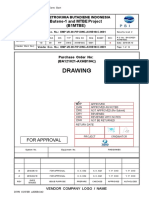

Professional Documents

Culture Documents

Technical Clarification Record (TCR) : S/N Date From TO Discipline Doc. Ref

Technical Clarification Record (TCR) : S/N Date From TO Discipline Doc. Ref

Uploaded by

null nullCopyright:

Available Formats

You might also like

- Alvar Aalto - The Complete Work 3 Vols (Architecture Art Ebook)Document764 pagesAlvar Aalto - The Complete Work 3 Vols (Architecture Art Ebook)Alexandru Barna100% (2)

- Specification For Pedestrian Restraint Systems in Metal: British Standard BS 7818:1995Document44 pagesSpecification For Pedestrian Restraint Systems in Metal: British Standard BS 7818:1995James Ellis60% (5)

- Viscotube r2Document15 pagesViscotube r2wisnu prabowo muktiNo ratings yet

- Template in Excel For PE's (By CPDEP)Document36 pagesTemplate in Excel For PE's (By CPDEP)BibizhanKadyrberliNo ratings yet

- All Latest Pricelist Download Link UpdaDocument4 pagesAll Latest Pricelist Download Link UpdaAmit Patel0% (1)

- Vv216a-109-A-808 - 07 - 0001 - Bolt Tightening ProcedureDocument17 pagesVv216a-109-A-808 - 07 - 0001 - Bolt Tightening Proceduretonful143No ratings yet

- Leaf SpringDocument16 pagesLeaf SpringThayumanavan KSNo ratings yet

- LIFTWELL PRESSURIZATION FAN TDS-PML HO APPROVED WITH COMMENTS - GDPL CommentedDocument25 pagesLIFTWELL PRESSURIZATION FAN TDS-PML HO APPROVED WITH COMMENTS - GDPL CommentedshafeeqadeptNo ratings yet

- Laporan Piutang DetailDocument48 pagesLaporan Piutang DetailHadi SiswantoNo ratings yet

- BMP VD 00 Pip DWG Axhb104c 0001 SignedDocument14 pagesBMP VD 00 Pip DWG Axhb104c 0001 Signeddimas prasetyoNo ratings yet

- Commissioning Engineering & Execution Plan - Rev2 - 20160302-97Document16 pagesCommissioning Engineering & Execution Plan - Rev2 - 20160302-97richardykeNo ratings yet

- Marca Modelo Ubicacion InfoDocument42 pagesMarca Modelo Ubicacion InfoGabriel GriecoNo ratings yet

- Vv216a-109-A-807 - 12 - 0001 - Laminator's Training ProcedureDocument27 pagesVv216a-109-A-807 - 12 - 0001 - Laminator's Training Proceduretonful143No ratings yet

- 15250-192-EN02-LM-001 Rev-D Load ListDocument7 pages15250-192-EN02-LM-001 Rev-D Load Listmusab shabbirNo ratings yet

- f75146080 ERECTION PROGRESS REPORT FOR Gulf MallDocument5 pagesf75146080 ERECTION PROGRESS REPORT FOR Gulf MallAbdulrahman AlkilaniNo ratings yet

- OAB Current Project Schedule 3-12-13Document20 pagesOAB Current Project Schedule 3-12-13RecordTrac - City of Oakland100% (1)

- Ivar Aasen Field Development Project - PDQ: Wiring DiagramDocument5 pagesIvar Aasen Field Development Project - PDQ: Wiring DiagramKonge Thethtunaung100% (1)

- Roof Weld TestDocument14 pagesRoof Weld TestPramod GrNo ratings yet

- EoI Doc BS-IV MysDocument11 pagesEoI Doc BS-IV MysgunadevanNo ratings yet

- Condenstae Pot FOR 17-E-9102 Condenstae Pot FOR 17-E-9108 Eru Dga Drain Drum Caustic Drain DrumDocument2 pagesCondenstae Pot FOR 17-E-9102 Condenstae Pot FOR 17-E-9108 Eru Dga Drain Drum Caustic Drain DrumrahulNo ratings yet

- Critical Goods ManagementDocument1 pageCritical Goods Managementfaraz ahmedNo ratings yet

- Form 124-13 Supercedes Form 124-10Document1,308 pagesForm 124-13 Supercedes Form 124-10البريكي لقطع الغيار100% (2)

- Inspection Request For Police CameraDocument9 pagesInspection Request For Police Cameramohib.dlinkcssNo ratings yet

- Transmittal Ube P-2001-012-01&2-001 (2022 04 13)Document1 pageTransmittal Ube P-2001-012-01&2-001 (2022 04 13)alimuhtar10No ratings yet

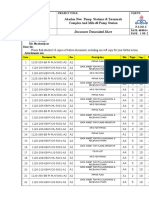

- Vendor Document Requirement List (VDRL)Document2 pagesVendor Document Requirement List (VDRL)Muthazhagan SaravananNo ratings yet

- Betagro Project Document List and Material SpecificationDocument3 pagesBetagro Project Document List and Material SpecificationThai ChheanghourtNo ratings yet

- R10 H11C23 Abt PH GF SDW ST 10021Document3 pagesR10 H11C23 Abt PH GF SDW ST 10021Adel MagdyNo ratings yet

- Hino Trucks 2011 - 2013MY NAPS Vin SetupDocument2 pagesHino Trucks 2011 - 2013MY NAPS Vin SetupABDUL SAMADNo ratings yet

- Abadan New Pump Stations & Terminals Complex and Mile 40 Pump StationDocument1 pageAbadan New Pump Stations & Terminals Complex and Mile 40 Pump StationmNo ratings yet

- TQCQ Steel Strong ValvesDocument5 pagesTQCQ Steel Strong ValvesParampreet singhNo ratings yet

- Gel in Hmel Poly LTP V Doc 001Document25 pagesGel in Hmel Poly LTP V Doc 001rinkukachhelaNo ratings yet

- TBC - SWTF - SLFE Response - 30th MarchDocument21 pagesTBC - SWTF - SLFE Response - 30th MarchMuhammad SalmanNo ratings yet

- Biecco Lawrie Ece Gec Reyrolle Burn Jyoti SwitchgearDocument18 pagesBiecco Lawrie Ece Gec Reyrolle Burn Jyoti SwitchgearSharafat AliNo ratings yet

- 0603 ME Control SystemDocument12 pages0603 ME Control Systemch100% (1)

- FIM 13 - Installation ReportDocument1 pageFIM 13 - Installation Reportajay singhNo ratings yet

