER QUALITY EXCELLENCE PROCESS (SQEP) procedure details the Scope,

Vision, Value, Program Notes and Forms associated with Caterpillar’s supplier certification process that

provides a means for recognizing supplier quality excellence; while clearly communicating expectations

for a world-classs supply base. SQEP ensures that suppliers implement a quality management system

(QMS) that emphasizes process control, reduction in variation, defect prevention and elimination of

waste

It is the vision of the Supplier Quality Excellence Process that management within Caterpillar and at

suppliers targeted by procurement teams actively support the certification process and that it is fully

deployed at their production facilities.

Additional information about SQEP expectations and guidelines can be found in Supplier Connect and

on the Supplier Quality Excellence Process (SQEP) Connections Community.

1.2 Value of SQEP

Recognizes suppliers who provide quality excellence via formal process.

Drives a “zero defect” culture and mindset that will become a natural part of a supplier’s production

philosophy.

Provides a platform through which Caterpillar teams can clearly communicate their expectations for

developing a world-class supply base.

Leverages a supplier’s ISO9001: and/or TS16949 registrations and the associated Quality

Management System (QMS).

Drives “process management” across a supplier’s production processes that produce product for

Caterpillar.

Drives the deployment of Continuous Improvement methodologies for problem resolution.

Mandates the use of metrics for the supplier’s production facility’s processes.

Requires increased focus on the expectations of the Caterpillar facility through the alignment and

control of processes to meet identified performance targets.

Involves all operational levels within a supplier’s production facility.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 3 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

1.3 Roles & Responsibilities - Caterpillar

Supplier Management Support Responsibilities

For an effective deployment of the Supplier Quality Excellence Process to occur, the following

obligations must be embraced by a supplier’s leadership:

Commitment is vital; a supplier’s organization will be looking for positive leadership.

Allocation of adequate resources needed for a successful deployment.

Creation of an environment and structure that will accelerate needed changes.

Caterpillar Global Supply Network

Global Procurement

Responsible for management commitment and resource availability.

Category Managers

Has overall responsibility for the identification of suppliers targeted for certification.

Responsible for deployment of the SQEP certification process within their organization.

Ensures targeted suppliers are set-up for Supplier Performance Management (SPM).

Responsible to provide adequate time and resources for SQEP certification tasks.

Ensures staff involved in the SQEP certification process possesses adequate skills.

Approves each supplier’s request for certification or recertification.

Facility Supply

Provides SQEP representation for assigned Caterpillar facilities.

Reviews all certification requests submitted for suppliers seeking SQEP certification.

Supplier Development Engineer (SDE)

Assures each supplier’s ISO9001 and/or TS16949 registration is current

Along with the suppliers and the appropriate Caterpillar Product/Design Engineers, participates

in the identification of any Special Characteristics in effect for Caterpillar product; the

establishment of Key Product Characteristics and/or Key Process Parameters for Caterpillar

product; and the establishment of targets for each.

Development of Supplier Certification audit plans.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 4 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

In conjunction with the supplier’s trained ISO Auditor, conducts required Caterpillar audit at the

supplier’s production facility, closes all open issues, and completes all necessary reports.

Accountable to assure that all of the supplier’s certification metrics are at the required level of

excellence to warrant initial certification or annual recertification.

Approves eBook as part of the SQEP certification process.

SQEP Coordinators

Provides guidance and training to SDE’s as they work with suppliers pursuing SQEP

certification.

Accountable to ensure that all of the supplier’s certification metrics are at the required level of

excellence to warrant initial certification or annual recertification.

Ensures that certification plans for initial certification and recertification comply with all

requirements of SQEP.

Approves eBook as part of the SQEP certification process and provides final approval for all

books.

Caterpillar Engineering

Product / Design Engineers/Engineering Manager

Authorized to approve the “Field Issues Statement” on the Request for Supplier Certification /

Recertification.

Reviews and approves the Key / Special Product Metrics to ensure that the measurements

identified in the supplier’s Metrics Summary are appropriate.

1.4 Roles & Responsibilities - Suppliers

General Manager (or equivalent)

Responsible for program’s overall integrity and effectiveness through established Supplier

Performance Management (SPM) reviews and oversight processes.

Provides an environment that drives customer satisfaction and continuous improvement at all

levels of the organization.

Responsible for management commitment and resource availability.

Assures the supplier’s ISO9001 or TS16949 registration is current with a valid registrar.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 5 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Supplier’s Process Control Managers

Responsible for deployment of the SQEP certification process within their organization.

Along with Caterpillar’s PCE, participates in the identification of any Special Characteristics in

effect for Caterpillar product; the establishment of Key Product Characteristics and/or Key

Process Parameters for Caterpillar product; and the establishment of targets for each.

Coordinates the compilation of a Supplier Certification audit plan for Caterpillar.

With the assistance of Caterpillar’s PCE, ensures that certification plans submitted for initial cert

/ annual recert comply with all SQEP requirements.

Interfaces with Caterpillar on various process/product related issues.

Supplier’s ISO Qualified Auditor

Possesses and maintains applicable auditing skills and knowledge requirements.

With the assistance of Caterpillar’s PCE, conducts required Caterpillar audit at the supplier’s

production facility and completes all necessary reports.

Validates the effectiveness of all Corrective Action Requests resulting from the supplier self-

audit.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 6 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

2 INITIAL & RECERTIFICATION

PROCESS

2.1 Certification Decision

Category Managers determine which Caterpillar suppliers under their scope of responsibility will be

targeted for SQEP certification each calendar year. Their decisions are based on criteria such as:

A supplier’s status as a designated supplier

QCLDM performance

Support of Caterpillar NPI programs and APQP requirements

ISO registration

Suppliers certified under the Caterpillar Supplier Quality Excellence Process shall complete annual

recertification on their assigned recertification due date.

2.2 Application of Certification

For the purpose of Caterpillar record keeping, the following four possible scenarios exist: The Supplier

Quality Excellence Process requires that certifications across the supply base be awarded at the

individual production facility level; even if multiple production facilities fall under the same Caterpillar-

issued “supplier code”.

**Warehouse-only type facilities are not to be awarded SQEP certification; only the production

facility/facilities that provide product to a warehouse are eligible. SQEP is targeted at Direct

Suppliers who can be measured on PPM, PPAP, and shipping performance. Tier 2 and 3 rd party

suppliers are excluded from SQEP certification.

Single Supplier Code, Single Production Facility

This is the most common and straight forward scenario – one production facility, one unique

supplier code.

