Professional Documents

Culture Documents

Bill of Material For 19'-6" Curved Split Switch

Bill of Material For 19'-6" Curved Split Switch

Uploaded by

Toni Garrote FerreroCopyright:

Available Formats

You might also like

- AREMA Vol. 3 - (2009) PDFDocument1,184 pagesAREMA Vol. 3 - (2009) PDFLuis Emilio Bosio100% (2)

- CASE 580N Backhoe Service Manual Diagram ElectricDocument1 pageCASE 580N Backhoe Service Manual Diagram ElectricErick David100% (2)

- CASE 580N-Backhoe-Service-Manual-diagram-electricDocument1 pageCASE 580N-Backhoe-Service-Manual-diagram-electricWuillians GuzmanNo ratings yet

- QuickStart Using OpenRail Designer - 2018R4!03!01Document50 pagesQuickStart Using OpenRail Designer - 2018R4!03!01naveenNo ratings yet

- 02-Light Rail Transit Capital Cost Bill of QuantitiesDocument16 pages02-Light Rail Transit Capital Cost Bill of QuantitiesSatria Pinandita100% (1)

- A History of Railway SignallingDocument18 pagesA History of Railway SignallingWindow SeatNo ratings yet

- Plates No. 4-9: S R T U V WDocument1 pagePlates No. 4-9: S R T U V WToni Garrote FerreroNo ratings yet

- Bill of Material For 16'-6" Straight Split SwitchDocument1 pageBill of Material For 16'-6" Straight Split SwitchToni Garrote FerreroNo ratings yet

- Final Copy For ApprovalDocument2 pagesFinal Copy For Approvalcontact.loksewabookNo ratings yet

- 40 Feet Wide Road: First Floor Brick Work Detail DrawingDocument1 page40 Feet Wide Road: First Floor Brick Work Detail DrawingPriya DarshiniNo ratings yet

- B85-L3 - Var-Part 12 Construction DetailsDocument10 pagesB85-L3 - Var-Part 12 Construction Detailsissam.qamhiaNo ratings yet

- Biruwa PlaningDocument1 pageBiruwa Planingcontact.loksewabookNo ratings yet

- GTG CD Sem 1402Document1 pageGTG CD Sem 1402Gourishankar MishraNo ratings yet

- 1 J I:'a L / Gi: I I I I I I I I IDocument1 page1 J I:'a L / Gi: I I I I I I I I IShivendra KumarNo ratings yet

- 0-8936-2 Golden Triangle Polymers Company LLCDocument1 page0-8936-2 Golden Triangle Polymers Company LLCLester MuscaNo ratings yet

- Master Plan of Dairy Farm: Ans AssociatesDocument9 pagesMaster Plan of Dairy Farm: Ans AssociatesIrfan MunirNo ratings yet

- MRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3Document1 pageMRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3arman gauNo ratings yet

- Uvls.2 Uqair-A.12 PDFDocument1 pageUvls.2 Uqair-A.12 PDFAnonymous BZQOJwWIh6No ratings yet

- Construction DWG (S-17)Document1 pageConstruction DWG (S-17)Umer FarooqNo ratings yet

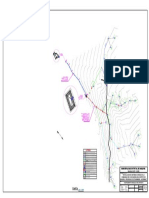

- P02 Planteamiento Hidraulico Ccocharara PL 1Document1 pageP02 Planteamiento Hidraulico Ccocharara PL 1Luis Flores GarciaNo ratings yet

- Span Arrangementpackage-59 - P3L2 PDFDocument23 pagesSpan Arrangementpackage-59 - P3L2 PDFJ. Kumar Infraprojects LtdNo ratings yet

- SLD - CBSE Patna - PDF 2Document1 pageSLD - CBSE Patna - PDF 2nbcccbsepatnaNo ratings yet

- 03 150000 4200000005 Ace Mec DRG 005204 - 02Document1 page03 150000 4200000005 Ace Mec DRG 005204 - 02Anas TawfiqNo ratings yet

- Prestressed Concrete Sheet PilingDocument1 pagePrestressed Concrete Sheet PilingNaresh GajNo ratings yet

- 1.existing Plan (Blow Up 000 - 100)Document1 page1.existing Plan (Blow Up 000 - 100)bappyNo ratings yet

- Lakepoint Apartments (Emerson) - RFI 67Document3 pagesLakepoint Apartments (Emerson) - RFI 67jhamiralexNo ratings yet

- 00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 002Document9 pages00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 002tiantaufikNo ratings yet

- Desague (1) - Planta GeneralDocument1 pageDesague (1) - Planta Generalkristian MéndezNo ratings yet

- Tilal Mall and Hotel Sharjah, UAE: Detail 1Document22 pagesTilal Mall and Hotel Sharjah, UAE: Detail 1Michael Camit Eso100% (1)

- Hwy 49 Roadwork2Document1 pageHwy 49 Roadwork2The UnionNo ratings yet

- CBD Bp18a C127D2 SDW Co Co NL 07025 01Document1 pageCBD Bp18a C127D2 SDW Co Co NL 07025 01rakeshamechNo ratings yet

- 4'0"X8'6" D8 3'6"X8'6" W W1 W2 V Column: Cupola FurnaceDocument1 page4'0"X8'6" D8 3'6"X8'6" W W1 W2 V Column: Cupola FurnaceAvinash ChouhanNo ratings yet

- 05-KSCPP-B-1906 - A - Code 2Document1 page05-KSCPP-B-1906 - A - Code 2Mohd KhaidirNo ratings yet

- P-0004-Ph01-D01-01e001-Mrc-Sdr-Str-100011 - 3-6Document1 pageP-0004-Ph01-D01-01e001-Mrc-Sdr-Str-100011 - 3-6yasirjurabaNo ratings yet