- Technical Query Sheet Format - ColumnDocument8 pagesTechnical Query Sheet Format - ColumnChetan PatelNo ratings yet

- VDRL PT. Alfa Valve Indonesia 22 Desember 2019Document8 pagesVDRL PT. Alfa Valve Indonesia 22 Desember 2019Yusri FakhrizalNo ratings yet

- Electrical Load List: Project: South Yaran Oil Field Development ProjectDocument8 pagesElectrical Load List: Project: South Yaran Oil Field Development ProjectmNo ratings yet

- PO21000220-OQ-10120 - LSTK of Reactors & Agitators - DCIDocument4 pagesPO21000220-OQ-10120 - LSTK of Reactors & Agitators - DCIsachinpsawantNo ratings yet

- 2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02Document7 pages2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02teethai2524No ratings yet

- r2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Document377 pagesr2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Diana Paula Echartea MolinaNo ratings yet

- Fire Fighting Equipment Sample SubmittalDocument6 pagesFire Fighting Equipment Sample SubmittalYusuf Ziya DilbazNo ratings yet

- SHOP Drawings - LogDocument16 pagesSHOP Drawings - LogburereyNo ratings yet

- SHOP Drawings - LogDocument18 pagesSHOP Drawings - LogburereyNo ratings yet

- ArranqueDocument60 pagesArranqueAuxiliar MantenimientoNo ratings yet

- Civil Drawing For Swyd L Design Calculation Drawing NameDocument4 pagesCivil Drawing For Swyd L Design Calculation Drawing NameneerajNo ratings yet

- Project MonitoringDocument37 pagesProject MonitoringAnonymous Clm40C1No ratings yet

- MDL UsplDocument1 pageMDL Usplaravind grandhiNo ratings yet

- Attachment - 3 Technical Clarification Sheet: Oakwell/Sonepar Singapore Ltd. (Ceag Lightings)Document2 pagesAttachment - 3 Technical Clarification Sheet: Oakwell/Sonepar Singapore Ltd. (Ceag Lightings)Budi Putra NasutionNo ratings yet

- DATA SHEET PRY System V2Document3 pagesDATA SHEET PRY System V2Jorge RamosNo ratings yet

- Volume-Vi: O/O Chief Engineer (Procurement) MPPTCL, JabalpurDocument76 pagesVolume-Vi: O/O Chief Engineer (Procurement) MPPTCL, JabalpurRamphani NunnaNo ratings yet

- 077625-B51Document ListDocument3 pages077625-B51Document ListvinayNo ratings yet

- Tba19 2008 10 01Document5 pagesTba19 2008 10 01Sherif MoustafaNo ratings yet

- Initial Punch List - WWTP - 17.12.2018 - Final FinalDocument10 pagesInitial Punch List - WWTP - 17.12.2018 - Final FinalBebe BucătaruNo ratings yet

- Request For Information: Qatar Foundation Warehouse & Distribution CentreDocument2 pagesRequest For Information: Qatar Foundation Warehouse & Distribution Centrevhin84No ratings yet

- SVDN-CPP-M-0017-D01-0007-Rev.01-GA Drawing For MP Gas Suction Scrubber - PTC Code 2Document9 pagesSVDN-CPP-M-0017-D01-0007-Rev.01-GA Drawing For MP Gas Suction Scrubber - PTC Code 2123aefNo ratings yet

- A&i Scsei Rfi 3485Document2 pagesA&i Scsei Rfi 3485PolAngelesNo ratings yet

- Classification Moteurs A Reaction Reglem2010Document7 pagesClassification Moteurs A Reaction Reglem2010Boris Van CyrulnikNo ratings yet

- 6267 Enquirytechnicalspecification - KnifegatevalveDocument17 pages6267 Enquirytechnicalspecification - KnifegatevalveAnonymous XBq5J84No ratings yet

- Elevador Manual D MO MM MP IngDocument87 pagesElevador Manual D MO MM MP Ingmarco lezcanoNo ratings yet

- Spare Part List - 2 Years OptionalDocument5 pagesSpare Part List - 2 Years OptionalTrịnh Đức HạnhNo ratings yet

- Chapter 9Document5 pagesChapter 9nicenightmareNo ratings yet

- Mechanical Engineering DesignDocument22 pagesMechanical Engineering DesignFarid AsyrafNo ratings yet

- Scheme & Cost of Gis ProjectDocument2 pagesScheme & Cost of Gis Projectahmad idhanNo ratings yet

- Eviews 5 Users Guide PDFDocument2 pagesEviews 5 Users Guide PDFFredNo ratings yet

- Component Activities in Liquid Mixture, Using NRTL - File Exchange - MATLAB Central PDFDocument3 pagesComponent Activities in Liquid Mixture, Using NRTL - File Exchange - MATLAB Central PDFbakhtyar21No ratings yet

- Wheatly XDocument2 pagesWheatly XElinton SarmientoNo ratings yet

- Operating System AdministrationDocument6 pagesOperating System AdministrationRahulsrivasNo ratings yet

- RSW Ex 01 BackgroundDocument4 pagesRSW Ex 01 BackgroundTạ ThốnNo ratings yet

- Wine Celler: Service ManualDocument38 pagesWine Celler: Service ManualaderlochNo ratings yet

- Executive Summary - (System Connectivity - Owner's Study) : Cluster XIV & XVDocument26 pagesExecutive Summary - (System Connectivity - Owner's Study) : Cluster XIV & XVsrinivas69No ratings yet

- BCR02 - Brochure - EN Sample Gas PumpDocument2 pagesBCR02 - Brochure - EN Sample Gas PumptenggarayNo ratings yet

- Transportation, Transshipment, and Assignment Problems: Chapter TopicsDocument20 pagesTransportation, Transshipment, and Assignment Problems: Chapter TopicsHaseeb AhmedNo ratings yet

- ProCAST CapabilitiesDocument3 pagesProCAST Capabilitiesvdmoorthy123No ratings yet

- Lecture 6 Grain Boundary Displocation Defects VancancyDocument8 pagesLecture 6 Grain Boundary Displocation Defects VancancyAl-Kawthari As-SunniNo ratings yet

- DESCH Complete Press DriveDocument8 pagesDESCH Complete Press DriveSerdar FildisNo ratings yet

- Competing With Information TechnologyDocument32 pagesCompeting With Information TechnologySana GuptaNo ratings yet

- Sibin Application FormDocument9 pagesSibin Application FormShyamly DeepuNo ratings yet

