Professional Documents

Culture Documents

High Prepackaged Magensium Anode Specificaiton

High Prepackaged Magensium Anode Specificaiton

Uploaded by

Naim RoniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Prepackaged Magensium Anode Specificaiton

High Prepackaged Magensium Anode Specificaiton

Uploaded by

Naim RoniCopyright:

Available Formats

KARATEC RESOURCES SDN BHD

KARATEC

CORROSION PROTECTION & CONTROL

SERVICE

MATERIALS SPECIFICATION

&

TECHNICAL DATA SHEET

HIGH PREPACKAGED MAGNESIUM

ANDOE

Product Catalogue KARATEC RESOURCES SDN BHD

HIGH POTENTIAL MAGNESIUM ANODE

General

Power in galvanic cathodic protection is generated at the anode. Cast from high-purity

magnesium. This type of anode produces an open circuit potential of 1.65 – 1.70 volts, which

is 20 – 30 % greater than conventional magnesium anodes. This high driving voltage means

greater protection can be delivered from fewer anodes. Efficiency of the anode is enhanced

even further when installed in a backfill of 75 % gypsum, 20 % Bentonite and 5 % sodium

sulfate. This special mixture lowers anode-to-earth resistance and allows electrical current to

flow more easily to the targeted structure.

Typical Applications

High potential anodes can be used to protect most buried metallic structures found in a range

of soil resistivities. Because they produce a higher driving voltage than conventional

magnesium anodes, they are ideally suited for structures buried in soils with resistivities in

excess of 2000 ohm.cm or containing numerous corrosion ‘hot spots’.

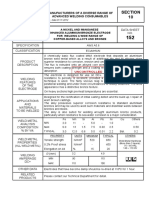

Chemical Composition

The magnesium anodes are HP magnesium alloy casting pre-packaged in a low resistivity

backfill and fitted with a cable tail.

Note: Various sizes of Magnesium Alloy Anode are available.

The magnesium compositions by weight are:

Copper 0.015 % max

Aluminium 0.0033 % max

Iron 0.0027 % max

Manganese 0.59 % min

Nickel 0.0007 % max

Magnesium Remainder

Potential - 1.65 to -1.7 Volts w.r.t. Cu./CuSO4 ref. Cell.

Utilization factor 0.85

The castings are homogeneous, with a smooth surface free from major defects such as voids,

porosity, blowholes, pitting, inclusions and any other characteristics likely to detract from its

performance in terms of current output

and life.

Anodes are provided with a 3 meters

length of single core copper cable

6mm2 HMWPE 300/500 volt grade.

The magnesium alloys are cast onto a

galvanized steel core to which the

cable were securely brazed within a

suitable recess and the connection

encapsulated with an epoxy

compound, which totally seal the core,

and cable connection.

Anodes are pre-packaged in a backfill of the following composition:

Powered Hydrated Gypsum 75 %

Granular Bentonite 20 %

Anhydrous Sodium Sulphate 5 %

2

Product Catalogue KARATEC RESOURCES SDN BHD

The anode and backfill are contained in a permeable cotton cloth bag.

EXTRUDED MAGNESIUM ANODES

General

Magnesium anodes have the highest protection capability of any galvanic material. While

these anodes are most commonly used in the cast metal form, certain structures can be

better protected through the use of extruded magnesium configurations. Extruded magnesium

anodes have high surface and length ratios in relation to cross sectional size. This allows

these anodes to deliver a greater amount of current per weight than their cast magnesium

counterparts. By supplying more current, extruded anodes can deliver effective protection to

structures buried in even highly resistive electrolytes.

Typical Applications

Extruded magnesium anodes are most suitable for structure buried or submerged in high

resistivity electrolytes. The rod shape anodes, with their small diameters, are often used in

commercial and industrial water heaters and storage tanks, or driven into the ground to

protect gas service risers. The ribbon anode is used for the protection of pipelines and

storage tanks. Extruded anodes are also employed to pre-polarize offshore structures which

are to be protected with aluminium anodes.

Chemical Composition

The extruded magnesium anodes are manufactured in flexible coils which can be easily

shaped for use on a multitude of protection projects. They are constructed with a solid steel

core which runs lengthwise through the anodes for efficient electrical discharge.

The magnesium compositions by weight are:

Copper 0.02 % max

Aluminium 0.010 % max

Iron 0.03 % max

Manganese 0.50 – 1.3 % min

Nickel 0.001 % max

Magnesium Remainder

Potential - 1.75 to -1.77 Volts w.r.t. Cu./CuSO4 ref. Cell.

