Professional Documents

Culture Documents

Brochure Desiccant Dryers D - IL and D - IB English Version 6 PDF

Brochure Desiccant Dryers D - IL and D - IB English Version 6 PDF

Uploaded by

Shaka Shalahuddin Shantika PutraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochure Desiccant Dryers D - IL and D - IB English Version 6 PDF

Brochure Desiccant Dryers D - IL and D - IB English Version 6 PDF

Uploaded by

Shaka Shalahuddin Shantika PutraCopyright:

Available Formats

Ingersoll Rand

Heatless and Heated Blower Desiccant Air Dryers

160-14,900 m3/hr

Ingersoll Rand Industrial Technologies provides products, services and solutions that enhance our customers'

energy efficiency, productivity and operations. Our diverse and innovative products range from complete

compressed air systems, tools and pumps to material and fluid handling systems and environmentally friendly

microturbines. We also enhance productivity through solutions created by Club Car®, the global leader in golf

and utility vehicles for businesses and individuals.

www.ingersollrandproducts.com

Ingersoll Rand Industrial Technologies

Swan Lane, Hindley Green

Wigan WN2 4EZ, UK

Tel: +44 (0) 1942 257171

Fax: +44 (0) 1942 254162 Member of Pneurop

Email: asgesawebleads@irco.com

Ingersoll Rand compressors are not designed, intended or approved for breathing air applications. Ingersoll Rand does not approve specialised equipment for

breathing air applications and assumes no responsibility or liability for compressors used for breathing air service.

Nothing contained on these pages is intended to extend any warranty or representation, expressed or implied, regarding the product described herein. Any such

warranties or other terms and conditions of sale of product shall be in accordance with Ingersoll Rand's standard terms and conditions of sale for such products,

which are available upon request.

Product improvement is a continuing goal at Ingersoll Rand. Designs and specifications are subject to change without notice or obligation.

Printed in the UK. October 2009 © 2009 Ingersoll-Rand Company Limited

Innovative Design is Now Within Reach

Ingersoll Rand

Innovative Controls and Design Lower Energy Costs A heated blower dryer with EMS can save

Ingersoll Rand heatless and heated blower desiccant Our new dryers offer the state-of-the-art Energy Management you over ¤20,000 in just 3 years!

dryers—are engineered for easy access, maximum System (EMS) that maximises energy efficiency while

¤40,320

maintaining a constant dew point. By using a humidity sensor

efficiency and long life—are delivered in a to continuously monitor the dew point, EMS minimises the ¤29,916

state-of-the-art low profile package, making compressed air used in regeneration, and optimises heater ¤19,944

and blower operation.

installation and operation a snap!

Heated blower models are equipped with solid state soft

starters that limit inrush current to ensure a smooth start

and longer blower motor life.

The dryers are engineered for low pressure drop through

valve selection, tower size and filter design.

Energy

Heated Blower Dryer with EMS

Costs

On heated blower models, the heater and blower are Heated Blower Dryer

controlled by the outlet regeneration temperature that Heatless Dryer

Our low profile design allows for upright Low profile design Traditional design shuts off to save electrical power once desiccant has been These calculations are approximations based on the following

shipping and transportation. assumptions: Heatless model D3300IL, Heated model D3200IB,

thoroughly regenerated. 55 m3/min, 1,800 CFM, 400 kW Compressor Motor, ¤0.07 per kW/hr

80 hours per week, and 40 weeks per year.

Solid state relays provide precise heater control, reduced

Angled manifolds make valves

Low Profile for Easy Maintenance heating times and extended heater life.

easy to access and maintain

One look tells you that Ingersoll Rand

desiccant dryers are like no others. State-of-the-art Microprocessor Controller

Our low profile design provides easy ■ Maintains dryer performance at optimum levels, constantly

access to key maintenance points at monitors functions and provides maintenance alerts and

operator level for faster servicing and protection notification, minimising downtime.

less downtime. The lower silhouette also

allows upright shipment and facilitates ■ Matches the dryer control to the load/unload state of the

simpler installation. air compressor.