- SLD SamalkhaDocument1 pageSLD SamalkhaDarshit VyasNo ratings yet

- Key Plan: RSXX-DT Capacitor Bank RSXX-CAP-01Document6 pagesKey Plan: RSXX-DT Capacitor Bank RSXX-CAP-01Mrinal KayalNo ratings yet

- Rfi Cscec D01 Me 04 0129 00Document10 pagesRfi Cscec D01 Me 04 0129 00Ali ElkahlawyNo ratings yet

- Highway Drawings of Nukhas-Etah DRAWING (1) - 15Document1 pageHighway Drawings of Nukhas-Etah DRAWING (1) - 15Thakur AnkithNo ratings yet

- Keyplan: PT Katalis Sinergi IndonesiaDocument1 pageKeyplan: PT Katalis Sinergi IndonesiaFebry YantaNo ratings yet

- 33 KV OUTDOOR SWITCH YARD For Earthing Layout 1 RABI - (Sheet-1of2)Document1 page33 KV OUTDOOR SWITCH YARD For Earthing Layout 1 RABI - (Sheet-1of2)SUSOVAN BISWASNo ratings yet

- 03 150000 4200000005 Ace Mec DRG 005501 - 02Document1 page03 150000 4200000005 Ace Mec DRG 005501 - 02Anas TawfiqNo ratings yet

- Kuttamvathukkal GD - For ConstDocument1 pageKuttamvathukkal GD - For ConstjithinNo ratings yet

- g214599 Hmod 65 Paulander DR Kitchener DWGDocument2 pagesg214599 Hmod 65 Paulander DR Kitchener DWGJhonn StevNo ratings yet

- Thorrur LayoutDocument1 pageThorrur LayoutPavanNo ratings yet

- Fire Pump Interfacing Information: Water ReservoirDocument1 pageFire Pump Interfacing Information: Water ReservoirAlvi SarowarNo ratings yet

- Key Plan N.T.S: Detail of R.C.C. StairsDocument1 pageKey Plan N.T.S: Detail of R.C.C. StairsSaif UllahNo ratings yet

- Floor Slab of Basement Foundation DetailDocument1 pageFloor Slab of Basement Foundation DetailMohammad MoinuddeenNo ratings yet

- بلان الدور الارضي 1-ModelDocument1 pageبلان الدور الارضي 1-ModelShrook Nasr AbdElKarimNo ratings yet

- G216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgDocument5 pagesG216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgJhonn StevNo ratings yet

- E-F.62971-02-DTI-1022 Rev A 150520Document1 pageE-F.62971-02-DTI-1022 Rev A 150520ELPIDIO LUCERONo ratings yet

- Mac - Tar-Ndl - Ac Layout-052923Document1 pageMac - Tar-Ndl - Ac Layout-052923Jay MarkNo ratings yet

- KJ 117 o en Sac 00 Zme 0303Document1 pageKJ 117 o en Sac 00 Zme 0303Abdullah ObeidatNo ratings yet

- Elementos de Curvas: Universidad Catolica Santo Toribio de Mogrovejo Municipalidad Distrital de ArequipaDocument1 pageElementos de Curvas: Universidad Catolica Santo Toribio de Mogrovejo Municipalidad Distrital de ArequipaJhosut GonzalesNo ratings yet

- E-M1-02 Basement 2 ACMV Layout PDFDocument1 pageE-M1-02 Basement 2 ACMV Layout PDFJohn InacayNo ratings yet

- UM NO. 14-093 IHL NO. 207-390 Vaught-Hemingway Stadium South End ZoneDocument1 pageUM NO. 14-093 IHL NO. 207-390 Vaught-Hemingway Stadium South End ZoneMofasa ENo ratings yet

- T V Color Abbreviations: HPCR Engine Sps/Ps Transmission 580SN, 580SN-WT AND 590SN Electrical SchematicDocument2 pagesT V Color Abbreviations: HPCR Engine Sps/Ps Transmission 580SN, 580SN-WT AND 590SN Electrical SchematicFútbol y más100% (1)

- Ad 90.0 e 02061 PDF Earthing Details B 4Document1 pageAd 90.0 e 02061 PDF Earthing Details B 4mcaslamNo ratings yet

- Plano General de Plantas de Tratamiento-Planta de Tratamiento GeneralDocument1 pagePlano General de Plantas de Tratamiento-Planta de Tratamiento GeneralarmandoteranbNo ratings yet

- Lax Airport DiagramDocument1 pageLax Airport DiagramKLAXATCNo ratings yet

- MDF326 Yvette Letter A4 TiledDocument48 pagesMDF326 Yvette Letter A4 Tiledvir najNo ratings yet

- Planos de Casa Bungalow Americano 2 HabitacionesDocument1 pagePlanos de Casa Bungalow Americano 2 HabitacionesGabriel CostaNo ratings yet

- DRIVEWAY ModelDocument1 pageDRIVEWAY ModelaxecubertoneNo ratings yet

- COLOUR ELECTRICAL DIAGRAM EDTS 103 REV.D AMD.7 RCF COR.1-Model-1Document1 pageCOLOUR ELECTRICAL DIAGRAM EDTS 103 REV.D AMD.7 RCF COR.1-Model-1Srizee Shri HariNo ratings yet

- Sateba M312 Sleeper Data SheetDocument2 pagesSateba M312 Sleeper Data SheetToni Garrote FerreroNo ratings yet

- Typical Plan View: G F A B C D EDocument1 pageTypical Plan View: G F A B C D EToni Garrote FerreroNo ratings yet

- Cross Section of FillerDocument1 pageCross Section of FillerToni Garrote FerreroNo ratings yet