Single Supplier Code, Multiple Production Facilities

For this scenario, each of the multiple production facilities operating under the single

unique supplier code will require an audit at each facility. Approval from SQEP

Coordinator/SQEP process owner will be needed prior to starting this type of

certification.

Multiple Supplier Codes, Single Production Facility

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 7 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

In this scenario, one of the assigned supplier codes will be used as the “primary” code, with all

others being recorded as “secondary” codes to the single primary code.

Multiple Supplier Codes, Multiple Production Facilities

In this scenario, each production facility shall have its own certification.

2.3 SQEP Certification Requirements

1. Been awarded and maintained an ISO 9001 or ISO/TS 16949 Registration from an accredited

organization as recognized by Global Quality. Supplier’s Registration applies to all of the

manufacturing processes that produce Caterpillar product.

2. They have addressed, with the assistance of Caterpillar’s Category Team, responsible PCE,

and appropriate Product/Design Engineer(s), the Special Characteristics, Key Product

Characteristics, and Key Process Parameters that are to be identified, tracked, and reported

during the supplier’s certification cycle to assure they provide evidence as to the quality of the

product being produced for Caterpillar. As deemed appropriate by the responsible

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 8 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

product/design engineer(s) for the supplier’s new certification cycle, additional Special or Key

metrics may be added, or metrics previously tracked may be changed or removed.

3. Submitted and maintained the completed Supplier Certification eBook to the appropriate

personnel for review and final approval.

4. Acquired a minimum of 9 months of measurable data. A book may have NA or NP months, but

must have at least 9 months of data.

NA – Not Applicable, meaning the process is not able to be measured

NP – No production, meaning no production has occurred during that particular month

5. A Non-Disclosure Agreement has been completed and is on file between Caterpillar and the

supplier.

6. A completed SQEP Audit performed by the Caterpillar SDE and also the supplier’s self- audit (or

signed waiver by Director is included). No Major Findings remain open at time of certification

plan submission and Corrective Action Request (CAR) has been documented and is included

for all findings identified. . Supplier has addressed each of the SQEP audit requirements in their

Quality Management System.

7. Caterpillar Customers have been identified and listed. SQEP Certification is a Global Process

and is to include Global Metrics. The metrics are calculated globally and not measured at an

individual site level. While we want to address any potential issues at a site level, a certification

will not be held if the metrics are passing globally, but a specific site is experiencing

performance issues.

8. Category Manager Approvals are no more than 90-days old at the time of certification plan

submission.

2.4 Duration of Certification

Supplier certifications are awarded for a period of one year.

The recertification anniversary date is the date established by final approval during a supplier’s

initial certification. This recertification date may only be changed by the SQEP process owner.

A supplier’s certification will be revoked if a recertification has not been approved within the 90

day period pass the anniversary date.

2.5 Cert Status Definitions

Current – The book is in process or not certified. When a book is generated for a certification,

that book is considered current. Once it becomes certified, inactive or decertified, the book is

no longer current.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 9 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Completed – This book is considered closed. Once a book has been certified, the book is then

closed. No editing function can take place on completed books. When a book becomes

completed, eBook system will auto generate the next cycle book; that book then becomes the

current eBook.

Inactive – a book can be Inactive for 2 potential reasons. If a book becomes decertified, this

will cause the status to change to inactive, or a book has an inactive status if a category

manager requests that a supplier be placed in an inactive status. This could be requested for

several reasons (plant closure, reduced business, etc.).

3 DECERTIFICATION AND DECISION

NOT TO RECERTIFY

3.1 Decertification

It is not the desire of the Supplier Quality Excellence Process for any certified supplier to be decertified.

Therefore, before decertification is applied to a supplier, significant labor by all involved parties shall

occur in an effort to remedy the existing undesired condition. If a supplier fails to correct relevant issues

following adequate communications, decertification becomes a necessary option.

For justifiable reasons, decertification can be initiated against a supplier by either the responsible

Category Manager, or by the Caterpillar SQEP process owner.

Possible reasons for the Decertification of a supplier include the following:

Loss of 3rd Party Registration

Deterioration in the performance of their metrics

Failure to comply with their signed Non-Disclosure Agreement with Caterpillar

Inability to obtain necessary management approvals

Failure to obtain recertification within established timeframes (exceeded the 90 -days past due

on the Anniversary date for recertification

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 10 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Supplier Decertification Process

A decertification may occur if a supplier does not recertify by their Anniversary date or if a Category

Manager requests it. In the absence of the supplier’s recertification at the 90-days past due period,

notification is issued to the responsible SDE, Category Manager, Global Procurement Manager,

Director, and Vice President that the supplier in question is being officially decertified. The process

below details the action that should be taken by a Category Manager during the decertification of a

supplier when compelling issues warrant such action.

3.2 Decision Not to Recertify

Due to one or more of the conditions noted below, a Supplier or Caterpillar may decide to not recertify a

supplier’s production facility by officially placing them on an Inactive status:

Supplier’s decision not to recertify their production facility:

The supplier has closed their production facility that was producing Caterpillar product

The supplier has ceased production of the Caterpillar product for which they initially

received certification

The supplier has moved production of Caterpillar product to another

Facility

Caterpillar’s decision not to recertify a supplier’s production facility:

Changes have occurred to Caterpillar’s sourcing strategy

Supplier is no longer capable of producing desired product due to changes in technology

When Caterpillar decides not to recertify a supplier’s production facility and move code

to Inactive Status, the process is:

The responsible Category Manager shall notify SQEP Process Owner through email of the

decision so the supplier can be officially placed on an Inactive status. The email request will

include the SDE, and SQEP Coordinator.

The inactive supplier status identifies a supplier that:

o is no longer certified;

o has a certification plan that is no longer up-to-date

o Is not being pursued for recertification.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 11 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Residual Business - At times Caterpillar may continue to purchase small amounts of

product from a supplier placed on inactive status.

Return to Active Certification Status

To return a supplier to an active certification status requires the supplier to

complete all activities associated with an initial certification. Such a decision will

normally depend on the supplier relationship desired and on both the dollar

volume of business and / or the criticality of the product being produced.

4 AUDIT

Supplier audits are an integral part of achieving, and maintaining, certification under the Supplier

Quality Excellence Process. The supplier Self-Audit, performed on-site at the supplier’s production

facility must be by a qualified auditor from the Supplier. It is recommended that a Supplier performs

this gap self-audit prior to scheduling a Supplier Initial/Recertification on site audit. The supplier self-

audit shall be performed annually and self-audit date must be recorded in certification eBook.

