Professional Documents

Culture Documents

Work Observation Form - Field Work: Instructions

Work Observation Form - Field Work: Instructions

Uploaded by

saraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Observation Form - Field Work: Instructions

Work Observation Form - Field Work: Instructions

Uploaded by

saraCopyright:

Available Formats

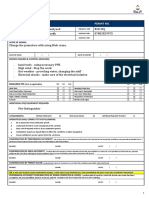

Work Observation Form – Field Work

Date: Location:

Employee(s) and/or Crew Being Observed: Job Description:

Work Order # (if applicable):

Instructions:

1. Check boxes that apply to the work being completed.

2. If an item applies, but is not being done, note opportunities for improvements in the comments box.

3. Please use this observation as an opportunity to discuss safety, environment and security aspects associated with the employee’s work.

4. Obtain the signature of the employee’s Supervisor or send a copy of the completed work observation form to the Supervisor if a signature cannot be obtained.

General/Job Planning: ☐ Documented Hazard, Aspect and Risk Assessment ☐ Orientations Received (check for contractor

(HARA) completed and signed by everyone on jobsite. orientation, site orientation, general orientation, etc.)

☐ Housekeeping Requirements were Reviewed and ☐ Approvals are On Site (check for environmental ☐ Site Emergency Response Plan was Reviewed (check

Work Areas are Clean permit, hot work permit, confined space permit, stand- for an understanding of directions, muster location and

off permit, over length permit, etc.) emergency phone number)

☐ Job Emergency Response Plan was Reviewed (i.e. ☐Ergonomic Issues and Controls were Discussed and ☐ Warn Public of Work Area (check for signage,

SF6, spill response) Implemented barricades, pedestrian control, etc.)

☐ Job Changes were Discussed ☐ Communicated Written Job Plan is On Site ☐ Drawings/Maps were Reviewed and are Available

☐ Applicable Policy/Standard/Procedures Reviewed ☐ Qualified People are Performing the Task(s) ☐ Working Alone Standard was Reviewed

☐ Other

Comments:

Personal Protective Equipment (PPE): ☐ Hard Hat, Eye Protection and Appropriate Footwear ☐ Appropriate Clothing is Worn (i.e. Natural Fibre

(i.e. oil resistant, electric shock resistant, acid resistant, Flame Resistant (FR), chemical suits, high visibility,

etc.) are Worn confined space specific, chain saw pants)

☐ Hearing Protection is Used ☐ Face Shields are Used ☐ Pesticide Mask/Smock/Arm Protection is Worn

☐ Air Monitors are Used (check for up-to-date ☐ Respiratory Protection is Used (check filter expiry ☐ Self-Contained Breathing Apparatus (SCBA) or

calibration and proper gas monitor) dates and fit test dates) Supplied Air is Used (check for up-to-date training)

☐ Appropriate Work Gloves are worn (check for ☐ Other

correct type of glove and expiry dates)

Comments:

Standard Protection Code: ☐ Permit Holder is Identified ☐ Appropriate Type of Permit is Obtained

☐ Switching Plans were Reviewed ☐ Permit Holder Walked Down/Discussed the Permit ☐ Other

with the Operator and/or Crews

Comments:

Mechanical/Electrical Work: ☐ Communication Process/Plan Reviewed and ☐ Limits of Approach are Maintained

Understood

☐ Appropriate Cover Up in Place ☐ Appropriate Grounding/Bonding in Place ☐Top Control on Bucket Near Electrical Conductors

☐ Outriggers (Pads) are in Place ☐ Observers are Used ☐ Vehicle(s) are Grounded

☐ Lifting Beams are Marked with Load Ratings ☐ Other

Comments:

Tools, Vehicles, Equipment and Traffic: ☐ Tools are in Acceptable Condition ☐ Correct Tools are used for the Job

☐ Tools have been Tested/Inspected before Use (i.e. ☐ Insulated Tools are Calibrated/Maintained (check ☐ Unit Lifting Capacity/Load Rating not Exceeded

slings, hooks, lugs, comealongs) test dates) (check that load ratings are visible)

☐ Check for training for Powered Mobile Equipment ☐ Clear Below Workers/Suspended Loads ☐ Tag Lines are placed on Rotating Loads

☐ Using a Signaler (Obstructed View of Crane ☐ Weight of Load has been Determined & Loads are ☐ Equipment Safeguards are Used (check for auto

Operation) Secure shut-off, guards)

