Professional Documents

Culture Documents

Clutch: Pdf 文件使用 "Pdffactory Pro" 试用版本创建

Clutch: Pdf 文件使用 "Pdffactory Pro" 试用版本创建

Uploaded by

rafael alcantaraCopyright:

Available Formats

You might also like

- 2007-2013 Toyota Tundra Electrical Wiring Diagrams PDFDocument502 pages2007-2013 Toyota Tundra Electrical Wiring Diagrams PDFMarcos Cabrera100% (2)

- Diagrama ECU 2018 Ford Fiesta L4-1.6LDocument4 pagesDiagrama ECU 2018 Ford Fiesta L4-1.6LGerardo Sinco Masharely100% (1)

- CLUTCH Clutch System FIAT 500Document28 pagesCLUTCH Clutch System FIAT 500FSR1407100% (3)

- Manuali Officina Yj/Xj 1993Document18 pagesManuali Officina Yj/Xj 1993stormchidNo ratings yet

- Daewoo Matiz 2000-2013 Clutch PDFDocument14 pagesDaewoo Matiz 2000-2013 Clutch PDFsheoNo ratings yet

- KZJ70 HZJ PZJ Chassis Body PDFDocument680 pagesKZJ70 HZJ PZJ Chassis Body PDFmasakpNo ratings yet

- IMMO Training MaterialDocument33 pagesIMMO Training Materialrafael alcantara100% (1)

- MPV Facelift PDF PDFDocument33 pagesMPV Facelift PDF PDFEkrem SadakNo ratings yet

- Ciaz Car Manual PDFDocument340 pagesCiaz Car Manual PDFtapas pandaNo ratings yet

- 08-Clutch System PDFDocument28 pages08-Clutch System PDFAditiana SukadarusmanNo ratings yet

- Digital 125452 S 5756 Tinjauan Persepsi LiteraturDocument12 pagesDigital 125452 S 5756 Tinjauan Persepsi Literaturneon erzNo ratings yet

- 06.clutch SystemDocument24 pages06.clutch SystemTony D'AngeloNo ratings yet

- Focus ClutchDocument8 pagesFocus ClutchJose Luis LopezNo ratings yet

- CK30 WM 03 ClutchDocument16 pagesCK30 WM 03 ClutchvixentdNo ratings yet

- Clutch: Section 5CDocument24 pagesClutch: Section 5CJarry PotterNo ratings yet

- 17 - Trouble DiagnosisDocument18 pages17 - Trouble DiagnosisFrederikusNo ratings yet

- 1999 Jeep TJ Wrangler Service Manual - 06. ClutchDocument14 pages1999 Jeep TJ Wrangler Service Manual - 06. Clutchbfranklin33100% (1)

- Activity Sheet SampleDocument5 pagesActivity Sheet SampleDhan GregorioNo ratings yet

- Clutch: Fig. 1 Clutch Pedal ComponentsDocument10 pagesClutch: Fig. 1 Clutch Pedal ComponentsPelis CloneNo ratings yet

- Volume 2 V80 Workshop ManualDocument440 pagesVolume 2 V80 Workshop Manualantonio wongNo ratings yet

- Trouble DiagnosisDocument22 pagesTrouble Diagnosisdmitry esaulkovNo ratings yet

- Z Clutch 6 - 1Document14 pagesZ Clutch 6 - 1helgith74No ratings yet

- Module 3 - Lesson 3 - MEEC 101A PDFDocument4 pagesModule 3 - Lesson 3 - MEEC 101A PDFErica May MundinaNo ratings yet

- Troubleshooting: LiningDocument48 pagesTroubleshooting: Liningplanner samulosNo ratings yet

- Ew60C - Steering System, TroubleshootingDocument2 pagesEw60C - Steering System, Troubleshootingmaintenance 2kpbNo ratings yet

- My First PresentationDocument23 pagesMy First Presentationjayant pathakNo ratings yet

- M35c ClutchDocument14 pagesM35c ClutchJesus TimaureNo ratings yet

- Clutch PDFDocument13 pagesClutch PDFNam TranNo ratings yet

- Fault Finding: Section F - TransmissionDocument1 pageFault Finding: Section F - TransmissionIonut GrozaNo ratings yet

- ClutchDocument14 pagesClutchArt DoeNo ratings yet

- Steering Clutch and BrakeDocument18 pagesSteering Clutch and BrakeLucky OkoteNo ratings yet

- Activity (Clutch Assembly)Document6 pagesActivity (Clutch Assembly)Ardelyn PaybanoNo ratings yet