Utilization factor 0.85

You might also like

- Erector Parts GuideDocument24 pagesErector Parts Guidedomingojs233710No ratings yet

- Corrpro Magnesium AnodesDocument4 pagesCorrpro Magnesium Anodeswhah11No ratings yet

- AodDocument20 pagesAodanon_945096555100% (2)

- Leroy Somer MotorsDocument8 pagesLeroy Somer MotorsAmir HussainNo ratings yet

- Rheology and Processing 2016Document65 pagesRheology and Processing 2016Shailendra PatelNo ratings yet

- Anodes - Magnesium AnodesDocument7 pagesAnodes - Magnesium Anodesradityayoga20No ratings yet

- Sacrificial Anode Cathodic ProtectionDocument8 pagesSacrificial Anode Cathodic Protectionnero daunaxilNo ratings yet

- Mangnese SteelDocument5 pagesMangnese SteelsurajNo ratings yet

- ICCP Mixed Metal Anodes R8 12 PDFDocument2 pagesICCP Mixed Metal Anodes R8 12 PDFAndika SiregarNo ratings yet

- Cathodic Protection en - WikipediaDocument8 pagesCathodic Protection en - WikipediaPRABHU SHANKAR MNo ratings yet

- Conductor and SuperconductorDocument12 pagesConductor and Superconductorankesh_ghoghariNo ratings yet

- Mixed Metal Anodes Data Sheet: Pipeline Maintenance LimitedDocument5 pagesMixed Metal Anodes Data Sheet: Pipeline Maintenance LimitedDotty RoseNo ratings yet

- Deep Anodes: 74 Pipeline Corrosion and Cathodic ProtectionDocument10 pagesDeep Anodes: 74 Pipeline Corrosion and Cathodic ProtectionM SuheriNo ratings yet

- L12-Cathodic & Anodic ProtectionDocument41 pagesL12-Cathodic & Anodic ProtectionAmir Khalid100% (1)

- Cathodic Protection of Steel in ConcreteDocument5 pagesCathodic Protection of Steel in ConcretegersomNo ratings yet

- Impressed Current Anode System Jetty PilingDocument5 pagesImpressed Current Anode System Jetty Pilingmohamed.eldesouky9120No ratings yet

- Impressed Current Systems: 1213 Design CriteriaDocument1 pageImpressed Current Systems: 1213 Design CriteriaamrinderNo ratings yet

- Cathodic ProtectionDocument22 pagesCathodic ProtectiondevanbongiriNo ratings yet

- Co2 Welding WireDocument2 pagesCo2 Welding WireCharles JacobNo ratings yet

- Cathodic ProtectionDocument11 pagesCathodic ProtectionsiswoutNo ratings yet

- Aircraft Welding CabrianaDocument5 pagesAircraft Welding CabrianaJunemar ManlaweNo ratings yet

- Corrosion Prevention 1-4Document77 pagesCorrosion Prevention 1-4Anonymous nFGwmwv9No ratings yet

- ICCPDocument4 pagesICCPVyas SrinivasanNo ratings yet

- A Seminar On Cathodic Protection TechniquesDocument9 pagesA Seminar On Cathodic Protection TechniquesDevashish JoshiNo ratings yet

- Welding Austenitic Manganese Steel RailDocument6 pagesWelding Austenitic Manganese Steel RailaladinsaneNo ratings yet

- Smart Brains Institute of Engineering Design & Research: Cabling SystemDocument11 pagesSmart Brains Institute of Engineering Design & Research: Cabling SystemAshwin SevariaNo ratings yet

- Catalogue of CCS Zhenglan ChinaDocument14 pagesCatalogue of CCS Zhenglan ChinagestordecomprasNo ratings yet

- Austenitic Manganese Steels: Total Materia ArticleDocument9 pagesAustenitic Manganese Steels: Total Materia ArticleCarlos Ediver Arias RestrepoNo ratings yet

- Cathode ProtectionDocument2 pagesCathode ProtectionAnonymous kdFzbQ4jfNo ratings yet

- METALS PresentationDocument28 pagesMETALS PresentationTheresa TuliaoNo ratings yet

- Cladding PDFDocument6 pagesCladding PDFlibid_rajNo ratings yet

- Resistors Module 02 PDFDocument17 pagesResistors Module 02 PDFShubham kumarNo ratings yet

