Professional Documents

Culture Documents

Pipe Wall THK Calc For External Pressure

Pipe Wall THK Calc For External Pressure

Uploaded by

ktejankarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Wall THK Calc For External Pressure

Pipe Wall THK Calc For External Pressure

Uploaded by

ktejankarCopyright:

Available Formats

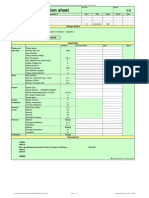

11/10/2020 SPREADSHEETS SERIES No.

0005S_2

Discussion and References

Information about Wall thickness calculation of straight pipes under external pressure:

ASME Section VIII Div 1 paragraphs UG-28, UG-29 and UG-30

ASME B31.3 Process Piping, paragraph 304.1.3

Tables and Standards

- ASME Sec on VIII Div 1 paragraph UG-28, Thickness of Shells and Tubes under External Pressure

- ASME Sec on VIII Div 1 paragraph UG-29, S ffening Rings for Cylindrical Shells Under External Pressure

- ASME Sec on VIII Div 1 paragraph UG-30, A achment of S ffening Rings

- ASME B31.3 Process Piping, paragraph 304.1.3, Straight Pipe Under External Pressure

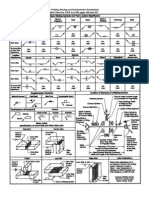

- ASME Sec. II D Fig. G, Geometric Chart for Components Under External or Compressive Loadings (All Materials)

- ASME Sec. II D Fig. CS, Chart for Determining Shell Thickness of Components Under External Pressure Developed

for Carbon or Low Alloy Steel

- ASME Sec. II D Fig. HA, Chart for Determining Shell Thickness of Components Under External Pressure Developed

for Austeni c Steel

- ASME Sec. II D Fig. HT, Chart for Determining Shell Thickness of Components Under External Pressure Developed

for Quenched and Tempered Low Alloy Steel

- ASME Sec. II D Table TM-1 ( Modulus of Elas city, E )

- ASME B36.10M-Welded and Seamless Wrought Steel Pipe

- ASME B36.19M-Stainless Steel Pipe

Cylinders having Do/t values ≥ 10

Step 1. Assume a value for t and determine the ra os L/Do and Do/t.

Step 2. Enter Figure G in Subpart 3 of Sec on II, Part D at the value of L/Do determined in Step 1. For

values of L/Do greater than 50, enter the chart at a value of L/Do = 50. For values of L/Do less

than 0.05, enter the chart at a value of L/Do = 0.05.

Step 3. Move horizontally to the line for the value of Do /t determined in Step 1. Interpola on may be

made for intermediate values of Do/t; extrapola on is not permi ed. From this point of

intersec on move ver cally downward to determine the value of factor A.

Step 4. Using the value of A calculated in Step 3, enter the applicable material chart in Subpart 3 of

Sec on II, Part D for the material under considera on. (See figures CS for Carbon and Low Alloy

Steel and HT for Ferri c Steels with Proper es Enhanced by Heat Treatment). Move ver cally to

an intersec on with the material/temperature line for the design temperature (see UG-20).

Interpola on may be made between lines for intermediate temperatures. If tabular values in

Subpart 3 of Sec on II, Part D are used, linear interpola on or any other ra onal interpola on

method may be used to determine a B value that lies between two adjacent tabular values for a

specific temperature. Such interpola on may also be used to determine a B value at an

intermediate temperature that lies between two sets of tabular values, a er first determining

B values for each set of tabular values.

In cases where the value of A falls to the right of the end of the material/temperature line,

assume an intersec on with the horizontal projec on of the upper end of the material/

temperature line. If tabular values are used, the last (maximum) tabulated value shall be used.

For values of A falling to the le of the material/temperature line, see Step 7.

Step 5. From the intersec on obtained in Step 4, move horizontally to the right and read the value of

factor B.