- Activity (Clutch Assembly)Document6 pagesActivity (Clutch Assembly)Ardelyn PaybanoNo ratings yet

- Eclipse 2011 2.4LDocument99 pagesEclipse 2011 2.4LHarold SarmientoNo ratings yet

- Compresores SandenDocument81 pagesCompresores SandenMiguel Carlin JimenezNo ratings yet

- ClutchDocument16 pagesClutchChristian Linares AbreuNo ratings yet

- B234 Camshaft and TappetsDocument9 pagesB234 Camshaft and TappetsAndri OdeNo ratings yet

- Clutch PDFDocument20 pagesClutch PDFClaudio Godoy GallegosNo ratings yet

- 11-Brake System PDFDocument81 pages11-Brake System PDFAditiana SukadarusmanNo ratings yet

- Group 2 Operational Checks and TroubleshootingDocument3 pagesGroup 2 Operational Checks and TroubleshootingAndré TarginoNo ratings yet

- RM 64Document632 pagesRM 64Jabita Aguilera CabreraNo ratings yet

- Hyundai Excel X2 1989-1998 Clutch System CableDocument11 pagesHyundai Excel X2 1989-1998 Clutch System CableAshraf MuhmdNo ratings yet

- Motor OutlanderDocument62 pagesMotor OutlanderHillan VieiraNo ratings yet

- 38 EmbragueDocument52 pages38 EmbragueCarlos CandelaNo ratings yet

- Hyundai Santa FE (2005-2007) Workshop Manual - Clutch SystemDocument12 pagesHyundai Santa FE (2005-2007) Workshop Manual - Clutch SystemJenny Mora LeonNo ratings yet

- 02 RH40E UndercarriageDocument16 pages02 RH40E UndercarriageBladimir PadillaNo ratings yet

- Manual Transmission: Section 5BDocument48 pagesManual Transmission: Section 5BJose Luis Rodriguez CruzNo ratings yet

- Troubleshooting ClutchesDocument2 pagesTroubleshooting ClutchesjohnNo ratings yet

- Final Drive Troubleshooting: Symptom Problem Possible Cause SolutionDocument2 pagesFinal Drive Troubleshooting: Symptom Problem Possible Cause SolutionMohamad Nadzri YahayaNo ratings yet

- PL Clutch 6 - 1Document12 pagesPL Clutch 6 - 1Pelis CloneNo ratings yet

- Introduction To Prime MoverDocument45 pagesIntroduction To Prime Movermuthukumaran TanujNo ratings yet

- Pump, Troubleshooting: Service InformationDocument1 pagePump, Troubleshooting: Service InformationPreett Rajin MenabungNo ratings yet

- TUCSON (JM) 2008 G 2.7 DOHC Clutch SystemDocument20 pagesTUCSON (JM) 2008 G 2.7 DOHC Clutch Systemrobin machadoNo ratings yet

- ClutchDocument25 pagesClutchBob DesmetNo ratings yet

- Clutch Master Cylinder: FunctionDocument4 pagesClutch Master Cylinder: FunctionNguyễn DũngNo ratings yet

- Gr21 EmbragueDocument26 pagesGr21 EmbragueJosue Alvarez VegaNo ratings yet

- Endeavor 2010 3.8LDocument95 pagesEndeavor 2010 3.8Lgersoncoimbra010905No ratings yet

- Galant-2009 5-2 4LDocument103 pagesGalant-2009 5-2 4LRuben MoncalunaNo ratings yet

- Eclipse 2008 2.4LDocument142 pagesEclipse 2008 2.4LDiego.S SanchezNo ratings yet

- Clutch JL430 : Structure and Working Principles of Clutch CL-2Document21 pagesClutch JL430 : Structure and Working Principles of Clutch CL-2Mauricio IbañezNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- ChasisDocument43 pagesChasisrafael alcantaraNo ratings yet

- H13 EngineDocument50 pagesH13 Enginerafael alcantaraNo ratings yet

- ABS Trouble ShootingDocument10 pagesABS Trouble Shootingrafael alcantaraNo ratings yet

- Manual Fiesta Motores Duratec PDFDocument320 pagesManual Fiesta Motores Duratec PDFrafael alcantaraNo ratings yet

- New X-431 (3G) PDFDocument33 pagesNew X-431 (3G) PDFrafael alcantaraNo ratings yet

- Matiz Manualll PDFDocument37 pagesMatiz Manualll PDFrafael alcantaraNo ratings yet

- H13-Electronic Injection PDFDocument101 pagesH13-Electronic Injection PDFrafael alcantaraNo ratings yet

