Professional Documents

Culture Documents

Thermal Endurance Test

Thermal Endurance Test

Uploaded by

sabaris ksOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Endurance Test

Thermal Endurance Test

Uploaded by

sabaris ksCopyright:

Available Formats

Thermal endurance test

Thermal endurance test could be done using the below listed three cases depending upon the

ambient temp and the service temp.

Select the appropriate Case to test the sample to:

Case #1 (When the maximum service temperature is less than or equal to 75°C)

The sample(s) will be subjected to a thermal endurance to heat to continuous storage

for four weeks in an environment of __________ (90 ± 5) % relative humidity and at a

temperature of ____________°C (20 ± 2K above the maximum service temperature,

but at least 80°C).

Case #2 For Category 3( zone 2) apparatus (When the maximum service temperature is

less than or equal to 75°C)

The sample(s) will be subjected to a thermal endurance to heat to continuous storage

for four weeks in an environment of __________ (90 ± 5) % relative humidity and at a

temperature of ____________°C (10 ±2K above the maximum service temperature,

but at least 80°C).

Case #3 (When the maximum service temperature is greater than 75°C)

The sample(s) will be subjected to a thermal endurance to heat to continuous

storage for two weeks in an environment of ___________ (90 ± 5) % relative

humidity and at a temperature of _________°C (95 ± 2°C).

Followed by at least two weeks exposure at a temperature of ___________ °C (20

±2K higher than the maximum service temperature).

After subjecting the sample(s) to the selected case above, the sample(s) was subjected to the

following cold test.

The sample(s) will be subjected to a thermal endurance to cold test for 24 hrs in an

environment of __________°C (corresponding to the minimum service temperature

reduced by at least 5 K but at most 10 K).

Impact test:

The impact was created by dropping a 1 kg weight, concentrated at a 1 inch (25.4 mm)

diameter ball of hardened steel, from the height shown onto the surface indicated.

Dust exclusion test:

The test sample was suspended in a circulating dust atmosphere of 200 mesh talc while

connected to vacuum pump adjusted to draw a vacuum of _____ mBar on the sample.

The test was continued for ____ (T1) hours at an average air extraction rate of _____ (R3)

volumes per hours. At the conclusion of the test, excess dust was removed from the

sample exterior and the sample was opened and evaluated as follows:

IP5X - The enclosure excluded the entry of dust in sufficient quantity to interfere with

satisfactory operation.

IP6X - The enclosure excluded the entry of dust.

Unsatisfactory - The sample did not exclude the entry of dust in accordance with either

of the above evaluations.

You might also like

- VDA 270 1992-10 Odor Test Deterination of The Odour Characteristics PDFDocument4 pagesVDA 270 1992-10 Odor Test Deterination of The Odour Characteristics PDFsabaris ks100% (1)

- Astm D2961Document2 pagesAstm D2961hesham_tm3658No ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Astm D2584Document3 pagesAstm D2584kbrozzzNo ratings yet

- 野村商会 7043125SH1-SP1-R&D-77G Ver0Document9 pages野村商会 7043125SH1-SP1-R&D-77G Ver0Anonymous RgLs9INo ratings yet

- D2893Document3 pagesD2893rimi7alNo ratings yet

- Volatile Matter in Green Petroleum Coke Quartz Crucible ProcedureDocument4 pagesVolatile Matter in Green Petroleum Coke Quartz Crucible ProcedureAli VarmazyarNo ratings yet

- E145 PDFDocument2 pagesE145 PDFcenkunal100% (3)

- Physical and Chemical Methods of Testing Waste Water - Is 3025 - Part 15Document2 pagesPhysical and Chemical Methods of Testing Waste Water - Is 3025 - Part 15madhuwadiNo ratings yet

- Is-3025-Part-15-1984-Tests of Water For Total Residue (Total Solids - Dissolved and Suspended)Document2 pagesIs-3025-Part-15-1984-Tests of Water For Total Residue (Total Solids - Dissolved and Suspended)Sachin PawarNo ratings yet

- NT Build 485 (Edition 2)Document6 pagesNT Build 485 (Edition 2)bkollarou9632No ratings yet

- D 3236 - 88 r99 - RdmymzytodhsotkDocument8 pagesD 3236 - 88 r99 - Rdmymzytodhsotkjamaljamal20No ratings yet

- Astm D 5865-04Document12 pagesAstm D 5865-04Luis Alberto Curtidor GuataquiNo ratings yet

- AutoclaveDocument18 pagesAutoclaveGorwadiya_Hite_1818No ratings yet

- Professional Standard For Ferrous Metallurgy of The People's Republic of ChinaDocument8 pagesProfessional Standard For Ferrous Metallurgy of The People's Republic of Chinabobby chenNo ratings yet

