Professional Documents

Culture Documents

Dry Distillation: Jump To Navigation Jump To Search

Dry Distillation: Jump To Navigation Jump To Search

Uploaded by

Mohammad Jahid AlamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dry Distillation: Jump To Navigation Jump To Search

Dry Distillation: Jump To Navigation Jump To Search

Uploaded by

Mohammad Jahid AlamCopyright:

Available Formats

Dry distillation

Firefighting process hazards (dry distillation, chemical reactions, boiler uptake). ... (i) Use of

water for fire-extinguishing, the effect on ship stability, precautions ...

dry distillation, chemical reactions boiler uptake fires; Manage procedures for fire control on

board an oil, chemical or gas tanker; Manage fire-fighting ...

Laboratory display of distillation: 1: A source of heat 2: Round bottomed flask 3: Still

head 4: Thermometer/Boiling point temperature 5: Condenser 6: Cooling water in 7: Cooling water

out 8: Distillate/receiving flask 9: Vacuum/gas inlet 10: Still receiver 11: Heat control 12: Stirrer speed

control 13: Stirrer/heat plate 14: Heating (Oil/sand) bath 15: Stirring means e.g. (shown), boiling chips or

mechanical stirrer 16: Cooling bath.[

Dry distillation is the heating of solid materials to produce gaseous products (which may condense

into liquids or solids). The method may involve pyrolysis or thermolysis, or it may not (for instance, a

simple mixture of ice and glass could be separated without breaking any chemical bonds, but

organic matter contains a greater diversity of molecules, some of which are likely to break). If there

are no chemical changes, just phase changes, it resembles classical distillation, although it will

generally need higher temperatures. Dry distillation in which chemical changes occur is a type

of destructive distillation or cracking.

Jump to navigation Jump to search

Derivation of a wood-tar creosote from resinous woods[1]

Dry distillation

Distillation is the process of separating the components or substances from a liquid mixture by

using selective boiling and condensation.

Uses

The method has been used to obtain liquid fuels from coal and wood. It can also be used to break

down mineral salts such as sulfates (SO2−

4) through thermolysis, in this case producing sulfur dioxide (SO2) or sulfur trioxide (SO3) gas which

can be dissolved in water to obtain sulfuric acid. By this method sulfuric acid was first identified and

artificially produced. When substances of vegetable origin, e.g. coal, oil shale, peat or wood, are

heated in the absence of air (dry distillation), they decompose into gas, liquid products

and coke/charcoal. The yield and chemical nature of the decomposition products depend on the

nature of the raw material and the conditions under which the dry distillation is done. Decomposition

within a temperature range of 450 to about 600°C is called carbonization or low-temperature

degassing. At temperatures above 900°C, the process is called coking or high-temperature

degassing.[2] If coal is gasified to make coal gas or carbonized to make coke then Coal tar is among

the by-products.

Distillation is used to separate liquids from nonvolatile solids, as in the separation of

alcoholic liquors from fermented materials, or in the separation of two or more liquids

having different boiling points, as in the separation of gasoline, kerosene, and

lubricating oil from crude oil.

Coal oil

Destructive distillation

Gasworks

Tar

Syngas

You might also like

- Protein Precipitation ProceduresDocument2 pagesProtein Precipitation ProceduresPrakash BalakrishnanNo ratings yet

- Egg YolkDocument3 pagesEgg YolkGaurav ChandaranaNo ratings yet

- CrystallizationDocument23 pagesCrystallizationEbin ThankachanNo ratings yet

- Recrystallization and Aspirin (Full)Document32 pagesRecrystallization and Aspirin (Full)Yosita RahmawatiNo ratings yet

- Mononitration of TolueneDocument4 pagesMononitration of TolueneNur Syafiqah Izzuddin100% (1)

- Formal Report - AspirinDocument4 pagesFormal Report - AspirinMeah PachecoNo ratings yet

- Alarms and Fault Finding: FOPX Separation SystemDocument36 pagesAlarms and Fault Finding: FOPX Separation SystemMohammad Jahid Alam100% (4)

- PurifierDocument14 pagesPurifierMohammad Jahid Alam100% (1)

- Basic Schematic Symbols Chart (Hydraulic and Pneumatic Circuit DesignDocument10 pagesBasic Schematic Symbols Chart (Hydraulic and Pneumatic Circuit DesignMohammad Jahid Alam100% (3)