- Repuestos en Consignacion en La Obra Häggloader 10HRDocument6 pagesRepuestos en Consignacion en La Obra Häggloader 10HRwladimirNo ratings yet

- 24-INCH MICROWAVE DRAWER® OVEN ManualDocument1 page24-INCH MICROWAVE DRAWER® OVEN ManualProduccion TAMNo ratings yet

- High Altitude Aeronautical Platform Systems (Presentation)Document30 pagesHigh Altitude Aeronautical Platform Systems (Presentation)Mahenoor SiddiquiNo ratings yet

- F4Physics Test2 (2016)Document10 pagesF4Physics Test2 (2016)TS Shong100% (1)

- Detector TechnologyDocument42 pagesDetector TechnologyCosmin DuceaNo ratings yet

- Getting Started With IFIXDocument138 pagesGetting Started With IFIXchris75726No ratings yet

- Request For Inspection Summary: Project Name: ClientDocument2 pagesRequest For Inspection Summary: Project Name: ClientAmit MaityNo ratings yet

- QuestionsDocument20 pagesQuestionsmaheshNo ratings yet

- Datasheet DiacDocument4 pagesDatasheet DiacOrlandoTobonNo ratings yet

Technical Clarification Record (TCR) : S/N Date From TO Discipline Doc. Ref

Technical Clarification Record (TCR) : S/N Date From TO Discipline Doc. Ref

Uploaded by

null nullOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Clarification Record (TCR) : S/N Date From TO Discipline Doc. Ref

Technical Clarification Record (TCR) : S/N Date From TO Discipline Doc. Ref

Uploaded by

null nullCopyright:

Available Formats

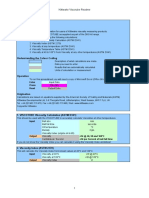

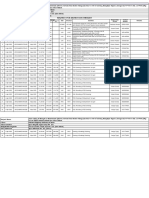

TECHNICAL CLARIFICATION RECOR

S/N DATE FROM TO DISCIPLINE DOC. REF.

1 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

2 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

3 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

LARIFICATION RECORD (TCR)

STATUS

COST IMPACT

CLARIFICATIONS (Open /

(Yes or No)

Closed)

It is noted that Bidder’s offer is in full compliance to RFQ

E4454-EM261 requirements and attached specifications,

standards, other than exceptions / deviations listed in “List of

Exceptions and / or Deviations Format” specified in Technical

offer.

Any other deviations/ exceptions specified elsewhere in offer

other than listed in format are Null & Void.

In the absence of any specific deviations /exceptions and

general exceptions with offer, BWE construed that Bidder is in

full compliance to all the requirements. Responses like “No

comments” / “Noted” / “Yes” / “OK” are considered “Fully

Complied to Specifications / Standards / RFQ”.

Bidder to confirm.

Bidder to confirm that Updated documents indicated in “List of

Tech Docs_Ruche RFQs_CI Package” attached with this TCR

Dt. 11-11-2019 are received, reviewed and in full compliance

with the same. If there are any deviations Bidder to highlight in

Deviations list Format for BWE review.

The equipment (including auxiliaries) covered by this Package

shall be designed and constructed for a minimum service life

of 20 years and at least three years of uninterrupted

operation.

Bidder to confirm Compliance

4 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

5 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

6 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

7 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

8 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

9 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

Based on revised Chemical Dosage Rates and day tank sizes

required, Max Plot Space to be used for Package is 4m W X

4m m L X 5 m H (2 level skid) with Common bunding for all

the chemicals. Vendor to propose 2 Level skid with tanks top

level and "pumps+motors" sitting towards the edge of the

bottom level of the skid with maintenance access for the

Pumps/motors exceeding 25 Kg with a provision for

accessibility/ operability/ maintainability of Pumps,

Instruments, valves etc.,

Bidder to advise the revised skid size on this basis and advise

cost reduction to comply with this.

The pump discharge shall be provided with an external

pressure relieving device for protection of the piping against a

closed pump discharge. This external device shall be in

addition to any internal pressure relieving device which may

be supplied as an integral part of the pump. The external

pressure relieving device set pressure shall be as per the

Project Data Sheets.

Drgs: Bidder to provide REVISED preliminary P&IDs, GA drgs

for the skid with the arrangement of Chemical day Tanks,

Pumps, Motors based on proposed equipment layout for BWE

review along with TCR response in-line with Point no. 4 based

on Process DS.

Based on revised chemicals and dosage rates, Bidder to

provide revised sizing datasheets for Pumps and Motors

considering the water as the fluid for BWE review based on

Process DS.

Order of Precedence of documents shall be as indicated in

Section 5.4 of General Technical Requirements Doc no.

4454-BWE-Z-SA-00003. Bidder to confirm Compliance

Tanks Design: Rectangular storage tanks shall be designed

as per Roark's Formulas for Stress Strain and the Nozzles

shall be designed as per API 650. Bidder to Confirm

Compliance

10 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

11 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

12 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE LEWA

[Insert Date] LEWA BWE

13 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

14 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

15 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] LEWA BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

Methanol Injection and some other chemical are removed

from Chemical Injection package, there by associated item

scope gets reduced. Bidder to Provide cost reduction in their

revised quotation.

Electric driven, controlled volume positive displacement,

double diaphragm type pumps Compliant with API 675 with

design pressure as per Relief valve Set Pressure indicated in

Process DS4454-BWE-P-DS-00003 (latest revision) and

hydro tested to 1.5 times design pressure. Bidder to confirm

compliance.

Materials of Construction is indicated as SS316. Bidder to

note that the Tank (Except Water Softener) materials to be

SS316L and Pump components exposed to chemicals are to

be SS316L. Diaphragm Leak detection tubing/Fittings to be

Alloy 2507. Bidder to confirm compliance.

Against LEWA PUMP Details, Suction and Discharge Lines

are indicated as ASME 1/2 - 14 NPT and ASME 1/4 - 18

NPT for tubing. Bidder to note that minimum sizing for tubing

shall be considered as 1/2 Inch. Bigger size can be chosen as

required for Pressure drop calculations, however terminal

connection shall be suitable for 1/2 Inch NPT at discharge

battery limits.

Bidder proposal indicates that Special Tools such as

"Pulsation Dampener Charging Kit" is included in scope of

supply. Bidder to confirm that Proposed 1 set of kit is suitable

for all the Pulsation Dampeners and its sizes.