With manifolds angled toward the centre ■ Modbus compatible.

at operator level, the high performance

Digital Microprocessor Controller

valves are easily accessed for ■ LCD display for easy viewing.

maintenance. For example, a typical

diaphragm valve in a heatless dryer Heavy Duty Filters For Longevity

can be rebuilt in less than ten minutes, Heavy duty filters ■ Standard heavy duty pre-filters and after-filters extend

without removing the valve from desiccant life and provide maximum particle protection of

the manifold. the downstream air.

2 Desiccant Dryers Desiccant Dryers 3

Selecting the Right Desiccant Dryer

Heatless Desiccant Dryers

It’s all about choices. Whether it’s lower operating costs or To air system

Drying: (1) From the air compressor, the air

a lower capital investment, Ingersoll Rand has a desiccant enters the dryer through a pre-filter that removes Regeneration tower Drying tower

contaminates to protect the desiccant. (2) The air

dryer that fits your needs.

is directed through the drying tower. (3) The

desiccant removes moisture from the air through

What Differentiates Ingersoll Rand Desiccant Dryers Heatless dryers are lower in adsorption. (4) Dry air passes through an after-

capital investment, but require

Ingersoll Rand desiccant dryers are designed to virtually a small portion of the dried filter removing any contaminate particles before

compressed air to be diverted

eliminate costly production interruptions due to from the air system for desiccant entering into the air system. (5) A small amount

regeneration.

moisture. All of our dryers use twin desiccant towers and of the compressed air (15%) is redirected to the

strategically positioned valves for drying compressed air. regenerating tower.

Switching valves are normally open, while purge valves

are normally closed to allow air flow through the dryer in Regeneration: (1) Dry air flows in the reverse

case of power loss. Strategically-placed filters that direction through the regenerating tower,

remove oil and contaminants ensure only clean, dried air removing trapped moisture from the desiccant.

exits the dryer. Every dryer features an IP54 package, (2) Moist air exits the dryer through an exhaust

providing increased protection of electrical components, port equipped with a silencing muffler to

controls and displays. Both heatless and heated blower reduce noise.

Heated blower dryers have a

dryers have several standard features to ensure high higher initial investment, but From air compressor

with no or little diversion of

quality operation as well as options to customise dryers compressed air from the Heated Blower Desiccant Dryers

system for regeneration, they

to fit the needs of your air system. offer significantly lower Drying: (1) From the air compressor, the air From air compressor

operating costs.

enters the dryer through a pre-filter that removes

How Desiccant Dryers Work contaminates to protect the desiccant. (2) The air Drying tower Regeneration tower

Highly adsorbent desiccant removes moisture from is directed through the drying tower. (3) The

compressed air as it passes through the online dryer desiccant removes moisture from the air through

tower. The difference between our two technologies is adsorption. (4) The dry air passes through an

how moisture is desorbed from the desiccant after-filter removing any contaminate particles

Blower air intake

(regeneration) – see diagrams on page 5. before entering into the air system.

Features and Options Heatless Desiccant Dryer Heated Blower Desiccant Dryer Regeneration: (1) Ambient air enters through

Energy Management System (EMS) Option Standard the blower intake. (2) Air temperature is elevated

Compressed Air Used for Regeneration 15% 0% Heater

as air moves across the external heater. (3) The

Controller Digital Microprocessor Digital Microprocessor

Environmental Protection IP54 (Option for IP65) IP54 (Option for IP65) hot air is directed to the regenerating tower. (4)

Available Flow Range (2.8 m3/min - 55.9 m3/min) (8.9 m3/min - 248.6 m3/min)

Constant Pressure Dew Point -40°C (Option for -70°C) -40°C Hot air flows in the reverse direction through the

Included Filtration Heavy Duty Pre-filters & After-filters Heavy Duty Pre-filters & After-filters regenerating tower, removing the adsorbed

Pressure Rating 10 bar g 10 bar g

Tower Insulation Not Available Option moisture from the desiccant. (5) Moist air exits

Stainless Steel Control Lines Option Option

the dryer through an exhaust port equipped with

Dryer Bypass Option Option

Heatless Back-up Mode Not Applicable Standard a silencing muffler to reduce noise.

