Professional Documents

Culture Documents

PTFE Envelope Gasket ED30 Graphite 2009 04 en

PTFE Envelope Gasket ED30 Graphite 2009 04 en

Uploaded by

Alberto LazzarettiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTFE Envelope Gasket ED30 Graphite 2009 04 en

PTFE Envelope Gasket ED30 Graphite 2009 04 en

Uploaded by

Alberto LazzarettiCopyright:

Available Formats

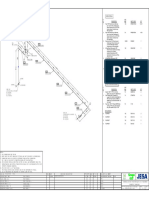

PTFE envelope gasket with inner diffusion barrier,

corrugated ring and two SIGRAFLEX® Email graphite inserts

(IDT Style: ED30)

The PTFE envelope is made of modified DyneonTM TFMTM 1600 and incorporates an inner

diffusion barrier (3 mm wide), a corrugated ring (1.4571) and two graphite inserts in

SIGRAFLEX® Email (each 2 mm thick). The seal features high resilience and is recommended by

leading enamel flange manufacturers from DN 250 upwards; it is however available in all

nominal widths.

The sealing system requires a low minimum seating stress on installation; it is resistant to most

chemicals, it neither ages nor becomes brittle. The gasket is particularly suitable for use in environments

with highly corrosive media, where a high degree of product purity is required, for FDA applications

and in flanges sensitive to tension and bending.

Construction

PTFE envelope:

Graphite insert: SIGRAFLEX® Email

DyneonTM TFMTM 1600

All information given in this Technical Information sheet represents our current level of knowledge and serves as information on our products and their respective scope. It is not meant to ensure

Stainless steel

corrugated ring:

s=0.5 mm;

Standard 1.4571

Operating limits

any particular properties of any product or the suitability of any product for any specific application, neither does it create any liability on our part.

■ Operating pressure : max. 40 bar

■ Operating temperature : -200 °C to +200 °C

short-term: 230 °C

Gasket characteristics DIN 28090 (thickness = 6.5 mm)

σVU : 8 N/mm²

σVO : 60 N/mm²

σBO 150°C : 55 N/mm²

mDIN 2505 : 1.1

Approvals

■ Blowout safety as per TÜV report AW6/0580-97

■ FDA compliant (parts in contact with product)

■ Fire Safe test as per API 607 / DIN ISO 10497

■ TA-Luft 2002 (VDI 2440/2200) 1)

1)

TA-Luft: German Technical Instructions on Air Quality Control

© Copyright by IDT.

General information

04/2009

Rev. 02

You might also like

- Heat Transfer Design Methods by John MC Ketta PDFDocument607 pagesHeat Transfer Design Methods by John MC Ketta PDFAlberto LazzarettiNo ratings yet

- Thermal Stress Creep in HRSG Pressure PartsDocument274 pagesThermal Stress Creep in HRSG Pressure PartsAlberto Lazzaretti100% (2)

- Contact ProcessDocument16 pagesContact ProcessOmar Almonte100% (1)

- Spiral-Wound Gasket With Graphite or PTFE Filler and Inner RingDocument1 pageSpiral-Wound Gasket With Graphite or PTFE Filler and Inner RingwongngganthengNo ratings yet

- 05-071-072 PTFE-enveloped Gaskets PDFDocument2 pages05-071-072 PTFE-enveloped Gaskets PDFZain ZulfiqarNo ratings yet

- 11 SCH80Document16 pages11 SCH80Ro ViNo ratings yet

- High Temp Tape Darco 10.16Document1 pageHigh Temp Tape Darco 10.16Jose ArangoitiaNo ratings yet

- Datasheet Sigraflex MF - en 2010Document6 pagesDatasheet Sigraflex MF - en 2010m bNo ratings yet

- Tricoflex® Profile: Product Data SheetDocument4 pagesTricoflex® Profile: Product Data SheetARY ASANNo ratings yet

- Ptfe TeaditDocument12 pagesPtfe TeaditDimitriNo ratings yet

- 0 10/24/2022 A.N Y.S K.M 10/24/2022 Issued For ConstructionDocument1 page0 10/24/2022 A.N Y.S K.M 10/24/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- Sigma 588Document1 pageSigma 588shahbaz1979No ratings yet

