Professional Documents

Culture Documents

Amberlite IR 120 Na L

Amberlite IR 120 Na L

Uploaded by

william guillermo valencia mezaCopyright:

Available Formats

You might also like

- MOPX 309 Separation System With Build-On PumpDocument38 pagesMOPX 309 Separation System With Build-On PumpBalaNo ratings yet

- Aquasensor As 1000 & As 2000 Series.: Frequently Asked Questions (Faqs) and GlossaryDocument6 pagesAquasensor As 1000 & As 2000 Series.: Frequently Asked Questions (Faqs) and GlossaryThais Roberta CamposNo ratings yet

- Seplite LSC750 PDFDocument6 pagesSeplite LSC750 PDFDiegoNo ratings yet

- Formulas PyroDocument23 pagesFormulas PyroMyguEl MurrieTa100% (1)

- Terpenoids and Steroids - Vol1Document574 pagesTerpenoids and Steroids - Vol1Ngoc Hong TranNo ratings yet

- IR120Na MetricDocument2 pagesIR120Na MetricMahmudul HasanNo ratings yet

- Amberjet 1000 Na LDocument2 pagesAmberjet 1000 Na LRisali AddiniNo ratings yet

- AMBERJET™ 4200 CL: Industrial Grade Strong Base Anion ExchangerDocument2 pagesAMBERJET™ 4200 CL: Industrial Grade Strong Base Anion ExchangerPanca Erlangga SiregarNo ratings yet

- Amberjet™ 1000 H: Industrial Grade Strong Acid Cation ExchangerDocument2 pagesAmberjet™ 1000 H: Industrial Grade Strong Acid Cation ExchangerPanca Erlangga SiregarNo ratings yet

- Amberlite Ira 410 CL L Anion SpecsDocument2 pagesAmberlite Ira 410 CL L Anion SpecsgsyaoNo ratings yet

- Amberlite IRA 96 LDocument2 pagesAmberlite IRA 96 LLoera AntonioNo ratings yet

- Rohm & Haas Amberjet 1500 H LDocument2 pagesRohm & Haas Amberjet 1500 H LthanhhuyenNo ratings yet

- Amberjet 4400 CL LDocument2 pagesAmberjet 4400 CL LVirga AndikaNo ratings yet

- Amberlite Ir120 H PDFDocument2 pagesAmberlite Ir120 H PDFArooba AsharNo ratings yet

- Amberlite™ Ira405 CL: Ion Exchange ResinsDocument2 pagesAmberlite™ Ira405 CL: Ion Exchange ResinsMOST PASONNo ratings yet

- Amberlite™ Ira402 CL: Industrial Grade Strong Base Anion ExchangerDocument2 pagesAmberlite™ Ira402 CL: Industrial Grade Strong Base Anion ExchangerFahima AididNo ratings yet

- Amberlite IRN 150 LDocument2 pagesAmberlite IRN 150 LMuhammad ImranNo ratings yet

- Rohm & Haas Amberlite IRN 150 LDocument2 pagesRohm & Haas Amberlite IRN 150 LMuhammad ImranNo ratings yet

- Resin AmberliteDocument2 pagesResin Amberlitegreat_1No ratings yet

- Cation Exchange Resin DUOLITE C20 PDS PDFDocument4 pagesCation Exchange Resin DUOLITE C20 PDS PDFArunkumar ChandaranNo ratings yet

- Amberlite IRN 160 LDocument2 pagesAmberlite IRN 160 LJayanath Nuwan SameeraNo ratings yet

- Ayvaz CV10S1S2 Disco Cekvalf ENGDocument2 pagesAyvaz CV10S1S2 Disco Cekvalf ENGVlad AncutaNo ratings yet

- Case Studies, Optimizations and Trials For PSDDocument5 pagesCase Studies, Optimizations and Trials For PSDIbrahim Nick DibalNo ratings yet

- Pro XP1Document2 pagesPro XP1sunil patelNo ratings yet

- Amberlite Ira743Document2 pagesAmberlite Ira743Gregorio Antonio Valero VerdeNo ratings yet