- Pulsar 150 150R 180 Abs PDFDocument44 pagesPulsar 150 150R 180 Abs PDFMuhammed AlwaniNo ratings yet

- Suzuki Swift SportDocument17 pagesSuzuki Swift SportleciellemonNo ratings yet

- Types of Roads Road ComponentsDocument28 pagesTypes of Roads Road ComponentsEllieNo ratings yet

- Shop Manual: 1. General Information 2. Fuel & Engine 3. Frame & Chassis 4. Electrical SystemDocument31 pagesShop Manual: 1. General Information 2. Fuel & Engine 3. Frame & Chassis 4. Electrical SystemArun Risal50% (2)

- Shock AbsorberDocument21 pagesShock AbsorberSlamet ArifinNo ratings yet

- Letter From Chairman To Railway Board ChairmanDocument4 pagesLetter From Chairman To Railway Board ChairmanShashank SrivastavaNo ratings yet

- Zachary Haverkamp - Research EssayDocument6 pagesZachary Haverkamp - Research Essayapi-537739326No ratings yet

- Name: Obias, Ricci Eugenia Date: August, 31 2021 Exercise No. 1Document4 pagesName: Obias, Ricci Eugenia Date: August, 31 2021 Exercise No. 1Ricci ObiasNo ratings yet

- Determination of Tramway Wheel and Rail Profiles To Minimise DerailmentDocument122 pagesDetermination of Tramway Wheel and Rail Profiles To Minimise Derailmentnandoreis123No ratings yet

- Selection of Suspension Arrangement of Traction Motors A Right Approach PDFDocument13 pagesSelection of Suspension Arrangement of Traction Motors A Right Approach PDFRamesh YadlaNo ratings yet

- Jeppview For Windows: List of Pages in This Trip KitDocument24 pagesJeppview For Windows: List of Pages in This Trip KitCatalin CiocarlanNo ratings yet

- Design of All Terrain VehicleDocument13 pagesDesign of All Terrain VehiclekalaiNo ratings yet

- TOPIC 1 DCC3113 JUN2020 - Introduction To Highway and TrafficDocument42 pagesTOPIC 1 DCC3113 JUN2020 - Introduction To Highway and TrafficMuhd FareezNo ratings yet

- Hatz 2g40Document8 pagesHatz 2g40Tesla EcNo ratings yet

- How To Prevent Car AccidentsDocument2 pagesHow To Prevent Car AccidentsNashaz ZainonNo ratings yet

- Crossfire XZ250R Manual Download PDFDocument66 pagesCrossfire XZ250R Manual Download PDFFrank AvilaNo ratings yet

- Examen de Ingles Franco A. Ticona M. Grupo ADocument2 pagesExamen de Ingles Franco A. Ticona M. Grupo AFranco A. Teicon67% (3)

- Balancing of Radial and V-Shape Engine by Ijaz AliDocument20 pagesBalancing of Radial and V-Shape Engine by Ijaz AliMuhammad QasimNo ratings yet

- DVAPower Website K-SERIESDocument82 pagesDVAPower Website K-SERIESstefan.vince536100% (1)

- Ringfeder Towing Eyes BrochureDocument4 pagesRingfeder Towing Eyes BrochureJasmin BijedicNo ratings yet

- Grove TMS700B NA BrochureDocument26 pagesGrove TMS700B NA BrochureNELSON CHAPARRONo ratings yet

- GS4 UserDocument287 pagesGS4 UserIgnacioNo ratings yet

- 1999-05 - Volvo - S40 - 5 Cylinders 2.5L FI Turbo DOHC - 32993902 PDFDocument121 pages1999-05 - Volvo - S40 - 5 Cylinders 2.5L FI Turbo DOHC - 32993902 PDFGolf variant PineappleNo ratings yet

- Mobileye New BrochureDocument2 pagesMobileye New Brochureradu_pop_52No ratings yet

- RCC T Girder & Deck Slab For Major Bridge 02 - Deck-21Document1 pageRCC T Girder & Deck Slab For Major Bridge 02 - Deck-21mrinal kayalNo ratings yet

- Suzuki PricelistDocument5 pagesSuzuki PricelistjohnNo ratings yet

Clutch: Pdf 文件使用 "Pdffactory Pro" 试用版本创建

Clutch: Pdf 文件使用 "Pdffactory Pro" 试用版本创建

Uploaded by

rafael alcantaraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clutch: Pdf 文件使用 "Pdffactory Pro" 试用版本创建

Clutch: Pdf 文件使用 "Pdffactory Pro" 试用版本创建

Uploaded by

rafael alcantaraCopyright:

