Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

130 viewsSPECIFICATIONS

SPECIFICATIONS

Uploaded by

ARJAY LERUMThis document outlines specifications for a three-storey residential project. [1] It specifies materials for backfilling, concrete blocks, concrete works, reinforcing steel bars and electrical, plumbing, and painting works. [2] Concrete hollow blocks of varying thicknesses will be used for interior and exterior walls. [3] Finishing materials include floor and wall tiles, gypsum board ceilings, doors, windows, and terrace grills made of galvanized iron sheets and tubing.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Sample Building SpecificationsDocument3 pagesSample Building SpecificationsJan Alexis Monsalud78% (23)

- Utilization of Solid Waste As Raw Materials in Paper Cement Composite Board (PCCB)Document12 pagesUtilization of Solid Waste As Raw Materials in Paper Cement Composite Board (PCCB)gcsblue stacksNo ratings yet

- Architectural Spec SampleDocument13 pagesArchitectural Spec SampleEquilibrium D.C.No ratings yet

- Sample Building SpecificationsDocument3 pagesSample Building SpecificationsSyrille alarcon100% (2)

- Technical SpecificationsDocument17 pagesTechnical Specificationslarry0lao0iiiNo ratings yet

- Specification Nov. 25, 2013Document4 pagesSpecification Nov. 25, 2013Mary Ann LictaoaNo ratings yet

- Sample Project Specs 10 STOREY COMMERCIALDocument3 pagesSample Project Specs 10 STOREY COMMERCIALBernie RomeroNo ratings yet

- MODULE 5 Concrete WorksDocument5 pagesMODULE 5 Concrete WorksMac KYNo ratings yet

- 10 28 13 - Toilet Accessories PDFDocument6 pages10 28 13 - Toilet Accessories PDFmasoodaeNo ratings yet

- General NotesDocument2 pagesGeneral NotesCharmaine FresnilloNo ratings yet

- QAUDocument90 pagesQAUakclams77No ratings yet

- Spiral RampDocument15 pagesSpiral RampgouharNo ratings yet

- Project Name: Glass BalustradeDocument11 pagesProject Name: Glass BalustradeNp Pw100% (1)

- PDFDocument20 pagesPDFsimiyu cciNo ratings yet

- Specification For General Construction FroilanDocument6 pagesSpecification For General Construction FroilanRafael Luis So100% (1)

- Technical Specification of 2 Storey ResidentialDocument7 pagesTechnical Specification of 2 Storey Residentializzy umandalNo ratings yet

- Proposed Two Specification WritingDocument4 pagesProposed Two Specification WritingKelly Santiago100% (1)

- Marces Osmeña General SpecificationsDocument5 pagesMarces Osmeña General SpecificationsAlexander Osmeña IINo ratings yet

- TS - Rough Carpentry (Interior Fit - Out) PDFDocument4 pagesTS - Rough Carpentry (Interior Fit - Out) PDFJo BompatNo ratings yet

- Practice problems-STEELDocument14 pagesPractice problems-STEELreanNo ratings yet

- Technical Specification: A. Demolition, Clearing and Preparation of The SiteDocument4 pagesTechnical Specification: A. Demolition, Clearing and Preparation of The SiteZen Marl Gaor0% (1)

- BT SPECS FinalDocument25 pagesBT SPECS FinalDUMLAO, ANGELIE M.No ratings yet

- General SpecificationsDocument10 pagesGeneral SpecificationsChy GomezNo ratings yet

- Ns 18 Steel DesignDocument49 pagesNs 18 Steel DesignKrm ChariNo ratings yet

- Tile Works Reyes EstimatesDocument4 pagesTile Works Reyes EstimatesVicent John ParedesNo ratings yet

- Specifications: Project: Proposed Two (2) Storey Residential Location: OwnerDocument4 pagesSpecifications: Project: Proposed Two (2) Storey Residential Location: OwnerJ.P.Almera ArDesignNo ratings yet

- Technical Specifications: Name of Project Location OwnerDocument2 pagesTechnical Specifications: Name of Project Location OwnerLerie Lou R. PenarroyoNo ratings yet

- SPECIFICATIONSDocument6 pagesSPECIFICATIONSWalter Garcia100% (1)

- Lorna Taira General Construction SpecificationsDocument3 pagesLorna Taira General Construction SpecificationsLimar SetatraNo ratings yet

- Construction SpecificationsDocument10 pagesConstruction SpecificationsDarwin AquinoNo ratings yet