Step 6. Using this value of B, calculate the value of the maximum allowable external working pressure

Pa using the following equa on:

https://ssccust1.spreadsheethosting.com/1/ff/389ed46f22bc5a/SPREADSHEETS SERIES No. 0005S_2/SPREADSHEETS SERIES No. 0005S_2.htm 1/2

11/10/2020 SPREADSHEETS SERIES No. 0005S_2

4B

Pa =

3(Do/t)

Step 7. For values of A falling to the left of the applicable material/temperature line, the value of Pa can be

calculated using the following equation:

2AE

Pa =

3(Do/t)

If tabular values are used, determine B as in Step 4 and apply it to the equa on in Step 6.

Step 8. Compare the calculated value of Pa obtained in Step 6 or Step 7 with P. If Pa is smaller than P,

select a larger value for t and repeat the design procedure un l a value of Pa is obtained that is

equal to or greater than P.

The parameters in the wall thickness calcula on of straight pipes under external pressure

equa ons above are:

A = factor determined from Figure G in Subpart 3 of Sec on II, Part D and used to enter the

applicable material chart in Subpart 3 of Sec on II, Part D. For the case of cylinders having

Do/t values less than 10, see (c)(2).

B = factor determined from the applicable material chart or table in Subpart 3 of Sec on II,

Part D (Figures CS, HA, HT) for maximum design metal temperature [see UG-20(c)]

Do = outside diameter of cylindrical shell course or tube.

E = modulus of elas city of material at design temperature. For external pressure design in

accordance with this Sec on, the modulus of elas city to be used shall be taken from the

applicable materials chart in Subpart 3 of Sec on II, Part D. (Interpola on may be made

made between lines for intermediate temperatures.)

L = the running centerline length between any two sec ons s ffened in accordance with

UG-29. in. (mm).

P = external design pressure [see Note in UG-28 (f)].

Pa = calculated value of maximum allowable external working pressure for the assumed

assumed value of t, [see Note in UG-28(f)].

t = minimum required thickness of cylindrical shell or tube, or spherical shell, in. (mm)

https://ssccust1.spreadsheethosting.com/1/ff/389ed46f22bc5a/SPREADSHEETS SERIES No. 0005S_2/SPREADSHEETS SERIES No. 0005S_2.htm 2/2

You might also like

- Cbest Cset Writing UpdateDocument36 pagesCbest Cset Writing Updatedistanceprep89% (9)

- Es Emp Iocal Colo en 13480Document25 pagesEs Emp Iocal Colo en 13480castibraNo ratings yet

- External Pressure Pipe Thickness CalcDocument3 pagesExternal Pressure Pipe Thickness CalcArindomNo ratings yet

- Pipe Support Span CalculationsDocument2 pagesPipe Support Span CalculationsktejankarNo ratings yet

- Managing Risk in Alternative Investment-@meet Book Storage PDFDocument321 pagesManaging Risk in Alternative Investment-@meet Book Storage PDFktejankarNo ratings yet

- Calculation Cover SheetDocument8 pagesCalculation Cover SheetYogesh PangareNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document4 pagesCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- PipestresDocument4 pagesPipestresRevankar B R ShetNo ratings yet

- Trunnion Calcualtion SheetDocument22 pagesTrunnion Calcualtion SheetAbhijit50% (2)

- ASME PipingOffice - Piping CalculatorsDocument5 pagesASME PipingOffice - Piping CalculatorsJohn PaulNo ratings yet

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument8 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeAndres Rodriguez HerreraNo ratings yet

- CS-150-2c3 - Pulled Bend Min THKDocument1 pageCS-150-2c3 - Pulled Bend Min THKJoanna NewtonNo ratings yet

- Design ReportDocument30 pagesDesign Reportshahroze mustafaNo ratings yet

- Branch Calculation Table: XXX XXXDocument4 pagesBranch Calculation Table: XXX XXXmaz100% (1)

- Compress CalculationDocument106 pagesCompress CalculationKrupal Patel100% (1)