Both the Supplier self-audit and the Caterpillar on-site audit must be completed within the time frame of

the certification. For example, if a supplier is being evaluated from Jan through December, the audits

may be completed anytime during those months. It cannot be completed before or after.

Audit Purpose

This Audit Process has the following objectives:

A. Evaluate a Supplier’s ability to effectively execute quality processes & procedures required by Caterpillar as part of the

Supplier Quality Excellence Process (SQEP). Completed Supplier Self and Caterpillar Audits will be archived in the E-Book

application.

B. Facilitate improvement in a Supplier's quality system by driving corrective action in areas of nonconformance.

C. In addition to meeting a SQEP requirement, audit results will be used to objectively evaluate Suppliers' Quality Systems

and assist in facilitating Supplier Selection and Development.

4.1 Auditor Training Requirements

Supplier Development Engineers (SDE) responsible for performing audits at a supplier’s production

facility should complete Internal Auditor Training which is conducted and managed by Caterpillar’s

Global Quality group. It is the responsibility of the SDE and the Supplier ISO qualified auditor to

perform both the Supplier Initial Certification Audit and all Supplier Recertification Audits; while the

Supplier ISO qualified auditor shall perform all Supplier Self Audits. When possible, the responsible

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 12 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

SDE is encouraged to participate in the self-audit performed by the Supplier ISO qualified auditor. For

the Supplier Self-Audits, any employee of the supplier who is trained in auditing principles can perform

this audit.

Regardless of the audit being performed, it is the function of the auditor(s) to verify that a supplier

meets the requirements of the Quality Management System and Supplier Quality Excellence Process.

They must ensure that the supplier’s Certification Plan and all relevant standard operating procedures,

work instructions, visual aids, etc. supporting the company’s Quality Management System (QMS) are

verified. For each audit type performed, the auditor(s) shall complete a “Certification Audit Summary

Report” and all “Corrective Action Reports” (if necessary) to document the performance of these audits.

As a minimum requirement, a supplier’s ISO/TS Quality Management System shall be audited for

compliance according to the schedule dictated by the appropriate approving body. Any Corrective

Action Requests (CAR’s) issued during such audits shall be actively worked until successfully closed

within the timeframe stipulated by the auditing team. The Caterpillar SDE on-site audit and supplier

self-audit must follow Caterpillar SQEP Audit.

The following auditor training is offered through CLMS. It is listed as the following:

CQMS Internal Auditor Training: 3-day course 08E35925

4.2 SQEP Audit Safe Source Details

.

All details and instructions for the on-site audit as well as the supplier self-audit are outlined in the audit

form.

The safe source for this document is the Supplier Quality Excellence Process (SQEP) Teams Web site

https://connections.cat.com/communities/service/html/communityview?communityUuid=30904a73-

7aa2-4886-824d-d40c2d385e70

Location: supplierconnect.cat.com / Performance / Certification / Certification SQEP

Link: SQEP Program on Supplier Connect-

https://supplierconnect.cat.com/wps/myportal/catconnect/!ut/p/a1/04_Sj9CPykssy0xPLMnMz0vMAfGjz

OJdwoxCLZ0MHQ0MvD3NDDyNLd2DLIx9jA1MTYAKIoEKDHAARwNC-

sP1o8BKnC39jXyNnJydLEwMgryczB1dYGZAFeCxoiA3wiDTUVERAJTItdA!/dl5/d5/L2dJQSEvUUt3QS

80SmlFL1o2X0RWMlU5QjFBME9URUYwQTRVSUw0RjIzR001/

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 13 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

This completed audit cannot be more than 365-days old at the time the supplier’s certification

eBook is submitted.

On-site Caterpillar led audits shall be required for recertifications based on the approved SQEP

performance; Frequency of audits shall vary by medal level and is listed as follows:

Bronze Caterpillar on-site audit performed within last 24 months,

Silver Caterpillar on-site audit performed within last 36 months,

Gold Caterpillar on-site audit performed within last 48 months, and

Platinum Caterpillar on-site audit performed within last 60 months

All initial certifications, including initial after decertification will require an on-site audit. No waiver

exceptions are allowed, expect with a Director approval.

5 PROCESS & PRODUCT CONTROLS

& PROGRAMS

5.1 Control Plan

Process / Product Failure Mode and Effect Analysis (PFMEA): Process, and Product if

available

o A table/listing is included that identifies those PFMEA’s that have been completed for

production processes that produce Special / Key metrics on Caterpillar product.

o The listing includes the following for each PFMEA identified: (1) PFMEA # (if used); (2)

Caterpillar part numbers/process family covered; (3) current revision level; (4) current

revision date; and 5) last review date (Must be within past 12-months).

o If any of the following conditions occurred during the past 12-months on product produced

for Caterpillar, the applicable PFMEA(s) have been reviewed / updated as needed:

Caterpillar identified Special or Key metrics have been added or changed

A rejection or field failure occurred on Caterpillar product

Product Characteristics and Key Process Parameters. Detailed PFMEA’s shall be

completed for each production process that produces Caterpillar product having Special

Characteristics, Key Product Characteristics and/or Key Process Parameters and they shall be

re-reviewed on at least an annual basis.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 14 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Process Flowcharts: Process flowcharts have been produced and made available at the time

of audit (if asked) for each production process that produces Caterpillar product having Special

Characteristics, Key Product Characteristics and/or Key Process Parameters. These

documents provide a quick means for understanding how process initiators, input activities,

tasks, outputs, etc., relate to each other. These documents can be produced in varying degrees

of sophistication. The challenge is not to be so detailed as to become stifling, and not so vague

that they provide little value. As a minimum requirement, flowcharts shall include all key

activities associated with the production of Caterpillar product.

Process Control Plans: A detailed Process Control Plan shall be developed and included in

the Supplier Certification Plan for each production process producing Caterpillar product having

Special Characteristics, Key Product Characteristics and/or Key Process Parameters. An

organized approach that uses appropriate quality tools (e.g., Process FMEA) shall be used in

the determination of which process / product points are most significant. All Special

Characteristics and Key metrics (Key Product Characteristics & Key Process Parameters) shall

be clearly denoted with the appropriate operation / station using the “reference identification

number” assigned. Operators producing Caterpillar product shall be aware of all Caterpillar

Special Characteristics, Key Product Characteristics, and Key Process Parameters applicable to

their workstation. Note: If a supplier believes they have proprietary / confidential information

contained in a particular process control plan, they have the option to include a Control Points

Matrix table with the required headings (reference the table in eBook or the Sample Supplier

Certification Plan) in its place. The use of a Control Points Matrix table removes the concern

that confidential or proprietary information may be at risk of disclosure since only general

information is presented.