To air system

4 Desiccant Dryers Desiccant Dryers 5

Desiccant Dryer Features and Benefits So, how do you select the right desiccant dryer technology?

That depends on the variables, such as system demand,

compressed air capacity, air quality requirements and applicable

life cycle costs that are unique to your compressed air system.

A Microprocessor Controller Heatless Desiccant Dryer Specifications

Controls valve switching to correctly direct air flow and Flow Flow Dimensions

operation of blowers and heaters. Protects the dryer via Model -40°C PDP -70°C PDP In/Out Width Depth Height Weight

continuously monitoring operating parameters. B cfm m3/hr cfm m3/hr Connection mm mm mm kg

A

D160IL 94 160 75 128 1.0 BSP 1,029 762 1,600 241

N

B Environmental Protection D200IL 118 200 94 160 1.0 BSP 1,029 762 1,600 256

G

IP54 rating provides protection against dust and moisture D275IL 162 275 130 220 1.5 BSP 1,130 813 1,676 321

contamination (IP65 option for wash down applications). M D350IL 206 350 165 280 1.5 BSP 1,130 813 1,676 332

D500IL 294 500 236 400 2.0 BSP 1,232 813 1,702 419

C

C Motor Protection/Soft Starter (heated blower only) D700IL 412 700 330 560 2.0 BSP 1,334 813 1,727 506

Reduces inrush current and stress on the mechanical system. D900IL 530 900 424 720 2.0 BSP 1,435 864 2,083 710

F D

D1000IL 589 1,000 471 800 2.0 BSP 1,435 864 2,083 755

D Power Supply D1600IL 942 1,600 754 1,280 3.0 BSP 1,626 1,067 2,235 1,016

Dryers operate at 50 Hz (all models) or 60 Hz (optional). D2000IL 1,178 2,000 942 1,600 3.0 BSP 1,626 1,067 2,235 1,100

Pneumatic options also available on heatless models. D2500IL 1,472 2,500 1,178 2,000 DN100 1,994 1,397 2,057 1,350

E D3300IL 1,943 3,300 1,554 2,640 DN125 2,134 1,549 2,388 1,773

E Centrifugal Blower (heated blower only)

High performance centrifugal blower enables the use of Heated Blower Desiccant Dryer Specifications

ambient air for regeneration, eliminating compressed air loss.

Flow Dimensions

Model -40°C PDP Heater Blower In/Out Width Depth Height Weight

F High Performance Heater (heated blower only) cfm m3/hr kW kW Connection mm mm mm kg

Heats the air used for regeneration to increase the efficiency D500IB 294 500 6 3.0 1.5 BSP 1,334 813 1,727 670

of moisture removal. D900IB 530 900 12 4.0 2.0 BSP 1,435 864 2,023 958

D1400IB 824 1,400 18 6.0 3.0 BSP 1,626 1,194 2,184 1,451

G Desiccant D1800IB 1,060 1,800 24 9.0 3.0 BSP 1,994 1,219 2,032 1,710

Reliable high strength non-acidic desiccant provides maximum I D2200IB 1,295 2,220 24 9.0 3.0 BSP 1,994 1,219 2,032 1,857

performance and is easily stored and handled. L

D2600IB 1,531 2,600 30 15.0 3.0 BSP 2,134 1,397 2,337 2,504

J D3200IB 1,884 3,200 36 15.0 DN125 2,134 1,524 2,337 2,775

H Silencing Muffler D3900IB 2,296 3,900 45 15.0 DN125 2,134 1,524 2,337 3,138

Reduce the exhausted air noise level to ensure a D5300IB 3,120 5,300 60 18.5 DN150 2,438 1,676 2,489 4,417

worker-friendly environment. D7000IB 4,121 7,000 80 22.0 DN150 2,591 1,930 2,286 5,524