- Bitumen TestDocument6 pagesBitumen TestSayal SattarNo ratings yet

- 8.material Finer Than 75 MicronDocument1 page8.material Finer Than 75 MicronSamrendra UdgirkarNo ratings yet

- Method 2.2 2014Document4 pagesMethod 2.2 2014FelisbertoNo ratings yet

- .Archivetemptest 4 - Flash and Fire Point Test (By Cleveland Open Cup)Document9 pages.Archivetemptest 4 - Flash and Fire Point Test (By Cleveland Open Cup)Sadon B AsyNo ratings yet

- Freeze Testing - PQS E003 RF03-VP - 20150916Document10 pagesFreeze Testing - PQS E003 RF03-VP - 20150916DiplomadoEnTecnicasCromatograficasNo ratings yet

- Flash Point and Fire Point of Liquids by Tag Open-Cup ApparatusDocument8 pagesFlash Point and Fire Point of Liquids by Tag Open-Cup Apparatusmanox007No ratings yet

- E102 PDFDocument3 pagesE102 PDFGovind RajNo ratings yet

- TunnelDocument2 pagesTunnelMahesh MahiNo ratings yet

- Jedec Standard No. 22-A110 Test Method A110 Highly-Accelerated Temperature and Humidity Stress Test (Hast) 1.0 PurposeDocument5 pagesJedec Standard No. 22-A110 Test Method A110 Highly-Accelerated Temperature and Humidity Stress Test (Hast) 1.0 PurposeAylia RizviNo ratings yet

- 320 Other 1210 2 10 20180111Document10 pages320 Other 1210 2 10 20180111Vivek PrasadNo ratings yet

- D 938 - 92 R98 - Rdkzoc05mli5oaDocument2 pagesD 938 - 92 R98 - Rdkzoc05mli5oaStuartNo ratings yet

- D938Document2 pagesD938rpajaro75No ratings yet

- InfoBulletin01 Fuels v1111Document4 pagesInfoBulletin01 Fuels v1111Nicholas KoutsouvanosNo ratings yet

- C566Document3 pagesC566Jonathan Mendoza Chavez100% (1)

- Standard Test Method For Moisture in The Analysis Sample of Coal and CokeDocument7 pagesStandard Test Method For Moisture in The Analysis Sample of Coal and CokemuchtarNo ratings yet

- Determining The Water Vapor Sorption of Unfaced Mineral Fiber InsulationDocument3 pagesDetermining The Water Vapor Sorption of Unfaced Mineral Fiber Insulationdinhtung2210100% (1)

- c3 Accelerated Aging Tests 10Document10 pagesc3 Accelerated Aging Tests 10thinker_No ratings yet

- D5972Document5 pagesD5972rimi7alNo ratings yet

- Interpretation of DSC Curves in Polymer Analysis 2000 - ToledoDocument0 pagesInterpretation of DSC Curves in Polymer Analysis 2000 - ToledoyrecoverNo ratings yet

- Autoclave MethodDocument16 pagesAutoclave MethodGretta100% (1)

- Standard Atmosphere For Measuring and TestingDocument2 pagesStandard Atmosphere For Measuring and TestingDinh Viet HaiNo ratings yet

- Me-Lab (Ass#1-Midterm)Document8 pagesMe-Lab (Ass#1-Midterm)Jeffrey RegondolaNo ratings yet

- ASTM D56-16a Procedural OutlineDocument10 pagesASTM D56-16a Procedural Outlinederek vaughnNo ratings yet

- 2 AGC SamplingDocument25 pages2 AGC Samplingmahmudkurnia88No ratings yet

- ASTMD937-97 PetrolatumDocument2 pagesASTMD937-97 Petrolatuminfinity1200100% (1)

- D 2669Document5 pagesD 2669Asep TheaNo ratings yet

- Automated Temperature Controller For ATEDocument1 pageAutomated Temperature Controller For ATEGrace LatNo ratings yet

- Generator Thermal LifeDocument2 pagesGenerator Thermal LifelunikmirNo ratings yet

- ASTM D3173 - Standard Test Method For Moisture in The Analysis Sample of Coal and CokeDocument3 pagesASTM D3173 - Standard Test Method For Moisture in The Analysis Sample of Coal and CokeFabian E. Quesada-Plata80% (5)

- Specific Heat of Liquids and Solids: Standard Test Method ForDocument6 pagesSpecific Heat of Liquids and Solids: Standard Test Method ForJean-Patrice DeliaNo ratings yet

- Thermal Conductivity of Refractory Brick: Standard Test Method ForDocument3 pagesThermal Conductivity of Refractory Brick: Standard Test Method ForStuartNo ratings yet

- Cui-N95 Disinfection and Resuse 2020-3-25Document8 pagesCui-N95 Disinfection and Resuse 2020-3-25dian prasetyaniNo ratings yet