Scope does not clearly indicate that Lighting and associated

components are included. Bidder to consider the scope of

supply, Installation and testing of Lighting within the Chemical

Injection Skid including the cable tray/cable routing as per

C04-4119-BWE-E-XS-00002.001_01_01 Electrical Installation

Standard Details – Lighting Installation Details

16 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

17 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

18 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

19 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

20 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

21 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

22 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

Fabrication Location: Bidder to confirm if the Skid base Frame

Fabrication and Package assembly and testing in Singapore

is accounted in Bidder proposal?

Vendor Data Requirements and submission dates to be in

compliance with doc No. 4454-BWE-O-LA-00001 SDRL

Template-Ruche_CIP. Bidder to confirm Compliance.

It is noted that Spare parts for comm/start up are included in

based scope of supply. Bidder to re-confirm in compliance

with requisition 4454-BWE-M-SA-00007 Item 2.2 of Scope of

supply "20% bolts, nuts, 8 nos washers of each size and

100% spare gaskets.

Bidder to provide list of 2 Year Operation spares

recommended for Company review.

Bidder shall comply with NON-ELECTRICAL

INSTALLATIONS IN HAZARDOUS AREA PHILOSOPHY

4454-BWE-Z-FD-00012 for Non-Electrical items within

Chemical injection package.

Bidder to confirm that Mechanical Completion and Pre-

commissioning is included in the scope of supply by following

BWE forms and strategy as indicated in Section 14 of

EQUIPMENT SPECIFICATION FOR CHEMICAL INJECTION

PACKAGE

Packing for transportation shall be Sea Worthy and

Preservation shall be good for long term outdoor storage of 12

months.

Bidder to confirm compliance.

23 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

24 13-Nov-19 BWE LEWA Mechanical Motor Torque

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

25 8-Nov-19 BWE LEWA Mechanical Hose Coupling

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

26 13-Nov-19 BWE LEWA Mechanical Skid lifting Lug

Welds

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

27 13-Nov-19 BWE LEWA Mechanical Flange

Management

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

28 13-Nov-19 BWE LEWA Process Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

Metering Pumps

Bidder to confirm that pumps are provided with manual step-

less stroke adjustment from 0 to 100%, which shall ensure

repeatability from 100 to 0% as well for flow control. The

pumps does not require remote control from FCS

Please clarify the margin of motor torque against the required

pump load torque at 80% voltage considered in the motor

rating selection refer to Section 8.2 of 4454-BWE-E-SA-

00004.

Chemical tank hose coupling.

Bidder to confirm that Hose Coupling for each Tank fill

connection shall be unique, i.e. different from and

mechanically incompatible to avoid inadvertent mixing as per

Process data sheet 4454-BWE-P-DS-00003 note 8. Bidder to

confirm Compliance.

The unit shall have lifting lugs for single point lifting for

installation. The lifting lug welds shall be 100 % non-

destructive volumetric examined

Bidder to confirm that Flange Management procedure to be

submitted for BWE Review and to be carried out for CI

Package in accordance with PIPING CONTROLLED BOLT

TORQUEING PROCEDURE 4454-BWE-L-KA-00003

Process DS 4454-BWE-P-DS-00003 is revised by deleting

some of the chemicals and reducing the dosage rate of other

Chemicals. Bidder to revise their quotation in compliance with

the same and provide preliminary P&IDs (representative for all

chemicals) as per Process DS 4454-BWE-P-DS-00003 (latest

revision) and Tie-in Connections as per the BWE P&IDs 4454-

BWE-P-XB-420001.001 & 4454-BWE-P-XB-420002.001

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

29 13-Nov-19 BWE LEWA Process Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

30 13-Nov-19 BWE LEWA Process Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

31 13-Nov-19 BWE LEWA Process Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

32 13-Nov-19 BWE LEWA Process Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

33 13-Nov-19 BWE LEWA Process Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

34 13-Nov-19 BWE LEWA Process Bidder Proposal

Q19-21551

Design Pressure for Rectangular Tanks shall be Full of Liquid

+ 70mbarg, Methanol Vessel shall be of 12 barg and Pumps

as per Relief valve Set Pressure indicated in Process

DS4454-BWE-P-DS-00003 (latest revision).

Tanks Operational Volume typically between the 5 to 95 % of

the Tank Volume, hence Maximum 90% of the Tank Volume.

However if the tank size and physical location of nozzles are

such that it requires operating volume indicated to be less

than 90% of the tank volume, the same shall be

accommodated at no additional cost. In other terms the

required operation volume to be accommodated between LAL

and LAH in the Tank. Bidder to Confirm compliance

Bidder to provide Process/Hydraulic calculation for Pumps

NPSH and PSV sizing by following BWE Specifications and

standards as per the Process DS4454-BWE-P-DS-00003

(latest revision).

All chemical injection pumps shall be provided with pump

recirculation line with PCV & bypass globe

All the pumps and motors to be rated to deliver full flow

against blocked discharge with flow through the relief valve to

the storage tank

Confirm that the following are included in the scope of supply:

a) Tanks overflow line to the drip pan

b) Bypass globe for the PCV on injection pump minimum flow

recirculation line

c) All individual Chemical injection Lines supplied with IRCDs

d) Isolation valve on PSV outlet

e) PIT to be provided on pump discharge

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

35 13-Nov-19 BWE LEWA Process Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

36 13-Nov-19 BWE LEWA Process Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

37 13-Nov-19 BWE LEWA Piping Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

38 13-Nov-19 BWE LEWA Piping Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

39 13-Nov-19 BWE LEWA Piping Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

40 13-Nov-19 BWE LEWA Piping Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

Design Pressure for Tubing, Pump, Fitting, Instrument Etc.,

shall be FV/PSV Set pressure as indicated in page 3 of

Process DS.

Design temperature shall be equal to or higher than black

body temperature of 80°C

3D Model Reviews shall be presented at BWE office by

Bidder and attended by Supplier competent personnel to

demonstrate the Operability, Maintainability, Accessibility for

the equipment and systems etc., and close out action items

timely.

30% model review

60% Model Review

90% Model Review

As defined in 3D Model Review Procedure 4454-BWE-L-KA-

00002. Bidder to Confirm Compliance

3D Model shall be preferably in PDMS and *.STEP Files to be

provided along with model review in each phase. 3D Model

presentation for model review in Navis Works which facilitate

dimensional measurement.

