Professional Documents

Culture Documents

Asphalt Surfacing

Asphalt Surfacing

Uploaded by

Kasun UdaraCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Stub Design (ASCE)Document10 pagesStub Design (ASCE)Saurabh TiwariNo ratings yet

- PERI Presentation 1 - Formwork Handset-Domino-Trio PDFDocument98 pagesPERI Presentation 1 - Formwork Handset-Domino-Trio PDFHaris Omerika100% (1)

- Building Cost Guide: Building Type Estimated ValueDocument2 pagesBuilding Cost Guide: Building Type Estimated Valuezain ulabdeenNo ratings yet

- Contractor Mix Design Guidelines: Oregon Department of TransportationDocument17 pagesContractor Mix Design Guidelines: Oregon Department of TransportationKasun UdaraNo ratings yet

- Tarh Rosazi Forodgah PDFDocument172 pagesTarh Rosazi Forodgah PDFKasun UdaraNo ratings yet

- Flexible Pavements of Ohio: Technical BulletinDocument4 pagesFlexible Pavements of Ohio: Technical BulletinKasun UdaraNo ratings yet

- Method Statement For The Arrangement of Pilot Road at Ch. 4+300 4+400 GPAR (Add Sub)Document5 pagesMethod Statement For The Arrangement of Pilot Road at Ch. 4+300 4+400 GPAR (Add Sub)Kasun UdaraNo ratings yet

- Highway Schedule of Rates - 2008 Basic Rates - Colombo: Item No Description Unit Rate RsDocument6 pagesHighway Schedule of Rates - 2008 Basic Rates - Colombo: Item No Description Unit Rate RsKasun UdaraNo ratings yet

- Highway Engineering Exchange Program Strategic Plan - 2006: HEEP Mission StatementDocument3 pagesHighway Engineering Exchange Program Strategic Plan - 2006: HEEP Mission StatementKasun UdaraNo ratings yet

- Method Statement For The Preparation of The Ground For Installation of Right of Way Fence at Marshy AreasDocument3 pagesMethod Statement For The Preparation of The Ground For Installation of Right of Way Fence at Marshy AreasKasun UdaraNo ratings yet

- Amit Kumar 2Document52 pagesAmit Kumar 2ravi singhNo ratings yet

- Steel Frame Construction Limited Architects, Planners, Engineers. Proforma InvoiceDocument4 pagesSteel Frame Construction Limited Architects, Planners, Engineers. Proforma Invoicetambulira edrineNo ratings yet

- Jss 1 Basic Technology Week 4 - 10Document9 pagesJss 1 Basic Technology Week 4 - 10Victory OjugbaNo ratings yet

- GFRP Roofing - CADocument16 pagesGFRP Roofing - CAEngineering ACPNo ratings yet

- DOWs THEORYDocument4 pagesDOWs THEORYHemant SinghNo ratings yet

- Product Range & Specifications: Pre-Stressed Hollow Core SlabsDocument2 pagesProduct Range & Specifications: Pre-Stressed Hollow Core Slabskhajarasool786No ratings yet

- Unit-Iv: The Sourcing DecisionsDocument31 pagesUnit-Iv: The Sourcing DecisionsGangadhara Rao100% (1)

- CSB0028Document2 pagesCSB0028chinnaNo ratings yet

- Earthquake Resistant Design of A Building Using Shear WallDocument7 pagesEarthquake Resistant Design of A Building Using Shear Wallnithya kjNo ratings yet

- Simplified Structural Analysis of Retaining Walls On Stepped FootingsDocument15 pagesSimplified Structural Analysis of Retaining Walls On Stepped Footingsalvaro sangurimaNo ratings yet

- Volume Ii: Specifications (Wall Cladding) : Issue: FINAL, 14th FEB 2013Document10 pagesVolume Ii: Specifications (Wall Cladding) : Issue: FINAL, 14th FEB 2013Ahmad SaadeldinNo ratings yet

- Erection Girder - PPTX (Autosaved)Document31 pagesErection Girder - PPTX (Autosaved)Aulia Noval Hersyahputra100% (1)

- MS - Casting of I Beam - Double Track - UEDocument9 pagesMS - Casting of I Beam - Double Track - UEMAYMODERN STEELNo ratings yet

- Faculty of Architecture and Planning, AKTU, Lucknow: Research AssignmentDocument12 pagesFaculty of Architecture and Planning, AKTU, Lucknow: Research AssignmentVikash KumarNo ratings yet

- Sheet Pile Wall IntroductionDocument19 pagesSheet Pile Wall IntroductionSâu HeoNo ratings yet

