Professional Documents

Culture Documents

Exc 9030B Mod. Controlador Nexsb00800 - 60KB

Exc 9030B Mod. Controlador Nexsb00800 - 60KB

Uploaded by

Ingeniero ElectromecanicoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exc 9030B Mod. Controlador Nexsb00800 - 60KB

Exc 9030B Mod. Controlador Nexsb00800 - 60KB

Uploaded by

Ingeniero ElectromecanicoCopyright:

Available Formats

Service

Bulletin

FILING INSTRUCTIONS

Binder: CE EQUIPMENT BINDER Page: 1 of 1

Binder Section: EXCAVATOR Document No: NEX SB 008-00

Machine Loc Code: 4000 / Electrical Supersedes:

Issued By: Excavator Product Support Group Date Issued: 7/10/00

Family: EXCAVATOR

Model: 9010B, 9020B, 9030B, 9040B, 9050B, & 9060B

Units Affected: ALL

Subject: Computer Programming Procedure Update

BACKGROUND INFORMATION: The auto adjustment procedure in the service manual, section 4001

has been updated to include the selection of the emission certified model codes.

ACTION REQUIRED: Insert one of the attached sheets between pages 4001-42, 43 in each of the

9010B 9020B, 9030B, 9040B, and pages 4001-44,45 in the 9050B and 9060B service manuals. Put an

"X" across the old procedure.

SERVICE INFORMATION: Machine serial number information with the Emissions Engine is listed below.

MACHINE MODEL SERIAL NUMBER RANGE MACHINE MODEL SERIAL NUMBER RANGE

9010B DAC0102001 and after 9040B 1 DAC0402001 and after

9020B DAC0202001 and after 9050B EAC0501122 and after

I 9030B 1 DAC0302001 and after 9060B EAC0601026 and after

Note: The 9045 Excavator only comes equipped with the Emissions Engine.

THIS BULLETIN IS FOR INFORMATIONAL PURPOSES ONLY. SERVICE BULLETINS DO NOT

CONSTITUTE WARRANTY AUTHORIZATION TO UPDATE UNITS. A COPY OF THIS BULLETIN

SHOULD BE PLACED IN THE APPROPRIATE PARTS AND SERVICE MANUAL FOR FURTHER

REFERENCE.

4001-

AUTOMATIC ADJUSTMENT

Always perform automatic adjustment when the For setting breaker, breaker 2, auto idle time or

controller and the throttle motor are replaced and battery selection, refer to optional reset procedures.

when the throttle link at the engine side is adjusted.

l If the controller was replaced, perform steps 6 NOTE: When the ambient temperature is below 30o

F, warm the engine to 120o F before starting this

through 11 and perform automatic adjustment.

procedure.

l If the throttle motor was replaced and the throttle

link was adjusted, perform steps 1 through 11 and

perform automatic adjustment. (Steps 1 through 5

are to erase what is memorized at present. Steps 6

through 11 are for new input.)

Automatic Adjustment Procedures

STEP 1 STEP 4

-Self-check Message.

Cover installation if

Screws 2

BS98F267

BS98F264 Press select switch 4 or 5 times until RESET appears

Self-check switches are under the cover for the clock in message display.

adjustment, manual throttle, and backup switches on

the right rear control panel. Remove 2 screws STEP 5

holding cover then remove cover.

STEP 2

Push and hold’for 20 seconds

BS98F268

Press and hold reset switch for 20 seconds until a

confirmation beep sounds. When beep is heard, turn

key switch OFF. The controller is ready to be

I

reprogrammed.

BS98F265

Turn key switch ON and press change switch once. STEP 6

Work Mode Message

STEP 3

I 99:99 1

Time

BS98F269

Turn key switch ON. When controller is not

I programmed, only 9’s are indicated in work mode

[E~:t3 (RPM) ]

p5q and clock displays. No messages are displayed in

BS98F266 message panel.