Bidder to confirm compliance to section 10.1 of the document

4454-BWE-Z-SA-00003 General Technical Requirements for

the small bore connections. Bidder to Confirm Compliance

Bidder to include and provide material handling facilities within

the skid. Maintenance / Withdrawal space reservation to be

indicated in accordance with philosophy document 4454-

BWE-S-FD-00004. Bidder to Confirm Compliance

41 13-Nov-19 BWE LEWA Piping Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

42 13-Nov-19 BWE LEWA Piping Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

43 13-Nov-19 BWE LEWA Piping Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

44 13-Nov-19 BWE LEWA Piping Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

45 13-Nov-19 BWE LEWA Piping Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

46 13-Nov-19 BWE LEWA Piping Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

47 13-Nov-19 BWE LEWA Piping Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

Bidder to confirm compliance to document 4454-BWE-L-FD-

00002 Piping and Pipe Support Design Premise. Bidder to

Confirm Compliance

Tie-in connections will be considered as Anchor and allowable

loads to be in accordance with document 4454-BWE-L-FD-

00001 Attachment-1. Bidder to confirm compliance. Also

stress analysis as applicable shall be in accordance with the

referenced document. Bidder to Confirm Compliance.

Bidder to confirm compliance to document 4454-BWE-L-SA-

00003 for Pressure Testing of Piping. Bidder to Confirm

Compliance.

Welding and Non-destructive testing for Piping to be in

accordance with document 4454-BWE-L-SA-00004. Bidder to

confirm compliance

Piping Tie-in connections shall be WNRF for Class 150 &

Class 300, WNRTJ for Class 600 & above. Bidder to confirm

compliance

Manual valves selected for the isolation purpose shall be in

compliant with WHP PROCESS DESIGN PHILOSOPHY Doc.

4454-BWE-P-FD-00001. Bidder to confirm compliance

Bidder to note that Piping and Valves shall be in accordance

with document 4454-BWE-L-SA-00001 Piping Material

Specifications. All SS316 Piping components and valves shall

be duel certified to SS316/316L as per this Specification.

Bidder to Confirm Compliance

48 13-Nov-19 BWE LEWA Structural Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

49 13-Nov-19 BWE LEWA Structural Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

50 13-Nov-19 BWE LEWA Electrical Bidder Proposal

Q19-21551

Sub-Suppliers

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

51 13-Nov-19 BWE LEWA Electrical Bidder Proposal

Q19-21551

Area Classification

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

52 13-Nov-19 BWE LEWA Electrical Bidder Proposal

Q19-21551 LCS

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

53 13-Nov-19 BWE LEWA Electrical Bidder Proposal

Q19-21551

Motor Rating

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

Bidder to confirm compliance to document4454-BWE-N-SA-00002

Structural-Material Specification

Bidder to refer to Specification “Structural Fabrication, Installation

and Tolerances for Jacket and deck” , 4454-BWE-N-SA-00001 for

relevant requirements about structural fabrication, installation and

tolerances . The bidder shall submit material, fabrication sequence

(pre-fabrication of elements, assembly sequence and welding

sequence), welding and inspection to the Company for review and

approval prior to fabrication.

Vendors of EIT equipment shall be in accordance with

Preferred Manufacturers List for EIT Items, 4454-BWE-E-LA-

00002. Any deviation to be flagged and cost adder if any to be

flagged.

Do note that although the unit will be installed in hazardous

area zone 2, equipment/Items shall be suitable for zone 1,

Group IIB Class T3.

For LCS bidder to supply and install shall be of CEAG GHG

411 series. Please consider and include in the quotation.

Ex-protection motor are stated as Exe while in technical

proposal it is stated as Ex de. Ex de is preferred. Bidder to

provide motor rating for all pumps with the technical proposal

as per latest revision of Process DS. Power system is 60Hz

not 50Hz.

54 13-Nov-19 BWE LEWA Electrical Bidder Proposal

Q19-21551

IECEx Certified

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

55 13-Nov-19 BWE LEWA Electrical Bidder Proposal

Q19-21551

IECEx Certified

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

56 13-Nov-19 BWE LEWA Electrical General

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

57 13-Nov-19 BWE LEWA Electrical General,

applicable for all

EIT Items

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

58 13-Nov-19 BWE LEWA Instrumentation General

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

59 13-Nov-19 BWE LEWA Instrumentation Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

60 13-Nov-19 BWE LEWA Instrumentation Bidder Proposal

Q19-21551

Tubing and Fittings

Material

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

All electrical and instrumentation equipment shall be IECEx

certified. Ex register in BWE template to be submitted as per

SDRL.

Bidder to provide cable trays from equipment to skid edge for

integration cabling. The cable trays shall be SS316L with VCI

coating.

Equipment shall be tagged as per BWE tagging format. Refer

TECHNICAL CODING SPECIFICATION - 4454-BWE-Z-SA-

00004.

Bidder shall refer to ELECTRICAL INSTALLATIONS IN

HAZARDOUS AREA PHILOSOPHY 454-BWE-E-FD-00003

and comply with the requirements.

Air Medium will not be available for the instrument Services.

Bidder to consider the electrical medium for motive force

Instruments shall be Exd ( Zone 1 ) , IP 66 and IECEX

certified

All Tubing and Fittings Material shall be Super Duplex SS

(Alloy 2507). SS316 is not acceptable. Bidder shall be

responsible for selection of tube material and thickness

considering the above, suitable for tubing test pressure as per

the project requirements.

Bidder to confirm compliance to 4454-BWEB-LA-0002

approved Vendor list

61 13-Nov-19 BWE LEWA Instrumentation General

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

62 13-Nov-19 BWE LEWA Instrumentation General

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

63 13-Nov-19 BWE LEWA Instrumentation IRCDs

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

64 13-Nov-19 BWE LEWA Instrumentation Bidder Proposal

Q19-21551

Pressure & Flow

Measuring

Instruments

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

65 13-Nov-19 BWE LEWA Weight Control Weight Control

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

66 13-Nov-19 BWE LEWA Painting Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

67 13-Nov-19 BWE LEWA Painting Bidder Proposal

Q19-21551

Bidder to confirm compliance with INSTRUMENTATION,

AUTOMATION, ELECTRICAL AND TELECOM

REQUIREMENTS FOR THIRD PARTY 4454-BWE-I-SA-

00002

Bidder to provide the estimated IO interface with DCS

Bidder to note that IRCDs manually operated (at Local) are

acceptable. Remote operated IRCDs are not required and

hence Bidder to provide cost reduction on the same from their

base quote on this

Valves for Pressure & Flow Measuring Instruments shall be

DBB valves to facilitate future calibration and service purpose.