- Products RangeDocument12 pagesProducts Rangejayeshsangani30No ratings yet

- New Developments in Non Cement RefractoriesDocument9 pagesNew Developments in Non Cement RefractoriesfelipecastilhodesouzaNo ratings yet

- BWT LogDocument3 pagesBWT LogCHI-MING WENNo ratings yet

- Engineering Data Sheet - Amberlite Irc86Document1 pageEngineering Data Sheet - Amberlite Irc86Algirdas BaranauskasNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- MIB 303 AC Separation System, Module - System Reference - 2016Document18 pagesMIB 303 AC Separation System, Module - System Reference - 2016Centrifugal SeparatorNo ratings yet

- PTssGlobal Technical Presentation OnlineTransformerDryoutSystemsDocument54 pagesPTssGlobal Technical Presentation OnlineTransformerDryoutSystemsYogesh SoodNo ratings yet

- Momentive Silicon Data Sheet - MPMtsf451-50e - EDocument4 pagesMomentive Silicon Data Sheet - MPMtsf451-50e - EMutharasan VishnuNo ratings yet

- LPH 65320 LPH 65327Document9 pagesLPH 65320 LPH 65327Eko WageurNo ratings yet

- OTC 19531 Compact Electrostatic Separation ProcessDocument6 pagesOTC 19531 Compact Electrostatic Separation Process1mmahoneyNo ratings yet

- Eastman TTC Em300 DiamondDocument4 pagesEastman TTC Em300 Diamondsithira.yNo ratings yet

- M82Document1 pageM82FRANZ RICHARD SARDINAS MALLCO100% (1)

- Climatic-Chambers DS FDMDocument3 pagesClimatic-Chambers DS FDMconkhimocNo ratings yet

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Document10 pagesLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNo ratings yet

- Data Sheet FC-70Document4 pagesData Sheet FC-70sshaffer_9No ratings yet

- DcaDocument5 pagesDcaederNo ratings yet

- Hot Mix Asphalt Materials and Characteristics IIDocument69 pagesHot Mix Asphalt Materials and Characteristics IIKhin Khin ThawNo ratings yet

- Hydraulic Vane Pumps Subplate and Flange Mounted: RA 10 336/12.04 Replaces: 07.03 1/12Document12 pagesHydraulic Vane Pumps Subplate and Flange Mounted: RA 10 336/12.04 Replaces: 07.03 1/12Bryan Edu Curay ZavalaNo ratings yet

- Laboratory Activity No. 2Document7 pagesLaboratory Activity No. 2nasser07.1000No ratings yet

- Katalog SIHI Liquid Ring Vacuum PumpsDocument12 pagesKatalog SIHI Liquid Ring Vacuum PumpsTrisna RamadhanNo ratings yet

- ConditionMonitoring CMPDocument6 pagesConditionMonitoring CMPibrahem fawzy (اعرف اكثـــــر)No ratings yet

- Ch. Krause - Moisture Effects On The Electric Strength of Oil-Pressboard Insulation Used in Power TransformersDocument4 pagesCh. Krause - Moisture Effects On The Electric Strength of Oil-Pressboard Insulation Used in Power Transformersnamsaigon316No ratings yet

- Awm 700Document4 pagesAwm 700azerinoNo ratings yet

- ENGINEERING DATA SHEET - AMBERLITE IR120 Na - H SO - RFRDocument2 pagesENGINEERING DATA SHEET - AMBERLITE IR120 Na - H SO - RFRAlgirdas BaranauskasNo ratings yet

- 2 Ny 7 QR 2 SnzagsniaDocument6 pages2 Ny 7 QR 2 SnzagsniaSamir FrendiNo ratings yet

- Amberjet 1200 Na LDocument2 pagesAmberjet 1200 Na LbayusetyaNo ratings yet

- Model Selection Guide: Main Line Sub LineDocument4 pagesModel Selection Guide: Main Line Sub LinejhoffreNo ratings yet

- Service Life Factors For Vrla BatteriesDocument11 pagesService Life Factors For Vrla BatterieshashimelecNo ratings yet

- CMP ADocument8 pagesCMP AFotos WD DiacoNo ratings yet

- Tds Panaoil Amon SHCDocument1 pageTds Panaoil Amon SHCMuhammad FarhanNo ratings yet