- Recommended Usage of Various Types of Frogs: and Maintenance of Way Association American Railway EngineeringDocument1 pageRecommended Usage of Various Types of Frogs: and Maintenance of Way Association American Railway EngineeringToni Garrote FerreroNo ratings yet

- Table D-Gages - Curved Track - LocomotivesDocument1 pageTable D-Gages - Curved Track - LocomotivesToni Garrote FerreroNo ratings yet

- Plates No. 4-9: S R T U V WDocument1 pagePlates No. 4-9: S R T U V WToni Garrote FerreroNo ratings yet

- Arema Specifications For Special Trackwork 100-08 For Rails 115 Lb. and HeavierDocument13 pagesArema Specifications For Special Trackwork 100-08 For Rails 115 Lb. and HeavierToni Garrote Ferrero100% (2)

- Bill of Material For 16'-6" Straight Split SwitchDocument1 pageBill of Material For 16'-6" Straight Split SwitchToni Garrote FerreroNo ratings yet

- April 2012: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeDocument25 pagesApril 2012: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeToni Garrote FerreroNo ratings yet

- Arema Mre 2012 Volume 3Document1,352 pagesArema Mre 2012 Volume 3ALINE HAZEL LINO REYNOSONo ratings yet

- TrackworkDocument28 pagesTrackworkEmanuel MurilloNo ratings yet

- Railway Operation & ControlDocument58 pagesRailway Operation & ControlchinnuvarkeyscribdNo ratings yet

- L1 CHE STD 022 v2 Rail GrindingDocument37 pagesL1 CHE STD 022 v2 Rail Grinding4493464No ratings yet

- Any Rail 4 enDocument99 pagesAny Rail 4 enHassan_ChauhanNo ratings yet

- T-Exp, CSM, DUO, Unimat, MPT & DTS: M. D. Jadhav SI/COMP-2Document67 pagesT-Exp, CSM, DUO, Unimat, MPT & DTS: M. D. Jadhav SI/COMP-2Deepak Bhardwaj100% (1)

- Railway TerminologyDocument9 pagesRailway TerminologyDraj KumarceNo ratings yet

- Training Manual Drives & Back-Drives Presentation: BMRCL Project 2S&TDM-TRG-0006 - A2Document16 pagesTraining Manual Drives & Back-Drives Presentation: BMRCL Project 2S&TDM-TRG-0006 - A2Dhruva SenNo ratings yet

- CXT Concrete TieDocument16 pagesCXT Concrete Tiehiginito1410No ratings yet

- 1406180385795-Signal Engineering Manual IIDocument319 pages1406180385795-Signal Engineering Manual IIaab0989No ratings yet

- 1307078105903-TSC - 81-RBOrders FinalDocument100 pages1307078105903-TSC - 81-RBOrders FinalSatish DmNo ratings yet

- Ballast Cleaning Machine Brief - 3Document2 pagesBallast Cleaning Machine Brief - 3SystemNo ratings yet

- KCS-Standards (1 de 2)Document85 pagesKCS-Standards (1 de 2)vladibladeNo ratings yet

- Civil ExampleDocument37 pagesCivil ExampleKim AutoNo ratings yet

- Underground RailDocument23 pagesUnderground RailBlessy MabasaNo ratings yet

- Railway Engineering1Document69 pagesRailway Engineering1Wol Monydeng BolditNo ratings yet

- Basic Concepts of SignallingDocument92 pagesBasic Concepts of SignallingGopipavanNo ratings yet

- Unit10-PDMS Pipe Routing OverviewDocument4 pagesUnit10-PDMS Pipe Routing OverviewshubhamNo ratings yet

- Attachment 0 PDFDocument161 pagesAttachment 0 PDFsutani wardiNo ratings yet

- CSX Industrial Sidetrack Manual 063003 PDFDocument57 pagesCSX Industrial Sidetrack Manual 063003 PDFSidney RiveraNo ratings yet

- Service Manual For The Kodak M35 and M35A X-OMAT ProcessorsDocument106 pagesService Manual For The Kodak M35 and M35A X-OMAT ProcessorsSergio Montes100% (1)

- INT-FINDEL-D-TRV-002-01 - In2Track D2.1 Research Into Enhanced Tracks Switches and Structures PDFDocument191 pagesINT-FINDEL-D-TRV-002-01 - In2Track D2.1 Research Into Enhanced Tracks Switches and Structures PDFOm SinghNo ratings yet

- Industrial Track Specification Guide enDocument30 pagesIndustrial Track Specification Guide enkulbrsingh4975No ratings yet

- Rahe-Qb 4 - BY Civildatas - Blogspot.in PDFDocument8 pagesRahe-Qb 4 - BY Civildatas - Blogspot.in PDFMeera KumarNo ratings yet

- Railway Signalling PrinciplesDocument85 pagesRailway Signalling PrinciplesGauravkumar VaidyaNo ratings yet

- Railway.11 20Document10 pagesRailway.11 20CgpscAspirantNo ratings yet

Bill of Material For 19'-6" Curved Split Switch

Bill of Material For 19'-6" Curved Split Switch

Uploaded by

Toni Garrote FerreroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bill of Material For 19'-6" Curved Split Switch

Bill of Material For 19'-6" Curved Split Switch

Uploaded by

Toni Garrote FerreroCopyright:

Available Formats

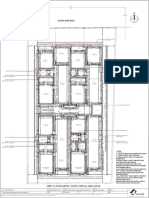

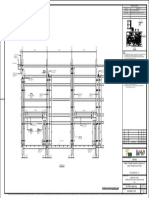

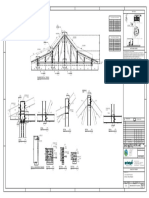

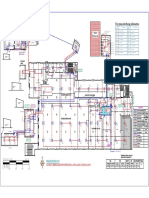

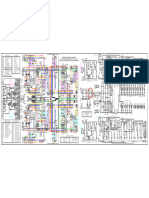

123-08

Bill of Material for 19’-6" Curved Split Switch

Note: ANGLE BETWEEN TANGENTS AT WELDED Qty For Track Qty For Elastic Description Plan No. Detail No.