Weight & COG datasheet, Weight Control Report and

Weighing and Weighing Certificates shall be in compliance

with Weight Management Procedure 4454-BWE-W-KA-

00001. Bidder to confirm compliance.

Tanks (SS316L) does not require Coating, surfaces shall be

Pickled and passivated to remove surface

contamination/stains and protect surfaces.

As per Section 10.3 of 4454-BWE-R-SA-00001, Painting with

relevant system is applicable on exposed 316L SS. Painting

can be limited to exposed 316L SS Piping, Fittings and

Valves. Bidder to confirm Compliance.

For Pumps and Motors, Bidder to specify the Coating system

proposed which is suitable for the offshore applications for

Company Review.

67

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

68 13-Nov-19 BWE LEWA Painting Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

69 13-Nov-19 BWE LEWA Painting Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

70 13-Nov-19 BWE LEWA HSEQ Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

71 13-Nov-19 BWE LEWA HSEQ Quality System

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

72 13-Nov-19 BWE LEWA HSEQ Preservation

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

73 13-Nov-19 BWE LEWA HSEQ PMI For materials

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

As per Section 13.8 of 4454-BWE-R-SA-00001, Contractor to

propose minimum 3 coat system for Offshore environment for

all carbon Steel Structures. Contractor can use coating

systems specified in BWE Project specification

As per Section 14.5 OF 4454-BWE-R-SA-00001, Coating

inspections will be required by in-house coating inspector of

the contractor. NACE Level 2 coating inspector will be

acceptable.

Bidder to provide typical Inspection and Test Plan as part of

your bid for evaluation covering all the Structural Fabrication,

Load Testing, tanks fabrication, Pumps Manufacturing, Motors

manufacturing, Functional Testing, FAT for the CI Package

etc.,

Bidder to confirm compliance to the "QUALITY SYSTEM

REQUIREMENTS FOR MATERIAL MANAGEMENT 4454-

BWE-Q-SA-00001"

Bidder to confirm compliance with PRESERVATION

PROCEDURE 454-BWE-Z-KA-00001 and ensure that

Preservation provided shall be suitable for 12 months outdoor

storage.

Bidder to confirm compliance with Positive Material

Identification for all Stainless Steel materials as per PMI

PROCEDURE 4454-BWE-Q-KA-00001.

74 13-Nov-19 BWE LEWA Documentation Document

Management

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

75 13-Nov-19 BWE LEWA Documentation Final

documentation

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

76 13-Nov-19 BWE LEWA Tech Safety Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

77 13-Nov-19 BWE LEWA Tech Safety Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

78 13-Nov-19 BWE LEWA Tech Safety Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

79 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

Bidder to confirm compliance with DOCUMENT

MANAGEMENT REQUIREMENTS FOR SUPPLIERS -

DUSSAFU PHASE 34454-BWE-A-SA-00002

Bidder to confirm compliance with FINAL DOCUMENTATION

DELIVERY REQUIREMENTS AND MRB SET-UP -

DUSSAFU PHASE 3 4454-BWE-O-SA-00002

GA for the skid is not provided with the bid. G.A. is needed to

evaluate the skid arrangement w.r.t. access/ ladder/ grating/

handrails/step etc. The skid arrangement shall comply to

Human Factor Engineering Requirements and Technical

Safety Philosophy document 4454-BWE-S-FD-00001

Proper access way shall be provided at top level to access

level gauges, manways if any at top of the tanks.

Bidder to confirm the noise limits for the Pumps and motors in

Chemical Injection Package shall be ≤ 85 dBA @ 1 meter.

Noise test shall be performed as per ISO 37xx series for

demonstration.

All Pumps supplied shall be Static hydro Tested and Dynamic

Performance Tested for Linearity, Repeatability and accuracy

as per API 675 at Factory along with Job motors. Additionally

Complete CI Package shall be Functional and FAT tested

before delivery covering the following:

1) Dimensional Check

2) Run Up to Flow rate

3) Run Up to Discharge Pressure

4) Tank leak Test

5) Hydro test of Piping and Leak Testing of tubing

6) Functional Test of Local Instrumentation

7) Electrical Loop Checks

8) Weighing of Complete Skid Package

[Insert Date] Bidder BWE

80 13-Nov-19 BWE Bidder Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

81 13-Nov-19 BWE Bidder Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

82 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

83 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

84 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

85 13-Nov-19 BWE LEWA Mechanical Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

86 13-Nov-19 BWE Bidder Instrumentation Bidder Proposal

Q19-21551

[Insert Date] Bidder BWE

Material for Water Softener tank to be High Density

Polyethylene (HDPE) with interface Mating flanges to be

SS316L Flanges with tapped plug connected with suction

tubing. This is to avoid welded components exposed to

chemicals not to be SS316. Bidder to confirm Compliance.

All Tubing/Fittings installation within CI Package to be carried

out by Swagelok Trained and certified personnel. Bidder to

confirm Compliance.

Lifting

- Please clarify, for maintainable component with a weight of

25-50 kg, shall consider material handling equipment. The

maintainable equipment must be furnished with a certified

lifting device such as eyebolt or lug.

Bidder to confirm that remote diaphragm rapture monitor is

provided in the quote.

Please furnish the estimated dry weight and operating weight

and corresponding COG for Chemical Injection package and

Individual Pumps/Motors

Bidder to note that Hydrosure Chmcial is added to the list in

Rev E of the Process DS 4454-BWE-P-DS-00003_E for CI

Package. Accordingly bidder to revise the quotation with all

the items requried for this Chemcial as well.

Chemical Storage Tanks

Please re-confirm if remote monitoring of tank level is included

in the quote.