- Specification Sheet: Density Measurement of Petroleum Products by Hydrometer MethodDocument9 pagesSpecification Sheet: Density Measurement of Petroleum Products by Hydrometer Methodh8pb8jzyhgNo ratings yet

- S1-16-ppt - Adoption of K Class Fluids For Distribution TransformersDocument21 pagesS1-16-ppt - Adoption of K Class Fluids For Distribution TransformersRAVINDERNo ratings yet

- 225 Na Engg DataDocument8 pages225 Na Engg DatadeyprasenNo ratings yet

- WCM 7300 - Specification PDFDocument2 pagesWCM 7300 - Specification PDFzaffarNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesFrom EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNo ratings yet

- Sn10a Var RPMDocument1 pageSn10a Var RPMwilliam guillermo valencia mezaNo ratings yet

- Sn10a Var RPMDocument1 pageSn10a Var RPMwilliam guillermo valencia mezaNo ratings yet

- Nivel de SumergenciaDocument1 pageNivel de Sumergenciawilliam guillermo valencia mezaNo ratings yet

- PV40B y 50BDocument5 pagesPV40B y 50Bwilliam guillermo valencia mezaNo ratings yet

- IOM RevAb 1112Document16 pagesIOM RevAb 1112william guillermo valencia mezaNo ratings yet

- Blackmer PV80BDocument4 pagesBlackmer PV80Bwilliam guillermo valencia mezaNo ratings yet

- Form 6600Document2 pagesForm 6600william guillermo valencia mezaNo ratings yet

- 100 Years of Boiler Technology LeadershipDocument6 pages100 Years of Boiler Technology Leadershipwilliam guillermo valencia mezaNo ratings yet

- Annex 6 20110501 E K20110505Document154 pagesAnnex 6 20110501 E K20110505Agus Mustofa SolehNo ratings yet

- Chemistry of Crude OilDocument33 pagesChemistry of Crude OilCNAltNo ratings yet

- Curing Characteristics of Low Emission Urea-Formaldehyde Adhesive in The Presence of WoodDocument13 pagesCuring Characteristics of Low Emission Urea-Formaldehyde Adhesive in The Presence of WoodNam Phạm VănNo ratings yet

- Atom-Solution - Exam PracticeDocument11 pagesAtom-Solution - Exam PracticeWilliam ChongNo ratings yet

- Lecture Note For 1.weekDocument72 pagesLecture Note For 1.weekTrần ĐạiNo ratings yet

- Biosynthetic Pathways: Frederick A. Bettelheim William H. Brown Mary K. Campbell Shawn O. FarrellDocument28 pagesBiosynthetic Pathways: Frederick A. Bettelheim William H. Brown Mary K. Campbell Shawn O. FarrellShereen AlobinayNo ratings yet

- Conbextra UHSDocument2 pagesConbextra UHSabhay_joshi20020% (1)

- Invisible Ink: Modeling A Molecular SwitchDocument2 pagesInvisible Ink: Modeling A Molecular SwitchAbhinav AbhilashNo ratings yet

- Silicones Additives 2017Document36 pagesSilicones Additives 2017Bilson ShuklaNo ratings yet

- 102 MSJC 13Document11 pages102 MSJC 13noelNo ratings yet

- AkcDocument4 pagesAkcGirishmaNo ratings yet

- Clarke 1988Document14 pagesClarke 1988aruna prasadNo ratings yet

- Calcium Hypochlorite or Calcium OxychlorideDocument56 pagesCalcium Hypochlorite or Calcium OxychlorideSuraj GuptaNo ratings yet

- Iron and Steel - J.H StansbieDocument402 pagesIron and Steel - J.H StansbieHernán SalvayNo ratings yet

- SolutionsDocument509 pagesSolutionssknoushad126No ratings yet

- Study of Cellwall Constituents and Cell InclusionsDocument42 pagesStudy of Cellwall Constituents and Cell Inclusionsharshe v73% (11)

- Tungsten Carbide: Tungsten Carbide (Chemical Formula: WC) Is A ChemicalDocument10 pagesTungsten Carbide: Tungsten Carbide (Chemical Formula: WC) Is A Chemicalroberto jimenezNo ratings yet