- DEPROTEC R - PUR Product Information PR00218808-1Document2 pagesDEPROTEC R - PUR Product Information PR00218808-1pedro davilaNo ratings yet

- Wound SpiralDocument2 pagesWound SpiralMircea Dan StanciuNo ratings yet

- Flexpro Therm 845Document1 pageFlexpro Therm 845Benoit LabreNo ratings yet

- Delta Adhesive Tapes & Foam Tapes 2020 R1Document8 pagesDelta Adhesive Tapes & Foam Tapes 2020 R1Shafeek070No ratings yet

- Mass Timber Pitched Roof Eaves, SOLITEX ADHERO Var. 2Document2 pagesMass Timber Pitched Roof Eaves, SOLITEX ADHERO Var. 2deanNo ratings yet

- Model TC190 - DS - Vacuum Relief ValveDocument5 pagesModel TC190 - DS - Vacuum Relief ValveJimenena2No ratings yet

- Systemseals - Series 109Document6 pagesSystemseals - Series 109Efe IrtemNo ratings yet

- Fiberglass Insulation: Softr Duct Wrap FRKDocument2 pagesFiberglass Insulation: Softr Duct Wrap FRKHo Dac ThanhNo ratings yet

- FLEXmount 344 Series AdhesivesDocument4 pagesFLEXmount 344 Series Adhesiveshuynh thi y viNo ratings yet

- Et5428 TDSDocument2 pagesEt5428 TDSaria.iza.gbNo ratings yet

- Gasket Tombo 9013-EPDocument3 pagesGasket Tombo 9013-EP0ch3No ratings yet

- Novaphit Professional Technolgy eDocument8 pagesNovaphit Professional Technolgy eajaysharma_1009No ratings yet

- Plaster Profiles and Other Accessories - ENDocument9 pagesPlaster Profiles and Other Accessories - ENaayasirNo ratings yet

- Thermiculite 835: Product DatasheetDocument2 pagesThermiculite 835: Product DatasheetBenoit LabreNo ratings yet

- Terminal and Junction Boxes Ex e / Ex I, Glass Fiber Reinforced Polyester (GRP) GR.TDocument6 pagesTerminal and Junction Boxes Ex e / Ex I, Glass Fiber Reinforced Polyester (GRP) GR.TAlex DzatkoNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- Afico Pipe InsulaionDocument4 pagesAfico Pipe InsulaionProcurement Alamco100% (1)

- Gore-Tex GR: Sheet GasketingDocument2 pagesGore-Tex GR: Sheet GasketingserpecoraroNo ratings yet

- 20 Year Colour Guarantee : Be Proud of What You BuildDocument6 pages20 Year Colour Guarantee : Be Proud of What You BuildCal MoranNo ratings yet

- Thermiculite GasketDocument5 pagesThermiculite GasketthanakomNo ratings yet

- Flamex Fire Protection: Flexible Intumescent SealantsDocument4 pagesFlamex Fire Protection: Flexible Intumescent SealantsOMAZNo ratings yet

- Trespa Ventileeritav Fassaad UkDocument2 pagesTrespa Ventileeritav Fassaad UkprwillisNo ratings yet

- Certoplast 514 TD EnglischDocument1 pageCertoplast 514 TD Englischgutman98No ratings yet

- Fletchers Product-Info-Sheet-Drainage-batten-Rev0Document2 pagesFletchers Product-Info-Sheet-Drainage-batten-Rev0kresho sNo ratings yet

- Fisa TehnicaDocument2 pagesFisa TehnicaAlexandru GamanNo ratings yet

- Mass Timber Pitched Roof With Rafters Ridge, INTELLO PLUSDocument2 pagesMass Timber Pitched Roof With Rafters Ridge, INTELLO PLUSdeanNo ratings yet

- 0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionDocument1 page0 25/10/2022 A.N Y.S K.B 25/10/2022 Issued For ConstructionABDERRAZZAKNo ratings yet

- EMPAQUES FLEXITALLICbroPackingsDocument11 pagesEMPAQUES FLEXITALLICbroPackingsSantiago SeveinNo ratings yet