- A Review On Magnesium Aluminate (Mgal2O4) Spinel: Synthesis, Processing and ApplicationsDocument51 pagesA Review On Magnesium Aluminate (Mgal2O4) Spinel: Synthesis, Processing and ApplicationsSajan P ShamsudeenNo ratings yet

- Mica CapacitorsDocument3 pagesMica Capacitorsnick7simichNo ratings yet

- Overhead ConductorsDocument46 pagesOverhead Conductorsمحمد كهرباءNo ratings yet

- Technicalupdate RepairWeldingofSeawaterpipesDocument8 pagesTechnicalupdate RepairWeldingofSeawaterpipesSpeederz freakNo ratings yet

- A1 - ICCP Sample ManualDocument88 pagesA1 - ICCP Sample Manualalisson de francaNo ratings yet

- Data Sheet AL-BRONZEDocument1 pageData Sheet AL-BRONZEAris WicaksonoNo ratings yet

- 21SPTE313 - Lecture 10Document40 pages21SPTE313 - Lecture 10Mohamed SolimanNo ratings yet

- CuW Sintered E USDocument5 pagesCuW Sintered E USanuragsngNo ratings yet

- Cathodic Protection: Jump To Navigationjump To SearchDocument7 pagesCathodic Protection: Jump To Navigationjump To SearchfayasNo ratings yet

- It Is The Prevention of Corrosion By: Anodic ProtectionDocument53 pagesIt Is The Prevention of Corrosion By: Anodic ProtectionalaialiNo ratings yet

- Simulation of Cathodic Protection System Using Matlab: March 2013Document14 pagesSimulation of Cathodic Protection System Using Matlab: March 2013adnantanNo ratings yet

- Anti Corrosion JournalDocument4 pagesAnti Corrosion JournalJuandi CanNo ratings yet

- Anodic ProtectionDocument30 pagesAnodic ProtectionLuis Eduardo PereiraNo ratings yet

- Electrodeposition of ManganeseDocument42 pagesElectrodeposition of ManganeserichardNo ratings yet

- Canistered AnodeDocument2 pagesCanistered AnodesubbaraoNo ratings yet

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeOnM deptNo ratings yet

- FusesDocument19 pagesFusesMichael Calizo PacisNo ratings yet

- Day 2 Part 1Document90 pagesDay 2 Part 1Edukondalu PentapatiNo ratings yet

- Cathodic Protection - Wikipedia PDFDocument62 pagesCathodic Protection - Wikipedia PDFSiddhartha Archana SharmaNo ratings yet

- TDS 2023oct - Galvashield - SM DASDocument3 pagesTDS 2023oct - Galvashield - SM DASvivekNo ratings yet

- Abhishek Mishra Arunn Kumar Manish Kumar: Corrosion Control MethodsDocument28 pagesAbhishek Mishra Arunn Kumar Manish Kumar: Corrosion Control MethodsVaibhav GuptaNo ratings yet

- Module 3 Basics of CPDocument76 pagesModule 3 Basics of CPAbdul Wajid AliNo ratings yet

- Study of Mechanical Properties Microstru PDFDocument6 pagesStudy of Mechanical Properties Microstru PDFAyyappanSubramanianNo ratings yet

- Austenitic Stainless SteelsDocument10 pagesAustenitic Stainless SteelsbramNo ratings yet

- Corrosion Paper Royal SocietyDocument9 pagesCorrosion Paper Royal SocietySakib Al Razi KhanNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- Effects of Zinc Addition On The Performance of Aluminium As Sacrificial Anode in SeawaterDocument14 pagesEffects of Zinc Addition On The Performance of Aluminium As Sacrificial Anode in SeawaterLeelaram YadavNo ratings yet

- Cathodic ProtectionDocument10 pagesCathodic Protectionmayank dhokeNo ratings yet

- Magnesium Anodes: Sacrificial Anode, Cathodic ProtectionDocument2 pagesMagnesium Anodes: Sacrificial Anode, Cathodic ProtectionJoy Arief JanuarNo ratings yet

- Application For Science Officer C41 (Biological Science) at Ministry of Science Technology and InnovationDocument2 pagesApplication For Science Officer C41 (Biological Science) at Ministry of Science Technology and InnovationNaim RoniNo ratings yet

- Earthing Single Chamber PDFDocument2 pagesEarthing Single Chamber PDFNaim RoniNo ratings yet

- Project Work InstructionDocument2 pagesProject Work InstructionNaim RoniNo ratings yet