Available Formats

CL-1

Clutch

Pages

Troubleshooting.................................................................................................................................................CL-2

Check and adjust clutch pedal...........................................................................................................................CL-3

Deflation of clutch.............................................................................................................................................CL-3

Clutch master cylinder.......................................................................................................................................CL-4

Clutch slave cylinder..........................................................................................................................CL-5

Clutch assembly.................................................................................................................................................CL-6

ININ CL

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

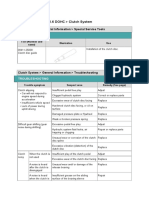

CL-2 Clutch — troubleshooting

Troubleshooting

Problem Possible Cause Remedy

Adjust free stroke of

Free stroke of clutch pedal too long

clutch pedal

Air in clutch pipeline

Exhaust air in clutch

Clutch slave cylinder faulty

system

Difficult to change Clutch master cylinder faulty

Displace slave cylinder

gear or cannot change Installation position of clutch disc faulty

Displace master cylinder

gear Friction lining is stuck to oil or broken

Check clutch disc

Spline of input shaft or clutch disc is contaminated or adhered

Repair as necessary

to something

Displace clutch pressure

Clutch pressure disc faulty

disc

Displace guide bearing

Guide bearing of clutch worn Adjust free stroke of

Transmission not

Free stroke of clutch pedal short clutch pedal

meshing

Friction lining of clutch disc is adhered to oil or worn Check clutch disc

Clutch sliding

Clutch pressure disc faulty Displace clutch pressure

Release fork seized disc

Check release fork

Check clutch disc

Friction lining of clutch disc is adhered to oil or worn

Clutch seized/ Displace clutch pressure

Clutch pressure disc faulty

vibrating disc

Engine bracket loose

Repair as necessary

Air in clutch pipeline Exhaust air in clutch

Clutch slave cylinder faulty system

Clutch pedal spongy

Clutch master cylinder faulty Displace slave cylinder

Displace master cylinder

Displace clutch pressure

Components and parts loose in clutch pressure disc

disc

Release bearing worn or contaminated

Clutch loud noise Displace release bearing

Guide bearing worn

Displace guide bearing

Release fork seized

Repair as necessary

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

Clutch — check and adjust clutch pedal; deflation of clutch CL-3

Adjusting point of push rod stroke Check and adjust clutch pedal

1. Check pedal height and position of push rod, right or not.

Pedal height is counting from front boarding.

Admiral (165±5)mm

Adjusting point of

If wrong, adjust pedal height.

pedal height 2. If necessary, adjust pedal height.

(1)Loosen locknut, swivel the bolt until the height is right. Install

Pedal height the locknut.

(2)Loosen locknut, swivel the push rod until the position is right.

Install the locknut.

3. Check whether free stroke of pedal is right or not.

Press the pedal gently until you could feel the resistance force

against the clutch.

Free stroke of pedal: 16-28 mm

4. If necessary, adjust free stroke of pedal.

(1)Loosen locknut, swivel push rod until the stroke is right.

(2)Install the locknut.

(3)After adjusting free stroke of pedal, check pedal height.

Free stroke of pedal

Deflation of clutch

Remarks: If operating the clutch system or air in the clutch, you

should exhaust the air.

Note:Do not leave brake fluid on the painting surface. If yes, wash

it away immediately.

1.Inject the brake fluid into the oil cup of the clutch master

cylinder.

Check the oil cup of the master cylinder regularly. If necessary,

inject the brake fluid.

2.Connect ethylene resin tube to deflation valve.

Insert the other end of the tube into the container which

contains half of brake fluid.

3.Deflation of clutch system

(1)Make upward and downward reciprocating motion of the

clutch pedal several times slowly.

(2)When putting pressure on the pedal, loosen the deflation valve

until the brake fluid flows out, and then install the deflation

valve.

(3)Make the abovementioned operations repeatedly until the

bubble in the brake fluid disappears.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

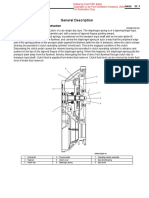

CL-4 Clutch — clutch master cylinder

Clutch master cylinder

Components

Pin spindle

Toggle fork

Elastic clamping Locknut

band

Cotter pin

Connecting hose

Clutch master

Elastic clamping cylinder

band

Pushrod

Fluid supply

connector

Clutch control

oil tube

单位N﹒m

Unit: N·m

Removal of clutch master cylinder

1.Remove cotter pin and pushrod pin.

2.Take apart clutch control oil tube with a spanner.

3.Remove elastic clamping band.

4.Remove clutch master cylinder.

(1)Remove fixing nut.