H K

D9300IB 5,475 9,300 100 30.0 DN150 3,505 2,210 2,464 6,072

I High Performance Valves

D10600IB 6,241 10,600 125 37.0 DN150 3,810 2,337 2,616 7,264

High performance butterfly valves with self-energised sealing

D14900IB 8,772 14,900 175 45.0 DN200 4,267 2,489 2,667 9,035

provide quick response and long life. The valves are centrally

angled for easy access. Referenced to 20°C and 1 bar a, inlet 35°C and 7 bar g. Maximum working pressure is 10 bar g.

Desiccant is factory-installed on all models except D5300IB to D14900IB. Dimensions and weights are approximate.

J Heavy Duty Filters

Pre-filter: High efficiency removing oil aerosol content down

to .01 mg/m3 @ 21°C protecting and extending the life of

the desiccant. Ingersoll Rand Ultra Care

After-filter: Heavy duty removing particles down to 1 micron

insuring high air quality downstream to the customer. Helping you maintain a healthy business

UltraCare five year maintenance and performance

K Safety Relief Valve M Humidity Sensor

The sensor is part of the EMS package that allows

agreements have been designed to be easy to understand

Protects the dryer from over pressurisation incase of fire.

continuous monitoring of the dew point. with absolutely no surprises.

L Desiccant Towers Find out more about protecting the heart of your business

The towers are rated for continuous 10 bar g operation. N Cool Sweep Mode (heated blower only)

contact your local distributor or Ingersoll Rand Sales office.

The digital controller turns the towers off and on for Reduces temperature and humidity spikes that may

regeneration regulation. occur during switching.

Desiccant Dryers 7

6 Desiccant Dryers

You might also like

- ZL50H Manual PDFDocument77 pagesZL50H Manual PDFMasoodKan75% (4)

- Specsheet Payne PY3Document28 pagesSpecsheet Payne PY3TheRandoGuyNo ratings yet

- Compressor CT Series (DD310)Document6 pagesCompressor CT Series (DD310)sanamehNo ratings yet

- Hisense Air Cond Catalogue 2019Document12 pagesHisense Air Cond Catalogue 2019Kukan Nallapen0% (2)

- Thermostar Refrigeration Air DryersDocument8 pagesThermostar Refrigeration Air DryersJesus GomezNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- CTI 203 STD 05 TocDocument1 pageCTI 203 STD 05 Tocpriyo21jw0% (2)

- Heatless Desiccant Dryers Bochure A4Document8 pagesHeatless Desiccant Dryers Bochure A4rodonganjaya22No ratings yet

- Irits 0323 Euen Heated Heatless Desiccant DryersDocument8 pagesIrits 0323 Euen Heated Heatless Desiccant DryersGibran Al HudaNo ratings yet

- Perkins CatalogsDocument16 pagesPerkins CatalogsAmit KudvaNo ratings yet

- F2HS-F59HS F40HS-F1800HS8Document4 pagesF2HS-F59HS F40HS-F1800HS8gouwstheuns6No ratings yet

- Turbo CompressorsDocument8 pagesTurbo CompressorskhibusinessdevelopmentNo ratings yet

- Compressoriserie TrinityDocument4 pagesCompressoriserie TrinityIngeniería AplicacionesNo ratings yet

- ERV Ceiling MountDocument8 pagesERV Ceiling MountTMVR's TVNo ratings yet

- RMF 111-160 ENG 6999200550 LowresDocument8 pagesRMF 111-160 ENG 6999200550 Lowresshafikul islamNo ratings yet

- Irits 1119 076 0823 Inen Oil Flooded Rotary Screw 200 355 KWDocument12 pagesIrits 1119 076 0823 Inen Oil Flooded Rotary Screw 200 355 KWsumit sutarNo ratings yet

- Modular Desiccant Dryers - USDocument3 pagesModular Desiccant Dryers - USHfksosnaaoNo ratings yet