- Lec.2-3 - Main Items of Work & UnitsDocument29 pagesLec.2-3 - Main Items of Work & UnitsSugam Sehgal100% (1)

- Material Details and SpecificationsDocument4 pagesMaterial Details and SpecificationsManuelito ZapataNo ratings yet

- 4 One Way SlabDocument22 pages4 One Way SlabCandice Aberin Mag-alasinNo ratings yet

- Sangandaan General SpecificationsDocument9 pagesSangandaan General SpecificationsCarlo EloyNo ratings yet

- Metal Roofing Prices Philippines - PHILCON PRICESDocument1 pageMetal Roofing Prices Philippines - PHILCON PRICESjohn reyesNo ratings yet

- Standard Classroom Building - DPWH As of 021524 A1Document1 pageStandard Classroom Building - DPWH As of 021524 A1designers.starlightNo ratings yet

- Division 1 General Requirements-0004Document190 pagesDivision 1 General Requirements-0004Adam SniffNo ratings yet

- Assignment No. 3Document8 pagesAssignment No. 3Nathanniel GonzalesNo ratings yet

- Project: 4 Storey Commercial and Residential Bldg. Subject: SpecificationDocument5 pagesProject: 4 Storey Commercial and Residential Bldg. Subject: SpecificationKURONo ratings yet

- Three Story Residence MandaluyongDocument14 pagesThree Story Residence MandaluyongSayra SapornaNo ratings yet

- Topic 1. Road Classification DesignDocument39 pagesTopic 1. Road Classification DesignRoopen FearkyNo ratings yet

- Tondo Residence Plumbing EstimateDocument2 pagesTondo Residence Plumbing EstimateEvans CorpNo ratings yet

- Sample House Construction Cost Estimate PhilippinesDocument7 pagesSample House Construction Cost Estimate PhilippinesJebong A. MarquezNo ratings yet

- Compressive Strength For Cast-In-Place Concrete: Table 1.7Document25 pagesCompressive Strength For Cast-In-Place Concrete: Table 1.7Ayban Dela CruzNo ratings yet

- DESCRIPTION: ITEM 405-Structural ConcreteDocument11 pagesDESCRIPTION: ITEM 405-Structural ConcreteKioNo ratings yet

- Island Super Kinis Skim Coat (TDS)Document1 pageIsland Super Kinis Skim Coat (TDS)WILAN ENGINEERING INCNo ratings yet

- Sample Project EstimateDocument218 pagesSample Project EstimateMichael Jorge Bernales0% (1)

- Material Specifications PDFDocument11 pagesMaterial Specifications PDFJEAN-YVES TRONCONo ratings yet

- Textbook For CMT (Asphalt, Wood, & Steel)Document15 pagesTextbook For CMT (Asphalt, Wood, & Steel)vincelordNo ratings yet

- Standard Specification For General Construction Proposed Two-Storey Residential House Mrs. Maria Rechel B.EricksonDocument5 pagesStandard Specification For General Construction Proposed Two-Storey Residential House Mrs. Maria Rechel B.EricksonRocky SioresNo ratings yet

- Sample Construction SpecificationsDocument9 pagesSample Construction SpecificationsMark Anjo Palero ErlanoNo ratings yet

- Technical Data Sheet 3#5 Copper Clad Steel Wire: ITEM CODE - 600305Document2 pagesTechnical Data Sheet 3#5 Copper Clad Steel Wire: ITEM CODE - 600305Victor DoyoganNo ratings yet

- NSCP Reviewer 1 PDFDocument78 pagesNSCP Reviewer 1 PDFanon_716820639No ratings yet

- Item 1018Document5 pagesItem 1018Ester MarianNo ratings yet

- Project Specifications Abuab SINGLE ATTACHEDDocument6 pagesProject Specifications Abuab SINGLE ATTACHEDmaria cristina santosNo ratings yet

- Arch 530 - BT4 Technical SpecificationsDocument13 pagesArch 530 - BT4 Technical SpecificationsAlyanna PanganibanNo ratings yet

- DIV 4 Masonry PDFDocument12 pagesDIV 4 Masonry PDFMa Monica M. MuncadaNo ratings yet

- Item 1009Document3 pagesItem 1009Ester Marian100% (1)

- Iguzzini The Product Book EN - 2021 PDFDocument962 pagesIguzzini The Product Book EN - 2021 PDFSangeeta SikariaNo ratings yet