(2)Pull the clutch master cylinder.

Installation of clutch master cylinder

1.Install the fixing nut and swivel.

2.Link up the clutch control oil tube.

3.Link up the pushrod, and install the pin and cotter pin.

4.Connect the connecting hose to the fuel outlet connector of the

clutch master cylinder with elastic clamping band.

5.Exhaust air in the clutch system, and adjust the height of the

clutch pedal.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

Clutch—clutch slave cylinder CL-5

Clutch slave cylinder

Components

Clutch slave

cylinder Bleed ing plug

18±2N·m

19±1N·m

Piston Pushrod

Spring

Dust cover

Fixing nut

Seal

gasket

Sealing bolt

Locknut Adjusting nut

◆ 用过后不能再使用的零件

Removal of slave cylinder

1.Take apart the clutch pipeline.

2.Loosen the two bolts, remove the clutch slave cylinder.

Installation of slave cylinder

1.Install slave cylinder with two bolts.

2.Link up clutch pipeline.

3.Exhaust air in clutch system.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

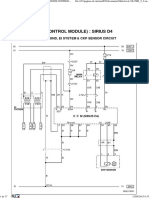

CL-6 Clutch—clutch assembly

Clutch assembly

Components

Flywheel

Clutch disc Clutch pressure disc 30 N·m

Locating clip of

release bearing

Release fork

Dust cover

Release bearing

Support pin of release fork

Removal of clutch components

1.Remove transmission

Remarks: Do not make gear oil dried.

2.Remove clutch pressure disc and clutch disc

(1)Mark the clutch pressure disc and flywheel with an alignment

mark. (Alignment mark: in order to keep dynamic balance,

you need to install them by the mark.)

(2)Loosen the bolt slowly until the spring tension is fully

released.

(3)Loosen the fixing bolt, pull the clutch pressure disc and clutch

disc.

3.Take apart the bearing and release fork from transmission

4JB1、491 Engine:

(1)Remove the clip, pull the bearing.

(2)Remove the release fork and dust cover.

4YDA1K、SD4W55A Engine:

(1)Remove the dust cover.

(2)Remove the release fork, pull the bearing.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

Clutch—clutch assembly CL-7

Checking of parts of clutch

1.Check the clutch disc, if worn or damaged

Measure the depth of rivet head with a vernier caliper.

The minimum depth of the rivet head: 0.3mm

It’s necessary to displace the clutch disc if the depth of rivet

head exceeds the limit value.

2.Check the radial runout of the clutch

百分表

Dial indicator Runout mandrel Check the radial runout of the clutch disc with a dial indicator.

摆差芯轴 Max. Radial Runout: 0.8mm

It’s necessary to displace the clutch disc if the radial runout

exceeds the limit value.

摆差仪

Runout instrument

3.Measure the radial runout of the flywheel

Check the radial runout of the flywheel with a dial indicator.

Max. Radial Runout: 0.2mm

It’s necessary to displace the flywheel if the radial runout

exceeds the limit value.

4.Check the guide bearing

Apply a force in the direction of axial line, turn the bearing by

hand.

It’s necessary to displace the guide bearing if it cannot be turned

or too much resistance existed.

Remarks:This bearing is permanently lubricated. Thus it is no

need to be cleaned and lubricated.

5.If necessary, displace the guide bearing.

(1)Remove the guide bearing.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

CL-8 Clutch — clutch assembly

(2)Install the guide bearing.

Remarks: After fitting the guide bearing into the flywheel

hub, make sure rotation of the bearing in good condition.

2.Check whether the diaphragm spring is worn or not.

Check the wearing depth and width of the diaphragm spring

with a vernier caliper.

Limit value:

Max. depth:0.6mm

Max. width:5mm

It’s necessary to displace the diaphragm spring if the wearing

depth and width of the diaphragm spring exceeds the limit

value.

3.Check release bearing

Apply a force in the direction of axial line, turn the bearing by

hand.

It’s necessary to displace the release bearing if it cannot be

turned or too much resistance existed.

Remarks:This bearing is permanently lubricated. Thus it is no

need to be cleaned and lubricated.

Installation of clutch assembly

1.Locate the friction disc and flywheel through guide bearing of

crankshaft by using special tools.(locating shaft or locating pin).

At the

side of

飞轮侧

flywheel

2.Installation of clutch pressure disc

(1)The mark is used to align the clutch pressure disc and flywheel,

and to make sure of keeping dynamic balance of crankshaft,

Alignment

mark

flywheel and pressure disc.(Alignment mark:make sure of

对准标记 keeping dynamic balance of crankshaft, flywheel and pressure

disc).