- IR Desiccant Driers BrochureDocument3 pagesIR Desiccant Driers BrochureTom KleinNo ratings yet

- 2012 10 15 Infrafone LAND Broschyr WebDocument7 pages2012 10 15 Infrafone LAND Broschyr Webjromero_rpgNo ratings yet

- PDF Usdsd FSD DSD Esd FSD Series 12 2022-46-37070Document20 pagesPDF Usdsd FSD DSD Esd FSD Series 12 2022-46-37070Firman AldianNo ratings yet

- Ingersoll Rand Desiccant DryersDocument12 pagesIngersoll Rand Desiccant DryersAnonymous Jd6v1D6rNo ratings yet

- PubliciteDocument12 pagesPubliciteHugues DescharmesNo ratings yet

- Ingersoll Rand Desiccant Dryer Brochure JECDocument11 pagesIngersoll Rand Desiccant Dryer Brochure JECDen TseNo ratings yet

- Desiccant Air DryersDocument12 pagesDesiccant Air DryersVENICIO FERREIRA DE ALMEIDANo ratings yet

- Catalogo Split Central Convencional Ymsfzc0 (36 - 60) Baqkb-X Trifasico AhriDocument4 pagesCatalogo Split Central Convencional Ymsfzc0 (36 - 60) Baqkb-X Trifasico AhriLuis Carlos PardoNo ratings yet

- BE Engineering Guide YST Steam Turbine Chillers PDFDocument54 pagesBE Engineering Guide YST Steam Turbine Chillers PDFenlightened1718No ratings yet

- Kaeser Marine CompressorsDocument24 pagesKaeser Marine CompressorsMazhar SafdarNo ratings yet

- 114 Paper Industry en 170705Document12 pages114 Paper Industry en 170705Christian MendozaNo ratings yet

- Fresh Air Package UnitRTP BrochureDocument4 pagesFresh Air Package UnitRTP BrochurespsamcNo ratings yet

- Oilflooded 437 KwbrochurescreenDocument12 pagesOilflooded 437 KwbrochurescreenJose Miguel SánchezNo ratings yet

- NEW Wall Mounted KMTC ModelsDocument2 pagesNEW Wall Mounted KMTC ModelsFnBNo ratings yet

- Characteristics Winterwarm XR SeriesDocument4 pagesCharacteristics Winterwarm XR SeriesVictor GheorgheNo ratings yet

- Marine Compressed Air Systems: KAESER S Reliable Marine Compressors With Sigma ProfileDocument13 pagesMarine Compressed Air Systems: KAESER S Reliable Marine Compressors With Sigma ProfileMario SilvaNo ratings yet

- Document Qmgcqvj3cd03hbbb2pauclfj1rDocument16 pagesDocument Qmgcqvj3cd03hbbb2pauclfj1rJucimar CarpeNo ratings yet

- SM Serie LeafletDocument16 pagesSM Serie LeafletJANo ratings yet

- CRD SzaritokDocument4 pagesCRD SzaritoknarimanNo ratings yet

- Rotary Screw Compressors ASD Series: With The World-Renowned SIGMA PROFILEDocument5 pagesRotary Screw Compressors ASD Series: With The World-Renowned SIGMA PROFILELuis Rodrigo GarciaNo ratings yet

- 001 Booster en 20190214 3Document7 pages001 Booster en 20190214 3ahmedshaaban922No ratings yet

- SM Series Kaeser CompressorrenDocument16 pagesSM Series Kaeser CompressorrenarieprachmanNo ratings yet

- Irits 0818079 Euenoilflooded 45160 Kwbrochurea 4Document12 pagesIrits 0818079 Euenoilflooded 45160 Kwbrochurea 4Santiago RubioNo ratings yet

- 058 Rev2 Sahara HOC Air Dryer Brochure 02 2019Document22 pages058 Rev2 Sahara HOC Air Dryer Brochure 02 2019Israel PerezNo ratings yet

- Assignment HVAC LATESTDocument18 pagesAssignment HVAC LATESTajmalnasa99No ratings yet