Process Flow Charts and/or Control Plans / Control Points Matrices (updates are only

necessary when changes have occurred with the production processes producing Caterpillar

product or with the identified Special Characteristics, Key Product Characteristics, and/or Key

Process Parameters).

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 15 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

6 METRICS

6.1 General Metric Results Requirements - Applicable to All Metrics

(Special Characteristic Metrics, Key Product & Parameter Metrics, Supplier Performance Management

Metrics)

Required metrics have been tracked and evidence from the ASC Portal has been uploaded into

eBook.

o Only exception for not using Caterpillar ASC Portal data is if the facilities that the

supplier is shipping to are not connected to MRC data. With this scenario, collaborations

must take place with the SDE and the SQEP coordinator. The SQEP Coordinator may

sign a waiver allowing for site data to be used.

o Any other exception requests must have the Director approval documenting the reasons

why Caterpillar portal data is not being used.

Metric results meet the required performance target levels needed for certification

All metrics are reported on a monthly frequency (Note: indicate ‘no prod (np)’ if none occurred

during a month)

A minimum of nine months of data is required for metrics that are “new” or have been “changed”

since initially established. This rule applies to recertifying early to avoid using previous monthly

data in the next certification.

The capability of Special & Key metrics shall be reported using Cpk (if at all possible). Use

short-run SPC techniques for low lot sizes when possible.

CPK values shall be calculated from actual variables data, not mathematically derived by

converting nonconformance rates or Sigma levels.

Capability data shall be representative of all product produced.

The most recent month reported for each metric must meet at least Bronze certification level.

The most recent month reported for each metric is no more than two months old at time of cert

submission (e.g., a plan submitted on any date in October must include metrics reported

through the end of August)

Supplier shall be required to report Special & Key metric results that include: 1) Metric reference

numbers; 2) Characteristic names; 3) Monthly results; 4) Metric targets; 5) Quantity of product

produced; 6) Number of pieces checked to establish each month’s results.

Corrective action have been provided for each monthly results that did not meet bronze level or

that fell below targeted cert level

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 16 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

6.2 Rules for Determining Certification Levels

Supplier performance metrics must meet either 9 out of 12 months or L12M Average. eBook will

analyze the 9 out of 12 months and the last 12 month average; awarding the certification to the

highest level. Example being: if the 9 out of 12 months meets Bronze but the L12 month average

meets Gold, eBook will award Gold.

*Either or rule for last 12 months applies to SPM metrics only*

The final certification level awarded to a supplier (Bronze thru Platinum) is based on the worst

performing metric from those identified (i.e. ASC Portal and Special/Key metrics).

6.3 General Special / Key Metrics Identification

Metrics shall be derived and clearly defined in the quality management system plan. Caterpillar

staff (primarily SDE & the responsible product / design engineers) and the Supplier’s management

(primarily the Process Control Manager) must determine which metric characteristics are significant

to Caterpillar and the supplier and therefore need to be managed. Possible sources of input for the

identification and selection of metrics may include:

Prints and Specifications (to include Special Characteristics as outlined in1E2966)

Advanced Product Quality Planning (APQP)

Failure Mode and Effect Analysis (FMEA)

Quality Functional Deployment (QFD)

Voice of the Customer (Caterpillar)

Voice of the Internal Production Partner (At Supplier)

Metrics Summary: The Caterpillar and Supplier staff shall determine the methods to collect,

assess, and report the results of identified metrics on a monthly basis. Product-Specific

Metrics (Special: SRC-SDC-SPC; KPC & KPP Metrics)

All Special Characteristics, identified on Caterpillar drawings by 1E2966A, on product

selected as being representative of product being produced

All Key Product Characteristic & Key Process Parameter Metrics, identified in the Control

Plans or Control Points Matrix, including all print identified cleanliness specifications (i.e. 1E-

0318, 1E-2500, 1E-2860, etc.)

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 17 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

No Production (NP) Clause – Product Specific Metrics & Not Applicable – Supplier Performance

Metrics

If no production has occurred during the certification period, the supplier shall provide Special/Key

metric data for the most recent 9-month period available. If metrics do not exist for a minimum of 9

months in the most recent 24 months, the supplier will not be certifiable until they have collected 9

months of current data that meet current certification requirements. These months of data do not have

to be consecutive when there is use of a NP. The NP clause is specific to Product Specific Metrics and

would only be entered if the specific PSM that is being measured has had no production.

For example: A specific part number that is being measured has not been produced; then that would

be entered as a NP. You will still need to have 9 months of data; however, this may fall outside of your

certification range.

If a specific process is being measured, the NP would only be entered if there was no measurement of

that process for that month.

The N/A entry will be used for Supplier performance metrics that are not applicable. Evidence will need

to be provided to support the N/A entry. SQEP Coordinators will review all N/A entries and the

documented evidence. There are instances where a supplier may not have PPAP requirements; this

will be reviewed by the SQEP Coordinator for final decision. A book cannot be submitted without PPM,

PPAP and Shipping performance.

6.4 Supplier Performance Metrics

Caterpillar data must be used as evidence to support the metrics entered on the Supplier Performance

Metrics Results Table (include rolling 12-months of metric results)

If Caterpillar data is approved to not be utilized as evidence because of connectivity issues,

supporting evidence for each of the Supplier Performance Metrics must be included. Approval to

use Facility data or Supplier Data must be approved by the SQEP Coordinator/SQEP Process

owner. Only those sites that are not connected through MRC will be allowed to use facility/site

data. This must be collaborated through the SQEP Coordinator prior to submitting a book for

certification.

If all sites are connected through MRC, Caterpillar data must be used from the ASC Portal

The ASC Portal is considered the safe source

The ASC Portal extracts the data from the sites so if there is a question on a specific metric, the site

is responsible for answering and/or correcting. The ASC team does not change any data.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 18 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

It is the responsibility of the SDE, Buyer, and the Supplier Process control manager to review their

monthly metrics. ASN issues, roll posting, and PPM issues should be reviewed monthly.

Supplier Performance Metrics Definitions

The summary includes metrics as defined below.

Parts Per Million (PPM)

Definition Measure of component rejections based on piece-part quantities received.

Reference MQ4006 – Rejection Rules for PPM Reporting

Methodology Ratio of piece-part rejections to total pieces received multiplied by 1,000,000.

