Professional Documents

Culture Documents

Butterfly Valve Maintenance - NEW PDF

Butterfly Valve Maintenance - NEW PDF

Uploaded by

Mohamed Akak0 ratings0% found this document useful (0 votes)

18 views1 pageOriginal Title

Butterfly Valve Maintenance - NEW.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views1 pageButterfly Valve Maintenance - NEW PDF

Butterfly Valve Maintenance - NEW PDF

Uploaded by

Mohamed AkakCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

5.

Lubricate the body ID or seat OD with a

Weco Butterfly Valve

silicone spray such as Dow Corning #316.

® Using lower stem in the seat/disc assembly

and a lower stem in the body, lay the seat/

disc assembly on top of the body using a

right angle alignment fixture to align the

stems. Insert the seat enough to get started

and then remove the stems from the body

Maintenance Instructions and the seat/disc assembly. Complete

inserting the seat/disc assembly into the

body with uniform pressure.

Disassembly 6. Install third O-ring in groove of upper stem.

If butterfly valve has a grease fitting, skive

1. Close valve and remove from the line. Turn cut third O-ring prior to installation onto

the valve to the open position. Handle may upper stem. Lubricate upper and lower

be left on the upper stem or taken off by stems with Climax 422 CM or equivalent

removing cap screw and washer. (ref. FMC specification 3259721). Apply

2. Remove both the upper and lower roll pins lubricant on smaller surfaces at disc end of

with a drift pin or pin punch and hammer. the lower stem. Apply lubricant on large

(Use any strong piece of steel rod which OD surfaces of upper stem, between the

fits the roll pin hole ID) O-ring groove and the hex end. Do not

3. Pull both the upper and lower stems from apply lubricant in roll pin groove or on

the body. If the stems cannot be removed smaller surfaces on hex end.

readily, grasp the stem in a vise and gently 7. Install the lower stem into the body. The

tap the body with a hammer. A twisting lower stem is in correct position when the

motion between the body and stems will roll pin hole in the body is aligned with the

allow the stems to be removed easily. A groove on the stem.

groove on the lower stem permits prying 8. Before installing the upper stem, orient the

the lower stem from the body by using a indicator groove on top of the upper stem

screwdriver. so that it is aligned with the disc. Install

4. Remove the disc from the seat. the upper stem into the body by pushing

5. Remove the seat from the body. The seat the stem while slightly turning back and

may have to be tapped lightly and evenly forth. This will allow the stem to engage

around the edge from one end since the and align with the disc hex. The upper

seat fits snugly the body ID. Take care not stem is in the correct position when the

to damage the inside of the body. roll pin hole in the body is aligned with the

groove on the stem.

Maintenance and Repair 9. Install roll pins into body with start of

outside of coil 180° away from stem groove.

1. Inspect the disc and stems. If worn or Make certain roll pins pass through grooves

pitted, substitute new ones. 1. Body of stems and are flush with body. Apply a

2. When replacing the seat, new O-rings 2. Disc clear silicone adhesive sealant to the ends

should be installed. 3. Upper Stem of the roll pins.

3. It is recommended that all rubber parts 12 4. Lower Stem 10. Install the cap screw and washer to retain

(seats, O-rings) be lightly but thoroughly 13 5. Seat the handle.

lubricated with a grease such as Dow 11 6. Detent Plate 11. Install the cap screw and washer to retain

Corning® #111 silicone, to facilitate 7. Cap Screw the handle.

assembly. Spread lubricant on the inside 8. Lock Washer 12. Install detent plate. Tighten detent plate

7

diameter of the seat. 9. Hex Nut

mounting bolts until lock washer is

10. Roll Pin

6 flat. If installing a 180° detent plate, the

Assembly (Ref: FMC Specification 11. O-Ring

plate should be installed so the

12. Cap Screw

3253718 or Q50038) 13. Washer

valve will have 2 closed positions and 1

open position. Countersunk holes

1. Place well lubricated O-rings into the top 3 of the detent plate should be installed on

and bottom holes of the seat. top.

2. Place the seat in a vise with the stem holes 11

13. Hand tighten retaining cap screw and

10

parallel to the vise jaws. Use smooth jaws washer on the upper stem.

or otherwise protect the seat OD from

8 5

damage. Carefully apply pressure to distort

1

Installation with Flanges

the seat and only enough pressure to insert

the disc. Excessive pressure can damage the Valves should be in the closed position during

9

seat. Slide the disc into the seat and center installation to prevent damage to the disc. Check

the disc by inserting the upper and lower indicator groove on top of upper stem for proper

stems. Remove the seat/disc subassembly disc alignment. After tightening flanges against

from the vise. the valve, valve may be opened, but caution

3. Using the upper stem, rotate the disc to the should be taken to ensure opening of disc does

partially closed position. 2 not contact ID of flange or pipe. Striking of disc

4. Remove the upper stem (leaving the lower can result in possible leak paths.

stem in place). 10

11

FMC Technologies Inc. Manufacturing

4

1803 Gears Road 2825 West Washington

Houston, TX 77067 Stephenville, TX 76401

281 260 2121 800 772 8582

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 2011dec07 2012jan06Document2 pages2011dec07 2012jan06Cowdrey Ilan100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AB Unit 3 HRM Semester - Jan2021Document13 pagesAB Unit 3 HRM Semester - Jan2021Fahmina AhmedNo ratings yet

- Free ProgramDocument16 pagesFree ProgramCowdrey IlanNo ratings yet

- Acid DewpointDocument4 pagesAcid DewpointCowdrey IlanNo ratings yet

- Study Plan of The 1 Year - General Medicine For The Academic Year 2012/2013Document1 pageStudy Plan of The 1 Year - General Medicine For The Academic Year 2012/2013Cowdrey IlanNo ratings yet