- Architectural EstimatesDocument12 pagesArchitectural EstimatesNavi GabotNo ratings yet

- Swimming Pool General RequirementsDocument23 pagesSwimming Pool General RequirementsVee KeeNo ratings yet

- Section 1 (39.353 M) 711,912.72 PHP 18,090.43 PHP/l.m. Footing: 247,091.12 PHPDocument4 pagesSection 1 (39.353 M) 711,912.72 PHP 18,090.43 PHP/l.m. Footing: 247,091.12 PHPRafael Obusan IINo ratings yet

- Steel DesignDocument31 pagesSteel DesignARJAY LERUMNo ratings yet

- Ce502-Fc1 - Lerum - Arjay (C1C2)Document15 pagesCe502-Fc1 - Lerum - Arjay (C1C2)ARJAY LERUMNo ratings yet

- 2ND & 3RD Floor PDFDocument1 page2ND & 3RD Floor PDFARJAY LERUMNo ratings yet

- Ground Floor Plan: A B C D E FDocument1 pageGround Floor Plan: A B C D E FARJAY LERUMNo ratings yet

- Wall Panelling SystemsDocument70 pagesWall Panelling SystemsNicole Francis100% (1)

- Design Guide For Steel Railway BridgesDocument161 pagesDesign Guide For Steel Railway Bridgespratip_b100% (1)

- Advanced Construction Techniques UNIT-3 Large Span Structures ConstructionDocument31 pagesAdvanced Construction Techniques UNIT-3 Large Span Structures ConstructionRishav MandalNo ratings yet

- MAIR Binongan Br.Document37 pagesMAIR Binongan Br.FBVid UploadsNo ratings yet

- AISC - Local Check PDFDocument2 pagesAISC - Local Check PDFThai Binh MinhNo ratings yet

- A Restaurant DialogueDocument5 pagesA Restaurant DialogueEndar Abdi Dasopang100% (1)

- K Type Bolted GlandDocument1 pageK Type Bolted GlandDaviwongNo ratings yet

- Hand Made School, BangladeshDocument9 pagesHand Made School, Bangladeshrushil jainNo ratings yet

- Painting Contractor QA/QC Plan Sample: Selected Pages (Not A Complete PlanDocument19 pagesPainting Contractor QA/QC Plan Sample: Selected Pages (Not A Complete PlanPuvent SanthrasegaranNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerSreni Excel MacrosNo ratings yet

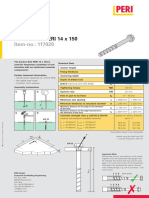

- 19 - Anchor Bolt PERI 14 X 150Document2 pages19 - Anchor Bolt PERI 14 X 150Gaetano ScorsoneNo ratings yet

- Contractor'S Statement of Work Accomplished: Environmental Management Bureau 10Document3 pagesContractor'S Statement of Work Accomplished: Environmental Management Bureau 10Razul DaranginaNo ratings yet

- Production Planning and Inventory ManagementDocument31 pagesProduction Planning and Inventory ManagementChindu JosephNo ratings yet

- Design Note of Box Culvert 2M X 1.5M (4M Filling)Document26 pagesDesign Note of Box Culvert 2M X 1.5M (4M Filling)Manupriya KapleshNo ratings yet

- 2022-1106 - Arpp02 - Arch401 - Jeciel Marielle - Assignment No. 1Document13 pages2022-1106 - Arpp02 - Arch401 - Jeciel Marielle - Assignment No. 1Marielle JecielNo ratings yet

- Monthly Utilization CapacityDocument4 pagesMonthly Utilization CapacitySWAPNILNo ratings yet

- Footing Pourcard Check ListDocument2 pagesFooting Pourcard Check ListJAYASHREE CONSULTANTNo ratings yet

- Direct Fastening Technology Manual Technical Information ASSET DOC 3162576Document650 pagesDirect Fastening Technology Manual Technical Information ASSET DOC 3162576Alin DanielNo ratings yet

- 11.solid Waste Management PDFDocument4 pages11.solid Waste Management PDFVivek KodoorNo ratings yet

- High-Strength Concrete in U.S. Codes and Standards S.K. GhoshDocument16 pagesHigh-Strength Concrete in U.S. Codes and Standards S.K. GhoshGuilhermeFregoneziNo ratings yet

- Chapter-2 Functional Planning of BuildingsDocument17 pagesChapter-2 Functional Planning of BuildingsSileshi AzagewNo ratings yet