- Supply Chain Management (3rd Edition)Document24 pagesSupply Chain Management (3rd Edition)CeceNo ratings yet

- Design and Analysis of Pre-Engineered Building With Subjected To Seismic Loads Using E-TabsDocument4 pagesDesign and Analysis of Pre-Engineered Building With Subjected To Seismic Loads Using E-TabsFaisal AminNo ratings yet

- Performance Evaluation of Waste PlasticDocument6 pagesPerformance Evaluation of Waste PlasticVijayakrishna SingamsettiNo ratings yet

- Structural Engineering For SolarDocument9 pagesStructural Engineering For SolarO'Donnell & NaccaratoNo ratings yet

- National Institute of Fashion Technology, New DelhiDocument8 pagesNational Institute of Fashion Technology, New DelhiHimangi VermaNo ratings yet

- TOS III Chapter V Design of Steel Structures. A.PropertiesDocument4 pagesTOS III Chapter V Design of Steel Structures. A.PropertiesShyam WanaskarNo ratings yet

- ACO Bridge Drain GullyDocument5 pagesACO Bridge Drain GullyValiNo ratings yet

- Bursting Reinforcement DesignDocument4 pagesBursting Reinforcement Designvenkatd123603No ratings yet

- Agitator Supply List Till: 06-05-2019: SL No Client Tank Size KW Sot No Remarks DIA (M) HT (M)Document43 pagesAgitator Supply List Till: 06-05-2019: SL No Client Tank Size KW Sot No Remarks DIA (M) HT (M)hari prasadNo ratings yet

- Course Outline For Reinforced Concrete IDocument2 pagesCourse Outline For Reinforced Concrete ITefera TemesgenNo ratings yet

- SCAFFOLD CALCULATION Rev.003Document3 pagesSCAFFOLD CALCULATION Rev.003Andy IrawanNo ratings yet

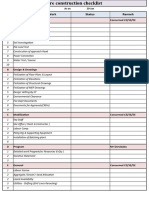

- SL No Description of Work Status Remark: A Pre Construction Site Works Concerned CE/SE/EEDocument6 pagesSL No Description of Work Status Remark: A Pre Construction Site Works Concerned CE/SE/EERadhakrishna KPNo ratings yet

Asphalt Surfacing

Asphalt Surfacing

Uploaded by

Kasun UdaraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asphalt Surfacing

Asphalt Surfacing

Uploaded by

Kasun UdaraCopyright:

Available Formats

13515 version 3

31-Oct-05

1 of 5

ASPHALT SURFACING

Carry out acceptance testing for asphalt

paving

level: 4

credit: 10

final date for comment: October 2009

expiry date: December 2010

sub-field: Pavement Surfacing

purpose: This unit standard is for people who design hot mix asphalts.

People credited with this unit standard are able to:

demonstrate knowledge of the aspects of asphalt pavement

construction that affect quality; demonstrate knowledge of

the compaction of asphalt pavements; and carry out quality

assurance and acceptance testing requirements.

entry information: Open.

accreditation option: Evaluation of documentation and visit by NZQA and industry.

moderation option: A centrally established and directed national moderation

system has been set up by InfraTrain New Zealand.

special notes: 1 References for element 1 include:

the following Transit New Zealand specifications at

http://www.transit.govt.nz/technical_information/specific

ations.jsp –

TNZ P/9 Specification for Construction of

Asphaltic Concrete Paving;

TNZ P/9P (Auckland) Specification for

Construction of Asphaltic Concrete Paving;

TNZ P/11 Specification for Open Graded Porous

Asphalt;

TNZ P/11 Notes Notes to the Specification for

Open Graded Porous Asphalt;

© New Zealand Qualifications Authority 2005

13515 version 3

31-Oct-05

2 of 5

ASPHALT SURFACING

Carry out acceptance testing for asphalt

paving

where specified in the contract documents, the

following pilot specification, or confirmation of its

currency, is available by contacting the Roading

Engineer, Highway Strategy and Standards, Transit

New Zealand, Telephone 04 496 6630 –

TNZ P/18P Performance Based Specification for

Hot Mix Asphalt.

2 References for element 3 include current editions of the

following:

TNZ Q/2 Specification for Quality Assurance for Hot Mix

Asphalt, Transit New Zealand; and one of

Transit Quality Standard TQS1 Quality System for

Road Construction, Road Maintenance and Structures

Physical Works Contracts having a High QA Level;

or

Transit Quality Standard TQS2 Quality System for

Road Construction, Road Maintenance and Structures

Physical Works Contracts having a Normal QA Level;

or

AS/NZS ISO 9000:2000 Quality management systems

– Fundamentals and vocabulary.