Safe Source ASC system or corporately recognized quality tracking system

Frequency Monthly

Percentage of Dollars Rejected (% of $ Rejected)

Definition Measure of component rejections based on $ value of piece parts received.

Methodology Ratio of piece-part rejections in $ to total $ received.

Safe Source ASC system or corporately recognized quality tracking system

Frequency Monthly

Percentage of PPAPs Completed On-Time

Definition Measure of the PPAP submission timeliness.

Ratio of PPAP submissions approved prior to receipt of material to

Methodology the total number of PPAP submissions that should have been completed.

Safe Source Cognos

Frequency Monthly

Supplier Shipping Performance – Production Facilities

Measure of the supplier schedules shipped by assigned ship date to

Definition

Caterpillar production facilities.

Ratio of material orders shipped on time (Advance Shipping Notice ASN) to

Methodology the total number of material orders shipped.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 19 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Priority-1) Assurance of Supply Center (ASC) data,

Priority-2) Local facility system data if ASC data is not available or

Safe Source

Priority-3) Validated supplier shipping performance data based on supplier's

recognized shipping-tracking system.

Frequency Monthly

Supplier Shipping Performance – Service Parts Facilities

Measure of the supplier schedules shipped by assigned ship date to

Definition Caterpillar service parts facilities.

Ratio of material orders shipped on time (Advance Shipping Notice

Methodology – ASN) to the total number of material orders shipped.

Priority-1) Assurance of Supply Center (ASC) data,

Priority-2) Local facility system data if ASC data is not available or

Safe Source

Priority-3) Validated supplier shipping performance data based on supplier's

recognized shipping-tracking system.

Frequency Monthly

Supplier Capacity Planning

Measure of part-specific capacity availability by supplier.

Definition

Capacity Planning shall be managed by the category. After evidence is

reviewed, approval form must be signed by Segment Manager and

Methodology

uploaded into eBook for capacity evidence. All will qualify as 5 year.

Safe Source Approval form from Segment Manager

Frequency Annually

6.5 Capacity Planning

Capacity Planning - Remains a requirement for SQEP certification, but the (2year vs 5 year) will no

longer impact the level of certification. ECCP is no longer providing 5-year evidence. All books will need

to submit capacity planning evidence along with the attached approval form from the appropriate

Segment Manager. All submitted books are to have the (5) year capacity radio button checked if they

have obtained the Segment manager sign off and uploaded this into eBook.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 20 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

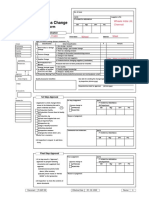

Supplier Certification Capacity Planning Evidence

I, as the Segment Manager for Supplier, _________________________________ have reviewed the capacity planning

evidence and approve this as sufficient and appropriate.

_____________________________ ___________________________ _______________

_______________________________

__________________________________________________________________________________________

(Segment Manager Printed Name) (Signature) (Date)

____________________________ ___________________________ _______________

_______________________________

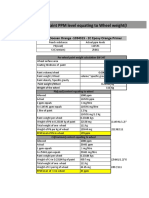

6.6 PPM Exception Table Do not submit if PPM

exception is not necessary

Sub-Category Bronze Target Silver Target Gold Target Platinum Target

Complex Fabs 1,000 500 250 125

(Refer to *1 below)

Fully Trimmed /

Fully Assembled 2,000 1,000 500 250

Cabs

1,000 500 250 125

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 21 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Cab Structures

All certifications that are requesting a PPM exception must have the form below signed by

the Category Manager and uploaded in the eBook under SPM evidence. This must be

collaborated with through your SQEP Coordinator prior to submission.

For suppliers that provide BOTH simple and complex fabrications, a separate “weighted” target

(based on the total number of fabrications received by Caterpillar in each category) will need to

be determined for the most recent 12-months of data being reported.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 22 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Do not submit if PPM

exception is not necessary

Rough Casting SQEP Certification PPM Targets

Number in 1000's

High

Green Sand Green Pressure Gravity/Perm Low

Green Sand

Air Set Automated Sand Die Pressure Centrifugal Shell Investment

Cope/Drag Mold

Horizontal Disa Casting Die

Steel Castings

Bronze 9 6.5 5.5 5 NA NA NA 6 5 3

Silver 5.5 5 3.5 3 NA NA NA 4 3 2

Gold 3 3 2 1.5 NA NA NA 2 1 1

Platinum 0.5 0.5 0.5 0.5 NA NA NA 0.5 0.5 0.5

Iron Castings

Bronze 9 6.5 5.5 5 NA NA NA 6 5 5

Silver 5.5 5 3.5 3 NA NA NA 4 3 3

Gold 3 3 2 1.5 NA NA NA 2 1 1

Platinum 0.5 0.5 0.5 0.5 NA NA NA 0.5 0.5 0.5

Aluminum Castings

Bronze 9 6 5.5 5 5 8 5 NA NA NA

Silver 5.5 5 3.5 3 2.5 5 2.5 NA NA NA

Gold 3 3 2 1.5 1 2.5 1 NA NA NA

Platinum 0.5 0.5 0.5 0.5 0.5 0.5 0.5 NA NA NA

Blocks - High Moly

Bronze 15 15 15 15 NA NA NA NA NA NA

Silver 10 10 10 10 NA NA NA NA NA NA

Gold 7 7 7 7 NA NA NA NA NA NA

Platinum 1 1 1 1 NA NA NA NA NA NA

Heads - High Moly

Bronze 20 20 20 20 NA NA NA NA NA NA

Silver 15 15 15 15 NA NA NA NA NA NA

Gold 10 10 10 10 NA NA NA NA NA NA

Platinum 3 3 3 3 NA NA NA NA NA NA

Blocks - Low Moly

Bronze 10 10 10 10 NA NA NA NA NA NA

Silver 7 7 7 7 NA NA NA NA NA NA

Gold 5 5 5 5 NA NA NA NA NA NA

Platinum 1 1 1 1 NA NA NA NA NA NA

Heads - Low Moly

Bronze 15 15 15 15 NA NA NA NA NA NA

Silver 10 10 10 10 NA NA NA NA NA NA

Gold 7 7 7 7 NA NA NA NA NA NA

Platinum 1 1 1 1 NA NA NA NA NA NA

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 23 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Rough Casting SQEP % Dollar Rejected Targets corresponding to PPM Targets:

PPM % of $ Rejected PPM % of $ Rejected

500 0.30 5,500 0.61

1,000 0.30 6,000 0.66

1,500 0.30 6,500 0.71

2,000 0.30 7,000 0.77

2,500 0.30 8,000 0.87

3,000 0.35 9,000 0.97

3,500 0.41 10,000 1.08

4,000 0.46 15,000 1.59

5,000 0.56 20,000 2.11

Example:

For suppliers that provide BOTH rough castings and machined castings, a supplier may be certified if

the purchased finished components meet the PPM requirements outlined in section 3.5 and the

rough castings components (as defined by the Caterpillar PCE) meet the requirements for rough

castings as stated above. The rough casting part number/s must be identified and classified per

casting process by the Supplier and agreed to by the PCE and Category Manager. The PPM levels

for rough components listed for each process must meet the requirements outlined in PPM

addendum as shown below.