- 13048-TD-02-VOL3 - 5 TS BuildingsDocument729 pages13048-TD-02-VOL3 - 5 TS BuildingsgauravNo ratings yet

- Structural Design & Estimation Lecture Theater Building by HamzaDocument97 pagesStructural Design & Estimation Lecture Theater Building by HamzaIbrahimNo ratings yet

- Fiberglas Pipe Insulation: SSL Ii With ASJ Max No-WrapDocument2 pagesFiberglas Pipe Insulation: SSL Ii With ASJ Max No-WrapramkumarNo ratings yet

- Saahas Zero Waste Profile - 2018 PDFDocument25 pagesSaahas Zero Waste Profile - 2018 PDFRashmi PrasadNo ratings yet

- Sikaswell® A: Product Data SheetDocument4 pagesSikaswell® A: Product Data SheetKhin Sandi KoNo ratings yet

- Aisc Standard HoleDocument2 pagesAisc Standard HoleMoe Oo HtunNo ratings yet

- Eurocode 6 - IntroductionDocument24 pagesEurocode 6 - IntroductionAyis ANo ratings yet

SPECIFICATIONS

SPECIFICATIONS

Uploaded by

ARJAY LERUM0 ratings0% found this document useful (0 votes)

130 views4 pagesThis document outlines specifications for a three-storey residential project. [1] It specifies materials for backfilling, concrete blocks, concrete works, reinforcing steel bars and electrical, plumbing, and painting works. [2] Concrete hollow blocks of varying thicknesses will be used for interior and exterior walls. [3] Finishing materials include floor and wall tiles, gypsum board ceilings, doors, windows, and terrace grills made of galvanized iron sheets and tubing.

Original Description:

Original Title

SPECIFICATIONS.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines specifications for a three-storey residential project. [1] It specifies materials for backfilling, concrete blocks, concrete works, reinforcing steel bars and electrical, plumbing, and painting works. [2] Concrete hollow blocks of varying thicknesses will be used for interior and exterior walls. [3] Finishing materials include floor and wall tiles, gypsum board ceilings, doors, windows, and terrace grills made of galvanized iron sheets and tubing.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

130 views4 pagesSPECIFICATIONS

SPECIFICATIONS

Uploaded by

ARJAY LERUMThis document outlines specifications for a three-storey residential project. [1] It specifies materials for backfilling, concrete blocks, concrete works, reinforcing steel bars and electrical, plumbing, and painting works. [2] Concrete hollow blocks of varying thicknesses will be used for interior and exterior walls. [3] Finishing materials include floor and wall tiles, gypsum board ceilings, doors, windows, and terrace grills made of galvanized iron sheets and tubing.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

SPECIFICATIONS

PROJECT: (3) Three-storey Residential

CLIENT:

I. THE PROJECT SITE

II. MATERIAL SPECIFICATIONS

A. Backfilling Materials

The backfilling materials should be free from garbage and other materials that can

be tampered and already hardened before putting reinforcements and concrete on

slabs.

B. Concrete Masonry Units

Concrete hollow blocks to be use shall be 4” x 8” x 16” and the shape should be the

stretcher using 1:3 cement and sand ratio proportion to the exterior walls of the

proposed residential. The walls should be strong and reinforced by 10mm rebars,

horizontal and vertical reinforcements so to that can repel calamities like

earthquakes and strong water current if flood occurs in the near future.

For the interior walls, the concrete hollow blocks to be used shall be 4” thk using the

same cement and sand ratio for mortar filler, and 5” for exterior walls.

C. Concrete Works

The cement to be used shall be Portland cement or any approved type of cement. It

should be in good quality and stored at room temperature free from moisture so that

it will not be hard.

D. Reinforcing Steel Bars

All reinforcing steel bars shall be deformed with a minimum yield strength;

Fy = 275 MPa less than 16mm bar

Fy = 414 MPa more than 16mm bar

All reinforcing bar must be clean from rust, grease and other materials which tend to

impair bond.

All reinforcing steel bars shall be accurately and securely placed before pouring

concrete or applying mortar or grout.

Concrete slab thickness shall be 4” spaced 300mm on center bothways.

III. FINISHES

A. Floor and Wall Tiles

Floor tiles shall be 60 x 60 Arte floor tiles will be used for living, bedroom, dining, and

bathroom and except for kitchen counter top. At all toilets and bath floor used 60cm

x 60 cm (arte tiles) non-skid homogenous floor tiles and floor ceiling 60 x 60 cm tiles,

while at kitchen and lavatory counter top, use black Granalitic tiles.