- Design of Binary DistillationDocument75 pagesDesign of Binary Distillationfadyah100% (1)

- SolutionsDocument2 pagesSolutionsAlyssa Nicole Padilla0% (1)

- Isolation of Lactose From Milk: CHEM 334L Organic Chemistry Laboratory Revision 1.0Document9 pagesIsolation of Lactose From Milk: CHEM 334L Organic Chemistry Laboratory Revision 1.0Hasene Keskin100% (1)

- Industrial Production of Enzyme Protease PDFDocument25 pagesIndustrial Production of Enzyme Protease PDFAyushman Kumar BanerjeeNo ratings yet

- BC34.1 E5 Isolation of DNA From Bovine SpleenDocument4 pagesBC34.1 E5 Isolation of DNA From Bovine SpleenGlenn Vincent TumimbangNo ratings yet

- 6 - Toxicants Formed During ProcessingDocument45 pages6 - Toxicants Formed During Processingismailmannur100% (1)

- Exp 4 Complete - BLANCHINGDocument12 pagesExp 4 Complete - BLANCHINGLiyana HalimNo ratings yet

- The Iodimetric Method of Determining Lactose in MilkDocument4 pagesThe Iodimetric Method of Determining Lactose in MilkgustavoesanchezNo ratings yet

- Rna Formal Report 2Document2 pagesRna Formal Report 2janinamarie67% (3)

- Ninang Marj. Case StudyDocument2 pagesNinang Marj. Case StudyNicole RodilNo ratings yet

- Food Regulations in Sri Lanka: BFST 1105 Food Regulation and Food Quality ControlDocument20 pagesFood Regulations in Sri Lanka: BFST 1105 Food Regulation and Food Quality ControlSujani kaumadi bhagya GamagedaraNo ratings yet

- Milk Composition: DR Aneela HameedDocument98 pagesMilk Composition: DR Aneela HameedFaizan ChaudharyNo ratings yet

- Isolation and Characterization of ProteinsDocument3 pagesIsolation and Characterization of ProteinsVern NuquiNo ratings yet

- Exp 5 - Isolation of Casein and Lactose From MilkDocument7 pagesExp 5 - Isolation of Casein and Lactose From MilkDenise R. Samonte100% (2)

- Aspartame MSDSDocument6 pagesAspartame MSDSHuongThi KhongNo ratings yet

- FOODCHEM EXP 6 EnzymeDocument10 pagesFOODCHEM EXP 6 EnzymesitinurhanizaNo ratings yet

- Salt Content of Biscuit SticksDocument19 pagesSalt Content of Biscuit SticksNicole HoNo ratings yet

- Exp 3 DNSDocument10 pagesExp 3 DNSEmelya NatraNo ratings yet

- Preparation of Acetic AcidDocument9 pagesPreparation of Acetic Acidusman_uet0867% (3)

- Xanthoproteic Test Lab Report 1Document7 pagesXanthoproteic Test Lab Report 1KINISHAA A/P TAMIL SELVEN / UPMNo ratings yet

- 08 Microbial Control Physical MeansDocument13 pages08 Microbial Control Physical MeansSurendar KesavanNo ratings yet

- Magnesium CarbonateDocument26 pagesMagnesium CarbonateAlyana Dizon100% (1)

- Chemistry Investigatory Project: GuwahatiDocument13 pagesChemistry Investigatory Project: GuwahatiJhumur LodhNo ratings yet

- Synthesis of AspirinDocument13 pagesSynthesis of AspirinTriza AndradeNo ratings yet

- Lab Manual FinalDocument28 pagesLab Manual FinalErwin ManipolNo ratings yet

- Determination of Sugar As GlucoseDocument4 pagesDetermination of Sugar As GlucoseIpsita ChakravartyNo ratings yet

- CyclohexanoneDocument165 pagesCyclohexanoneChem2014EngNo ratings yet

- Estimation of Sugar by HAGEDORN - JensonDocument3 pagesEstimation of Sugar by HAGEDORN - JensonTrung Mai VanNo ratings yet

- Synthesis, Characterization of Borax Crosslinked Guar Gum Hydrogel and Its Effect in Treatment of Crude Oil Emulsified WaterDocument14 pagesSynthesis, Characterization of Borax Crosslinked Guar Gum Hydrogel and Its Effect in Treatment of Crude Oil Emulsified WaterEditor IJTSRDNo ratings yet