XYZ

ABC Company

Part Molding PPM Target July

May August

June September

July October

August November

September December

October Total Total Certification

Number Process Bronze Silver Pcs Rec Pcs Rej ppm Pcs Rec Pcs Rej ppm Pcs Rec Pcs Rej ppm Pcs Rec Pcs Rej ppm Pcs Rec Pcs Rej ppm Pcs Rec Pcs Rej ppm PCS PCS Rej PPM Level

1A1 Steel - Air Set 9000 5500 200 5 25000 200 5 25000 200 5 25000 200 6 30000 200 10 50000 200 10 50000

1A2 Steel - Air Set 9000 5500 1000 5 5000 1000 0 0 1000 5 5000 1000 5 5000 1000 5 5000 1000 5 5000

1A3 Steel - Air Set 9000 5500 300 0 0 300 0 0 300 0 0 300 0 0 300 0 0 300 0 0

1A4 Steel - Air Set 9000 5500 500 0 0 500 0 0 500 0 0 500 0 0 500 0 0 500 0 0

1A5 Steel - Air Set 9000 5500 2000 14 7000 2000 14 7000 2000 14 7000 2000 20 10000 2000 30 15000 2000 15 7500

1A6 Steel - Air Set 9000 5500 100 0 0 100 0 0 100 0 0 100 0 0 100 0 0 100 0 0

1A7 Steel - Air Set 9000 5500 500 2 4000 500 2 4000 500 2 4000 500 2 4000 500 2 4000 500 2 4000

1A8 Steel - Air Set 9000 5500 4000 20 5000 4000 10 2500 4000 10 2500 4000 20 5000 4000 20 5000 4000 20 5000

1A9 Steel - Air Set 9000 5500 300 1 3333 300 1 3333 300 1 3333 300 1 3333 300 1 3333 300 1 3333

1A10 Steel - Air Set 9000 5500 5 0 0 5 0 0 5 0 0 5 0 0 5 0 0 5 0 0

Sum 8905 47 5278 8905 32 3593 8905 37 4155 8905 54 6064 8905 68 7636 8905 53 5952 44525 223 5008 Silver

1A11 Steel - Green Sand 6500 5000 5000 10 2000 5000 0 0 5000 50 10000 5000 10 2000 5000 10 2000 5000 10 2000

1A12 Steel - Green Sand 6500 5000 10000 40 4000 10000 40 4000 10000 40 4000 10000 50 5000 10000 40 4000 10000 40 4000

1A13 Steel - Green Sand 6500 5000 4000 70 17500 4000 70 17500 4000 70 17500 4000 70 17500 4000 50 12500 4000 50 12500

1A14 Steel - Green Sand 6500 5000 3200 40 12500 3200 40 12500 3200 5 1563 3200 35 10938 3200 10 3125 3200 5 1563

1A15 Steel - Green Sand 6500 5000 500 0 0 500 0 0 500 0 0 500 0 0 500 0 0 500 0 0

1A16 Steel - Green Sand 6500 5000 6000 10 1667 6000 10 1667 6000 30 5000 6000 5 833 6000 10 1667 6000 10 1667

Sum 28700 170 5923 28700 160 5575 28700 195 6794 28700 170 5923 28700 120 4181 28700 115 4007 143500 735 5122 Bronze

2A1 Purchased Finished 500 200 200 0 0 5000 0 0 200 0 0 4000 2 500 500 0 0 4000 1 250

2A2 Purchased Finished 500 200 1000 1 1000 10000 2 200 1000 1 1000 3200 1 313 4000 1 250 3200 0 0

2A3 Purchased Finished 500 200 300 0 0 4000 1 250 300 0 0 500 0 0 300 1 3333 500 0 0

2A4 Purchased Finished 500 200 500 0 0 2000 1 500 500 0 0 6000 5 833 5 0 0 6000 4 667

Sum 2000 1 500 21000 4 190 2000 1 500 13700 8 584 4805 2 416 13700 5 365 43505 13 299 Bronze

Consolidated Results as Viewed in SPM, eSRM, or SPA

Supplier: ABC Company 39605 218 5504 58605 196 3344 39605 233 5883 51305 232 4522 42410 190 4480 51305 173 3372 231530 971 4194

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 24 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

The undersigned confirms they approve this supplier to use the PPM Exemption policy checked below:

Rough Casting

Complex Fabrications

Simple and Complex Fabrications

Fully Trimmed / Fully Assembled Cabs

Cab Structures

Category Manager:

______________________________ _____________________________ _________________

(Printed Name) (Signature) (Date)

6.7 Product-Specific Metrics

This summary shall include the following metric sub-groups:

Special Characteristic Metrics (SRC, SDC, SPC): It is a requirement that all Special

Characteristics identified on Caterpillar drawings with the (1E2966A Ident) designation be

controlled / monitored and included in the appropriate process control plans. For certification

purposes, the Special Characteristics identified on the product selected as being representative

of the product being produced by the supplier, and therefore requiring tracking, shall be

included.

o Special Required Characteristics (SRC)

o Special Design Characteristics (SDC)

o Special Process Characteristics (SPC)

Key Product Characteristic Metrics (KPC): List each of the Key Product Characteristics

identified by the Caterpillar / Supplier team in the supplier’s control plan. KPC’s shall be derived

from print or specification characteristics that must be controlled to assure product quality.

APQP, PFMEA’s, product / design engineers, a supplier’s internal process partners, and

Caterpillar end-users are good sources to use in determining these characteristics.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 25 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Key Process Parameter Metrics (KPP): List each of the Key Process Parameters identified by

the Caterpillar / Supplier team in the supplier’s control plan. These metrics are frequently

derived from Process Control Plans and /or PFMEA’s and include such parameters as

temperature, pressure, tool accuracy, etc.