B. Ceiling Finishes

9mm thick Gypsum board should be used for all ceiling surfaces and other approved

brand and supplier. It should be framed with 1 x 2” metal furrings riveted and

screwed.

C. Doors and Windows

Panel door is installed at main entrance of the proposed residential. Prefabricated

doors for bedrooms and CR using tanguile and marine plywood with 0.80m x 2.10m

for bedrooms and 0.70m x 2.10m for CR.

PVC windows shall be used with 3/16” glass.

D. Doorknobs and Lockets

Shall be Yale brand or quickset brand or any approved brands made of good quality

should be used to ensure safety. Doorknobs color will be aluminum or brass type

color.

E. Terrace grills and Railings

Shall be made of GI sheets, ¾“ flat bars, square bars, 1” tubular and 2 x 4 tubular.

IV. ROOFING

A. Roofing Materials

Use rib type roofing prepainted with gutted on the top roof. Second floor roof, use

existing tegula with corrugated sheet roofing in 2 x 3 C- purlins with angular bar

connector.

B. Roof Framing

Shall be use 2 x 2 x 3/16” thick MS-plate for steel connections. Sag rods and turn

buckles should be used accordingly to roof framing plans. All steel materials to be

used shall be painted with red oxide or lead red primer and must be free from rust to

ensure the durability of steel before installation.

All top chord and bottom chord to be used shall be 2 x 2 x 3/16 thick while members

should be 1 ½ x 1 ½ x 1/4 “ thick angular steel.

C-purlins 2 x 3 will be used and will be supported by 2 x 2 x 3/16” thick angular

connectors welded with purlins. Spacing shall be 0.60m on center bothways.

V. ELECTRICAL MATERIALS AND INSTALLATION

A. Moldflex UPVC corrugated Flexible Electrical Conduit use ½” O and ¾” O

moldflex for flexible electrical conduit for the proposed residential. Moldflex gives

guaranteed protection for the electrical wiring system. It is flexible and lightweight for

fast, easy and trouble free installation and it virtually eliminates the use of couplings,

elbows so it is more economical.

B. Switches – Use National or Toshiba brand or MCS brand for 2 x 4 switches, one

gang, two gang and three gang if it is possible of three gang.

C. Convenience Outlet – Use National or Universal brand for Duplex convenience

outlets, range outlets, refrigerator outlets and also weather proof outlets.

D. Junction box – Use 4 x 4 junction box with cover, orange color and made of

plastic.

E. Electrical Wires – Min. size to be used shall be 3.5mm^2 THW and the biggest

shall be 8.0mm^2 THW

F. Down lights/Pin lights – Use 5 watts and 13 watts pin lights, SL – 2000 without

housing by Philips and or other approved products as indicated on plans.

G. Panel board – Verify schematic riser diagram for the number of circuit braekers to

be used.

H. Circuit breakers – Min. size of breakers to be used shall be 20AT/50AF, while the

biggest shall be 60AT/50AF.

I. Light bulbs – 32 watts, SL-2000 light bulbs shall be used for toilets and baths

areas.

VI. PLUMBING FIXTURES AND ACCESSORIES

A. Sanitary Sewer Line – Use 4” sewer pipe and 2” sewer branches. The brand of

materials to be used shall be moldflex of neltex or any approved brand and pipe

installation shall maintain at least 1% slope as required by the plumbing code of

the Philippines.

B. Hot and Cold water lines – Use ¾” pipe and ½” pipe PPR German pipes for hot.

C. Sanitary Storm Drainage – Use 4 UPVC sewer pipe for sanitary storm drainage.

VII. PAINTIN|G WORKS

A. Use Boysen or any approved brand.

B. After applying the first coat, let it dry for 24 hours before applying the second

coat.