(2)Install the bolts with a balanced force. Apply a force around

the clutch pressure disc repeatedly until they are closely

jointed. Then tighten the bolts.

Moment of tightening:25-30 N·m

Remarks:

Order of tightening the bolts: each bolt should be tightened

one by one according to a diagonal line to ensure that each

bolt is under uniform stress.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

Clutch — clutch assembly CL-9

4.Smear No.2 lithium- based lubricant

Smear the lithium- based lubricant as follows:

· contact point of release fork and bearing cover

· contact point of release fork and pushrod

· fulcrum of release fork

· spline of clutch disc

5.Fit the dust cover, release fork, release bearing seat and bearing

into transmission

6.Install the transmission

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

You might also like

- 2007-2013 Toyota Tundra Electrical Wiring Diagrams PDFDocument502 pages2007-2013 Toyota Tundra Electrical Wiring Diagrams PDFMarcos Cabrera100% (2)

- Diagrama ECU 2018 Ford Fiesta L4-1.6LDocument4 pagesDiagrama ECU 2018 Ford Fiesta L4-1.6LGerardo Sinco Masharely100% (1)

- CLUTCH Clutch System FIAT 500Document28 pagesCLUTCH Clutch System FIAT 500FSR1407100% (3)

- Manuali Officina Yj/Xj 1993Document18 pagesManuali Officina Yj/Xj 1993stormchidNo ratings yet

- Daewoo Matiz 2000-2013 Clutch PDFDocument14 pagesDaewoo Matiz 2000-2013 Clutch PDFsheoNo ratings yet

- KZJ70 HZJ PZJ Chassis Body PDFDocument680 pagesKZJ70 HZJ PZJ Chassis Body PDFmasakpNo ratings yet

- IMMO Training MaterialDocument33 pagesIMMO Training Materialrafael alcantara100% (1)

- MPV Facelift PDF PDFDocument33 pagesMPV Facelift PDF PDFEkrem SadakNo ratings yet

- Ciaz Car Manual PDFDocument340 pagesCiaz Car Manual PDFtapas pandaNo ratings yet

- 08-Clutch System PDFDocument28 pages08-Clutch System PDFAditiana SukadarusmanNo ratings yet

- Digital 125452 S 5756 Tinjauan Persepsi LiteraturDocument12 pagesDigital 125452 S 5756 Tinjauan Persepsi Literaturneon erzNo ratings yet

- 06.clutch SystemDocument24 pages06.clutch SystemTony D'AngeloNo ratings yet

- Focus ClutchDocument8 pagesFocus ClutchJose Luis LopezNo ratings yet

- CK30 WM 03 ClutchDocument16 pagesCK30 WM 03 ClutchvixentdNo ratings yet

- Clutch: Section 5CDocument24 pagesClutch: Section 5CJarry PotterNo ratings yet

- 17 - Trouble DiagnosisDocument18 pages17 - Trouble DiagnosisFrederikusNo ratings yet

- 1999 Jeep TJ Wrangler Service Manual - 06. ClutchDocument14 pages1999 Jeep TJ Wrangler Service Manual - 06. Clutchbfranklin33100% (1)

- Activity Sheet SampleDocument5 pagesActivity Sheet SampleDhan GregorioNo ratings yet

- Clutch: Fig. 1 Clutch Pedal ComponentsDocument10 pagesClutch: Fig. 1 Clutch Pedal ComponentsPelis CloneNo ratings yet

- Volume 2 V80 Workshop ManualDocument440 pagesVolume 2 V80 Workshop Manualantonio wongNo ratings yet

- Trouble DiagnosisDocument22 pagesTrouble Diagnosisdmitry esaulkovNo ratings yet

- Z Clutch 6 - 1Document14 pagesZ Clutch 6 - 1helgith74No ratings yet

- Module 3 - Lesson 3 - MEEC 101A PDFDocument4 pagesModule 3 - Lesson 3 - MEEC 101A PDFErica May MundinaNo ratings yet

- Troubleshooting: LiningDocument48 pagesTroubleshooting: Liningplanner samulosNo ratings yet

- Ew60C - Steering System, TroubleshootingDocument2 pagesEw60C - Steering System, Troubleshootingmaintenance 2kpbNo ratings yet

- My First PresentationDocument23 pagesMy First Presentationjayant pathakNo ratings yet

- M35c ClutchDocument14 pagesM35c ClutchJesus TimaureNo ratings yet

- Clutch PDFDocument13 pagesClutch PDFNam TranNo ratings yet

- Fault Finding: Section F - TransmissionDocument1 pageFault Finding: Section F - TransmissionIonut GrozaNo ratings yet