- NMR ChitinDocument9 pagesNMR Chitinيحيى بورغدةNo ratings yet

- Stoichiometry 2 QPDocument10 pagesStoichiometry 2 QPYee MeiNo ratings yet

- Ropemanship and Knot TyingDocument44 pagesRopemanship and Knot TyingPHILLIP JOSEPH EBORDE94% (16)

- Artesunateinjection QAS10-365FINALDocument4 pagesArtesunateinjection QAS10-365FINALboddarambabuNo ratings yet

- Ch16 Kesetimbangan Kimia Konsep UmumDocument34 pagesCh16 Kesetimbangan Kimia Konsep UmumJovan PutrandaNo ratings yet

- List Obat BaksosDocument1 pageList Obat BaksosRaden Mas Nur HaryonoNo ratings yet

- Chapter 4: The Periodic Table of ElementsDocument14 pagesChapter 4: The Periodic Table of ElementsFarah Aisyah AhmadNo ratings yet

- Sika Intraplast ZDocument3 pagesSika Intraplast Zreborn_willyNo ratings yet

- LaidlerDexterBioJJB PDFDocument2 pagesLaidlerDexterBioJJB PDFSanthiyaNo ratings yet

- WorkseetDocument2 pagesWorkseetbigbuddhazNo ratings yet

- Pengenalan Karakterisasi MaterialDocument23 pagesPengenalan Karakterisasi Materialfikri wahyu pratamaNo ratings yet

Amberlite IR 120 Na L

Amberlite IR 120 Na L

Uploaded by

william guillermo valencia mezaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amberlite IR 120 Na L

Amberlite IR 120 Na L

Uploaded by

william guillermo valencia mezaCopyright:

Available Formats

Lenntech

info@lenntech.com

www.lenntech.com

PRODUCT DATA SHEET Tel. +31-15-261.09.00

Fax. +31-15-261.62.89

AMBERLITE™ IR120 Na

Industrial Grade Strong Acid Cation Exchanger

AMBERLITE IR120 Na resin is a gel type strongly IR120 Na resin is an excellent general purpose

acidic cation exchange resin of the sulfonated cation exchange resin that can be used for a wide

polystyrene type. It is used for water softening (in variety of industrial water treatment applications

Na+ form) as well as for water demineralisation (in including both softening and demineralisation.

H+ form) in co-flow regenerated units. AMBERLITE

PROPERTIES

Physical form_______________________________ Amber spherical beads

Matrix_____________________________________ Styrene divinylbenzene copolymer

Functional group ___________________________ Sulfonate

Ionic form as shipped _______________________ Na+

[1]

Total exchange capacity ___________________ ≥ 2.00 eq/L (Na+ form)

[1]

Moisture holding capacity __________________ 45 to 50 % (Na+ form)

Shipping weight ____________________________ 840 g/L

Particle size

[1]

Uniformity coefficient __________________ ≤ 1.9

[1]

Harmonic mean size ___________________ 0.600 to 0.800 mm

[1]

< 0.300 mm ___________________________ 2 % max

Maximum reversible swelling ______________ Na+ → H+ ≤ 11 %

[1]

Contractual value

Test methods available upon request.

SUGGESTED OPERATING CONDITIONS

Maximum operating temperature _____________ 135 °C

Minimum bed depth ________________________ 700 mm

Service flow rate ____________________________ 5 to 40 BV*/h

Regeneration

Regenerant _____________________________ HCl H2SO4 NaCl

Level (g/L) _____________________________ 50 to 150 60 to 240 80 to 250

Concentration (%) _______________________ 5 to 8 0.7 to 6 10

Minimum contact time____________________ 30 minutes

Slow rinse_______________________________ 2 BV at regeneration flow rate

Fast rinse _______________________________ 2 to 4 BV at service flow rate

3 3

* 1 BV (Bed Volume) = 1 m solution per m resin

PERFORMANCE determine the best resin choice and optimum

operating conditions.