Press the pattern switch once.

Rac 7-62401 Revised 6-98 Printed in U.S.A.

4001-

STEP 7 STEP 10

Work Mode

1: English BS98F272

BS98F270

Press fine mode switch to display 0 or 1 (pre-

emissions or emissions engine) in the fourth position

To set language, press standard mode switch until

of the clock display.

number or letter of desired language appears in

mode display.

STEP 11

Language Mode Language Mode Language Mode

No. No. No. Self-check

Japanese 0 Italian 6 Swedish E

Enalish 1 Spanish 7 Finnish C

tThai I 2 I Portuauese I a I I

Chinese 3 Dutch H

German 4 Danish L

BS98F273

French 5 Norwegian F

Press reset switch once to store code in controller.

STEP 8

STEP 12

Work Mode

Cushion

II

pq

Time

BS98F271

Message

To set model code, select model code from list below.

Standard Mode

Press light mode switch to change alpha prefix in

BS98F274

clock display.

Start engine and press cushion switch. Controller will

1 Machine Model 1 Model Code I

Pre-Emi Emissions Engine

J take engine to high idle and begin stepping engine

ssions Engine

90108 I C120 C121

RPM down. This will take several minutes. When

I

90208 I C150 C151 adjustment is complete, message display will show

90308 C200 STANDARD MODE and throttle knob will be

90408 I C220 I c221 operational. Throttle motor calibration is complete.

90408 LR C230 C231

90458 N/A c221

90508 C300 A301

NOTE: This procedure will not start until coolant

90608 C400 A401 temperature is above 50o C.

NOTE: Low idle RPM must be set below the

STEP 9 following values or throttle motor calibration will not

complete.

RPM

Model

Pre-Emissions Engine Emissions Engine

9010B 1000 1050

9020B 1000 1050

BS98F272 9030B 1000 1050

9040B / 9045B 1000 1000

Press heavy mode switch until desired model code

9050B 850 850

appears in second and third position of clock display. 9060B 850 850

Rac 7-62401 Revised 6-98 Printed in U.S.A.

You might also like

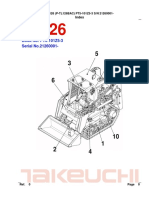

- Parts Manual TL126 PT5-101Z5-3Document183 pagesParts Manual TL126 PT5-101Z5-3АлексейNo ratings yet

- Material Transfer VehicleDocument20 pagesMaterial Transfer VehicleVictor ValenciaNo ratings yet

- COMPASS TrainingDocument383 pagesCOMPASS TrainingNikhil Barshettiwar100% (3)

- BS en 10293-2015Document24 pagesBS en 10293-2015Azima Zalfa AuliyakNo ratings yet

- McCormick C-L Mondial Tier 2 (2007-) - RT30 - C 75 L Tractor Service Repair Manual PDFDocument26 pagesMcCormick C-L Mondial Tier 2 (2007-) - RT30 - C 75 L Tractor Service Repair Manual PDFfjkkekmdmNo ratings yet

- E 25 Air Cleaner System (Engine - V2403M) Schaffer 4350ZDocument3 pagesE 25 Air Cleaner System (Engine - V2403M) Schaffer 4350ZSergeyNo ratings yet

- 2ND CLUTCH - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsDocument2 pages2ND CLUTCH - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsashraf elsayedNo ratings yet

- Reyco PDFDocument44 pagesReyco PDFJavier Yandun100% (1)

- 200942315249490Document56 pages200942315249490Miranda Davila ArleyNo ratings yet

- 4535VQ PDFDocument4 pages4535VQ PDFEvcol LtdaNo ratings yet

- Transaxle Assembly, Power Shuttle, Reverse ClutchDocument3 pagesTransaxle Assembly, Power Shuttle, Reverse ClutchNeftali FuentesNo ratings yet