Note: When possible, all Special Characteristics, Key Product Characteristics and Key Process

Parameters shall be tracked and reported using variable data (Cpk). When\variable data is not feasible,

the alternative(s) selected shall ensure process variability is controlled.

6.8 Customer Site Specific Metrics

Sites with the top 80% spend will be included in a notification email (based on $ sales volume) of all

site Caterpillar Customers (Caterpillar Production Facilities, ILC, and service Parts).

Customer-Specific Requirements: It is the responsibility of the Site Purchasing Manager to assure all

customer-specific requirements identified by their targeted customer(s) are accurate.

Site Customer Review for Certification: Customer Approval for Certification / Recertification has been

reviewed and not objected from each of the Caterpillar customers.

Metrics are considered passing if the Global Metrics are meeting the SQEP requirements. If a site is

having a specific issue with a supplier, then the SQEP process owner will review the issue and

collaborate with both the site and PCE.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 26 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

Any objections have been reviewed by the SQEP process owner along with Customer and SDE/SQEP

Coordinator.

SQEP Process owner will have final approval if any dispute is in question.

6.9 Continuous Improvements

Being the “best of the best” requires acceptance of the concept of continuous improvement and the

desire for higher levels of performance. Identified improvements should not only be directed toward a

supplier’s primary goals (reduction of variation and the cost of poor quality), but also toward being more

responsive, adaptive and efficient.

Include a listing of all projects (both opened & closed) that have been worked during the

certification / recertification cycle. The supplier shall have identified and worked projects (or) has

participated as a team member in Rapid Improvement Workshops (RIW) that specifically

benefited Caterpillar product.

The process used to document and track projects is left to the discretion of the supplier. The

supplier can either upload the log file or enter the data in eBook project log. As a minimum,

project documentation should include the following:

o Project number.

o Indication as to whether or not the project was worked as a 6 Sigma project.

o Caterpillar part number(s) or part families addressed.

o Problem statement / description.

o Objective of the project.

o Date the project was opened.

o Identification of the project manager / responsible party.

o Actions taken.

o The project’s actual completion date or projected completion date.

o Final gains resulting from the project.

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 27 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

7 ADDITIONAL INFORMATION

7.1 Contacts & Approval process

Point of contact for Assistance with the SQEP process or eBook

Suppliers contact their 1 SDE or 1 Buyer

SDE contacts the SQEP Coordinator

SQEP Coordinator will contact the SQEP Process Owner if needed

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 28 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

7.2 Communications & Additional Information

Supplier Connect-

https://supplierconnect.cat.com/wps/myportal/catconnect/!ut/p/a1/lZJLc4IwFIX_ii7YmssbugtQKIpAsSiy6aClyAyvAbT

Tf9_gaDtqRb2rJHO-

e05yg0IUoLCIdmkStWlZRFm3D4V3bc74skJjcN6edcCcb1qczrCGyRDBkghU2WGmjKIqEgfeWBGxBoe6j4crhc94wzNEwI5r

8uYrDZJ25P8MdF4FPJm90KIvsoZOn_KSIxH_Mc9MWd6mYU6f82cGlnhf_p6Aj_lfCm74L1B4KoGJKYDJyoYnsRYLPHcQ9I1

oL-ibQe8Uukc6i3k5hd57MCIaozDJytX-

yy03bVs9UUDBOmqrsm6jbERWo3WZo7DZVlWWxnXjuSgY04Igk4A3mBlh1A_3AeLXpYjyuOOMiT3wHHWiO542MG31H

ks7d6-huFixUoLCOv6M67gebWty8a5fs2-YlUlaHJtRoH41VndCnL4aCpqmHG3a_L8-

m7JpUXCCoyr3uwogNVM3X0gtv_pms52F8XD4A3J8AJg!/dl5/d5/L2dJQSEvUUt3QS80SmlFL1o2X0RWMlU5QjFBME9UR

UYwQTRVSUw0RjIzR00y/

ASC Portal

https://gsnportal.cat.com/wps/myportal/gp/!ut/p/a1/hc49D4IwEAbg38LA2js_aNStakI0bAaFLqZgbTHQklL5_aJxcFC87

b08b-

6AQwbciL5SwlfWiPqZOT1vj9N0uZ4wjFkyRxYfUkp3G0SMBpAPAH8Mw3_9E_BxQt9g5MQeuKpt8Xo3Z6aYLRRwJ6_SSUf

ublhr79tuFWKIqjMXUgpPStuEKA3Rvvna07bzkH1yaJsMb1HdJywIHgxUCks!/dl5/d5/L2dJQSEvUUt3QS80SmlFL1o2X0R

WMlU5QjFBMEc2M0QwQVQ5MElJNUkyTE02/

Supplier Connect Supplier Scorecard

https://login.cat.com/CwsLogin/cws/sso.htm

Global Quality

https://quality.cat.com/en.html

8 BACK UP INFORMATION

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 29 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

8.1 Checklist of SQEP Requirements

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 30 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

SQEP Checklist - eBook

WHAT WHERE

Director Contacts

Global Segment Mgr Contacts

Category Mgr Cert Set Up Page

Targeted Certification Submission Date Cert Set Up Page

Confidence Level Cert Set Up Page

ISO/TS Registration Metrics / SPM data

Supplier Certification Self-Audit Audit / Audit Summary

Non-conformities Documented & CARs Issued Audit / Audit Summary

CARs Completed / Solutions Implemented No Open Major Findings

Audit / Audit Summary- Must be completed and dated within the

On-site Certification Audit

targeted Certification timeline

PFMEA Table documented Suppliers / Supplier Process Control

PFMEA - Last review date < 12Mths Suppliers / Supplier Process Control

Control Plan or Control Point Matrix Suppliers / Supplier Process Control

Product Specific metrics are representative of

Metrics / Product Specific Metrics Setup

supplier processes

At least one KPP, KPC have 12 mths of data Metrics / Product Specific Metrics Data

Product specific metrics meets certifiable level Metrics / Product Specific Metrics Data

SPM results meets certifiable level Metrics / Supplier Performance Metrics Results

Evidences for SPM results are attached Metrics / Supplier Performance Metrics Results