1"

P.S.

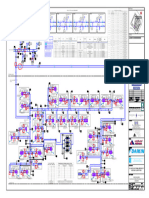

Top half of Plan View THE HEEL OF THE SWITCH 1^59’15" 8"

1" SHOULDER 8" 1" Spike Plates Fastener Plates

P.S.

shown for switch using

FOR TURNOUT CURVATURE SEE PLAN NO. 920. 2 2 Double Reinforced Switch Points Complete 221 5100

4" 22" 20" spiked plates. 4" LEFT HAND CURVED STOCK RAIL (TYPE "L")

TRACK SPIKE TURNOUT PLATES SCREW SPIKE TURNOUT PLATES

4" 4" Forged Stops 221 2024

No. 9, No. 10, No. 11, & No. 12 No. 9, No. 10, No. 11, & No. 12

12’-3" 22" 20" 20" 20" 20" 19" 19" 19" 19" 20" 19" 20" R S T U V W X Y

1 1 Curved Stock Rail 911 -

7" 7"

BP1

RAIL

GP1-2

GP1-1

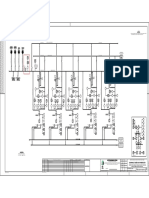

NO. DETAIL A B X NO. DETAIL A B X

GP0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 " 1 1 Straight Stock Rail 911 -

BASE

K 4 7420 6" " " 4E 6420 6" " 0" 2 2 Heel Block Assembly 221 1125

A +"

E E

B RAIL 2 2 Insulated Back Switch Rod 222 3117, 6011

"

5 7421 7" " " 5E 6421 7" " "

M BASE

LEFT HAND A Insulation Applied To Rods 222 3001

+"

GP1-1

STRAIGHT B

7422 8" " " 6422 8" " "

11

BP1

12

6 6E

BP1A

BP1A

BP1

16 16 Adjustable Rail Braces 224 -

BP1

RAIL

10

SP1

SWITCH POINT

SP1

BP1

BP1

SP1

9

X

8

SP1

SP1

BASE

7

B

SP1

6

2 2 Turnout Plate Sets Per Table for No. 9, 10, 11, 123 6420-6423, 6428-6432 or

5

7 7423 8" " " 7E 6423 8" " "

4

+" X

RAIL and 12 Turnouts 7420-7423, 7428-7432

C D E C D E

BASE HAND THROW SPLIT SWITCH WITH UNIFORM RISERS - SPEC. 123A

4" +"

8 7428 9" 10" 4" 8E 6428 9" 10" 7" Qty For Track Qty For Elastic Description Plan No. Detail No.

Spike Plates Fastener Plates

1" 9 7429 10" 10" 4" 9E 6429 10" 10" 7"

1 1 Insulated Head Switch Rod 222 3117, 6010

B 7"

10 7430 11" 11" 4" 10E 6430 11" 11" 7" 0 1 Gage Plate No. GP0 223 3126

PLATES NO. 4-7

11 7431 12" 13" 4" 11E 6431 12" 13" 7" 1 2 Gage Plate No. GP1 223 3127 or 4127

4 2 Plate No. BP1A 224 6026 or 7026

GP1E-1

GP1E-2

BP1E

GP0E

8" 1" 12 7432 13" 14" 4" 12E 6432 13" 14" 7"

10 8 Plate No. BP1 224 4020 or 6020

1" PLATES NO. 4E-7E

NOTES FOR PLATES 4-7: NOTES FOR TURNOUT PLATES: 12 12 Plate No. SP1 224 6021 or 7021

WELDED

1. OMIT SPIKE HOLE "K" WHEN 1. WHEN USING GAGE PLATES, REDUCE SHOULDER 0 2 Gage Plate No. GP3 223 3132

8" 1"

E 4" DISTANCE "M" IS LESS THAN 1" QUANTITY OF TURNOUT PLATES BASED

POWER OPERATED SPLIT SWITCH WITH UNIFORM RISERS - SPEC. 123B

2. OMIT SPIKE HOLES "E" WHEN ON NUMBER OF GAGE PLATES IN SET.

GP3E-13

GP3E-21

10E

6E

7E

SP1E

9E

8E

SP1E

SP1E

5E

11E

PLAN VIEW OF POWER

SP1E

SP1E

SP1E

GP1E-1

BP1AE

GP1E-5

2

3

BP1E

GP0E

BP1E

BP1E

BP1E

RAIL DISTANCE "M" IS LESS THAN " 2. TURNOUT PLATES ARE DESIGNED TO Qty For Track Qty For Elastic Description Plan No. Detail No.

1

OPERATED SWITCH

ROD

ROD

BASE " 3. FOR SIZE AND LOCATION OF SPIKE TO BE USED WITH 14" TIE PLATES. IF Spike Plates Fastener Plates

ROD

HOLES, SEE SECTION 7, Plan No.100. LARGER TIE PLATES ARE USED, EXTRA E

+" 7"

D 1 1 Insulated Head Switch Rod With Basket 222 3117, 7017

TURNOUT PLATES WILL BE REQUIRED.