- Experiment 4: The Aldol Condensation Reaction: Preparation of Benzalacetophenones (Chalcones)Document3 pagesExperiment 4: The Aldol Condensation Reaction: Preparation of Benzalacetophenones (Chalcones)Dang Humairah100% (1)

- Boiling Extraction Method Vs Commercial Kits For Bacterial Dna Isolation From Food SamplesDocument9 pagesBoiling Extraction Method Vs Commercial Kits For Bacterial Dna Isolation From Food SamplesSimon Hafeni100% (1)

- A Seminar Presentation On Bio-Activated CarbonDocument23 pagesA Seminar Presentation On Bio-Activated CarbonBOMA DOUGLASNo ratings yet

- Acid Hydrolysis and Chemical Characterization of DNADocument28 pagesAcid Hydrolysis and Chemical Characterization of DNAai_ferminNo ratings yet

- DNA Isolation From Spleen ProtocolDocument2 pagesDNA Isolation From Spleen ProtocolSherlock Wesley ConanNo ratings yet

- Fat, Acidity, LR, SNF, TS, Apt, CobDocument9 pagesFat, Acidity, LR, SNF, TS, Apt, CobSahar SanwalNo ratings yet

- Determination of Peroxide ValueDocument3 pagesDetermination of Peroxide ValueAswin VengatNo ratings yet

- Rancidity of Edible OilDocument2 pagesRancidity of Edible OilUsman Ghani0% (1)

- Glucose Found in UrineDocument3 pagesGlucose Found in UrineKevin Nave RiveraNo ratings yet

- Color Reactions of Protein Lab ReportDocument2 pagesColor Reactions of Protein Lab ReportBlack PastelNo ratings yet

- Iodine ValueDocument2 pagesIodine Valueaslio1No ratings yet

- Chemical Test To Determine The Presence of A Protein in A Sample Biuret MethodDocument4 pagesChemical Test To Determine The Presence of A Protein in A Sample Biuret MethodAnupam AdhikaryNo ratings yet

- Lab Report Experiment 3Document3 pagesLab Report Experiment 3Argel LargadoNo ratings yet

- The Philippine Women'S University Biochemistry Laboratory Experiment/sDocument4 pagesThe Philippine Women'S University Biochemistry Laboratory Experiment/sskyler andradaNo ratings yet

- A. Heme Pigments: Natural Food Pigments Part 1Document20 pagesA. Heme Pigments: Natural Food Pigments Part 1Balakumaran MNo ratings yet

- ParacetamolDocument2 pagesParacetamolDanielle PayneNo ratings yet

- Classification of Hydrocarbons Formal ReportDocument9 pagesClassification of Hydrocarbons Formal ReportBillQueNo ratings yet

- Analysis of ASH and MINERALSDocument15 pagesAnalysis of ASH and MINERALSMuhammad Taha Jilani100% (1)

- Estimation of Iodine ValueDocument13 pagesEstimation of Iodine ValueKarmega rajanNo ratings yet

- M-Kurifix CP-408 (R0) Cas 16 PDFDocument5 pagesM-Kurifix CP-408 (R0) Cas 16 PDFRichard SinambelaNo ratings yet

- Characterization of Saponifiable LipidsDocument6 pagesCharacterization of Saponifiable LipidsChristian Vincent Maranan LumabanNo ratings yet

- Imine ReductionDocument4 pagesImine ReductionRatna Siti KhodijahNo ratings yet

- Distillation: 8: Distillate/receiving Flask 9: Vacuum/gas Inlet 10: Still Receiver 11: Heat Control 12: StirrerDocument1 pageDistillation: 8: Distillate/receiving Flask 9: Vacuum/gas Inlet 10: Still Receiver 11: Heat Control 12: StirrerSubhash DhungelNo ratings yet

- GIRMADocument49 pagesGIRMAGirma TesemaNo ratings yet

- Ind Chem Chapter OneDocument11 pagesInd Chem Chapter OneYareda GeNo ratings yet

- Swern OxidationDocument4 pagesSwern OxidationMega Nur Hesti OktaviaNo ratings yet