☐ Fire Extinguisher/First Aid Kit/Survival Kit/Spill Kit in ☐ Pre-Trip Inspection was Completed (circle check) ☐ Weather related Hazards were Reviewed

vehicles (check expiry and completeness of kits)

☐ Brakes are Applied While Using Winch ☐ Powered Mobile Equipment Inspected Pre-Use ☐ Observer Used when Backing Up

☐ Vehicle Operator Log Book is Up-To-Date ☐ Operator Manual in Vehicle ☐ Beacons/4-Way Flashers are Used

☐ Appropriate Barricades are in Place (chains, pylons, ☐ Flag Person is Trained in Flagging and Wearing Class ☐ Proper Signage in Place

caution/danger tape) III High Visibility Clothing

☐ Traffic Plan Reference Onsite ☐ Other

Comments:

Version 6.0 Page 1 of 2

Work Observation Form – Field Work

Working from Heights/Ladders: ☐ Safety Chains and Handrails are Present and Used ☐ Ladder is in Good Condition with Non-Slip Feet

☐ Scaffolds Inspected Pre-Use (check inspection tag ☐ Anchor Point Used when Working from Elevated ☐ Ladder is Placed at an Angle of 1 Horizontal: 4

and kick plates) Platforms/Roofs Vertical and is 1 Meter Above Platform or Roof

☐ Fall Arrest Inspection & Use (check for up-to-date ☐ Safe Lifting Load Limits are not Exceeded (Aerial ☐ 3 Point Stance is Maintained on the Ladder

training and harness inspection dates) Device)

☐ Sky Genie/Descent Device is Available ☐ Braking/Holding Device in Place (Aerial Device) ☐ Ladder is Non-Conductive (Electrical)

☐ Pole Testing is Completed ☐ Other

Comments:

Ground Disturbance: ☐Line Locates have been Obtained (check expiry) ☐ Hydrovac or Hand Exposed Underground Utilities

☐ Exposed Underground Pipeline/Cables/Conduit are ☐ Appropriate Clearance of Equipment From Openings ☐ Appropriate sloping/shoring ratio is used for the

Supported is Maintained applicable soil type

☐ Observer for Backhoe is Used ☐ Openings are Barricaded ☐ Spoil Pile Proximity > 1 m from Excavation

☐ Protection from Cave-Ins in Place ☐ Other

Comments:

Confined Space Entries: ☐ Communication Plan Reviewed ☐ Test for Hazardous Atmosphere Completed

☐ Observer in Place ☐ Fresh Air Venting in Place ☐ Entry/Exit Plan Prepared

☐ Confirmed Adequate Space for Safe Passage of ☐ Approved Rescue Equipment Available ☐ Confined Space Rescue Procedure is Developed and

Worker with PPE Reviewed (check for confined space training)

☐ Rescue Harness in Place ☐ Other

Comments:

Vegetation Control: ☐ Fall Area was Defined and is Clear ☐ Chain Brake Test Completed

☐ Chipper Emergency Stop Test Completed ☐ Chain Saw is Shut Off While Walking ☐ Chain Saw Operated Below Shoulder Level

☐ Check for Up-To-Date Chainsaw Training ☐ Work Completed in Accordance with the Vegetation Management Policy (consider noxious weeds, Dutch Elm

Disease, pesticide/herbicide application license verified, etc.)

☐ Using Registered/Approved Pesticides ☐ Other

Comments:

Chemicals: ☐ Chemical/Crop Spray Procedures Reviewed ☐ Material Safety Data Sheets (MSDS) Reviewed

☐ Materials Stored Appropriately (check for chemical ☐ Emergency Shower/Eye Wash Location Reviewed ☐ Other

compatibility)

Comments:

Security: ☐ Gates/doors are closed and locked ☐ Fencing is in Good Condition

☐ Passwords are Used in Accordance with the ☐ Proper Signage for Secure/Restricted Areas or ☐ Site and Equipment (vehicles, etc.) are Secured

Password Standard Hazardous Areas is in Place When Unattended

☐ All Materials are Properly Stored and Secured ☐ Working in accordance with Code of Conduct ☐ Other

Comments:

Environment: ☐ Spill/Secondary Containment is in Place ☐ PCB Oil Risks were Addressed

☐ Transportation of Dangerous Goods (check for up-to- ☐ Environmental Best Management Practices and ☐ Appropriate Spill Kit Onsite and Employees are

date training) Operational Controls applicable to the work were Aware of its Location (check for completeness of kit)

Reviewed

☐ Waste Disposal Plan ☐ Other

Comments:

Other Comments/Follow Up:

Note: Opportunities for improvements should be discussed and monitored at tailboards and safety/environment talks. Serious issues should be communicated to the

Environmental Specialist or Safety Coordinator/Safety Management System Specialist for tracking as corrective actions.