- Screw Compressors: BSD SeriesDocument6 pagesScrew Compressors: BSD Seriesaplicacao.evolucaoNo ratings yet

- Irits 1119 076 Euen 1021 160 355 KWDocument12 pagesIrits 1119 076 Euen 1021 160 355 KWZohreh Malek HosseiniNo ratings yet

- AGRE IndustrialPistons Leaflet en LRDocument20 pagesAGRE IndustrialPistons Leaflet en LRmogwai71No ratings yet

- Irits 0223 001 Euen 75 22 KW Oil FloodedDocument12 pagesIrits 0223 001 Euen 75 22 KW Oil FloodedVăn HùngNo ratings yet

- 016 - Mikropor Mcy Brosur-Avr - 200821Document11 pages016 - Mikropor Mcy Brosur-Avr - 200821Mohsen ParpinchiNo ratings yet

- Compresor Keaser DSD y DFDDocument20 pagesCompresor Keaser DSD y DFDmfonloz11No ratings yet

- SB PS-Turbo Ver.2.1 enDocument5 pagesSB PS-Turbo Ver.2.1 engreyhound726415No ratings yet

- The Power of A Legend.: Airsource and Airsource Plus Portable CompressorsDocument4 pagesThe Power of A Legend.: Airsource and Airsource Plus Portable CompressorsJamal HabbasNo ratings yet

- Catalog KaeserDocument24 pagesCatalog KaeserAnonymous mZEUquNo ratings yet

- Brosura Completa R2.2-5.5IUDocument6 pagesBrosura Completa R2.2-5.5IUcristiNo ratings yet

- AHUDocument16 pagesAHUEddieNo ratings yet

- Catalogue ORION Heatless Air Dryer General D AG02 - 201311 PDFDocument98 pagesCatalogue ORION Heatless Air Dryer General D AG02 - 201311 PDFAde SurahmanNo ratings yet

- DSDDocument15 pagesDSDIvan KokićNo ratings yet

- Screw Compressors: ASD SeriesDocument6 pagesScrew Compressors: ASD Seriesaplicacao.evolucaoNo ratings yet

- GD New Frame 6 12pp WorkDocument12 pagesGD New Frame 6 12pp WorkAndres AlejandroNo ratings yet

- SM Series P 651 24 HPC 4 18Document9 pagesSM Series P 651 24 HPC 4 18jose pedro garduza sosaNo ratings yet

- Poster sgt6 5000f SeriesDocument1 pagePoster sgt6 5000f SeriesHmed Ben MohamedNo ratings yet

- Bryant - 582A - 2000Document24 pagesBryant - 582A - 2000bobNo ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- New Package BrochureDocument10 pagesNew Package Brochurepriyo21jwNo ratings yet

- Sium. ASTM STP 833. Philadelphia: American Society For Testing and MaterialsDocument1 pageSium. ASTM STP 833. Philadelphia: American Society For Testing and Materialspriyo21jwNo ratings yet

- Engineering Metrology and Measurements - 5th Sem Mechanical & Automobile SyllabusDocument1 pageEngineering Metrology and Measurements - 5th Sem Mechanical & Automobile Syllabuspriyo21jwNo ratings yet

- Presentasi Praktikum Fenomena Dasar MesinDocument25 pagesPresentasi Praktikum Fenomena Dasar Mesinpriyo21jwNo ratings yet

- Minimizing Angular Backlash of A Multi-Stage Gear TrainDocument6 pagesMinimizing Angular Backlash of A Multi-Stage Gear TrainJose Ancasi EspinalNo ratings yet

- Cracking in Concrete Structures - Calculation of Crack Width and Crack SpacingDocument48 pagesCracking in Concrete Structures - Calculation of Crack Width and Crack SpacingForood TorabianNo ratings yet

- Heat Transfer in Bioreactor: Manam Walait Lecturer FLS, UCP LahoreDocument8 pagesHeat Transfer in Bioreactor: Manam Walait Lecturer FLS, UCP LahoreJawadNo ratings yet