C

>

>

>

4" SWITCH 1 1 Gage Plate No. GP0 223 3126

RIGHT HAND STRAIGHT RIGHT HAND CURVED

THROW AT 17" 20" SWITCH POINT

5’-0" 6" HEEL STOCK RAIL (TYPE L) 2 3 Gage Plate No. GP1 223 3127 or 4127

> ROD 1 RAIL

"

SPREAD BASE 2 2 Plate No. BP1A 224 6026 or 7026

1" DIAMETER HOLES C D

13’-11" 19’-6" +" 8 6 Plate No. BP1 224 4020 or 6020

RAIL

P.S.

"

TIE SPACING FOR TURNOUT PLATES BASE 12 12 Plate No. SP1 224 6021 or 7021

+" 0 2 Gage Plate No. GP3 223 3132

FROG No. R S T U V W X Y

LEGEND 1" RAIL

"

9 19" 19" 19" 19" 19" 19" 19" 19" 4" BASE

RAIL BRACE

1" 2" 2" 1" +"

Note: ELASTIC FASTENER 10 20" 20" 20" 20" 20" 20" 21" 21" NOTES:

1"

Bottom half of Plan View shown for P.S. POINT OF SWITCH 8" 1- BILL OF MATERIAL. This plan illustrates and includes in the following Bills of

11 20" 20" 20" 21" 21" 21" 22" 22" Material several designs of split switch layouts, therefore purchaser shall state which

switch using elastic fasteners and 7"

PLATES NO.8-12 Bill of Material Specification is wanted. Purchaser to state which turnout plates to furnish.

plates for wood tie screw spikes. 12 20" 21" 21" 21" 22" 22" 23" 23"

SCREW SPIKE

Insulated hand-throw Split switch with uniform risers and adjustable rail braces, Spec. 123A

TRACK SPIKE TURNOUT PLATES HOLE DIMENSIONS

PLAN VIEW OF HAND THROW SWITCH (LEFT HAND SHOWN) Power Operated Split switch with uniform risers and adjustable rail braces, Spec. 123B

SWITCH POINT PLATE NO. 8E

RAIL AND JOINT BARS. For new installation, all switches are to be 115 lb. RE, 136 lb. RE, or

LENGTHS PER 141 lb. RE.

SIDE PLANING

TURNOUT 1" Purchaser shall specify hand of turnout and switch points and stock rails to suit. For right hand

1ST TOP " IN 9’-0" WELDED 8"

RAIL

DETAIL turnouts,the right hand switch point and left hand stock rail are straight and the left hand

2ND TOP HEAD SHOULDER

FROG NO. L 5100 switch point and right hand stock rail are curved. For left hand turnouts, the left hand switch

WIDTH

17’-6" (D-BAR)

"

(HB)

point and right hand stock rail are straight and the right hand switch point and left hand stock

(HB)

IN 24" 9 30’-10" rail are curved.

2" 10’-0"

"(H)

"(1B)

"(1B)

"(R)

"(1B)

"(1B)

"(H)

"(R)

"(H)

"(H)

"(H)

"(H)

"(H)

"(S)

"(S)

"(H)

"(H)

E 7"

"(R)

"(R)

"(R)

"(H)

"(H)

"(H)

"(R)

"(H)

10 31’-3" 2" 10’-4" 2- ALTERNATES:

"

TAG

(a) Any details of fittings that will apply per Plans No. 221, 222, 223, and 224.

"

"(B)

"(B)

"(B)

3" 10’-9"

12’-10

19’-10

11 31’-7" ALIGN WEB OF SWITCH POINT

2’-10

4’-11

7’-10

9’-11

11’-2

12’-0

13’-8

14’-4

15’-2

15’-7

16’-2

17’-3

19’-1

HOLE DIA. BOLTS (GRADE 5) * RAIL SAME AS ADJACENT STOCK (b) Switch rails furnished with manganese steel tips per Plan No. 220.

R

RAIL

I.D.

1’-2

1’-7

2’-0

2’-5

3’-3

3’-8

4’-1

4’-6

6’-2

6’-7

8’-3

9’-6

"

RAIL THROUGH SIDE PLANING. BASE

12 31’-11"

"

0"

B 1" 1" SQUARE THIN HEAD (c) Type "S" stock rails per Plan No. 921.

1

6

9

+"

ANGLE 1^-04’-24"

1

PURCHASER MAY REQUEST

2.17’

1B 1" 1" SQUARE THIN HEAD S 122 C D 3- Switch point rollers may be added per individual customer’s request.

LONGER SWITCH POINTS BEND 1" IN 4’-5" RADIU

ANGLE 1^-04’-24" 7.46’

R 1" FURNISHED WITH RODS S 121 4’-1"

4- SPRING SWITCH DETAILS - See Plan No. 182 for revisions in switch points,

RADIU SIDE PLANING

4" rods, plates, and Bills of Material recommended for spring switch operation.

H " " PIN

1" 0" POINT " 1"

0" POINT " 5- SPECIFICATIONS - See Plan No. 100

6"

S " " SQUARE FULL HEAD " " " " 6"

RAIL " 6- Gage plate I.D. stamping to include:

HB 1" 1" SQUARE FULL HEAD ELEVATED RUNOFFS BASE

"

4" 3’-4" 3’-4" 4" 3’-4" 3’-4" Plate Hand Tie Switch Rail

IN POINT RAILS 4’-1" +"

4’-1" Style (If Required) Number Length Weight

4

* BOLT HARDWARE TO INCLUDE: 12"

ING STOCK RAIL

SPRING WASHER, HEX NUT AND " COTTER SIDE PLAN Example: GP1 L 1 19’-6" 136

> STOP UNDERCUT ON

Example: GP3E L 13 19’-6" 136

GAGE SIDE 12"

17’-6" (D-BAR) 7"

> HEEL BLOCK AMERICAN RAILWAY ENGINEERING

19’-6" STRAIGHT SWITCH POINT CURVED SWITCH POINT AND MAINTENANCE OF WAY ASSOCIATION

DETAIL 5100 PER PLAN NO. 221 DETAIL 5100 PER PLAN NO. 221

L PLATES NO. 9E-12E

NOTE: SHOULDERS MAY BE

19’-6" CURVED SPLIT SWITCH

DETAILS SHOWN ABOVE ARE FURNISHED UNLESS OTHERWISE SPECIFIED. OFFSET IF REQUIRED.