C. The surfaces must be free from dirt and dust before the application of the paint.

You might also like

- Sample Building SpecificationsDocument3 pagesSample Building SpecificationsJan Alexis Monsalud78% (23)

- Utilization of Solid Waste As Raw Materials in Paper Cement Composite Board (PCCB)Document12 pagesUtilization of Solid Waste As Raw Materials in Paper Cement Composite Board (PCCB)gcsblue stacksNo ratings yet

- Architectural Spec SampleDocument13 pagesArchitectural Spec SampleEquilibrium D.C.No ratings yet

- Sample Building SpecificationsDocument3 pagesSample Building SpecificationsSyrille alarcon100% (2)

- Technical SpecificationsDocument17 pagesTechnical Specificationslarry0lao0iiiNo ratings yet

- Specification Nov. 25, 2013Document4 pagesSpecification Nov. 25, 2013Mary Ann LictaoaNo ratings yet

- Sample Project Specs 10 STOREY COMMERCIALDocument3 pagesSample Project Specs 10 STOREY COMMERCIALBernie RomeroNo ratings yet

- MODULE 5 Concrete WorksDocument5 pagesMODULE 5 Concrete WorksMac KYNo ratings yet

- 10 28 13 - Toilet Accessories PDFDocument6 pages10 28 13 - Toilet Accessories PDFmasoodaeNo ratings yet

- General NotesDocument2 pagesGeneral NotesCharmaine FresnilloNo ratings yet

- QAUDocument90 pagesQAUakclams77No ratings yet

- Spiral RampDocument15 pagesSpiral RampgouharNo ratings yet

- Project Name: Glass BalustradeDocument11 pagesProject Name: Glass BalustradeNp Pw100% (1)

- PDFDocument20 pagesPDFsimiyu cciNo ratings yet

- Specification For General Construction FroilanDocument6 pagesSpecification For General Construction FroilanRafael Luis So100% (1)

- Technical Specification of 2 Storey ResidentialDocument7 pagesTechnical Specification of 2 Storey Residentializzy umandalNo ratings yet

- Proposed Two Specification WritingDocument4 pagesProposed Two Specification WritingKelly Santiago100% (1)

- Marces Osmeña General SpecificationsDocument5 pagesMarces Osmeña General SpecificationsAlexander Osmeña IINo ratings yet

- TS - Rough Carpentry (Interior Fit - Out) PDFDocument4 pagesTS - Rough Carpentry (Interior Fit - Out) PDFJo BompatNo ratings yet

- Practice problems-STEELDocument14 pagesPractice problems-STEELreanNo ratings yet

- Technical Specification: A. Demolition, Clearing and Preparation of The SiteDocument4 pagesTechnical Specification: A. Demolition, Clearing and Preparation of The SiteZen Marl Gaor0% (1)

- BT SPECS FinalDocument25 pagesBT SPECS FinalDUMLAO, ANGELIE M.No ratings yet

- General SpecificationsDocument10 pagesGeneral SpecificationsChy GomezNo ratings yet

- Ns 18 Steel DesignDocument49 pagesNs 18 Steel DesignKrm ChariNo ratings yet

- Tile Works Reyes EstimatesDocument4 pagesTile Works Reyes EstimatesVicent John ParedesNo ratings yet

- Specifications: Project: Proposed Two (2) Storey Residential Location: OwnerDocument4 pagesSpecifications: Project: Proposed Two (2) Storey Residential Location: OwnerJ.P.Almera ArDesignNo ratings yet

- Technical Specifications: Name of Project Location OwnerDocument2 pagesTechnical Specifications: Name of Project Location OwnerLerie Lou R. PenarroyoNo ratings yet

- SPECIFICATIONSDocument6 pagesSPECIFICATIONSWalter Garcia100% (1)

- Lorna Taira General Construction SpecificationsDocument3 pagesLorna Taira General Construction SpecificationsLimar SetatraNo ratings yet

- Construction SpecificationsDocument10 pagesConstruction SpecificationsDarwin AquinoNo ratings yet

- Lec.2-3 - Main Items of Work & UnitsDocument29 pagesLec.2-3 - Main Items of Work & UnitsSugam Sehgal100% (1)

- Material Details and SpecificationsDocument4 pagesMaterial Details and SpecificationsManuelito ZapataNo ratings yet

- 4 One Way SlabDocument22 pages4 One Way SlabCandice Aberin Mag-alasinNo ratings yet

- Sangandaan General SpecificationsDocument9 pagesSangandaan General SpecificationsCarlo EloyNo ratings yet

- Metal Roofing Prices Philippines - PHILCON PRICESDocument1 pageMetal Roofing Prices Philippines - PHILCON PRICESjohn reyesNo ratings yet

- Standard Classroom Building - DPWH As of 021524 A1Document1 pageStandard Classroom Building - DPWH As of 021524 A1designers.starlightNo ratings yet

- Division 1 General Requirements-0004Document190 pagesDivision 1 General Requirements-0004Adam SniffNo ratings yet