- Tag LaminateDocument3 pagesTag LaminateNaim RoniNo ratings yet

- Inverter Station: ST ST ST STDocument1 pageInverter Station: ST ST ST STNaim RoniNo ratings yet

- Your Name: Mjsakjsalksa Title / Company AddressDocument1 pageYour Name: Mjsakjsalksa Title / Company AddressNaim RoniNo ratings yet

- Hulu Tajong IDocument1 pageHulu Tajong INaim RoniNo ratings yet

- Judskjd YNDocument1 pageJudskjd YNNaim RoniNo ratings yet

- A48Document6 pagesA48Luis Fernando LaverdeNo ratings yet

- Cable Glands For Armoured and Non-Armoured CablesDocument6 pagesCable Glands For Armoured and Non-Armoured CablesmustardbassmanNo ratings yet

- Mil HDBK 694aDocument106 pagesMil HDBK 694ahardik033No ratings yet

- Excalibur 9018-B3 MR: Typical Applications Key FeaturesDocument2 pagesExcalibur 9018-B3 MR: Typical Applications Key FeaturesAliakbar GhaderiNo ratings yet

- Mild Steel Pipe Dimensions, IS 1239, IS 3589, IS 4923Document2 pagesMild Steel Pipe Dimensions, IS 1239, IS 3589, IS 4923Gaurav KumarNo ratings yet

- The Restless Atom BY HOMARDocument82 pagesThe Restless Atom BY HOMARChandra SekharNo ratings yet

- Anvil Pipe Hanger CatalogDocument252 pagesAnvil Pipe Hanger Catalogneversirender100% (1)

- Neodymium Magnet DescriptionDocument4 pagesNeodymium Magnet DescriptionRizki Ari WijayantiNo ratings yet

- Astm A350 - A350mDocument11 pagesAstm A350 - A350mOrlando RNNo ratings yet

- Temperature Coefficient of ResistanceDocument3 pagesTemperature Coefficient of ResistanceShailesh SharmaNo ratings yet

- XL2000 Technical SpecificationDocument3 pagesXL2000 Technical SpecificationLeonardo SilvaNo ratings yet

- P C - C T: Roduct Atalogue Able RaysDocument12 pagesP C - C T: Roduct Atalogue Able RaysBoyzannaz100% (1)

- Iqwq FT LSPDS 00 032003 - 0a PDFDocument73 pagesIqwq FT LSPDS 00 032003 - 0a PDFhapinefeNo ratings yet

- Lecture - 5 Notes: Milling Basic Mechanical Engineering (Part - B, Unit - I) 1Document7 pagesLecture - 5 Notes: Milling Basic Mechanical Engineering (Part - B, Unit - I) 1Roop LalNo ratings yet

- Short Answers Questions DmeDocument51 pagesShort Answers Questions DmeAnonymous 3Txvb6UmNo ratings yet

- Alistair Doig - Some Metallurgical Aspects of Shaped Charge LinersDocument3 pagesAlistair Doig - Some Metallurgical Aspects of Shaped Charge LinersGhoree23456No ratings yet

- All About CleanerDocument22 pagesAll About CleanerMarlon GlodoNo ratings yet

- CBLM Install Pacu Cre PipingDocument54 pagesCBLM Install Pacu Cre PipingAlran Eric Cifra100% (2)

- Thermal Conductivity of MaterialDocument7 pagesThermal Conductivity of MaterialPhyu Mar Thein Kyaw0% (1)

- 1880 Katalog Meinhart ATen Low 20101210 01 PDFDocument271 pages1880 Katalog Meinhart ATen Low 20101210 01 PDFvalimironescuNo ratings yet

- BURNDY GroundingDocument95 pagesBURNDY Groundingmiguelpaltino100% (1)

- Typical Specifications: Model: Description CertificationsDocument1 pageTypical Specifications: Model: Description CertificationsMIGUELNo ratings yet

- Api 653 Preparatory Course: Final Exam - Open BookDocument8 pagesApi 653 Preparatory Course: Final Exam - Open Bookraobabar21No ratings yet

- A 447Document4 pagesA 447william_m08No ratings yet

- Cutting Tools and OperationDocument9 pagesCutting Tools and OperationramkumarNo ratings yet

- Levcon Jaykay: Licensee of Bonetti S. .A. ItalyDocument2 pagesLevcon Jaykay: Licensee of Bonetti S. .A. ItalyPankaj PandeyNo ratings yet