- Parts and Technical Service Guide Guía de Servicio Técnico y Recambio Guide D'instructions Et Pièces de Rechange Technische BedienungsanleitungDocument14 pagesParts and Technical Service Guide Guía de Servicio Técnico y Recambio Guide D'instructions Et Pièces de Rechange Technische BedienungsanleitungAlex Molina100% (2)

- Spare Parts List: R902482759 Drawing: Material NumberDocument24 pagesSpare Parts List: R902482759 Drawing: Material Numberchaky212No ratings yet

- Series 40 M46 Axial Piston Pump Parts Manual PDFDocument2 pagesSeries 40 M46 Axial Piston Pump Parts Manual PDFVAHAGNNo ratings yet

- Patg Pamg Turbo PartsDocument12 pagesPatg Pamg Turbo Parts1luckywolf0% (1)

- Cross Valve Directional ControlDocument36 pagesCross Valve Directional ControlariwibowoNo ratings yet

- Hub Wheel Drive TDH230: Robust & PowerfulDocument4 pagesHub Wheel Drive TDH230: Robust & Powerfuljoanvasquez61100% (1)

- Cat - D6C - Tractor - 17R - Parts - Steering Clutch - 17RDocument3 pagesCat - D6C - Tractor - 17R - Parts - Steering Clutch - 17Rzae nurdinNo ratings yet

- Mobile Directional Control Valve: Proportional, Load SensingDocument24 pagesMobile Directional Control Valve: Proportional, Load SensingTrần Quốc ĐôngNo ratings yet

- 547315-En 1.0.0Document160 pages547315-En 1.0.0Jose MustienesNo ratings yet

- 510B Backhoe Loader: Engine PerformanceDocument5 pages510B Backhoe Loader: Engine PerformancebalajimetturNo ratings yet

- Hydraulic Hammer Rammer 555: Parts Manual PM555CSSENG.415Document28 pagesHydraulic Hammer Rammer 555: Parts Manual PM555CSSENG.415Valourdos LukasNo ratings yet

- Spare-Parts Book: C-Service 3Document69 pagesSpare-Parts Book: C-Service 3Gora Fedotov100% (1)

- 210G and 210GLC Excavators PIN 1FF210GX C520001 PIN 1FF210GX D520001 IntroductionDocument5 pages210G and 210GLC Excavators PIN 1FF210GX C520001 PIN 1FF210GX D520001 IntroductionwilsonugshaNo ratings yet

- Ca250d Spare Parts ManualDocument609 pagesCa250d Spare Parts ManualPieter BothaNo ratings yet

- Dynapac CC122Document2 pagesDynapac CC122Corona CoronaNo ratings yet

- LayMore 6hc - 8hc SweeperDocument2 pagesLayMore 6hc - 8hc SweeperAlvaroValdebenitoValenzuela100% (1)

- Manual Partes Montcargas MCDocument178 pagesManual Partes Montcargas MCjorge_bustos_16100% (1)

- EPX25I 부품 10010Document111 pagesEPX25I 부품 10010mt thanh nguyen100% (1)

- Mixed Fleet Coupling ListDocument54 pagesMixed Fleet Coupling ListAli AdelNo ratings yet

- 773B Hydraulic (Air Supply Dan Brake System)Document2 pages773B Hydraulic (Air Supply Dan Brake System)Deni IndraNo ratings yet

- MBL 745s 745ht S BrochureDocument7 pagesMBL 745s 745ht S BrochureGaurav BhandariNo ratings yet

- Service Manual Bomag BW213 DDocument468 pagesService Manual Bomag BW213 Dgeoffchapple2No ratings yet

- Steering Unit: Service ManualDocument28 pagesSteering Unit: Service ManualmusafirNo ratings yet

- Parts and Service Interval DD90HF M@SH PDFDocument2 pagesParts and Service Interval DD90HF M@SH PDFjrincon26No ratings yet