- ClutchDocument14 pagesClutchArt DoeNo ratings yet

- Steering Clutch and BrakeDocument18 pagesSteering Clutch and BrakeLucky OkoteNo ratings yet

- Activity (Clutch Assembly)Document6 pagesActivity (Clutch Assembly)Ardelyn PaybanoNo ratings yet

- Activity (Clutch Assembly)Document6 pagesActivity (Clutch Assembly)Ardelyn PaybanoNo ratings yet

- Eclipse 2011 2.4LDocument99 pagesEclipse 2011 2.4LHarold SarmientoNo ratings yet

- Compresores SandenDocument81 pagesCompresores SandenMiguel Carlin JimenezNo ratings yet

- ClutchDocument16 pagesClutchChristian Linares AbreuNo ratings yet

- B234 Camshaft and TappetsDocument9 pagesB234 Camshaft and TappetsAndri OdeNo ratings yet

- Clutch PDFDocument20 pagesClutch PDFClaudio Godoy GallegosNo ratings yet

- 11-Brake System PDFDocument81 pages11-Brake System PDFAditiana SukadarusmanNo ratings yet

- Group 2 Operational Checks and TroubleshootingDocument3 pagesGroup 2 Operational Checks and TroubleshootingAndré TarginoNo ratings yet

- RM 64Document632 pagesRM 64Jabita Aguilera CabreraNo ratings yet

- Hyundai Excel X2 1989-1998 Clutch System CableDocument11 pagesHyundai Excel X2 1989-1998 Clutch System CableAshraf MuhmdNo ratings yet

- Motor OutlanderDocument62 pagesMotor OutlanderHillan VieiraNo ratings yet

- 38 EmbragueDocument52 pages38 EmbragueCarlos CandelaNo ratings yet

- Hyundai Santa FE (2005-2007) Workshop Manual - Clutch SystemDocument12 pagesHyundai Santa FE (2005-2007) Workshop Manual - Clutch SystemJenny Mora LeonNo ratings yet

- 02 RH40E UndercarriageDocument16 pages02 RH40E UndercarriageBladimir PadillaNo ratings yet

- Manual Transmission: Section 5BDocument48 pagesManual Transmission: Section 5BJose Luis Rodriguez CruzNo ratings yet

- Troubleshooting ClutchesDocument2 pagesTroubleshooting ClutchesjohnNo ratings yet

- Final Drive Troubleshooting: Symptom Problem Possible Cause SolutionDocument2 pagesFinal Drive Troubleshooting: Symptom Problem Possible Cause SolutionMohamad Nadzri YahayaNo ratings yet

- PL Clutch 6 - 1Document12 pagesPL Clutch 6 - 1Pelis CloneNo ratings yet

- Introduction To Prime MoverDocument45 pagesIntroduction To Prime Movermuthukumaran TanujNo ratings yet

- Pump, Troubleshooting: Service InformationDocument1 pagePump, Troubleshooting: Service InformationPreett Rajin MenabungNo ratings yet

- TUCSON (JM) 2008 G 2.7 DOHC Clutch SystemDocument20 pagesTUCSON (JM) 2008 G 2.7 DOHC Clutch Systemrobin machadoNo ratings yet

- ClutchDocument25 pagesClutchBob DesmetNo ratings yet

- Clutch Master Cylinder: FunctionDocument4 pagesClutch Master Cylinder: FunctionNguyễn DũngNo ratings yet

- Gr21 EmbragueDocument26 pagesGr21 EmbragueJosue Alvarez VegaNo ratings yet

- Endeavor 2010 3.8LDocument95 pagesEndeavor 2010 3.8Lgersoncoimbra010905No ratings yet

- Galant-2009 5-2 4LDocument103 pagesGalant-2009 5-2 4LRuben MoncalunaNo ratings yet

- Eclipse 2008 2.4LDocument142 pagesEclipse 2008 2.4LDiego.S SanchezNo ratings yet

- Clutch JL430 : Structure and Working Principles of Clutch CL-2Document21 pagesClutch JL430 : Structure and Working Principles of Clutch CL-2Mauricio IbañezNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- ChasisDocument43 pagesChasisrafael alcantaraNo ratings yet

- H13 EngineDocument50 pagesH13 Enginerafael alcantaraNo ratings yet

- ABS Trouble ShootingDocument10 pagesABS Trouble Shootingrafael alcantaraNo ratings yet

- Manual Fiesta Motores Duratec PDFDocument320 pagesManual Fiesta Motores Duratec PDFrafael alcantaraNo ratings yet