- Assignment No. 3Document8 pagesAssignment No. 3Nathanniel GonzalesNo ratings yet

- Project: 4 Storey Commercial and Residential Bldg. Subject: SpecificationDocument5 pagesProject: 4 Storey Commercial and Residential Bldg. Subject: SpecificationKURONo ratings yet

- Three Story Residence MandaluyongDocument14 pagesThree Story Residence MandaluyongSayra SapornaNo ratings yet

- Topic 1. Road Classification DesignDocument39 pagesTopic 1. Road Classification DesignRoopen FearkyNo ratings yet

- Tondo Residence Plumbing EstimateDocument2 pagesTondo Residence Plumbing EstimateEvans CorpNo ratings yet

- Sample House Construction Cost Estimate PhilippinesDocument7 pagesSample House Construction Cost Estimate PhilippinesJebong A. MarquezNo ratings yet

- Compressive Strength For Cast-In-Place Concrete: Table 1.7Document25 pagesCompressive Strength For Cast-In-Place Concrete: Table 1.7Ayban Dela CruzNo ratings yet

- DESCRIPTION: ITEM 405-Structural ConcreteDocument11 pagesDESCRIPTION: ITEM 405-Structural ConcreteKioNo ratings yet

- Island Super Kinis Skim Coat (TDS)Document1 pageIsland Super Kinis Skim Coat (TDS)WILAN ENGINEERING INCNo ratings yet

- Sample Project EstimateDocument218 pagesSample Project EstimateMichael Jorge Bernales0% (1)

- Material Specifications PDFDocument11 pagesMaterial Specifications PDFJEAN-YVES TRONCONo ratings yet

- Textbook For CMT (Asphalt, Wood, & Steel)Document15 pagesTextbook For CMT (Asphalt, Wood, & Steel)vincelordNo ratings yet

- Standard Specification For General Construction Proposed Two-Storey Residential House Mrs. Maria Rechel B.EricksonDocument5 pagesStandard Specification For General Construction Proposed Two-Storey Residential House Mrs. Maria Rechel B.EricksonRocky SioresNo ratings yet

- Sample Construction SpecificationsDocument9 pagesSample Construction SpecificationsMark Anjo Palero ErlanoNo ratings yet

- Technical Data Sheet 3#5 Copper Clad Steel Wire: ITEM CODE - 600305Document2 pagesTechnical Data Sheet 3#5 Copper Clad Steel Wire: ITEM CODE - 600305Victor DoyoganNo ratings yet

- NSCP Reviewer 1 PDFDocument78 pagesNSCP Reviewer 1 PDFanon_716820639No ratings yet

- Item 1018Document5 pagesItem 1018Ester MarianNo ratings yet

- Project Specifications Abuab SINGLE ATTACHEDDocument6 pagesProject Specifications Abuab SINGLE ATTACHEDmaria cristina santosNo ratings yet

- Arch 530 - BT4 Technical SpecificationsDocument13 pagesArch 530 - BT4 Technical SpecificationsAlyanna PanganibanNo ratings yet

- DIV 4 Masonry PDFDocument12 pagesDIV 4 Masonry PDFMa Monica M. MuncadaNo ratings yet

- Item 1009Document3 pagesItem 1009Ester Marian100% (1)

- Iguzzini The Product Book EN - 2021 PDFDocument962 pagesIguzzini The Product Book EN - 2021 PDFSangeeta SikariaNo ratings yet

- Architectural EstimatesDocument12 pagesArchitectural EstimatesNavi GabotNo ratings yet

- Swimming Pool General RequirementsDocument23 pagesSwimming Pool General RequirementsVee KeeNo ratings yet

- Section 1 (39.353 M) 711,912.72 PHP 18,090.43 PHP/l.m. Footing: 247,091.12 PHPDocument4 pagesSection 1 (39.353 M) 711,912.72 PHP 18,090.43 PHP/l.m. Footing: 247,091.12 PHPRafael Obusan IINo ratings yet

- Steel DesignDocument31 pagesSteel DesignARJAY LERUMNo ratings yet

- Ce502-Fc1 - Lerum - Arjay (C1C2)Document15 pagesCe502-Fc1 - Lerum - Arjay (C1C2)ARJAY LERUMNo ratings yet

- 2ND & 3RD Floor PDFDocument1 page2ND & 3RD Floor PDFARJAY LERUMNo ratings yet

- Ground Floor Plan: A B C D E FDocument1 pageGround Floor Plan: A B C D E FARJAY LERUMNo ratings yet