- Installation-Operation-Manual-30RBM RBP 160 520 PDFDocument72 pagesInstallation-Operation-Manual-30RBM RBP 160 520 PDFSlavisa StankovicNo ratings yet

- Study of Microstructure Degradation of Boiler Tubes Due To Creep For Remaining Life AnalysisDocument7 pagesStudy of Microstructure Degradation of Boiler Tubes Due To Creep For Remaining Life AnalysisRaka DaffaNo ratings yet

- CE12 - Uplift Pressure Under Hydraulic StructuresDocument17 pagesCE12 - Uplift Pressure Under Hydraulic StructuresLawliet LawfordNo ratings yet

- Group 14 - Report 4Document49 pagesGroup 14 - Report 4Akash ByjuNo ratings yet

- ML 1500 Product ManualDocument9 pagesML 1500 Product Manualhector castellanos rNo ratings yet

- Operation and Maintenance ManualDocument40 pagesOperation and Maintenance ManualRicardo PinheiroNo ratings yet

- DME Objective QuestionsDocument103 pagesDME Objective QuestionsaruchellamNo ratings yet

- Cylinder Combustion SensorDocument4 pagesCylinder Combustion SensorgosoriobNo ratings yet

- Interacción Tabique PórticoDocument225 pagesInteracción Tabique Pórticodalex_tauro93No ratings yet

- Pedrollo 2CPDocument8 pagesPedrollo 2CPBenicio Joaquín Ferrero BrebesNo ratings yet

- Ammonia Detection System Codes and Design Specifications PDFDocument7 pagesAmmonia Detection System Codes and Design Specifications PDFGilberto SanchezNo ratings yet

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasNo ratings yet

- Service Sheet - Mercedes Benz W211Document8 pagesService Sheet - Mercedes Benz W211Pedro ViegasNo ratings yet

- Diverter Damper Systems - BrochureDocument8 pagesDiverter Damper Systems - Brochuregionizz100% (1)

- Brazing of Copper To Stainless Steel With A Low Silver Content Brazing Filler Metal 1757-899X 61 1 012016Document7 pagesBrazing of Copper To Stainless Steel With A Low Silver Content Brazing Filler Metal 1757-899X 61 1 012016mohammed sabeehNo ratings yet

- Hall Ticket Sonu Copy 2Document2 pagesHall Ticket Sonu Copy 21422 Navin AmberkarNo ratings yet

- Module - 2 Physics of Welding ArcDocument31 pagesModule - 2 Physics of Welding ArcRajesh Shah0% (1)

- CRS3 3Document18 pagesCRS3 3prueba100% (1)

- Hydro Mechanics QuestionsDocument12 pagesHydro Mechanics Questionserudite_0206No ratings yet

- Well Intervention CoilHose A4Document2 pagesWell Intervention CoilHose A4William EvansNo ratings yet

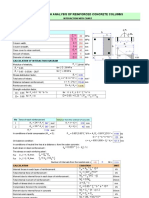

- Strength Analysis of Reinforced Concrete Columns: Interaction With ChartDocument7 pagesStrength Analysis of Reinforced Concrete Columns: Interaction With ChartStructural SpreadsheetsNo ratings yet

- Ripper PDFDocument52 pagesRipper PDFСергей Горовой100% (3)

- Submittal: Job Title: Elevation: (FT) Date: Submitted By: John DoeDocument35 pagesSubmittal: Job Title: Elevation: (FT) Date: Submitted By: John Doejfher87No ratings yet

- Academic Site Visit Report On Design of Steel Structures at Kimaya SteelDocument16 pagesAcademic Site Visit Report On Design of Steel Structures at Kimaya SteelKiranMDeoreNo ratings yet

- Dynamics of Machinery: Department of Mechanical EngineeringDocument19 pagesDynamics of Machinery: Department of Mechanical EngineeringEr Suraj HulkeNo ratings yet

- Research PaperDocument5 pagesResearch PaperJeevaNo ratings yet