- New X-431 (3G) PDFDocument33 pagesNew X-431 (3G) PDFrafael alcantaraNo ratings yet

- Matiz Manualll PDFDocument37 pagesMatiz Manualll PDFrafael alcantaraNo ratings yet

- H13-Electronic Injection PDFDocument101 pagesH13-Electronic Injection PDFrafael alcantaraNo ratings yet

- Pulsar 150 150R 180 Abs PDFDocument44 pagesPulsar 150 150R 180 Abs PDFMuhammed AlwaniNo ratings yet

- Suzuki Swift SportDocument17 pagesSuzuki Swift SportleciellemonNo ratings yet

- Types of Roads Road ComponentsDocument28 pagesTypes of Roads Road ComponentsEllieNo ratings yet

- Shop Manual: 1. General Information 2. Fuel & Engine 3. Frame & Chassis 4. Electrical SystemDocument31 pagesShop Manual: 1. General Information 2. Fuel & Engine 3. Frame & Chassis 4. Electrical SystemArun Risal50% (2)

- Shock AbsorberDocument21 pagesShock AbsorberSlamet ArifinNo ratings yet

- Letter From Chairman To Railway Board ChairmanDocument4 pagesLetter From Chairman To Railway Board ChairmanShashank SrivastavaNo ratings yet

- Zachary Haverkamp - Research EssayDocument6 pagesZachary Haverkamp - Research Essayapi-537739326No ratings yet

- Name: Obias, Ricci Eugenia Date: August, 31 2021 Exercise No. 1Document4 pagesName: Obias, Ricci Eugenia Date: August, 31 2021 Exercise No. 1Ricci ObiasNo ratings yet

- Determination of Tramway Wheel and Rail Profiles To Minimise DerailmentDocument122 pagesDetermination of Tramway Wheel and Rail Profiles To Minimise Derailmentnandoreis123No ratings yet

- Selection of Suspension Arrangement of Traction Motors A Right Approach PDFDocument13 pagesSelection of Suspension Arrangement of Traction Motors A Right Approach PDFRamesh YadlaNo ratings yet

- Jeppview For Windows: List of Pages in This Trip KitDocument24 pagesJeppview For Windows: List of Pages in This Trip KitCatalin CiocarlanNo ratings yet

- Design of All Terrain VehicleDocument13 pagesDesign of All Terrain VehiclekalaiNo ratings yet

- TOPIC 1 DCC3113 JUN2020 - Introduction To Highway and TrafficDocument42 pagesTOPIC 1 DCC3113 JUN2020 - Introduction To Highway and TrafficMuhd FareezNo ratings yet

- Hatz 2g40Document8 pagesHatz 2g40Tesla EcNo ratings yet

- How To Prevent Car AccidentsDocument2 pagesHow To Prevent Car AccidentsNashaz ZainonNo ratings yet

- Crossfire XZ250R Manual Download PDFDocument66 pagesCrossfire XZ250R Manual Download PDFFrank AvilaNo ratings yet

- Examen de Ingles Franco A. Ticona M. Grupo ADocument2 pagesExamen de Ingles Franco A. Ticona M. Grupo AFranco A. Teicon67% (3)

- Balancing of Radial and V-Shape Engine by Ijaz AliDocument20 pagesBalancing of Radial and V-Shape Engine by Ijaz AliMuhammad QasimNo ratings yet

- DVAPower Website K-SERIESDocument82 pagesDVAPower Website K-SERIESstefan.vince536100% (1)

- Ringfeder Towing Eyes BrochureDocument4 pagesRingfeder Towing Eyes BrochureJasmin BijedicNo ratings yet

- Grove TMS700B NA BrochureDocument26 pagesGrove TMS700B NA BrochureNELSON CHAPARRONo ratings yet

- GS4 UserDocument287 pagesGS4 UserIgnacioNo ratings yet

- 1999-05 - Volvo - S40 - 5 Cylinders 2.5L FI Turbo DOHC - 32993902 PDFDocument121 pages1999-05 - Volvo - S40 - 5 Cylinders 2.5L FI Turbo DOHC - 32993902 PDFGolf variant PineappleNo ratings yet

- Mobileye New BrochureDocument2 pagesMobileye New Brochureradu_pop_52No ratings yet

- RCC T Girder & Deck Slab For Major Bridge 02 - Deck-21Document1 pageRCC T Girder & Deck Slab For Major Bridge 02 - Deck-21mrinal kayalNo ratings yet

- Suzuki PricelistDocument5 pagesSuzuki PricelistjohnNo ratings yet