The operating capacity depends on several factors

such as the water analysis and the level of

HYDRAULIC CHARACTERISTICS

regeneration. The data to calculate the operating

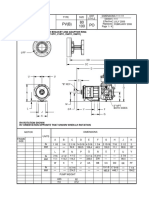

capacity and the ionic leakage with co-flow Figure 1 shows the bed expansion of AMBERLITE

regeneration are given in the Engineering Data IR120 Na resin, as a function of backwash flow rate

Sheets: EDS 0262 A, EDS 0264 A and EDS 0265 A. and water temperature. Figure 2 shows the pressure

drop data for AMBERLITE IR120 Na resin, as a

LIMITS OF USE function of service flow rate and water temperature.

Pressure drop data are valid at the start of the

AMBERLITE IR120 Na resin is suitable for service run with clear water and a correctly classified

industrial uses. For other specific applications such bed.

as pharmaceutical, food processing or potable water

applications, it is recommended that all potential

users seek advice from Rohm and Haas in order to

Figure 1: Bed Expansion Figure 2: Pressure Drop

5°C 10°C

kPa/m

150

20°C 100

5°C

125

80 10°C

30°C

Expansion %

100

Pressure drop

40°C 60 20°C

75

30°C

60°C 40 40°C

50

60°C

25 20

0 5 10 15 20 25 30 m/h

0 10 20 30 40 50 m/h

Backwash flow rate

Service flow rate

AMBERJET is a trademark of Rohm and Haas Company and its affiliates, Philadelphia, U.S.A.

Ion exchange resins and polymeric adsorbents, as produced, contain by-products resulting from the manufacturing process. The user must determine the extent to which

organic by-products must be removed for any particular use and establish techniques to assure that the appropriate level of purity is achieved for that use. The user must

ensure compliance with all prudent safety standards and regulatory requirements governing the application. Except where specifically otherwise stated, Rohm and Haas

Company does not recommend its ion exchange resins or polymeric adsorbents, as supplied, as being suitable or appropriately pure for any particular use. Consult your Rohm

and Haas technical representative for further information. Acidic and basic regenerant solutions are corrosive and should be handled in a manner that will prevent eye and skin

contact. Nitric acid and other strong oxidising agents can cause explosive type reactions when mixed with Ion Exchange resins. Proper design of process equipment to prevent

rapid buildup of pressure is necessary if use of an oxidising agent such as nitric acid is contemplated. Before using strong oxidising agents in contact with Ion Exchange Resins,

consult sources knowledgeable in the handling of these materials.

Rohm and Haas Company makes no warranties either expressed or implied as to the accuracy or appropriateness of these data and expressly excludes any liability upon Rohm and

Haas arising out of its use. We recommend that the prospective users determine for themselves the suitability of Rohm and Haas materials and suggestions for any use prior to their

adoption. Suggestions for uses of our products of the inclusion of descriptive material from patents and the citation of specific patents in this publication should not be understood as

recommending the use of our products in violation of any patent or as permission or license to use any patents of the Rohm and Haas Company and its affiliates. Material Safety Data

Sheets outlining the hazards and handling methods for our products are available on request.

You might also like

- MOPX 309 Separation System With Build-On PumpDocument38 pagesMOPX 309 Separation System With Build-On PumpBalaNo ratings yet

- Aquasensor As 1000 & As 2000 Series.: Frequently Asked Questions (Faqs) and GlossaryDocument6 pagesAquasensor As 1000 & As 2000 Series.: Frequently Asked Questions (Faqs) and GlossaryThais Roberta CamposNo ratings yet

- Seplite LSC750 PDFDocument6 pagesSeplite LSC750 PDFDiegoNo ratings yet

- Formulas PyroDocument23 pagesFormulas PyroMyguEl MurrieTa100% (1)

- Terpenoids and Steroids - Vol1Document574 pagesTerpenoids and Steroids - Vol1Ngoc Hong TranNo ratings yet

- IR120Na MetricDocument2 pagesIR120Na MetricMahmudul HasanNo ratings yet

- Amberjet 1000 Na LDocument2 pagesAmberjet 1000 Na LRisali AddiniNo ratings yet

- AMBERJET™ 4200 CL: Industrial Grade Strong Base Anion ExchangerDocument2 pagesAMBERJET™ 4200 CL: Industrial Grade Strong Base Anion ExchangerPanca Erlangga SiregarNo ratings yet