- Supersedes: Construction/Material DataDocument1 pageSupersedes: Construction/Material DataCowdrey IlanNo ratings yet

- Article Optical PyrometryDocument8 pagesArticle Optical PyrometryCowdrey IlanNo ratings yet

- Take-Out & Delivery: Appetizers & Starters Famous Rotisserie Chicken Dinners Sandwiches & WrapsDocument1 pageTake-Out & Delivery: Appetizers & Starters Famous Rotisserie Chicken Dinners Sandwiches & WrapsCowdrey IlanNo ratings yet

- 3/4-Inch Combination PH and ORP Sensor KitsDocument8 pages3/4-Inch Combination PH and ORP Sensor KitsCowdrey IlanNo ratings yet

- 2011-04-20 DC Battery TestDocument2 pages2011-04-20 DC Battery TestCowdrey IlanNo ratings yet

- GE Fanuc Automation: CIMPLICITY HMI Plant Edition Trend and XY ChartDocument228 pagesGE Fanuc Automation: CIMPLICITY HMI Plant Edition Trend and XY ChartCowdrey IlanNo ratings yet

- The Laws of Motion: Multiple ChoiceDocument42 pagesThe Laws of Motion: Multiple ChoiceCowdrey IlanNo ratings yet

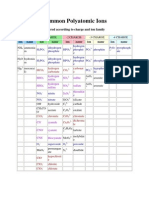

- Common Polyatomic IonsDocument3 pagesCommon Polyatomic IonsCowdrey IlanNo ratings yet

- Evaluate Vendor LTSADocument2 pagesEvaluate Vendor LTSAApri Kartiwan100% (1)

- Is 4031 5 1988 PDFDocument7 pagesIs 4031 5 1988 PDFRamesh Subramani Ramachandran100% (1)

- S - 5 1 0 L, S - 5 1 0 R: PioneerDocument4 pagesS - 5 1 0 L, S - 5 1 0 R: PioneermiliindianuNo ratings yet

- Duke Realty RezoningDocument79 pagesDuke Realty RezoningZachary HansenNo ratings yet

- Goblin Slayer v06 PDFDocument174 pagesGoblin Slayer v06 PDFdedajo ddNo ratings yet

- CAT Test Series 2015Document2 pagesCAT Test Series 2015Nikhil SiddharthNo ratings yet

- Digital Communications Project ReportDocument14 pagesDigital Communications Project ReportSonal Pinto0% (1)

- Depth of FocusDocument7 pagesDepth of FocusDr-Riya MondalNo ratings yet

- Chapter 10 Dealing With Uncertainty: General ProcedureDocument15 pagesChapter 10 Dealing With Uncertainty: General ProcedureHannan Mahmood TonmoyNo ratings yet

- USB TO RS232 Cable For Windows 2000 User's ManualDocument7 pagesUSB TO RS232 Cable For Windows 2000 User's ManualOsvaldo Loyde AlvaradoNo ratings yet

- T5 B68 Craig Unger FDR - 5-21-04 Stull Email - Unger Saudi Flight Docs 616Document6 pagesT5 B68 Craig Unger FDR - 5-21-04 Stull Email - Unger Saudi Flight Docs 6169/11 Document ArchiveNo ratings yet

- James L GordonDocument1 pageJames L Gordonpapan_5069No ratings yet

- D - 03 Pre Departure Checklist (Bridge) - 14.05.2009 NewDocument1 pageD - 03 Pre Departure Checklist (Bridge) - 14.05.2009 NewSantoso WahyudiNo ratings yet

- The 73rd Constitutional Amendment ActDocument26 pagesThe 73rd Constitutional Amendment ActYasser ArfatNo ratings yet

- CH 01 Wooldridge 5e PPTDocument23 pagesCH 01 Wooldridge 5e PPTKrithiga Soundrajan100% (1)

- DS Workbook 23SC1202Document199 pagesDS Workbook 23SC1202Arjun JagiriNo ratings yet

- Paint Data Sheet - National Synthetic Enamel Gloss IDocument3 pagesPaint Data Sheet - National Synthetic Enamel Gloss Iaakh0% (1)

- Object Oriented Programming Using C++ Viva Questions Coders LodgeDocument7 pagesObject Oriented Programming Using C++ Viva Questions Coders LodgeGulchetan SinghNo ratings yet

- The Incredible Analysis of W D GannDocument79 pagesThe Incredible Analysis of W D GannJohn Kent97% (31)

- Overhead Conductors Trefinasa 2016webDocument52 pagesOverhead Conductors Trefinasa 2016weboaktree2010No ratings yet

- Sauer90 ServiceManual PDFDocument72 pagesSauer90 ServiceManual PDFeng13100% (7)

- Father Dowling Mysteries - Wikipedia2Document11 pagesFather Dowling Mysteries - Wikipedia2Vocal Samir0% (1)

- Problem Cash FlowDocument3 pagesProblem Cash FlowKimberly AnneNo ratings yet

- KMA CVDocument5 pagesKMA CVKhandoker Mostak AhamedNo ratings yet

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document13 pages400 Bad Request 400 Bad Request Nginx/1.2.9USAFVOSBNo ratings yet

- DumbDocument10 pagesDumbJura LauraNo ratings yet

- Canadian Jeweller January / February 2011 IssueDocument84 pagesCanadian Jeweller January / February 2011 IssuerivegaucheNo ratings yet

- BNC - Dana Gas PipelineDocument4 pagesBNC - Dana Gas PipelinesebincherianNo ratings yet

- Waste Heat Boiler Deskbook PDFDocument423 pagesWaste Heat Boiler Deskbook PDFwei zhou100% (1)