WITH UNIFORM RISERS FOR

ELEVATION OF SWITCH POINT SCREW SPIKE TURNOUT PLATES TRACK SPIKES OR SCREW SPIKES

PLAN NO. 123-08

Adopted 1955. Converted to C.A.D. 1991. Revised 2008 Copyright c 2008 by the American Railway Engineering and Maintenance of Way Association (AREMA). All rights reserved.

You might also like

- AREMA Vol. 3 - (2009) PDFDocument1,184 pagesAREMA Vol. 3 - (2009) PDFLuis Emilio Bosio100% (2)

- CASE 580N Backhoe Service Manual Diagram ElectricDocument1 pageCASE 580N Backhoe Service Manual Diagram ElectricErick David100% (2)

- CASE 580N-Backhoe-Service-Manual-diagram-electricDocument1 pageCASE 580N-Backhoe-Service-Manual-diagram-electricWuillians GuzmanNo ratings yet

- QuickStart Using OpenRail Designer - 2018R4!03!01Document50 pagesQuickStart Using OpenRail Designer - 2018R4!03!01naveenNo ratings yet

- 02-Light Rail Transit Capital Cost Bill of QuantitiesDocument16 pages02-Light Rail Transit Capital Cost Bill of QuantitiesSatria Pinandita100% (1)

- A History of Railway SignallingDocument18 pagesA History of Railway SignallingWindow SeatNo ratings yet

- Plates No. 4-9: S R T U V WDocument1 pagePlates No. 4-9: S R T U V WToni Garrote FerreroNo ratings yet

- Bill of Material For 16'-6" Straight Split SwitchDocument1 pageBill of Material For 16'-6" Straight Split SwitchToni Garrote FerreroNo ratings yet

- Final Copy For ApprovalDocument2 pagesFinal Copy For Approvalcontact.loksewabookNo ratings yet

- 40 Feet Wide Road: First Floor Brick Work Detail DrawingDocument1 page40 Feet Wide Road: First Floor Brick Work Detail DrawingPriya DarshiniNo ratings yet

- B85-L3 - Var-Part 12 Construction DetailsDocument10 pagesB85-L3 - Var-Part 12 Construction Detailsissam.qamhiaNo ratings yet

- Biruwa PlaningDocument1 pageBiruwa Planingcontact.loksewabookNo ratings yet

- GTG CD Sem 1402Document1 pageGTG CD Sem 1402Gourishankar MishraNo ratings yet

- 1 J I:'a L / Gi: I I I I I I I I IDocument1 page1 J I:'a L / Gi: I I I I I I I I IShivendra KumarNo ratings yet

- 0-8936-2 Golden Triangle Polymers Company LLCDocument1 page0-8936-2 Golden Triangle Polymers Company LLCLester MuscaNo ratings yet

- Master Plan of Dairy Farm: Ans AssociatesDocument9 pagesMaster Plan of Dairy Farm: Ans AssociatesIrfan MunirNo ratings yet

- MRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3Document1 pageMRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3arman gauNo ratings yet

- Uvls.2 Uqair-A.12 PDFDocument1 pageUvls.2 Uqair-A.12 PDFAnonymous BZQOJwWIh6No ratings yet

- Construction DWG (S-17)Document1 pageConstruction DWG (S-17)Umer FarooqNo ratings yet

- P02 Planteamiento Hidraulico Ccocharara PL 1Document1 pageP02 Planteamiento Hidraulico Ccocharara PL 1Luis Flores GarciaNo ratings yet

- Span Arrangementpackage-59 - P3L2 PDFDocument23 pagesSpan Arrangementpackage-59 - P3L2 PDFJ. Kumar Infraprojects LtdNo ratings yet

- SLD - CBSE Patna - PDF 2Document1 pageSLD - CBSE Patna - PDF 2nbcccbsepatnaNo ratings yet

- 03 150000 4200000005 Ace Mec DRG 005204 - 02Document1 page03 150000 4200000005 Ace Mec DRG 005204 - 02Anas TawfiqNo ratings yet

- Prestressed Concrete Sheet PilingDocument1 pagePrestressed Concrete Sheet PilingNaresh GajNo ratings yet

- 1.existing Plan (Blow Up 000 - 100)Document1 page1.existing Plan (Blow Up 000 - 100)bappyNo ratings yet

- Lakepoint Apartments (Emerson) - RFI 67Document3 pagesLakepoint Apartments (Emerson) - RFI 67jhamiralexNo ratings yet

- 00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 002Document9 pages00UMF611 - LAYOUT A ARRANGEMENT POWER HOUSE - Equipment Location Plan - 002tiantaufikNo ratings yet

- Desague (1) - Planta GeneralDocument1 pageDesague (1) - Planta Generalkristian MéndezNo ratings yet

- Tilal Mall and Hotel Sharjah, UAE: Detail 1Document22 pagesTilal Mall and Hotel Sharjah, UAE: Detail 1Michael Camit Eso100% (1)

- Hwy 49 Roadwork2Document1 pageHwy 49 Roadwork2The UnionNo ratings yet

- CBD Bp18a C127D2 SDW Co Co NL 07025 01Document1 pageCBD Bp18a C127D2 SDW Co Co NL 07025 01rakeshamechNo ratings yet