- 286-7889 Soporte 12TNDocument8 pages286-7889 Soporte 12TNEdu Pastén MejiasNo ratings yet

- Sandvik LH203-11 PDFDocument3 pagesSandvik LH203-11 PDFEstyNo ratings yet

- Brochure bl60b bl70bDocument28 pagesBrochure bl60b bl70bMichael Puma ZeaNo ratings yet

- Carga y Prueba Sistema Piloto Del Acumulador Cat-988kDocument2 pagesCarga y Prueba Sistema Piloto Del Acumulador Cat-988kRAMON CALDERONNo ratings yet

- Manual de Partes TL642 PDFDocument402 pagesManual de Partes TL642 PDFjesus adrian mora perez100% (2)

- 13 - Servo Valve SV 10 - B (Boekwerk)Document36 pages13 - Servo Valve SV 10 - B (Boekwerk)Ivan MaltsevNo ratings yet

- HL 750 7-1Document2 pagesHL 750 7-1REMZONA100% (1)

- 2748 and 2948 Forwarder HydraulicDocument2 pages2748 and 2948 Forwarder Hydraulicwords2zhigang_612545100% (1)

- Alicon INSTRUCTION MANUALDocument43 pagesAlicon INSTRUCTION MANUALPaola SolanoNo ratings yet

- Herramientas Aceros de PerforaciónDocument18 pagesHerramientas Aceros de PerforaciónositorxNo ratings yet

- Remove Head IsmDocument67 pagesRemove Head IsmjeremyNo ratings yet

- SD22 Manuel D'instructionsDocument80 pagesSD22 Manuel D'instructionsjacques PerronNo ratings yet

- D 631 Series ValvesDocument12 pagesD 631 Series ValvesJosé OlaveNo ratings yet

- RT55H Parts Manual 053-118Document229 pagesRT55H Parts Manual 053-118Selmirije2No ratings yet

- BW125ADH 135AD 138AD AC OM - WM PDFDocument3 pagesBW125ADH 135AD 138AD AC OM - WM PDFPetrNo ratings yet

- Válvula de Freio SafimDocument12 pagesVálvula de Freio Safimwilson salesNo ratings yet

- Engine Electrical Circuitry (Engine Sensors, Battery, ALT & Starter) - S530 PDFDocument4 pagesEngine Electrical Circuitry (Engine Sensors, Battery, ALT & Starter) - S530 PDFLuis Felipe Valenzuela PantojaNo ratings yet

- WB140-150 Final - 66747-2Document16 pagesWB140-150 Final - 66747-2email sharingNo ratings yet

- 8 - Braking SystemDocument10 pages8 - Braking SystemOscar VazquesNo ratings yet

- Caterpillar 120g Grader Parts Manual S N 87v1138 87v5274Document11 pagesCaterpillar 120g Grader Parts Manual S N 87v1138 87v5274ManoliskiostNo ratings yet

- Despiece Trasero Parte 1Document3 pagesDespiece Trasero Parte 1leogerguz100% (1)

- Manual Instructivo CO 407Document34 pagesManual Instructivo CO 407Juan RafaelNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document9 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Denys Zhukov100% (1)

- Service ManualDocument236 pagesService ManualCristian Enson Vega RiosNo ratings yet

- Hensley Full Catalogue GZDocument161 pagesHensley Full Catalogue GZGeorge ZormpasNo ratings yet

- INV-FRD700-man-2014-ENG PELAZZA PEPPINODocument15 pagesINV-FRD700-man-2014-ENG PELAZZA PEPPINOENZONo ratings yet

- Delma Polaris 4Document24 pagesDelma Polaris 4nethelNo ratings yet

- Vessel Team Vessel Name Update Status WM SulawesiDocument6 pagesVessel Team Vessel Name Update Status WM SulawesiKomang DeliNo ratings yet