86

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

87 [Insert Date] BWE Bidder

[Insert Date] Bidder BWE

[Insert Date] BWE Bidder

[Insert Date] Bidder BWE

You might also like

- Alvar Aalto - The Complete Work 3 Vols (Architecture Art Ebook)Document764 pagesAlvar Aalto - The Complete Work 3 Vols (Architecture Art Ebook)Alexandru Barna100% (2)

- Specification For Pedestrian Restraint Systems in Metal: British Standard BS 7818:1995Document44 pagesSpecification For Pedestrian Restraint Systems in Metal: British Standard BS 7818:1995James Ellis60% (5)

- Viscotube r2Document15 pagesViscotube r2wisnu prabowo muktiNo ratings yet

- Template in Excel For PE's (By CPDEP)Document36 pagesTemplate in Excel For PE's (By CPDEP)BibizhanKadyrberliNo ratings yet

- All Latest Pricelist Download Link UpdaDocument4 pagesAll Latest Pricelist Download Link UpdaAmit Patel0% (1)

- Vv216a-109-A-808 - 07 - 0001 - Bolt Tightening ProcedureDocument17 pagesVv216a-109-A-808 - 07 - 0001 - Bolt Tightening Proceduretonful143No ratings yet

- Leaf SpringDocument16 pagesLeaf SpringThayumanavan KSNo ratings yet

- LIFTWELL PRESSURIZATION FAN TDS-PML HO APPROVED WITH COMMENTS - GDPL CommentedDocument25 pagesLIFTWELL PRESSURIZATION FAN TDS-PML HO APPROVED WITH COMMENTS - GDPL CommentedshafeeqadeptNo ratings yet

- Laporan Piutang DetailDocument48 pagesLaporan Piutang DetailHadi SiswantoNo ratings yet

- BMP VD 00 Pip DWG Axhb104c 0001 SignedDocument14 pagesBMP VD 00 Pip DWG Axhb104c 0001 Signeddimas prasetyoNo ratings yet

- Commissioning Engineering & Execution Plan - Rev2 - 20160302-97Document16 pagesCommissioning Engineering & Execution Plan - Rev2 - 20160302-97richardykeNo ratings yet

- Marca Modelo Ubicacion InfoDocument42 pagesMarca Modelo Ubicacion InfoGabriel GriecoNo ratings yet

- Vv216a-109-A-807 - 12 - 0001 - Laminator's Training ProcedureDocument27 pagesVv216a-109-A-807 - 12 - 0001 - Laminator's Training Proceduretonful143No ratings yet

- 15250-192-EN02-LM-001 Rev-D Load ListDocument7 pages15250-192-EN02-LM-001 Rev-D Load Listmusab shabbirNo ratings yet

- f75146080 ERECTION PROGRESS REPORT FOR Gulf MallDocument5 pagesf75146080 ERECTION PROGRESS REPORT FOR Gulf MallAbdulrahman AlkilaniNo ratings yet

- OAB Current Project Schedule 3-12-13Document20 pagesOAB Current Project Schedule 3-12-13RecordTrac - City of Oakland100% (1)

- Ivar Aasen Field Development Project - PDQ: Wiring DiagramDocument5 pagesIvar Aasen Field Development Project - PDQ: Wiring DiagramKonge Thethtunaung100% (1)

- Roof Weld TestDocument14 pagesRoof Weld TestPramod GrNo ratings yet

- EoI Doc BS-IV MysDocument11 pagesEoI Doc BS-IV MysgunadevanNo ratings yet

- Condenstae Pot FOR 17-E-9102 Condenstae Pot FOR 17-E-9108 Eru Dga Drain Drum Caustic Drain DrumDocument2 pagesCondenstae Pot FOR 17-E-9102 Condenstae Pot FOR 17-E-9108 Eru Dga Drain Drum Caustic Drain DrumrahulNo ratings yet

- Critical Goods ManagementDocument1 pageCritical Goods Managementfaraz ahmedNo ratings yet

- Form 124-13 Supercedes Form 124-10Document1,308 pagesForm 124-13 Supercedes Form 124-10البريكي لقطع الغيار100% (2)

- Inspection Request For Police CameraDocument9 pagesInspection Request For Police Cameramohib.dlinkcssNo ratings yet

- Transmittal Ube P-2001-012-01&2-001 (2022 04 13)Document1 pageTransmittal Ube P-2001-012-01&2-001 (2022 04 13)alimuhtar10No ratings yet

- Vendor Document Requirement List (VDRL)Document2 pagesVendor Document Requirement List (VDRL)Muthazhagan SaravananNo ratings yet

- Betagro Project Document List and Material SpecificationDocument3 pagesBetagro Project Document List and Material SpecificationThai ChheanghourtNo ratings yet

- R10 H11C23 Abt PH GF SDW ST 10021Document3 pagesR10 H11C23 Abt PH GF SDW ST 10021Adel MagdyNo ratings yet

- Hino Trucks 2011 - 2013MY NAPS Vin SetupDocument2 pagesHino Trucks 2011 - 2013MY NAPS Vin SetupABDUL SAMADNo ratings yet

- Abadan New Pump Stations & Terminals Complex and Mile 40 Pump StationDocument1 pageAbadan New Pump Stations & Terminals Complex and Mile 40 Pump StationmNo ratings yet

- TQCQ Steel Strong ValvesDocument5 pagesTQCQ Steel Strong ValvesParampreet singhNo ratings yet

- Gel in Hmel Poly LTP V Doc 001Document25 pagesGel in Hmel Poly LTP V Doc 001rinkukachhelaNo ratings yet

- TBC - SWTF - SLFE Response - 30th MarchDocument21 pagesTBC - SWTF - SLFE Response - 30th MarchMuhammad SalmanNo ratings yet

- Biecco Lawrie Ece Gec Reyrolle Burn Jyoti SwitchgearDocument18 pagesBiecco Lawrie Ece Gec Reyrolle Burn Jyoti SwitchgearSharafat AliNo ratings yet

- 0603 ME Control SystemDocument12 pages0603 ME Control Systemch100% (1)

- FIM 13 - Installation ReportDocument1 pageFIM 13 - Installation Reportajay singhNo ratings yet

- Technical Query Sheet Format - ColumnDocument8 pagesTechnical Query Sheet Format - ColumnChetan PatelNo ratings yet

- VDRL PT. Alfa Valve Indonesia 22 Desember 2019Document8 pagesVDRL PT. Alfa Valve Indonesia 22 Desember 2019Yusri FakhrizalNo ratings yet

- Electrical Load List: Project: South Yaran Oil Field Development ProjectDocument8 pagesElectrical Load List: Project: South Yaran Oil Field Development ProjectmNo ratings yet

- PO21000220-OQ-10120 - LSTK of Reactors & Agitators - DCIDocument4 pagesPO21000220-OQ-10120 - LSTK of Reactors & Agitators - DCIsachinpsawantNo ratings yet

- 2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02Document7 pages2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02teethai2524No ratings yet

- r2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Document377 pagesr2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Diana Paula Echartea MolinaNo ratings yet

- Fire Fighting Equipment Sample SubmittalDocument6 pagesFire Fighting Equipment Sample SubmittalYusuf Ziya DilbazNo ratings yet