Comfort Level: ☐ Comfortable Was Observation Discussed with all Workers Observed?

☐ UnComfortable ☐ Yes ☐ No

Printed Name of Worker: Signature of Worker: Date of Signature:

Printed Name of Person Performing Observation: Signature: Job Title Date of Signature or Date Sent to Supervisor:

Version 6.0 Page 2 of 2

You might also like

- Method of Statement - Sign Board InstallationDocument4 pagesMethod of Statement - Sign Board InstallationMohammed Amer Pasha50% (6)

- Google Ads Measurement Certification AnswersDocument33 pagesGoogle Ads Measurement Certification AnswersScribdTranslations100% (1)

- Organizational Behavior 4 CaseDocument8 pagesOrganizational Behavior 4 CaseWiko Rizki Wijaya100% (3)

- 2.25 - Fall Protection PlanDocument5 pages2.25 - Fall Protection PlanWAQAS AHMEDNo ratings yet

- Lifting Plan For Erection of 2nd To 6th Rev.3Document11 pagesLifting Plan For Erection of 2nd To 6th Rev.3Rhannie GarciaNo ratings yet

- Jsa CraneDocument3 pagesJsa Cranenattwa201075% (24)

- ExcavcklDocument5 pagesExcavcklvg1900No ratings yet

- FRM-00413 Corporate Safety - Excavation and Trenching Permit FormDocument3 pagesFRM-00413 Corporate Safety - Excavation and Trenching Permit FormAhmad Hafidz Mahendra100% (1)

- JLPT n5 Study Material - Nihongo IchibanDocument13 pagesJLPT n5 Study Material - Nihongo IchibankirankumarmrNo ratings yet

- VAULT Top 25 Banking EmployersDocument370 pagesVAULT Top 25 Banking EmployersMisliSlaluAdaNo ratings yet

- Appendix F - Sample FLRADocument5 pagesAppendix F - Sample FLRAkrisNo ratings yet

- Dozvola Za Dizanje TeretaDocument2 pagesDozvola Za Dizanje TeretaStrahinja IlicNo ratings yet

- Lifting Operation Permit-FinalDocument2 pagesLifting Operation Permit-FinalStrahinja IlicNo ratings yet

- OG-HSE-02-07.03 Equipment Site Assessment FormDocument2 pagesOG-HSE-02-07.03 Equipment Site Assessment Formzac.mechanicalNo ratings yet

- Workplace Comprehensive Health & Safety Program ChecklistDocument10 pagesWorkplace Comprehensive Health & Safety Program ChecklistalthaherashNo ratings yet

- PTW General Work - 2020, FilledDocument4 pagesPTW General Work - 2020, FilledPalaniappan SolaiyanNo ratings yet

- Scaffold Checklist - 0Document7 pagesScaffold Checklist - 0Herta SihiteNo ratings yet

- Isolation Permit/ High Voltage Permit NoDocument2 pagesIsolation Permit/ High Voltage Permit NoMohammed KadhimNo ratings yet

- Hot TapDocument7 pagesHot TapMuhammad NaqiuNo ratings yet

- SSSP Form 5 Site Inspection ChecklistDocument5 pagesSSSP Form 5 Site Inspection ChecklistDoaa GamalNo ratings yet

- SECTION 1 - Specification of Work & Permit ValidityDocument3 pagesSECTION 1 - Specification of Work & Permit ValidityJayson TorresNo ratings yet

- Lifting Plan For Erection of 2nd To 6th r.1Document10 pagesLifting Plan For Erection of 2nd To 6th r.1Rhannie GarciaNo ratings yet

- SSSP Form 5 Site Inspection ChecklistDocument5 pagesSSSP Form 5 Site Inspection ChecklistJoseph MairiNo ratings yet

- Unsafe Act Unsafe Condition (UAUC)Document4 pagesUnsafe Act Unsafe Condition (UAUC)Noryati Abdullah100% (5)

- Permit To WorkDocument1 pagePermit To WorkMohammed KadhimNo ratings yet

- Risk AssessementDocument2 pagesRisk Assessementmelik zewdeaNo ratings yet

- G-GD-PRS 005 Annex 9 MOC PSSRDocument4 pagesG-GD-PRS 005 Annex 9 MOC PSSRPhụng LêNo ratings yet