- Wall Panelling SystemsDocument70 pagesWall Panelling SystemsNicole Francis100% (1)

- Design Guide For Steel Railway BridgesDocument161 pagesDesign Guide For Steel Railway Bridgespratip_b100% (1)

- Advanced Construction Techniques UNIT-3 Large Span Structures ConstructionDocument31 pagesAdvanced Construction Techniques UNIT-3 Large Span Structures ConstructionRishav MandalNo ratings yet

- MAIR Binongan Br.Document37 pagesMAIR Binongan Br.FBVid UploadsNo ratings yet

- AISC - Local Check PDFDocument2 pagesAISC - Local Check PDFThai Binh MinhNo ratings yet

- A Restaurant DialogueDocument5 pagesA Restaurant DialogueEndar Abdi Dasopang100% (1)

- K Type Bolted GlandDocument1 pageK Type Bolted GlandDaviwongNo ratings yet

- Hand Made School, BangladeshDocument9 pagesHand Made School, Bangladeshrushil jainNo ratings yet

- Painting Contractor QA/QC Plan Sample: Selected Pages (Not A Complete PlanDocument19 pagesPainting Contractor QA/QC Plan Sample: Selected Pages (Not A Complete PlanPuvent SanthrasegaranNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerSreni Excel MacrosNo ratings yet

- 19 - Anchor Bolt PERI 14 X 150Document2 pages19 - Anchor Bolt PERI 14 X 150Gaetano ScorsoneNo ratings yet

- Contractor'S Statement of Work Accomplished: Environmental Management Bureau 10Document3 pagesContractor'S Statement of Work Accomplished: Environmental Management Bureau 10Razul DaranginaNo ratings yet

- Production Planning and Inventory ManagementDocument31 pagesProduction Planning and Inventory ManagementChindu JosephNo ratings yet

- Design Note of Box Culvert 2M X 1.5M (4M Filling)Document26 pagesDesign Note of Box Culvert 2M X 1.5M (4M Filling)Manupriya KapleshNo ratings yet

- 2022-1106 - Arpp02 - Arch401 - Jeciel Marielle - Assignment No. 1Document13 pages2022-1106 - Arpp02 - Arch401 - Jeciel Marielle - Assignment No. 1Marielle JecielNo ratings yet

- Monthly Utilization CapacityDocument4 pagesMonthly Utilization CapacitySWAPNILNo ratings yet

- Footing Pourcard Check ListDocument2 pagesFooting Pourcard Check ListJAYASHREE CONSULTANTNo ratings yet

- Direct Fastening Technology Manual Technical Information ASSET DOC 3162576Document650 pagesDirect Fastening Technology Manual Technical Information ASSET DOC 3162576Alin DanielNo ratings yet

- 11.solid Waste Management PDFDocument4 pages11.solid Waste Management PDFVivek KodoorNo ratings yet

- High-Strength Concrete in U.S. Codes and Standards S.K. GhoshDocument16 pagesHigh-Strength Concrete in U.S. Codes and Standards S.K. GhoshGuilhermeFregoneziNo ratings yet

- Chapter-2 Functional Planning of BuildingsDocument17 pagesChapter-2 Functional Planning of BuildingsSileshi AzagewNo ratings yet

- 13048-TD-02-VOL3 - 5 TS BuildingsDocument729 pages13048-TD-02-VOL3 - 5 TS BuildingsgauravNo ratings yet

- Structural Design & Estimation Lecture Theater Building by HamzaDocument97 pagesStructural Design & Estimation Lecture Theater Building by HamzaIbrahimNo ratings yet

- Fiberglas Pipe Insulation: SSL Ii With ASJ Max No-WrapDocument2 pagesFiberglas Pipe Insulation: SSL Ii With ASJ Max No-WrapramkumarNo ratings yet

- Saahas Zero Waste Profile - 2018 PDFDocument25 pagesSaahas Zero Waste Profile - 2018 PDFRashmi PrasadNo ratings yet

- Sikaswell® A: Product Data SheetDocument4 pagesSikaswell® A: Product Data SheetKhin Sandi KoNo ratings yet

- Aisc Standard HoleDocument2 pagesAisc Standard HoleMoe Oo HtunNo ratings yet

- Eurocode 6 - IntroductionDocument24 pagesEurocode 6 - IntroductionAyis ANo ratings yet