- SHOP Drawings - LogDocument16 pagesSHOP Drawings - LogburereyNo ratings yet

- SHOP Drawings - LogDocument18 pagesSHOP Drawings - LogburereyNo ratings yet

- ArranqueDocument60 pagesArranqueAuxiliar MantenimientoNo ratings yet

- Civil Drawing For Swyd L Design Calculation Drawing NameDocument4 pagesCivil Drawing For Swyd L Design Calculation Drawing NameneerajNo ratings yet

- Project MonitoringDocument37 pagesProject MonitoringAnonymous Clm40C1No ratings yet

- MDL UsplDocument1 pageMDL Usplaravind grandhiNo ratings yet

- Attachment - 3 Technical Clarification Sheet: Oakwell/Sonepar Singapore Ltd. (Ceag Lightings)Document2 pagesAttachment - 3 Technical Clarification Sheet: Oakwell/Sonepar Singapore Ltd. (Ceag Lightings)Budi Putra NasutionNo ratings yet

- DATA SHEET PRY System V2Document3 pagesDATA SHEET PRY System V2Jorge RamosNo ratings yet

- Volume-Vi: O/O Chief Engineer (Procurement) MPPTCL, JabalpurDocument76 pagesVolume-Vi: O/O Chief Engineer (Procurement) MPPTCL, JabalpurRamphani NunnaNo ratings yet

- 077625-B51Document ListDocument3 pages077625-B51Document ListvinayNo ratings yet

- Tba19 2008 10 01Document5 pagesTba19 2008 10 01Sherif MoustafaNo ratings yet

- Initial Punch List - WWTP - 17.12.2018 - Final FinalDocument10 pagesInitial Punch List - WWTP - 17.12.2018 - Final FinalBebe BucătaruNo ratings yet

- Request For Information: Qatar Foundation Warehouse & Distribution CentreDocument2 pagesRequest For Information: Qatar Foundation Warehouse & Distribution Centrevhin84No ratings yet

- SVDN-CPP-M-0017-D01-0007-Rev.01-GA Drawing For MP Gas Suction Scrubber - PTC Code 2Document9 pagesSVDN-CPP-M-0017-D01-0007-Rev.01-GA Drawing For MP Gas Suction Scrubber - PTC Code 2123aefNo ratings yet

- A&i Scsei Rfi 3485Document2 pagesA&i Scsei Rfi 3485PolAngelesNo ratings yet

- Classification Moteurs A Reaction Reglem2010Document7 pagesClassification Moteurs A Reaction Reglem2010Boris Van CyrulnikNo ratings yet

- 6267 Enquirytechnicalspecification - KnifegatevalveDocument17 pages6267 Enquirytechnicalspecification - KnifegatevalveAnonymous XBq5J84No ratings yet

- Elevador Manual D MO MM MP IngDocument87 pagesElevador Manual D MO MM MP Ingmarco lezcanoNo ratings yet

- Spare Part List - 2 Years OptionalDocument5 pagesSpare Part List - 2 Years OptionalTrịnh Đức HạnhNo ratings yet

- Chapter 9Document5 pagesChapter 9nicenightmareNo ratings yet

- Mechanical Engineering DesignDocument22 pagesMechanical Engineering DesignFarid AsyrafNo ratings yet

- Scheme & Cost of Gis ProjectDocument2 pagesScheme & Cost of Gis Projectahmad idhanNo ratings yet

- Eviews 5 Users Guide PDFDocument2 pagesEviews 5 Users Guide PDFFredNo ratings yet

- Component Activities in Liquid Mixture, Using NRTL - File Exchange - MATLAB Central PDFDocument3 pagesComponent Activities in Liquid Mixture, Using NRTL - File Exchange - MATLAB Central PDFbakhtyar21No ratings yet

- Wheatly XDocument2 pagesWheatly XElinton SarmientoNo ratings yet

- Operating System AdministrationDocument6 pagesOperating System AdministrationRahulsrivasNo ratings yet

- RSW Ex 01 BackgroundDocument4 pagesRSW Ex 01 BackgroundTạ ThốnNo ratings yet

- Wine Celler: Service ManualDocument38 pagesWine Celler: Service ManualaderlochNo ratings yet

- Executive Summary - (System Connectivity - Owner's Study) : Cluster XIV & XVDocument26 pagesExecutive Summary - (System Connectivity - Owner's Study) : Cluster XIV & XVsrinivas69No ratings yet

- BCR02 - Brochure - EN Sample Gas PumpDocument2 pagesBCR02 - Brochure - EN Sample Gas PumptenggarayNo ratings yet

- Transportation, Transshipment, and Assignment Problems: Chapter TopicsDocument20 pagesTransportation, Transshipment, and Assignment Problems: Chapter TopicsHaseeb AhmedNo ratings yet

- ProCAST CapabilitiesDocument3 pagesProCAST Capabilitiesvdmoorthy123No ratings yet

- Lecture 6 Grain Boundary Displocation Defects VancancyDocument8 pagesLecture 6 Grain Boundary Displocation Defects VancancyAl-Kawthari As-SunniNo ratings yet

- DESCH Complete Press DriveDocument8 pagesDESCH Complete Press DriveSerdar FildisNo ratings yet

- Competing With Information TechnologyDocument32 pagesCompeting With Information TechnologySana GuptaNo ratings yet

- Sibin Application FormDocument9 pagesSibin Application FormShyamly DeepuNo ratings yet

- Repuestos en Consignacion en La Obra Häggloader 10HRDocument6 pagesRepuestos en Consignacion en La Obra Häggloader 10HRwladimirNo ratings yet

- 24-INCH MICROWAVE DRAWER® OVEN ManualDocument1 page24-INCH MICROWAVE DRAWER® OVEN ManualProduccion TAMNo ratings yet

- High Altitude Aeronautical Platform Systems (Presentation)Document30 pagesHigh Altitude Aeronautical Platform Systems (Presentation)Mahenoor SiddiquiNo ratings yet

- F4Physics Test2 (2016)Document10 pagesF4Physics Test2 (2016)TS Shong100% (1)

- Detector TechnologyDocument42 pagesDetector TechnologyCosmin DuceaNo ratings yet

- Getting Started With IFIXDocument138 pagesGetting Started With IFIXchris75726No ratings yet

- Request For Inspection Summary: Project Name: ClientDocument2 pagesRequest For Inspection Summary: Project Name: ClientAmit MaityNo ratings yet

- QuestionsDocument20 pagesQuestionsmaheshNo ratings yet

- Datasheet DiacDocument4 pagesDatasheet DiacOrlandoTobonNo ratings yet