- Deltapt ToleranslarDocument18 pagesDeltapt ToleranslarGökhan AnliNo ratings yet

- Material MatrixDocument2 pagesMaterial MatrixFred HahnNo ratings yet

- Tesa Wire Harnessing SolutionsDocument4 pagesTesa Wire Harnessing Solutionsacarlessi1No ratings yet

- Grooved Kempchen PDFDocument11 pagesGrooved Kempchen PDFAnonymous Iev5ggSRNo ratings yet

- Automotive: Technical Data SheetDocument2 pagesAutomotive: Technical Data Sheetvaibhav dhandeNo ratings yet

- GTS GrafoilDocument1 pageGTS GrafoilAji HatmantoNo ratings yet

- Mass Timber Pitched Roof Ridge, SOLITEX ADHERODocument2 pagesMass Timber Pitched Roof Ridge, SOLITEX ADHEROdeanNo ratings yet

- Spiralwound: Product InformationDocument2 pagesSpiralwound: Product InformationMohamed RaafatNo ratings yet

- Fibre Expansion JointDocument2 pagesFibre Expansion JointalbertmunozNo ratings yet

- Kflex TitanDocument2 pagesKflex TitanShahab Z AhmedNo ratings yet

- Spiral Wound GasketsDocument1 pageSpiral Wound Gasketsgalici2002No ratings yet

- 5421, 5423 Uhmw-Pe TDS 2016Document2 pages5421, 5423 Uhmw-Pe TDS 2016Tesa NorberteNo ratings yet

- E-Fix Electrical Fixings Range: Safe, Time Saving & Versatile..Document16 pagesE-Fix Electrical Fixings Range: Safe, Time Saving & Versatile..duraeduNo ratings yet

- ToughandImpactResistantMaterials UltiMakerDocument8 pagesToughandImpactResistantMaterials UltiMakercgrosbeck1472No ratings yet

- Mea Polybit Tds Polybit Bitustick R 3000 en MeaDocument2 pagesMea Polybit Tds Polybit Bitustick R 3000 en MeaMuhamed RiskhanNo ratings yet

- BrayDocument4 pagesBrayfrancsanchezNo ratings yet

- 04-053-063 Grooved GasketsDocument11 pages04-053-063 Grooved Gasketsritesh sharmaNo ratings yet

- Promaseal ADocument4 pagesPromaseal AKamila JihaneNo ratings yet

- Bray Serie 20 - 21 (Ficha Tecnica)Document4 pagesBray Serie 20 - 21 (Ficha Tecnica)Oscar Horta PolaniaNo ratings yet

- Foster PDS 95 50 R0816Document2 pagesFoster PDS 95 50 R0816Ramy Abd Elkhalek Shahin100% (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Dielectric Materials at Microwave FrequenciesDocument5 pagesDielectric Materials at Microwave FrequenciesAlberto LazzarettiNo ratings yet

- Waveguide TransitionDocument4 pagesWaveguide TransitionAlberto LazzarettiNo ratings yet

- Waveguide Transition From Rectangular To CircularDocument3 pagesWaveguide Transition From Rectangular To CircularAlberto LazzarettiNo ratings yet

- Exporting To CU-2Document32 pagesExporting To CU-2Alberto LazzarettiNo ratings yet

- MeshStripsAllMetalGaskets ENDocument2 pagesMeshStripsAllMetalGaskets ENAlberto LazzarettiNo ratings yet

- Bursting Disc Devices in Series 3070 Chap9 1Document6 pagesBursting Disc Devices in Series 3070 Chap9 1Alberto LazzarettiNo ratings yet

- TB8102.8 PGDocument8 pagesTB8102.8 PGAlberto LazzarettiNo ratings yet

- An Easy Method To Design Gas Vapor Relief System With Rupture DiskDocument8 pagesAn Easy Method To Design Gas Vapor Relief System With Rupture DiskAlberto LazzarettiNo ratings yet

- Data Sheet VDM Alloy 22 PDFDocument13 pagesData Sheet VDM Alloy 22 PDFAlberto LazzarettiNo ratings yet

- Dichloromethane: Cautionary Response InformationDocument2 pagesDichloromethane: Cautionary Response InformationAlberto LazzarettiNo ratings yet