- News Letter For Expansion Bellow PDFDocument4 pagesNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Vibration Assessment of Barred TeeDocument1 pageVibration Assessment of Barred Teeข้าวเม่า ทอดNo ratings yet

- Weld Shear Stress Check For FAVID Clips Welded On CladDocument3 pagesWeld Shear Stress Check For FAVID Clips Welded On Cladrsubramani100% (1)

- Design by AnalysisDocument22 pagesDesign by AnalysisJEELE77No ratings yet

- Wind Calculation SheetDocument32 pagesWind Calculation SheetaauppalNo ratings yet

- Analisis of Stress in BellowsDocument101 pagesAnalisis of Stress in BellowsOswaldo Guerra100% (1)

- New Cut Length CalculatorDocument30 pagesNew Cut Length CalculatorsmdriyazbashaNo ratings yet

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNo ratings yet

- Hdpe Anchor Load CalcualtionDocument14 pagesHdpe Anchor Load CalcualtionPipeline EngineerNo ratings yet

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Shell Thickness CalcDocument1 pageShell Thickness CalcDidi KurniadiNo ratings yet

- FlangeCalculationASMEVIII Version5Document3 pagesFlangeCalculationASMEVIII Version5alvinchuan100% (2)

- Tubesheet PDFDocument8 pagesTubesheet PDFRitesh VishambhariNo ratings yet

- FEA Validation Release 2010Document7 pagesFEA Validation Release 2010DHAVAL PANCHALNo ratings yet

- Wall Thickness CalDocument6 pagesWall Thickness CalNorazlan Shah MahadiNo ratings yet

- Establishing ASME B16.5 Blind Flanges Pressure Ratings For Reduced Flange Thickness++++++++++Document6 pagesEstablishing ASME B16.5 Blind Flanges Pressure Ratings For Reduced Flange Thickness++++++++++Ali AlizadehNo ratings yet

- PV Newsletter - Skirt Connections PDFDocument5 pagesPV Newsletter - Skirt Connections PDFDivyesh Patel100% (1)

- Equivalent PressureDocument1 pageEquivalent PressureSarfaraz KhanNo ratings yet

- Dummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMDocument4 pagesDummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMashish shrivastav50% (2)

- Astm D3294 PtefDocument6 pagesAstm D3294 PtefIsabella RomeroNo ratings yet

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Pipe Thickness & RF Pad Calculations As Per Asme b313Document3 pagesPipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNo ratings yet

- Blind Calculation: This Calculation Is According To EN 13480Document2 pagesBlind Calculation: This Calculation Is According To EN 13480anas060No ratings yet

- Pipe Size Flange Rating Operating Condition: E F SFDocument4 pagesPipe Size Flange Rating Operating Condition: E F SFvivekpec100% (1)

- ASME B31 8 Riser CalcDocument12 pagesASME B31 8 Riser CalcEmmanuel LawrenceNo ratings yet

- Aws Welding SymbolsDocument2 pagesAws Welding SymbolsAlessio BarboneNo ratings yet

- Nozzle Load CheckDocument4 pagesNozzle Load CheckpipestressNo ratings yet

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Document17 pagesNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoNo ratings yet

- Api Tank 400M3 HCDocument10 pagesApi Tank 400M3 HCCharles Dogne100% (1)

- Design and Analysis of Pressure Vessel Skirt Considering Seismic Load As Per Uniform Building Code IJERTCONV4IS10007Document5 pagesDesign and Analysis of Pressure Vessel Skirt Considering Seismic Load As Per Uniform Building Code IJERTCONV4IS10007RSalehNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Top Pipe MomentDocument2 pagesTop Pipe Momentrsubramani100% (1)

- 42in Branch Reinforment CalDocument10 pages42in Branch Reinforment CalDhakshina KNo ratings yet

- Pressure Design Straight Pipe (Run Pipe)Document6 pagesPressure Design Straight Pipe (Run Pipe)gembirasekaliNo ratings yet