- Lifting Work Permit ColoredDocument2 pagesLifting Work Permit ColoredAJEET SINGHNo ratings yet

- R 03 Lifting and Shifting Work PermitDocument3 pagesR 03 Lifting and Shifting Work PermitPRIYESH . K. PRIYANNo ratings yet

- Working at HeightDocument2 pagesWorking at HeightMohammed KadhimNo ratings yet

- IKK Asphalt Batch Plant Recommissioning Checklist - May 2022Document6 pagesIKK Asphalt Batch Plant Recommissioning Checklist - May 2022Idris Adeshina AdeniranNo ratings yet

- 24 Des PagiDocument1 page24 Des Pagichristian vinsmokeNo ratings yet

- Hand ToolsDocument1 pageHand ToolsMackson NkhomaNo ratings yet

- Air Conditioning Health and SafetyDocument8 pagesAir Conditioning Health and SafetyCeline SVNo ratings yet

- Lifting Plan Install Top StructureDocument3 pagesLifting Plan Install Top Structurezoe fikarNo ratings yet

- Aerial Lift Inspection FormsDocument15 pagesAerial Lift Inspection FormsianNo ratings yet

- Hse JsaDocument22 pagesHse JsaAnonymous y1pIqcNo ratings yet

- Hot PermitDocument2 pagesHot Permitmohamed esmailNo ratings yet

- Water Tanker Inspection ChecklistDocument2 pagesWater Tanker Inspection ChecklistVepxvia Nadiradze0% (1)

- Accident Investigation Report: Investigator's InformationDocument2 pagesAccident Investigation Report: Investigator's InformationJack PNo ratings yet

- Lifting and HoistingDocument4 pagesLifting and Hoistingfadhil AbdullahNo ratings yet

- F-EHS-19-002 Job Safety Environment AnalysisDocument4 pagesF-EHS-19-002 Job Safety Environment AnalysisMasayu MeilinaNo ratings yet

- Equipment Inspection Checklist: Inspected By: Reviewed byDocument2 pagesEquipment Inspection Checklist: Inspected By: Reviewed byVepxvia NadiradzeNo ratings yet

- Task Risk AssesmentDocument6 pagesTask Risk Assesmentum erNo ratings yet

- Confined Space Entry PermitDocument2 pagesConfined Space Entry PermitdnmuleNo ratings yet

- Hazardous Manual Tasks Safety Scan Auto WorkshopsDocument4 pagesHazardous Manual Tasks Safety Scan Auto WorkshopsDann TanNo ratings yet

- Working at Heights Pre Start ChecklistDocument2 pagesWorking at Heights Pre Start ChecklistAdao Vianney MavungoNo ratings yet

- Method Statement For Hydro TestDocument3 pagesMethod Statement For Hydro TestSandeep kumar100% (1)

- Guidance Checklist WebDocument5 pagesGuidance Checklist WebmeidiansyahNo ratings yet

- Daily Inspection Checklist For Trenches and ExcavationsDocument3 pagesDaily Inspection Checklist For Trenches and Excavationskhajamoinuddine123No ratings yet

- Method Statement & Risk Assessment For LoadingUnloading of MaterialsDocument39 pagesMethod Statement & Risk Assessment For LoadingUnloading of MaterialsVishaul RamanNo ratings yet

- Sop of Road Tender Loading & Unloadin GDocument11 pagesSop of Road Tender Loading & Unloadin GShital 2No ratings yet

- URC EHS 39 Lifting and Shifting Work PermitDocument2 pagesURC EHS 39 Lifting and Shifting Work PermitBala VelmuruganNo ratings yet

- Confined Space Entry Permit - 01Document5 pagesConfined Space Entry Permit - 01ASLAM MULANINo ratings yet

- Safe Lifting and Rigging TrainingDocument84 pagesSafe Lifting and Rigging Trainingfaroz khan100% (2)

- Aviation Shop and Flight Line SafetyDocument47 pagesAviation Shop and Flight Line SafetyNizeth Jane Macion CuajotorNo ratings yet

- Checklist - Transformer Location Inspection ChecklistDocument3 pagesChecklist - Transformer Location Inspection ChecklistSachin wakeNo ratings yet

- Checklist - Transformer Location Inspection ChecklistDocument3 pagesChecklist - Transformer Location Inspection ChecklistSachin wakeNo ratings yet

- RIICFW307A Direct Cast In-Situ Piling Operations: Unit DescriptorDocument7 pagesRIICFW307A Direct Cast In-Situ Piling Operations: Unit DescriptorMaulik JoshiNo ratings yet