Evidences for SPM results are in line with SPM

Metrics / Supplier Performance Metrics Results

table

Metrics / Supplier Performance Metrics Results RCCP for 2 Year

Capacity Plan

ECCP for 5 Year

Shipping Performance ( Production) SPM - ASC must be used if available

Shipping Performance ( Service) SPM - ASC must be used if available

Listing of all projects attached for any metrics

Suppliers / Continuous Impr

that fall below Bronze or below targeted level

Supplier Process Control Manager Approvals / Management Approvals

Category Manager Approvals / Management Approvals

Metrics & Supp Issues Approvals / Metrics & Sup. Issues approvals

1 SDE Approvals / Management Approvals

SQEP Coordinator Approvals / Management Approvals

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 31 of 33

Caterpillar: Confidential Green

CATERPILLAR SQEP Procedures

SQEP Procedure 01

…Change Log…

Change Level & Date Module(s) Document(s) Change(s)

00 SQEP Procedures Initial

Aug 01, 2015

May 3, 2017 SQEP Procedures Review & Update

May 21, 2020 SQEP Procedures Updated Capacity

Planning

THE INFORMATION HEREON IS THE PROPERTY OF CATERPILLAR INC. AND/OR ITS SUBSIDIARIES. WITHOUT WRITTENPERMISSION, ANY COPYING, TRANSMITTAL TO OTHERS, AND ANY USE EXCEPT THAT FOR

WHICH IT IS LOANED, IS PROHIBITED.

DATE CHG NO AUTHORIZATION

Caterpillar SQEP Procedures

21 May 2020 03 SQEP Cert Team

Caterpillar: Confidential Green - Reproduction Constitutes an Uncontrolled Document - Page 32 of 33

Caterpillar: Confidential Green

You might also like

- Tourism and Hospitality Marketing Module No.1 PDFDocument42 pagesTourism and Hospitality Marketing Module No.1 PDFArian Mae Teman92% (12)

- SMCS Codes User Training ManualDocument38 pagesSMCS Codes User Training ManualJeffersson Gutierrez100% (2)

- Lesson 2 Breakout Trading SystemDocument26 pagesLesson 2 Breakout Trading Systemsesilya 14No ratings yet

- Companies Act 2013 - Ppt-1Document21 pagesCompanies Act 2013 - Ppt-1raj kumar100% (3)

- 04 Mobile Hose Van Guide Nov 14Document186 pages04 Mobile Hose Van Guide Nov 14EDWINNo ratings yet

- Cat 992K Wheel Loader: Fuel BurnDocument2 pagesCat 992K Wheel Loader: Fuel BurnDion Boediono100% (1)

- Engagement Activity-Akron Children's HospitalDocument3 pagesEngagement Activity-Akron Children's HospitalMs. MemeNo ratings yet

- NEHS0730 - 168-7720 Ultrasonic Wear Indicator III Group PDFDocument40 pagesNEHS0730 - 168-7720 Ultrasonic Wear Indicator III Group PDFjonel monge100% (1)

- BP - Wheel Stud ToolDocument4 pagesBP - Wheel Stud Toolwhmidi7331No ratings yet

- 040 Module 24 Drive Standard Work Overview v3Document68 pages040 Module 24 Drive Standard Work Overview v3enjoythedocs100% (1)

- BP Publication - Fluid Cooler D&a FixtureDocument4 pagesBP Publication - Fluid Cooler D&a Fixtureleaw81No ratings yet

- ReadmeDocument1 pageReadmeDaniel Alejandro Moreno HernándezNo ratings yet

- HandbookDocument767 pagesHandbookcientifictriveNo ratings yet

- Kitson Proposal For Civic CenterDocument52 pagesKitson Proposal For Civic CenterNews-Press0% (1)

- About CAT LogicticsDocument40 pagesAbout CAT Logicticsaskvishnu71120% (1)

- Labor Guidelines Overview For Dealer 22.09.15 TRGDocument17 pagesLabor Guidelines Overview For Dealer 22.09.15 TRGJean Claude Eid100% (1)

- FILTERSDocument35 pagesFILTERSeng100% (2)

- D11R Undercarriage Improvements - PEGP7031-00Document4 pagesD11R Undercarriage Improvements - PEGP7031-00Roger MendozaNo ratings yet

- Pedp7028 02Document20 pagesPedp7028 02atulnalawade1980100% (1)

- Tompkins Catalog UsaDocument332 pagesTompkins Catalog UsaLuis Puma100% (1)

- CSA PM Calculation - 07.2019 - FormuleDocument45 pagesCSA PM Calculation - 07.2019 - FormulejogremaurNo ratings yet

- Cap & Cap Guidebook - v3 - A4 - 08augDocument53 pagesCap & Cap Guidebook - v3 - A4 - 08augJean Claude EidNo ratings yet

- Faster, Easier, Safer: Cat Advansys Tips and AdaptersDocument2 pagesFaster, Easier, Safer: Cat Advansys Tips and AdaptersKawasakiNo ratings yet

- Caterpillar - Steering Selenoid 785Document4 pagesCaterpillar - Steering Selenoid 785globalindosparepartsNo ratings yet

- Who Is Caterpillar?: - Cat Dealers - Cat Business UnitsDocument17 pagesWho Is Caterpillar?: - Cat Dealers - Cat Business UnitsDigitaladda IndiaNo ratings yet

- PEHJ0069-03 Filters Hydraulik Adn TrainDocument4 pagesPEHJ0069-03 Filters Hydraulik Adn TrainErick Alarcon100% (1)

- 777d Update Test ChartsDocument38 pages777d Update Test ChartsnainindutzNo ratings yet

- Analisis de FallasDocument64 pagesAnalisis de Fallaschechar10No ratings yet

- TIBU7664 - The Third Clutch Friction Disc May Fail On Certain 777 Off-Highway Trucks (PN 391-4047) PDFDocument2 pagesTIBU7664 - The Third Clutch Friction Disc May Fail On Certain 777 Off-Highway Trucks (PN 391-4047) PDFCarlos LoboNo ratings yet

- CAT Hoses & CouplingsDocument148 pagesCAT Hoses & CouplingsJaya Angel100% (1)

- Way For Extending UC Life: UCFN04-001-2 3/5/04 MaintenanceDocument14 pagesWay For Extending UC Life: UCFN04-001-2 3/5/04 MaintenanceMiguelito Para Todos100% (1)

- Fuel Burn To Overhaul ModelDocument4 pagesFuel Burn To Overhaul ModelDwi NoviyantoNo ratings yet

- CAT Contamination ControlDocument34 pagesCAT Contamination ControlРинат Сагидов100% (1)

- PSK 3001 GET All PDFDocument718 pagesPSK 3001 GET All PDFRyan Abubakar Obili PakayaNo ratings yet

- Cashman EM Solutions Brochure 3 16Document2 pagesCashman EM Solutions Brochure 3 16jov100% (1)