- INNOVA 2.0E/2.0G (Auto) (Minor Change) : Model Code: TGN40Document4 pagesINNOVA 2.0E/2.0G (Auto) (Minor Change) : Model Code: TGN40Ismail IbrahimNo ratings yet

- 5 Dairy Processing - Clarification and Cream SeparationDocument6 pages5 Dairy Processing - Clarification and Cream SeparationSPMUSER9ANo ratings yet

- Mnit Admission LetterDocument1 pageMnit Admission LetterAjaj AlamNo ratings yet

- Transistor MCQDocument5 pagesTransistor MCQMark BelasaNo ratings yet

- Rolls-Royce Corporation AE 3007A Service Bulletin (SB) Technical Publications IndexDocument70 pagesRolls-Royce Corporation AE 3007A Service Bulletin (SB) Technical Publications IndexAnubhuti GhaiNo ratings yet

- Data Structures and Algorithms: (CS210/ESO207/ESO211)Document35 pagesData Structures and Algorithms: (CS210/ESO207/ESO211)Moazzam HussainNo ratings yet

- Storage Chart Freeze ItDocument1 pageStorage Chart Freeze ItKimbre BellhouseNo ratings yet

- Relay Board Connection InstructionDocument6 pagesRelay Board Connection Instructionkum512No ratings yet

- Information Gain CalculatorDocument16 pagesInformation Gain CalculatorShashiBhushanSahani0% (1)

- Dektec DTU 215Document5 pagesDektec DTU 215Alexander WieseNo ratings yet

- Manual Conefor 26Document19 pagesManual Conefor 26J. Francisco Lavado ContadorNo ratings yet

- Iec 364 4 41Document12 pagesIec 364 4 41Ramadan Dwiputra NurrachmadNo ratings yet

- Panoramic Power Wireless Sensors Bridge DatasheetDocument1 pagePanoramic Power Wireless Sensors Bridge DatasheettiagoorgadoNo ratings yet

- Inf Luence of Tip Clearance On The Flow Field and Aerodynamic Performance of The Centrif Ugal ImpellerDocument6 pagesInf Luence of Tip Clearance On The Flow Field and Aerodynamic Performance of The Centrif Ugal Impellerarm coreNo ratings yet

- Summary of Motor Greasing: Total Compliance %Document3 pagesSummary of Motor Greasing: Total Compliance %Amaresh NayakNo ratings yet

- Installation & Maintenance ManualDocument80 pagesInstallation & Maintenance ManualWleed KhledNo ratings yet

- PGG-EG Governor ActuatorDocument4 pagesPGG-EG Governor Actuatorrodruren010% (1)

- Alpha BasicDocument190 pagesAlpha Basicmiguel_pinheiro_10No ratings yet

- BIAS Amp Product ChartDocument4 pagesBIAS Amp Product ChartMarco ZamoranoNo ratings yet

- Extension of MDRRMO OfficeDocument12 pagesExtension of MDRRMO OfficeJustin YuabNo ratings yet

- Pompa Sirkulasi AP 156,3 LPM @60mDocument3 pagesPompa Sirkulasi AP 156,3 LPM @60mAndreas B KresnawanNo ratings yet

- Passive Fire Protection Solutions: Presented by International IpsDocument20 pagesPassive Fire Protection Solutions: Presented by International IpsTung Doan ThanhNo ratings yet

- Computer ScientistDocument15 pagesComputer ScientistRenz Banayat Del RosarioNo ratings yet

- MID 185 - PSID 3 - FMI 8 Renault VolvoDocument3 pagesMID 185 - PSID 3 - FMI 8 Renault VolvolampardNo ratings yet

- Salesforce Workflow CheatsheetDocument4 pagesSalesforce Workflow Cheatsheetgowtham 099091No ratings yet

- Pajero Catalogue2Document13 pagesPajero Catalogue2almirb7100% (1)

- GATE 2015 Information BrochureDocument84 pagesGATE 2015 Information BrochureAnweshaBoseNo ratings yet