- 3.3 Piping Design Criteria Rev 2Document15 pages3.3 Piping Design Criteria Rev 2Maheswaran KurusamyNo ratings yet

- Blank PageDocument1 pageBlank Pageanandgm35No ratings yet

- External PressureDocument3 pagesExternal PressureKingston RivingtonNo ratings yet

- Calculation of Pipe Thickness For External PressureDocument3 pagesCalculation of Pipe Thickness For External PressureArindomNo ratings yet

- FormulaDocument1 pageFormulakhasim15No ratings yet

- Lecture 3 External Pressure C1c8e496 66e8 4086 A720 0e726ced7edfDocument29 pagesLecture 3 External Pressure C1c8e496 66e8 4086 A720 0e726ced7edfAriHara SudhanNo ratings yet

- Allowable Compressive Stress1Document1 pageAllowable Compressive Stress1Shubham MistryNo ratings yet

- Pressure Vessels Lectures 77Document1 pagePressure Vessels Lectures 77Adeel NizamiNo ratings yet

- Max Allowable Pressure of Pipes and Pipellines CER 04022013Document89 pagesMax Allowable Pressure of Pipes and Pipellines CER 04022013Castro Quinteros WinstonNo ratings yet

- The Analysis of Piping Under PressureDocument21 pagesThe Analysis of Piping Under PressureTrungSon NguyenNo ratings yet

- Max Allowable Pressure of Pipes and PipellinesDocument104 pagesMax Allowable Pressure of Pipes and Pipellinesprasoon_eilNo ratings yet

- API CoursesDocument33 pagesAPI CoursesOmar Alkubaici100% (1)

- Pipe Bridge Design SheetDocument1 pagePipe Bridge Design SheetktejankarNo ratings yet

- Roark's Formulas For Excel Universal Technical Systems, IncDocument26 pagesRoark's Formulas For Excel Universal Technical Systems, Incktejankar100% (1)

- Support Load CalcDocument11 pagesSupport Load CalcktejankarNo ratings yet

- Api 1111 Collapse Pressure CalcDocument2 pagesApi 1111 Collapse Pressure CalcktejankarNo ratings yet

- Usfos HydrodynamicsDocument95 pagesUsfos Hydrodynamicsabhinavka123No ratings yet

- Pipe Wall Thickness Calc Per ASME B31.8Document1 pagePipe Wall Thickness Calc Per ASME B31.8ktejankarNo ratings yet

- Questions & Answers: Webinar: Static Load Case EditorDocument4 pagesQuestions & Answers: Webinar: Static Load Case EditorktejankarNo ratings yet

- Hexagon PPM L-T Chiyoda C2 Engineering Analysis Case Study USDocument2 pagesHexagon PPM L-T Chiyoda C2 Engineering Analysis Case Study USktejankarNo ratings yet

- Fire Water System Design PDFDocument22 pagesFire Water System Design PDFktejankarNo ratings yet

- Design For Pressure VesselDocument18 pagesDesign For Pressure VesselktejankarNo ratings yet

- NozzlePRO Brochure PDFDocument2 pagesNozzlePRO Brochure PDFktejankarNo ratings yet

- General: Warning: Windows Vista and Later Versions Have Increased Security. You Need To HaveDocument5 pagesGeneral: Warning: Windows Vista and Later Versions Have Increased Security. You Need To HavektejankarNo ratings yet

- CT 332 SDDocument16 pagesCT 332 SDEmi DNo ratings yet

- International Airline Passengers International Airline PassengersDocument8 pagesInternational Airline Passengers International Airline PassengersngojchieernNo ratings yet

- LLoyd - Kirk Contra PopperDocument19 pagesLLoyd - Kirk Contra PopperJOSEFINA FANo ratings yet

- Analysis and Design of Power Transmission Lines Steel TowersDocument48 pagesAnalysis and Design of Power Transmission Lines Steel Towersadnan-651358No ratings yet