- Amberjet™ 1000 H: Industrial Grade Strong Acid Cation ExchangerDocument2 pagesAmberjet™ 1000 H: Industrial Grade Strong Acid Cation ExchangerPanca Erlangga SiregarNo ratings yet

- Amberlite Ira 410 CL L Anion SpecsDocument2 pagesAmberlite Ira 410 CL L Anion SpecsgsyaoNo ratings yet

- Amberlite IRA 96 LDocument2 pagesAmberlite IRA 96 LLoera AntonioNo ratings yet

- Rohm & Haas Amberjet 1500 H LDocument2 pagesRohm & Haas Amberjet 1500 H LthanhhuyenNo ratings yet

- Amberjet 4400 CL LDocument2 pagesAmberjet 4400 CL LVirga AndikaNo ratings yet

- Amberlite Ir120 H PDFDocument2 pagesAmberlite Ir120 H PDFArooba AsharNo ratings yet

- Amberlite™ Ira405 CL: Ion Exchange ResinsDocument2 pagesAmberlite™ Ira405 CL: Ion Exchange ResinsMOST PASONNo ratings yet

- Amberlite™ Ira402 CL: Industrial Grade Strong Base Anion ExchangerDocument2 pagesAmberlite™ Ira402 CL: Industrial Grade Strong Base Anion ExchangerFahima AididNo ratings yet

- Amberlite IRN 150 LDocument2 pagesAmberlite IRN 150 LMuhammad ImranNo ratings yet

- Rohm & Haas Amberlite IRN 150 LDocument2 pagesRohm & Haas Amberlite IRN 150 LMuhammad ImranNo ratings yet

- Resin AmberliteDocument2 pagesResin Amberlitegreat_1No ratings yet

- Cation Exchange Resin DUOLITE C20 PDS PDFDocument4 pagesCation Exchange Resin DUOLITE C20 PDS PDFArunkumar ChandaranNo ratings yet

- Amberlite IRN 160 LDocument2 pagesAmberlite IRN 160 LJayanath Nuwan SameeraNo ratings yet

- Ayvaz CV10S1S2 Disco Cekvalf ENGDocument2 pagesAyvaz CV10S1S2 Disco Cekvalf ENGVlad AncutaNo ratings yet

- Case Studies, Optimizations and Trials For PSDDocument5 pagesCase Studies, Optimizations and Trials For PSDIbrahim Nick DibalNo ratings yet

- Pro XP1Document2 pagesPro XP1sunil patelNo ratings yet

- Amberlite Ira743Document2 pagesAmberlite Ira743Gregorio Antonio Valero VerdeNo ratings yet

- Products RangeDocument12 pagesProducts Rangejayeshsangani30No ratings yet

- New Developments in Non Cement RefractoriesDocument9 pagesNew Developments in Non Cement RefractoriesfelipecastilhodesouzaNo ratings yet

- BWT LogDocument3 pagesBWT LogCHI-MING WENNo ratings yet

- Engineering Data Sheet - Amberlite Irc86Document1 pageEngineering Data Sheet - Amberlite Irc86Algirdas BaranauskasNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- MIB 303 AC Separation System, Module - System Reference - 2016Document18 pagesMIB 303 AC Separation System, Module - System Reference - 2016Centrifugal SeparatorNo ratings yet

- PTssGlobal Technical Presentation OnlineTransformerDryoutSystemsDocument54 pagesPTssGlobal Technical Presentation OnlineTransformerDryoutSystemsYogesh SoodNo ratings yet

- Momentive Silicon Data Sheet - MPMtsf451-50e - EDocument4 pagesMomentive Silicon Data Sheet - MPMtsf451-50e - EMutharasan VishnuNo ratings yet

- LPH 65320 LPH 65327Document9 pagesLPH 65320 LPH 65327Eko WageurNo ratings yet

- OTC 19531 Compact Electrostatic Separation ProcessDocument6 pagesOTC 19531 Compact Electrostatic Separation Process1mmahoneyNo ratings yet

- Eastman TTC Em300 DiamondDocument4 pagesEastman TTC Em300 Diamondsithira.yNo ratings yet

- M82Document1 pageM82FRANZ RICHARD SARDINAS MALLCO100% (1)