- 4'0"X8'6" D8 3'6"X8'6" W W1 W2 V Column: Cupola FurnaceDocument1 page4'0"X8'6" D8 3'6"X8'6" W W1 W2 V Column: Cupola FurnaceAvinash ChouhanNo ratings yet

- 05-KSCPP-B-1906 - A - Code 2Document1 page05-KSCPP-B-1906 - A - Code 2Mohd KhaidirNo ratings yet

- P-0004-Ph01-D01-01e001-Mrc-Sdr-Str-100011 - 3-6Document1 pageP-0004-Ph01-D01-01e001-Mrc-Sdr-Str-100011 - 3-6yasirjurabaNo ratings yet

- SLD SamalkhaDocument1 pageSLD SamalkhaDarshit VyasNo ratings yet

- Key Plan: RSXX-DT Capacitor Bank RSXX-CAP-01Document6 pagesKey Plan: RSXX-DT Capacitor Bank RSXX-CAP-01Mrinal KayalNo ratings yet

- Rfi Cscec D01 Me 04 0129 00Document10 pagesRfi Cscec D01 Me 04 0129 00Ali ElkahlawyNo ratings yet

- Highway Drawings of Nukhas-Etah DRAWING (1) - 15Document1 pageHighway Drawings of Nukhas-Etah DRAWING (1) - 15Thakur AnkithNo ratings yet

- Keyplan: PT Katalis Sinergi IndonesiaDocument1 pageKeyplan: PT Katalis Sinergi IndonesiaFebry YantaNo ratings yet

- 33 KV OUTDOOR SWITCH YARD For Earthing Layout 1 RABI - (Sheet-1of2)Document1 page33 KV OUTDOOR SWITCH YARD For Earthing Layout 1 RABI - (Sheet-1of2)SUSOVAN BISWASNo ratings yet

- 03 150000 4200000005 Ace Mec DRG 005501 - 02Document1 page03 150000 4200000005 Ace Mec DRG 005501 - 02Anas TawfiqNo ratings yet

- Kuttamvathukkal GD - For ConstDocument1 pageKuttamvathukkal GD - For ConstjithinNo ratings yet

- g214599 Hmod 65 Paulander DR Kitchener DWGDocument2 pagesg214599 Hmod 65 Paulander DR Kitchener DWGJhonn StevNo ratings yet

- Thorrur LayoutDocument1 pageThorrur LayoutPavanNo ratings yet

- Fire Pump Interfacing Information: Water ReservoirDocument1 pageFire Pump Interfacing Information: Water ReservoirAlvi SarowarNo ratings yet

- Key Plan N.T.S: Detail of R.C.C. StairsDocument1 pageKey Plan N.T.S: Detail of R.C.C. StairsSaif UllahNo ratings yet

- Floor Slab of Basement Foundation DetailDocument1 pageFloor Slab of Basement Foundation DetailMohammad MoinuddeenNo ratings yet

- بلان الدور الارضي 1-ModelDocument1 pageبلان الدور الارضي 1-ModelShrook Nasr AbdElKarimNo ratings yet

- G216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgDocument5 pagesG216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgJhonn StevNo ratings yet

- E-F.62971-02-DTI-1022 Rev A 150520Document1 pageE-F.62971-02-DTI-1022 Rev A 150520ELPIDIO LUCERONo ratings yet

- Mac - Tar-Ndl - Ac Layout-052923Document1 pageMac - Tar-Ndl - Ac Layout-052923Jay MarkNo ratings yet

- KJ 117 o en Sac 00 Zme 0303Document1 pageKJ 117 o en Sac 00 Zme 0303Abdullah ObeidatNo ratings yet

- Elementos de Curvas: Universidad Catolica Santo Toribio de Mogrovejo Municipalidad Distrital de ArequipaDocument1 pageElementos de Curvas: Universidad Catolica Santo Toribio de Mogrovejo Municipalidad Distrital de ArequipaJhosut GonzalesNo ratings yet

- E-M1-02 Basement 2 ACMV Layout PDFDocument1 pageE-M1-02 Basement 2 ACMV Layout PDFJohn InacayNo ratings yet

- UM NO. 14-093 IHL NO. 207-390 Vaught-Hemingway Stadium South End ZoneDocument1 pageUM NO. 14-093 IHL NO. 207-390 Vaught-Hemingway Stadium South End ZoneMofasa ENo ratings yet

- T V Color Abbreviations: HPCR Engine Sps/Ps Transmission 580SN, 580SN-WT AND 590SN Electrical SchematicDocument2 pagesT V Color Abbreviations: HPCR Engine Sps/Ps Transmission 580SN, 580SN-WT AND 590SN Electrical SchematicFútbol y más100% (1)

- Ad 90.0 e 02061 PDF Earthing Details B 4Document1 pageAd 90.0 e 02061 PDF Earthing Details B 4mcaslamNo ratings yet

- Plano General de Plantas de Tratamiento-Planta de Tratamiento GeneralDocument1 pagePlano General de Plantas de Tratamiento-Planta de Tratamiento GeneralarmandoteranbNo ratings yet

- Lax Airport DiagramDocument1 pageLax Airport DiagramKLAXATCNo ratings yet

- MDF326 Yvette Letter A4 TiledDocument48 pagesMDF326 Yvette Letter A4 Tiledvir najNo ratings yet

- Planos de Casa Bungalow Americano 2 HabitacionesDocument1 pagePlanos de Casa Bungalow Americano 2 HabitacionesGabriel CostaNo ratings yet