- Steel 316 LDocument5 pagesSteel 316 LManjunatha VNo ratings yet

- Fiduciary Relationships: Ensuring The Loyal Exercise of Judgement On Behalf of Another Lionel SmithDocument27 pagesFiduciary Relationships: Ensuring The Loyal Exercise of Judgement On Behalf of Another Lionel Smithkevin leeNo ratings yet

- Module1 Activity SARMIENTODocument5 pagesModule1 Activity SARMIENTOMyrene SarmientoNo ratings yet

- Exercise 1.01 Bouncing Ball: Posted by George atDocument2 pagesExercise 1.01 Bouncing Ball: Posted by George atbigcow60No ratings yet

- Tanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVDocument2 pagesTanhov Industrial Co.,Ltd: ITP (Inspection and Test Plan) FOR PRVUmair AwanNo ratings yet

- Kodak - OG 5.48 DatasheetDocument2 pagesKodak - OG 5.48 DatasheetNhaca0% (1)

- Consumer Behavior AssignmentDocument34 pagesConsumer Behavior AssignmentREAZ HasanNo ratings yet

- Engineering Operations Research: Text Book: Operations Research: An Introduction Hamdy A. TahaDocument10 pagesEngineering Operations Research: Text Book: Operations Research: An Introduction Hamdy A. TahaMohamedAhmedAbdelazizNo ratings yet

- Paul Voodini - Psychic Show Cancelled!Document25 pagesPaul Voodini - Psychic Show Cancelled!jamesbalames50% (2)

- Rivaroxaban Tablets - British Pharmacopoeia 2021Document7 pagesRivaroxaban Tablets - British Pharmacopoeia 2021L_YolandaNo ratings yet

- Midterm SolutionsDocument6 pagesMidterm SolutionsCengiz KöseoğluNo ratings yet

- WebinarPresentation - AVEVA Predictive Analytics For Historian - 10-19Document22 pagesWebinarPresentation - AVEVA Predictive Analytics For Historian - 10-19sachin BhavsarNo ratings yet

- Downcomer PipesDocument9 pagesDowncomer Pipesk v rajeshNo ratings yet

- Science 10 Q1 Module 1Document11 pagesScience 10 Q1 Module 1Christopher Jorge BarredoNo ratings yet

- Betadex Sulfobutyl Ether SodiumDocument11 pagesBetadex Sulfobutyl Ether SodiumLeidy GonzalezNo ratings yet

- Especificacion y Manual Equipo HCBT-01 - C-13Document86 pagesEspecificacion y Manual Equipo HCBT-01 - C-13Anthony kalevi MiravalNo ratings yet

- Qual ExamSolsDocument203 pagesQual ExamSolsAndres NavarroNo ratings yet

- Limiting Factors: Key Words: Rate of Reaction, Enzymes, DenatureDocument13 pagesLimiting Factors: Key Words: Rate of Reaction, Enzymes, DenatureAref DahabrahNo ratings yet

- 09-24-16 EditionDocument32 pages09-24-16 EditionSan Mateo Daily JournalNo ratings yet

- Outdoor Ventilation Airflow Calculations: ControlDocument6 pagesOutdoor Ventilation Airflow Calculations: ControlAli HabibNo ratings yet

- List of Non ReadersDocument2 pagesList of Non ReadersCarol LaconsayNo ratings yet

- Thesis On Zero Energy BuildingDocument7 pagesThesis On Zero Energy BuildingWhitePaperWritingServicesCanada100% (2)

- Dailects Vs LanguageDocument6 pagesDailects Vs LanguageAliaNo ratings yet

- Factors Contributing To Drug Abuse Among The Youth in Kenya, A Case of Bamburi Location, MombasaDocument10 pagesFactors Contributing To Drug Abuse Among The Youth in Kenya, A Case of Bamburi Location, MombasaKasundu BoscoNo ratings yet

- Interview Questions For Reference-1Document2 pagesInterview Questions For Reference-1Rahul SoroutNo ratings yet