- Climatic-Chambers DS FDMDocument3 pagesClimatic-Chambers DS FDMconkhimocNo ratings yet

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Document10 pagesLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNo ratings yet

- Data Sheet FC-70Document4 pagesData Sheet FC-70sshaffer_9No ratings yet

- DcaDocument5 pagesDcaederNo ratings yet

- Hot Mix Asphalt Materials and Characteristics IIDocument69 pagesHot Mix Asphalt Materials and Characteristics IIKhin Khin ThawNo ratings yet

- Hydraulic Vane Pumps Subplate and Flange Mounted: RA 10 336/12.04 Replaces: 07.03 1/12Document12 pagesHydraulic Vane Pumps Subplate and Flange Mounted: RA 10 336/12.04 Replaces: 07.03 1/12Bryan Edu Curay ZavalaNo ratings yet

- Laboratory Activity No. 2Document7 pagesLaboratory Activity No. 2nasser07.1000No ratings yet

- Katalog SIHI Liquid Ring Vacuum PumpsDocument12 pagesKatalog SIHI Liquid Ring Vacuum PumpsTrisna RamadhanNo ratings yet

- ConditionMonitoring CMPDocument6 pagesConditionMonitoring CMPibrahem fawzy (اعرف اكثـــــر)No ratings yet

- Ch. Krause - Moisture Effects On The Electric Strength of Oil-Pressboard Insulation Used in Power TransformersDocument4 pagesCh. Krause - Moisture Effects On The Electric Strength of Oil-Pressboard Insulation Used in Power Transformersnamsaigon316No ratings yet

- Awm 700Document4 pagesAwm 700azerinoNo ratings yet

- ENGINEERING DATA SHEET - AMBERLITE IR120 Na - H SO - RFRDocument2 pagesENGINEERING DATA SHEET - AMBERLITE IR120 Na - H SO - RFRAlgirdas BaranauskasNo ratings yet

- 2 Ny 7 QR 2 SnzagsniaDocument6 pages2 Ny 7 QR 2 SnzagsniaSamir FrendiNo ratings yet

- Amberjet 1200 Na LDocument2 pagesAmberjet 1200 Na LbayusetyaNo ratings yet

- Model Selection Guide: Main Line Sub LineDocument4 pagesModel Selection Guide: Main Line Sub LinejhoffreNo ratings yet

- Service Life Factors For Vrla BatteriesDocument11 pagesService Life Factors For Vrla BatterieshashimelecNo ratings yet

- CMP ADocument8 pagesCMP AFotos WD DiacoNo ratings yet

- Tds Panaoil Amon SHCDocument1 pageTds Panaoil Amon SHCMuhammad FarhanNo ratings yet

- Specification Sheet: Density Measurement of Petroleum Products by Hydrometer MethodDocument9 pagesSpecification Sheet: Density Measurement of Petroleum Products by Hydrometer Methodh8pb8jzyhgNo ratings yet

- S1-16-ppt - Adoption of K Class Fluids For Distribution TransformersDocument21 pagesS1-16-ppt - Adoption of K Class Fluids For Distribution TransformersRAVINDERNo ratings yet

- 225 Na Engg DataDocument8 pages225 Na Engg DatadeyprasenNo ratings yet

- WCM 7300 - Specification PDFDocument2 pagesWCM 7300 - Specification PDFzaffarNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesFrom EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNo ratings yet

- Sn10a Var RPMDocument1 pageSn10a Var RPMwilliam guillermo valencia mezaNo ratings yet

- Sn10a Var RPMDocument1 pageSn10a Var RPMwilliam guillermo valencia mezaNo ratings yet

- Nivel de SumergenciaDocument1 pageNivel de Sumergenciawilliam guillermo valencia mezaNo ratings yet

- PV40B y 50BDocument5 pagesPV40B y 50Bwilliam guillermo valencia mezaNo ratings yet

- IOM RevAb 1112Document16 pagesIOM RevAb 1112william guillermo valencia mezaNo ratings yet

- Blackmer PV80BDocument4 pagesBlackmer PV80Bwilliam guillermo valencia mezaNo ratings yet