- Excavation Checklist PDFDocument4 pagesExcavation Checklist PDFPageduesca RouelNo ratings yet

- Pengamanan Umum Dan Tempat Kerja / General and Workplace PrecautionDocument1 pagePengamanan Umum Dan Tempat Kerja / General and Workplace PrecautionabdoelmaleacNo ratings yet

- Contractor Safety CSM-018 Project Observation LogDocument3 pagesContractor Safety CSM-018 Project Observation LogSuad BushiNo ratings yet

- Araldite PW 1036 Hardener HW 1036: Product Data SheetDocument4 pagesAraldite PW 1036 Hardener HW 1036: Product Data SheetAhmed HusseinNo ratings yet

- TM Tut 13 Credit Derivatives Revision PDFDocument5 pagesTM Tut 13 Credit Derivatives Revision PDFQuynh Ngoc DangNo ratings yet

- Risk and Opportunity ProcedureDocument5 pagesRisk and Opportunity Procedureizu chuNo ratings yet

- Case Kaz OilDocument10 pagesCase Kaz OilSHUBHI JAINNo ratings yet

- Weekly Home Learning Plan For Grade 12 Food & Beverage Services Week 5-6, Quarter 1Document2 pagesWeekly Home Learning Plan For Grade 12 Food & Beverage Services Week 5-6, Quarter 1Randy MagbudhiNo ratings yet

- Tshivenda FAL P1 Feb-March 2013 PDFDocument12 pagesTshivenda FAL P1 Feb-March 2013 PDFkhekhyNo ratings yet

- Business Finance: First Quarter Learning PacketDocument60 pagesBusiness Finance: First Quarter Learning PacketNikkie Desiongco100% (1)

- 1st Sessional Question Paper Production and Material ManagementDocument2 pages1st Sessional Question Paper Production and Material ManagementJoshua LoyalNo ratings yet

- Famous Native Americans: Word SearchDocument3 pagesFamous Native Americans: Word Searchapi-524919792No ratings yet

- Walters Ms With Images, 4-09-1Document66 pagesWalters Ms With Images, 4-09-1Robert BranchNo ratings yet

- Advanced Financial Accounting: 2 Year ExaminationDocument32 pagesAdvanced Financial Accounting: 2 Year ExaminationRobertKimtaiNo ratings yet

- Hazard-Database Mining BAGUS SEKALIDocument1,156 pagesHazard-Database Mining BAGUS SEKALIherikNo ratings yet

- CASE DIGEST - GR No. 166680Document3 pagesCASE DIGEST - GR No. 166680Roselyn PascobelloNo ratings yet

- LSPU Quiz No. 3Document4 pagesLSPU Quiz No. 3Jamie Rose AragonesNo ratings yet

- Radar Enginnering (Solved FTerm) 18 2 2021 PDFDocument10 pagesRadar Enginnering (Solved FTerm) 18 2 2021 PDFAhmed ZakiNo ratings yet

- DISC Personality Test Result - Free DISC Types Test Online atDocument5 pagesDISC Personality Test Result - Free DISC Types Test Online atFarahein YacobNo ratings yet

- The Central Excise Act, 1944Document10 pagesThe Central Excise Act, 1944sandeep1318100% (3)

- Overleaf Keyboard ShortcutsDocument2 pagesOverleaf Keyboard ShortcutsJBBARNo ratings yet

- Annual Report Idbi Staff Cooperative Credit Society 17 18Document36 pagesAnnual Report Idbi Staff Cooperative Credit Society 17 18Vaibhav GawandeNo ratings yet

- WYOMING - Tier II Reporting InstructionsDocument8 pagesWYOMING - Tier II Reporting InstructionsElisa CanoNo ratings yet

- ThesisDocument80 pagesThesisdthirunavukkarasuNo ratings yet

- Instructor II: Instructor and Course EvaluationsDocument42 pagesInstructor II: Instructor and Course Evaluationsjesus floresNo ratings yet

- Chapter 2 Web Services Delivered From The CloudDocument8 pagesChapter 2 Web Services Delivered From The Cloudali abbasNo ratings yet

- Brake Input Data SheetDocument8 pagesBrake Input Data SheetSureshNo ratings yet

- Rfi Novec R7&R8Document2 pagesRfi Novec R7&R8MOSTAFA SHARAFNo ratings yet

- CK CK CK With C C: Page 1 of 2Document2 pagesCK CK CK With C C: Page 1 of 2Akhil AjayakumarNo ratings yet