- DRIVEWAY ModelDocument1 pageDRIVEWAY ModelaxecubertoneNo ratings yet

- COLOUR ELECTRICAL DIAGRAM EDTS 103 REV.D AMD.7 RCF COR.1-Model-1Document1 pageCOLOUR ELECTRICAL DIAGRAM EDTS 103 REV.D AMD.7 RCF COR.1-Model-1Srizee Shri HariNo ratings yet

- Sateba M312 Sleeper Data SheetDocument2 pagesSateba M312 Sleeper Data SheetToni Garrote FerreroNo ratings yet

- Typical Plan View: G F A B C D EDocument1 pageTypical Plan View: G F A B C D EToni Garrote FerreroNo ratings yet

- Cross Section of FillerDocument1 pageCross Section of FillerToni Garrote FerreroNo ratings yet

- Recommended Usage of Various Types of Frogs: and Maintenance of Way Association American Railway EngineeringDocument1 pageRecommended Usage of Various Types of Frogs: and Maintenance of Way Association American Railway EngineeringToni Garrote FerreroNo ratings yet

- Table D-Gages - Curved Track - LocomotivesDocument1 pageTable D-Gages - Curved Track - LocomotivesToni Garrote FerreroNo ratings yet

- Plates No. 4-9: S R T U V WDocument1 pagePlates No. 4-9: S R T U V WToni Garrote FerreroNo ratings yet

- Arema Specifications For Special Trackwork 100-08 For Rails 115 Lb. and HeavierDocument13 pagesArema Specifications For Special Trackwork 100-08 For Rails 115 Lb. and HeavierToni Garrote Ferrero100% (2)

- Bill of Material For 16'-6" Straight Split SwitchDocument1 pageBill of Material For 16'-6" Straight Split SwitchToni Garrote FerreroNo ratings yet

- April 2012: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeDocument25 pagesApril 2012: in Case of Doubt, The German-Language Original Shall Be Considered AuthoritativeToni Garrote FerreroNo ratings yet

- Arema Mre 2012 Volume 3Document1,352 pagesArema Mre 2012 Volume 3ALINE HAZEL LINO REYNOSONo ratings yet

- TrackworkDocument28 pagesTrackworkEmanuel MurilloNo ratings yet

- Railway Operation & ControlDocument58 pagesRailway Operation & ControlchinnuvarkeyscribdNo ratings yet

- L1 CHE STD 022 v2 Rail GrindingDocument37 pagesL1 CHE STD 022 v2 Rail Grinding4493464No ratings yet

- Any Rail 4 enDocument99 pagesAny Rail 4 enHassan_ChauhanNo ratings yet

- T-Exp, CSM, DUO, Unimat, MPT & DTS: M. D. Jadhav SI/COMP-2Document67 pagesT-Exp, CSM, DUO, Unimat, MPT & DTS: M. D. Jadhav SI/COMP-2Deepak Bhardwaj100% (1)

- Railway TerminologyDocument9 pagesRailway TerminologyDraj KumarceNo ratings yet

- Training Manual Drives & Back-Drives Presentation: BMRCL Project 2S&TDM-TRG-0006 - A2Document16 pagesTraining Manual Drives & Back-Drives Presentation: BMRCL Project 2S&TDM-TRG-0006 - A2Dhruva SenNo ratings yet

- CXT Concrete TieDocument16 pagesCXT Concrete Tiehiginito1410No ratings yet

- 1406180385795-Signal Engineering Manual IIDocument319 pages1406180385795-Signal Engineering Manual IIaab0989No ratings yet

- 1307078105903-TSC - 81-RBOrders FinalDocument100 pages1307078105903-TSC - 81-RBOrders FinalSatish DmNo ratings yet

- Ballast Cleaning Machine Brief - 3Document2 pagesBallast Cleaning Machine Brief - 3SystemNo ratings yet

- KCS-Standards (1 de 2)Document85 pagesKCS-Standards (1 de 2)vladibladeNo ratings yet

- Civil ExampleDocument37 pagesCivil ExampleKim AutoNo ratings yet

- Underground RailDocument23 pagesUnderground RailBlessy MabasaNo ratings yet

- Railway Engineering1Document69 pagesRailway Engineering1Wol Monydeng BolditNo ratings yet

- Basic Concepts of SignallingDocument92 pagesBasic Concepts of SignallingGopipavanNo ratings yet

- Unit10-PDMS Pipe Routing OverviewDocument4 pagesUnit10-PDMS Pipe Routing OverviewshubhamNo ratings yet

- Attachment 0 PDFDocument161 pagesAttachment 0 PDFsutani wardiNo ratings yet

- CSX Industrial Sidetrack Manual 063003 PDFDocument57 pagesCSX Industrial Sidetrack Manual 063003 PDFSidney RiveraNo ratings yet

- Service Manual For The Kodak M35 and M35A X-OMAT ProcessorsDocument106 pagesService Manual For The Kodak M35 and M35A X-OMAT ProcessorsSergio Montes100% (1)

- INT-FINDEL-D-TRV-002-01 - In2Track D2.1 Research Into Enhanced Tracks Switches and Structures PDFDocument191 pagesINT-FINDEL-D-TRV-002-01 - In2Track D2.1 Research Into Enhanced Tracks Switches and Structures PDFOm SinghNo ratings yet

- Industrial Track Specification Guide enDocument30 pagesIndustrial Track Specification Guide enkulbrsingh4975No ratings yet

- Rahe-Qb 4 - BY Civildatas - Blogspot.in PDFDocument8 pagesRahe-Qb 4 - BY Civildatas - Blogspot.in PDFMeera KumarNo ratings yet

- Railway Signalling PrinciplesDocument85 pagesRailway Signalling PrinciplesGauravkumar VaidyaNo ratings yet

- Railway.11 20Document10 pagesRailway.11 20CgpscAspirantNo ratings yet