- Form 6600Document2 pagesForm 6600william guillermo valencia mezaNo ratings yet

- 100 Years of Boiler Technology LeadershipDocument6 pages100 Years of Boiler Technology Leadershipwilliam guillermo valencia mezaNo ratings yet

- Annex 6 20110501 E K20110505Document154 pagesAnnex 6 20110501 E K20110505Agus Mustofa SolehNo ratings yet

- Chemistry of Crude OilDocument33 pagesChemistry of Crude OilCNAltNo ratings yet

- Curing Characteristics of Low Emission Urea-Formaldehyde Adhesive in The Presence of WoodDocument13 pagesCuring Characteristics of Low Emission Urea-Formaldehyde Adhesive in The Presence of WoodNam Phạm VănNo ratings yet

- Atom-Solution - Exam PracticeDocument11 pagesAtom-Solution - Exam PracticeWilliam ChongNo ratings yet

- Lecture Note For 1.weekDocument72 pagesLecture Note For 1.weekTrần ĐạiNo ratings yet

- Biosynthetic Pathways: Frederick A. Bettelheim William H. Brown Mary K. Campbell Shawn O. FarrellDocument28 pagesBiosynthetic Pathways: Frederick A. Bettelheim William H. Brown Mary K. Campbell Shawn O. FarrellShereen AlobinayNo ratings yet

- Conbextra UHSDocument2 pagesConbextra UHSabhay_joshi20020% (1)

- Invisible Ink: Modeling A Molecular SwitchDocument2 pagesInvisible Ink: Modeling A Molecular SwitchAbhinav AbhilashNo ratings yet

- Silicones Additives 2017Document36 pagesSilicones Additives 2017Bilson ShuklaNo ratings yet

- 102 MSJC 13Document11 pages102 MSJC 13noelNo ratings yet

- AkcDocument4 pagesAkcGirishmaNo ratings yet

- Clarke 1988Document14 pagesClarke 1988aruna prasadNo ratings yet

- Calcium Hypochlorite or Calcium OxychlorideDocument56 pagesCalcium Hypochlorite or Calcium OxychlorideSuraj GuptaNo ratings yet

- Iron and Steel - J.H StansbieDocument402 pagesIron and Steel - J.H StansbieHernán SalvayNo ratings yet

- SolutionsDocument509 pagesSolutionssknoushad126No ratings yet

- Study of Cellwall Constituents and Cell InclusionsDocument42 pagesStudy of Cellwall Constituents and Cell Inclusionsharshe v73% (11)

- Tungsten Carbide: Tungsten Carbide (Chemical Formula: WC) Is A ChemicalDocument10 pagesTungsten Carbide: Tungsten Carbide (Chemical Formula: WC) Is A Chemicalroberto jimenezNo ratings yet

- NMR ChitinDocument9 pagesNMR Chitinيحيى بورغدةNo ratings yet

- Stoichiometry 2 QPDocument10 pagesStoichiometry 2 QPYee MeiNo ratings yet

- Ropemanship and Knot TyingDocument44 pagesRopemanship and Knot TyingPHILLIP JOSEPH EBORDE94% (16)

- Artesunateinjection QAS10-365FINALDocument4 pagesArtesunateinjection QAS10-365FINALboddarambabuNo ratings yet

- Ch16 Kesetimbangan Kimia Konsep UmumDocument34 pagesCh16 Kesetimbangan Kimia Konsep UmumJovan PutrandaNo ratings yet

- List Obat BaksosDocument1 pageList Obat BaksosRaden Mas Nur HaryonoNo ratings yet

- Chapter 4: The Periodic Table of ElementsDocument14 pagesChapter 4: The Periodic Table of ElementsFarah Aisyah AhmadNo ratings yet

- Sika Intraplast ZDocument3 pagesSika Intraplast Zreborn_willyNo ratings yet

- LaidlerDexterBioJJB PDFDocument2 pagesLaidlerDexterBioJJB PDFSanthiyaNo ratings yet

- WorkseetDocument2 pagesWorkseetbigbuddhazNo ratings yet

- Pengenalan Karakterisasi MaterialDocument23 pagesPengenalan Karakterisasi Materialfikri wahyu pratamaNo ratings yet