- British Solid Carbon Dioxide: Dry Ice, Sometimes Referred To As "Cardice" (ChieflyDocument4 pagesBritish Solid Carbon Dioxide: Dry Ice, Sometimes Referred To As "Cardice" (ChieflyjonanaNo ratings yet

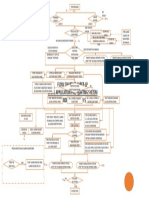

- Flow Chart of Hyper-Lp Local Application Fire Fighting System (Unattended Machinery Space)Document1 pageFlow Chart of Hyper-Lp Local Application Fire Fighting System (Unattended Machinery Space)Mohammad Jahid AlamNo ratings yet

- 5 Fireman Outfit & SCBADocument7 pages5 Fireman Outfit & SCBAMohammad Jahid AlamNo ratings yet

- Thank You Very Much For LISTENING!!! FromDocument1 pageThank You Very Much For LISTENING!!! FromMohammad Jahid AlamNo ratings yet

- Operating Instructions: FOPX Separation SystemDocument22 pagesOperating Instructions: FOPX Separation SystemMohammad Jahid AlamNo ratings yet

- EO Fire Detection System Test Record BLANK FORMDocument10 pagesEO Fire Detection System Test Record BLANK FORMMohammad Jahid AlamNo ratings yet

- FIRE EXTIGUISHER-S SarvothamDocument16 pagesFIRE EXTIGUISHER-S SarvothamMohammad Jahid AlamNo ratings yet

- Boiler Water TestDocument8 pagesBoiler Water TestMohammad Jahid AlamNo ratings yet

- Ege Water Washing: at Port or AnchorageDocument1 pageEge Water Washing: at Port or AnchorageMohammad Jahid AlamNo ratings yet

- Steering Gear SystemDocument6 pagesSteering Gear SystemMohammad Jahid AlamNo ratings yet

- 4 Portable Fire ExtinguishersDocument6 pages4 Portable Fire ExtinguishersMohammad Jahid AlamNo ratings yet

- Common Faults and DetectionDocument8 pagesCommon Faults and DetectionMohammad Jahid AlamNo ratings yet

- 3 Effect On StabilityDocument2 pages3 Effect On StabilityMohammad Jahid Alam0% (1)

- FWG & CoolerDocument5 pagesFWG & CoolerMohammad Jahid AlamNo ratings yet

- 7 Paint & Fire ManagementDocument1 page7 Paint & Fire ManagementMohammad Jahid AlamNo ratings yet

- 4 Fire HazardDocument3 pages4 Fire HazardMohammad Jahid Alam100% (1)

- Oily Water Separator Safety DevicesDocument15 pagesOily Water Separator Safety DevicesMohammad Jahid Alam100% (6)

- Sewage Treatment Plant: Q. State The Procedure For Discharging Sewage Into The SeaDocument5 pagesSewage Treatment Plant: Q. State The Procedure For Discharging Sewage Into The SeaMohammad Jahid AlamNo ratings yet

- 6 Precaution of FireDocument1 page6 Precaution of FireMohammad Jahid AlamNo ratings yet

- Piston Pump: PD LDDocument8 pagesPiston Pump: PD LDMohammad Jahid AlamNo ratings yet

- A Serious, Unexpected, and Often Dangerous Situation Requiring Immediate ActionDocument1 pageA Serious, Unexpected, and Often Dangerous Situation Requiring Immediate ActionMohammad Jahid AlamNo ratings yet

- 2 Control of Fire at SeaDocument4 pages2 Control of Fire at SeaMohammad Jahid AlamNo ratings yet

- Fire Triangle:: Fire Is The Combination of HEAT, FUEL & OXYGEN. Fire Is The Chemical Reaction of Heat, Fuel & OxygenDocument3 pagesFire Triangle:: Fire Is The Combination of HEAT, FUEL & OXYGEN. Fire Is The Chemical Reaction of Heat, Fuel & OxygenMohammad Jahid AlamNo ratings yet

- 2 Chemical ReactionDocument2 pages2 Chemical ReactionMohammad Jahid AlamNo ratings yet

- EE1040: Electrical Fundamentals Lecture 1 - Overview: W. D. PrasadDocument15 pagesEE1040: Electrical Fundamentals Lecture 1 - Overview: W. D. PrasadDk WijerathneNo ratings yet