- C201Document6 pagesC201maria tNo ratings yet

- D3173Document2 pagesD3173Timothy Ferguson100% (1)

- (Modified AASHTO T 327) : Constant Mass - Test Samples Dried at A Temperature of 230 9ºF (110 5ºC) To A ConditionDocument6 pages(Modified AASHTO T 327) : Constant Mass - Test Samples Dried at A Temperature of 230 9ºF (110 5ºC) To A Conditiontmt_salesNo ratings yet

- UL Subject 2775 Test Summary Electrical UnitsDocument2 pagesUL Subject 2775 Test Summary Electrical UnitsKhaled OmarNo ratings yet

- Muhamad Najat: Flash & Fire Point TestDocument7 pagesMuhamad Najat: Flash & Fire Point TestAso M. HawramiNo ratings yet

- D 6801 - 02 - Rdy4mdetmdiDocument4 pagesD 6801 - 02 - Rdy4mdetmdimorchedtounsiNo ratings yet

- Understanding PsychrometricDocument19 pagesUnderstanding Psychrometricpanji uteNo ratings yet

- Astm D - 127Document2 pagesAstm D - 127wjawichNo ratings yet

- D 6207-97 Test Method For Dimensional Stability of Fabrics TDocument6 pagesD 6207-97 Test Method For Dimensional Stability of Fabrics TAnonymous UoRu4s0% (1)

- T 103-08 Standard Method of Test For Soundness of Aggregates by Freezing and ThawingDocument6 pagesT 103-08 Standard Method of Test For Soundness of Aggregates by Freezing and ThawingMelissa SammyNo ratings yet

- Minimum Number of SamplesDocument5 pagesMinimum Number of SamplesEdwin KohNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Class No. 55 10 4 Contact Corrosion From Elastomers and Art Materials in Connection With Light Metals December 2002Document2 pagesClass No. 55 10 4 Contact Corrosion From Elastomers and Art Materials in Connection With Light Metals December 2002sabaris ksNo ratings yet

- ASTM F38 Gaskets Creep.Document8 pagesASTM F38 Gaskets Creep.sabaris ksNo ratings yet

- Disclosure To Promote The Right To InformationDocument9 pagesDisclosure To Promote The Right To Informationsabaris ksNo ratings yet

- 1 DSC ISO - 11357-3 - 2018 (En)Document12 pages1 DSC ISO - 11357-3 - 2018 (En)sabaris ksNo ratings yet

- Tensile Properties Astm D880-12Document12 pagesTensile Properties Astm D880-12sabaris ksNo ratings yet

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To Informationsabaris ksNo ratings yet

- 8 PDFDocument14 pages8 PDFsabaris ksNo ratings yet

- Disclosure To Promote The Right To InformationDocument12 pagesDisclosure To Promote The Right To Informationsabaris ksNo ratings yet

- Jis D0203 PDFDocument6 pagesJis D0203 PDFsabaris ksNo ratings yet

- Ol KKFN MPP ?kuro Iksyhbfkkbyhu (,P-Mh-Ih-Bz-) Cqus Dim+S Ls Cus Frjiky Fof'Kf"VDocument14 pagesOl KKFN MPP ?kuro Iksyhbfkkbyhu (,P-Mh-Ih-Bz-) Cqus Dim+S Ls Cus Frjiky Fof'Kf"Vsabaris ksNo ratings yet

- Iso 9513 PDFDocument19 pagesIso 9513 PDFsabaris ksNo ratings yet

- 10 PDFDocument12 pages10 PDFsabaris ksNo ratings yet

- 9 PDFDocument8 pages9 PDFsabaris ksNo ratings yet

- Disclosure To Promote The Right To InformationDocument32 pagesDisclosure To Promote The Right To Informationsabaris ksNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To Informationsabaris ksNo ratings yet

- Disclosure To Promote The Right To Information: IS 6655 (1972) : Methods of Test For Sulphur (CHD 1: Inorganic Chemicals)Document21 pagesDisclosure To Promote The Right To Information: IS 6655 (1972) : Methods of Test For Sulphur (CHD 1: Inorganic Chemicals)sabaris ksNo ratings yet

- Disclosure To Promote The Right To InformationDocument10 pagesDisclosure To Promote The Right To Informationsabaris ksNo ratings yet

- Jis D0205 1987 PDFDocument52 pagesJis D0205 1987 PDFsabaris ksNo ratings yet

- IS 7016 Part 10Document11 pagesIS 7016 Part 10sabaris ksNo ratings yet

- WRE and Transportation Mains QuestionsDocument3 pagesWRE and Transportation Mains QuestionsICE Group of Education BhopalNo ratings yet