- PED Guideline A-11Document1 pagePED Guideline A-11Alberto LazzarettiNo ratings yet

- Motor Starter Selection Guide Average Full - Load Current of 3 - Phase Squirrel Cage MotorsDocument13 pagesMotor Starter Selection Guide Average Full - Load Current of 3 - Phase Squirrel Cage MotorsOm PrakashNo ratings yet

- Labordental EnglischDocument64 pagesLabordental EnglischConstantin SturzaNo ratings yet

- Course Outline Djj1043Document4 pagesCourse Outline Djj1043mohdazizeeNo ratings yet

- The Application of Fibre Reinforced Shotcrete As Primary Support For A Tunnel in FlyschDocument8 pagesThe Application of Fibre Reinforced Shotcrete As Primary Support For A Tunnel in FlyschCristopher HernándezNo ratings yet

- RF Buildings SOR 2009-10-CIVIL PDFDocument93 pagesRF Buildings SOR 2009-10-CIVIL PDFdoosanapudi mounika naidu dmonNo ratings yet

- Silverfish and FirebratsDocument2 pagesSilverfish and Firebratsbec08busNo ratings yet

- Chemical Reactiochemical - Reactionsstoichiometry NsstoichiometryDocument16 pagesChemical Reactiochemical - Reactionsstoichiometry NsstoichiometryOuryhell ArevaloNo ratings yet

- 6 Separation Principles: Physical ContradictionsDocument21 pages6 Separation Principles: Physical ContradictionsKumar SanthanamNo ratings yet

- Repair of Corrosion Affected Reinforced ConcreteDocument27 pagesRepair of Corrosion Affected Reinforced Concretemanu_696100% (1)

- ChemicalDocument2 pagesChemicalTopuls ItigiNo ratings yet

- 05.lecture - 05 - Steam Generator or BoilersDocument26 pages05.lecture - 05 - Steam Generator or BoilersSakib RafeeNo ratings yet

- Application of Line Pipe and Hot Induction Bends in Hydrogen Gas PDFDocument6 pagesApplication of Line Pipe and Hot Induction Bends in Hydrogen Gas PDFgagodoy20No ratings yet

- Ridoline C 72 MSDS-PDocument5 pagesRidoline C 72 MSDS-PIslam SahafayatNo ratings yet

- HDGASA03-2006 HDG and Duplex Corrosion ProtectionDocument10 pagesHDGASA03-2006 HDG and Duplex Corrosion ProtectionOrnathNo ratings yet

- A Review of Binders in Iron Ore PelletizationDocument93 pagesA Review of Binders in Iron Ore Pelletizationsoheil_vjNo ratings yet

- 01 Surface ChemistryDocument66 pages01 Surface ChemistryPatrick PhamNo ratings yet

- BaddiDocument8 pagesBaddiabhishekNo ratings yet

- FF-Series Fact SheetDocument2 pagesFF-Series Fact SheetJose DAniel Figueroa100% (1)

- Air DrillingDocument69 pagesAir Drillingshahin500No ratings yet

- Saleem DMP Printer 4Document16 pagesSaleem DMP Printer 4Prince Saleem50% (2)

- Additive and Colour Preparations: For Extruded Polystyrene FoamsDocument22 pagesAdditive and Colour Preparations: For Extruded Polystyrene FoamsKarim HakimNo ratings yet

- Bilge Water SeparatorDocument121 pagesBilge Water SeparatorКостяNo ratings yet

- Finishing of Nonwovens - For MajorsDocument2 pagesFinishing of Nonwovens - For MajorsDeepankerBhateja100% (1)

- $MP 009 04Document4 pages$MP 009 04timbrant9129No ratings yet

- Screening Location For EnzymesDocument15 pagesScreening Location For EnzymesGreater Potential TutoringNo ratings yet

- Ipes-Ir3 R08Document2 pagesIpes-Ir3 R08naveedfndNo ratings yet

- Hobby 350Document70 pagesHobby 350Andore MartinusNo ratings yet

- 450 Watt 6m Amplifier: Chris, G3WOS - July 1993Document10 pages450 Watt 6m Amplifier: Chris, G3WOS - July 1993Adrian DrakesNo ratings yet