- Day 2 Passage 2Document2 pagesDay 2 Passage 2Aziza QutbiddinovaNo ratings yet

- Catalyst Characterization: Characterization Techniques: ElsevierDocument21 pagesCatalyst Characterization: Characterization Techniques: ElsevierThemba MasukuNo ratings yet

- The Parachute Problem: Ronald Phoebus and Cole ReillyDocument23 pagesThe Parachute Problem: Ronald Phoebus and Cole ReillyChathura ChamikaraNo ratings yet

- Gradient Divergence CurlDocument2 pagesGradient Divergence CurlNaik LarkaNo ratings yet

- Chapter 1 - Chemical Equilibrium Part 1Document36 pagesChapter 1 - Chemical Equilibrium Part 1Ng Kee NainNo ratings yet

- M1 Notes: Modelling AssumptionsDocument4 pagesM1 Notes: Modelling AssumptionsakaashpatelNo ratings yet

- Heat Transfer by Radiation: Virtual Lab ExperimentDocument13 pagesHeat Transfer by Radiation: Virtual Lab ExperimentGyani Jwal Singh KushwahaNo ratings yet

- Safety Data Sheet Petroleum, Crude Oil: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument12 pagesSafety Data Sheet Petroleum, Crude Oil: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingnivasmarineNo ratings yet

- Fountain SolutionDocument36 pagesFountain SolutionallUddinNo ratings yet

- Corrosion and Rusting Presentation (Chemistry Summer Holiday Homework)Document9 pagesCorrosion and Rusting Presentation (Chemistry Summer Holiday Homework)georgeNo ratings yet

- RPT Physics Lower 6 2015 Sem 1Document10 pagesRPT Physics Lower 6 2015 Sem 1Norhazli IbrahimNo ratings yet

- 7.2 Coulombs Law TemplateDocument4 pages7.2 Coulombs Law TemplateAyman HalimeNo ratings yet

- VecpotDocument20 pagesVecpotVishal DhakadNo ratings yet

- Horoscope Robert 2 PDFDocument3 pagesHoroscope Robert 2 PDFCandace WarrenNo ratings yet

- Atlas Notes 2015 00Document36 pagesAtlas Notes 2015 00Sridhar ChandrasekaranNo ratings yet

- Experiment 4: Basic Water Properties 1 Group Class: EH2202ADocument23 pagesExperiment 4: Basic Water Properties 1 Group Class: EH2202AAnonymous dJYic9XNo ratings yet

- Non Destructive Test On ConcreteDocument6 pagesNon Destructive Test On ConcreteOpany JuliusNo ratings yet

- CH-150: Basic Organic Chemistry (Sem-I) : Chapter 1-StereochemistryDocument11 pagesCH-150: Basic Organic Chemistry (Sem-I) : Chapter 1-StereochemistryRajesh PatilNo ratings yet

- Ch6. Work and Energy Work Done by A Constant ForceDocument93 pagesCh6. Work and Energy Work Done by A Constant ForceKtel R MacarioNo ratings yet

- Biomolecules: DefinitionsDocument50 pagesBiomolecules: DefinitionsSaket DubeyNo ratings yet

- Economics Thesis Blue VariantDocument38 pagesEconomics Thesis Blue Variant035 N ChanduNo ratings yet

- 2 - 11 July 2000 Copenhagen: Preparatory ProblemsDocument50 pages2 - 11 July 2000 Copenhagen: Preparatory ProblemsJoni WaldyNo ratings yet

- Practice Stoichiometry Test (V1 Jan 2019) FINALDocument14 pagesPractice Stoichiometry Test (V1 Jan 2019) FINALHo Lam YikNo ratings yet

- Application of An Efficient Exponential Wide Band Model For The NaturalDocument35 pagesApplication of An Efficient Exponential Wide Band Model For The NaturalperulesNo ratings yet

- Magnetic Resonance Imaging:-: How MRI WorksDocument4 pagesMagnetic Resonance Imaging:-: How MRI WorkscoolmushiNo ratings yet

- Conduction and Breakdown of Pure LiquidsDocument18 pagesConduction and Breakdown of Pure LiquidsPrakash Parajuli0% (1)

- Atomic Structure & Mole Concept (Question Paper)Document5 pagesAtomic Structure & Mole Concept (Question Paper)Param shahNo ratings yet