- ADU Financing GuideDocument62 pagesADU Financing GuideDavidNo ratings yet

- Microorganisms in The EnvironmentDocument7 pagesMicroorganisms in The EnvironmentvandanakakatkarNo ratings yet

- AP Practice Test - BreakdownDocument4 pagesAP Practice Test - BreakdowncheyNo ratings yet

- Raúl Edgardo Macchiavelli: Raul - Macchiavelli@upr - EduDocument53 pagesRaúl Edgardo Macchiavelli: Raul - Macchiavelli@upr - EduDhaval patelNo ratings yet

- ET-77 MSDS. - Online Contact CleanerDocument4 pagesET-77 MSDS. - Online Contact CleanerVishnu NNo ratings yet

- Checklist of Ants Silent Valley National Park, Western Ghats, KeralaDocument12 pagesChecklist of Ants Silent Valley National Park, Western Ghats, KeralaVishal VijayanNo ratings yet

- Literature Review On RainfallDocument7 pagesLiterature Review On Rainfallc5rc7ppr100% (1)

- Case Study On Plant Location and Plant Layout of Pharmaceutical IndustryDocument10 pagesCase Study On Plant Location and Plant Layout of Pharmaceutical IndustryJfjf86% (7)

- 39 390124347 883010rbcdilutingfluid (Hayems) MSDS PDFDocument6 pages39 390124347 883010rbcdilutingfluid (Hayems) MSDS PDFryujinNo ratings yet

- Biomass BoilersDocument57 pagesBiomass BoilersBinh NgoNo ratings yet

- Icap Report Web FinalDocument173 pagesIcap Report Web Finalapi-530265629No ratings yet

- Polymers: Production of Fuel From Plastic Waste: A Feasible BusinessDocument9 pagesPolymers: Production of Fuel From Plastic Waste: A Feasible BusinessBipin KumarNo ratings yet

- The 2020 Re-Excavation of Callao Cave NortheasternDocument56 pagesThe 2020 Re-Excavation of Callao Cave NortheasternFham GCNo ratings yet

- Els11 q2 Mod1 History of The EarthDocument28 pagesEls11 q2 Mod1 History of The EarthPaulene May Vargas33% (3)

- Levelized Cost of Energy Calculation - BV - ENDocument16 pagesLevelized Cost of Energy Calculation - BV - ENpankajmayNo ratings yet

- CCAA Environmental Guideline FinalDocument13 pagesCCAA Environmental Guideline FinalRaza Muhammad SoomroNo ratings yet

- Soraya Folley Final Fall 2017Document4 pagesSoraya Folley Final Fall 2017api-541467212No ratings yet

- Formulir Kualifikasi - Material - PTK007 Rev 3 - 07102016 MJ342077Document17 pagesFormulir Kualifikasi - Material - PTK007 Rev 3 - 07102016 MJ342077Nugrawan SatriaNo ratings yet

- Optimization of Tesla Turbine Using Computational Fluid Dynamics ApproachDocument6 pagesOptimization of Tesla Turbine Using Computational Fluid Dynamics ApproachhatemNo ratings yet

- PDD GHCLDocument36 pagesPDD GHCLNiroj MohantyNo ratings yet

- Challenges in NepalDocument4 pagesChallenges in NepalBipana BhujelNo ratings yet

- Trophic LevelsDocument4 pagesTrophic LevelsBaileyNo ratings yet

- Rosa Suñirach UNhabitatDocument12 pagesRosa Suñirach UNhabitatAlven BactadNo ratings yet

- 11Document5 pages11DoNi JanuarNo ratings yet

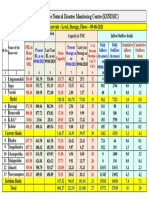

- Karnataka State Natural Disaster Monitoring Centre (KSNDMC) : Major Reservoir - Level, Storage, Flows - 09-06-2021Document1 pageKarnataka State Natural Disaster Monitoring Centre (KSNDMC) : Major Reservoir - Level, Storage, Flows - 09-06-2021true callNo ratings yet

- Materials For The Energy Transition: Dolf Gielen (Irena) and Carlo Papa (Enel Foundation)Document10 pagesMaterials For The Energy Transition: Dolf Gielen (Irena) and Carlo Papa (Enel Foundation)Will PatNo ratings yet

- CEE361 HW#8 Questions Spring20Document3 pagesCEE361 HW#8 Questions Spring20Muhammad UkashaNo ratings yet

- The Fauna Associated With Outer Shelf and Upper Slope SpongesDocument22 pagesThe Fauna Associated With Outer Shelf and Upper Slope SpongesPedro Henrique ClerierNo ratings yet

- Biofuels Engineering Process Technology 2Nd Edition Caye M Drapcho Full ChapterDocument51 pagesBiofuels Engineering Process Technology 2Nd Edition Caye M Drapcho Full Chapterjennifer.reed414100% (6)