3 Assessment against this unit standard must be based

on evidence from a workplace context.

4 Assessment against element 3 of this unit standard

requires compliance with contract specifications and the

company’s choice of quality assurance systems listed in

special note 2.

© New Zealand Qualifications Authority 2005

13515 version 3

31-Oct-05

3 of 5

ASPHALT SURFACING

Carry out acceptance testing for asphalt

paving

Elements and Performance Criteria

element 1

Demonstrate knowledge of aspects of asphalt pavement construction that affect quality.

performance criteria

1.1 Surface preparation is described in terms of tack coat, blinding course,

membrane seal, and levelling course.

1.2 Minimisation of segregation of asphalt mixes is described in terms of plant

loadout, transfer to paving machine, paver feed, and hand work.

1.3 Laying operations are described in terms of plant and sequence.

Range: includes but is not limited to – loading, transport, paving machine,

grader, placement by hand, screed.

element 2

Demonstrate knowledge of the compaction of asphalt pavements.

performance criteria

2.1 Compaction is described in terms of plant and sequence.

Range: plant includes but is not limited to – static steel roller, rubber-tyred

roller, vibrating roller, combination roller.

2.2 Selection of compaction equipment is described in terms of mix type, site

conditions, and specification requirements.

Range: pavement shape, geometric constraints, topography, available

materials, available equipment, clearances, live load limitations,

vibration, layer thickness.

© New Zealand Qualifications Authority 2005

13515 version 3

31-Oct-05

4 of 5

ASPHALT SURFACING

Carry out acceptance testing for asphalt

paving

2.3 Compaction is described in terms of achieving required strength, permeability,

and life of an asphalt layer and takes account of site conditions and constraints.

Range: examples of constraints are – pavement shape, geometric

constraints, topography, available materials, available equipment,

clearances, live load limitations, vibration, layer thickness.

2.4 Compaction is described in terms of factors that influence the result.

Range: factors include but are not limited to – road temperature, ambient

temperature, wind, mat thickness, mat temperature, mix type,

roller type.

element 3

Carry out quality assurance and acceptance testing requirements.

performance criteria

3.1 Quality criteria are described in accordance with TNZ Q/2; and TQS1, or TQS2,

or AS/NZS ISO 9000:2000.

3.2 Process control data from asphalt production plant is analysed and evaluated in

accordance with company quality assurance system.

3.3 Production testing is carried out in accordance with contract specifications,

company quality assurance system, and TNZ Q/2.

Range: may include but is not limited to – bitumen content, aggregate

grading, maximum theoretical specific gravity, moisture content.

3.4 Testing of field samples is carried out in accordance with contract

specifications, company quality assurance system, and TNZ Q/2.

3.5 Acceptance testing of finished pavement layer is carried out in accordance with

contract specifications.

Range: may include but is not limited to – thickness, in situ air voids,

shape, permeability, sand circles, skid resistance, roughness.

© New Zealand Qualifications Authority 2005

13515 version 3

31-Oct-05

5 of 5

ASPHALT SURFACING

Carry out acceptance testing for asphalt

paving

3.6 Test data is interpreted in accordance with contract specifications and takes into

account the inherent limitations of test methods.

Comments on this unit standard

Please contact the InfraTrain New Zealand askus@infratrain.co.nz if you wish to suggest

changes to the content of this unit standard.

Please Note

Providers must be accredited by the Qualifications Authority or a delegated inter-

institutional body before they can register credits from assessment against unit standards

or deliver courses of study leading to that assessment.

Industry Training Organisations must be accredited by the Qualifications Authority before

they can register credits from assessment against unit standards.

Accredited providers and Industry Training Organisations assessing against unit standards

must engage with the moderation system that applies to those standards.

Accreditation requirements and an outline of the moderation system that applies to this

standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The

AMAP also includes useful information about special requirements for providers wishing to

develop education and training programmes, such as minimum qualifications for tutors and

assessors, and special resource requirements.

This unit standard is covered by AMAP 0101 which can be accessed at

http://www.nzqa.govt.nz/site/framework/search.html.

© New Zealand Qualifications Authority 2005

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Stub Design (ASCE)Document10 pagesStub Design (ASCE)Saurabh TiwariNo ratings yet

- PERI Presentation 1 - Formwork Handset-Domino-Trio PDFDocument98 pagesPERI Presentation 1 - Formwork Handset-Domino-Trio PDFHaris Omerika100% (1)

- Building Cost Guide: Building Type Estimated ValueDocument2 pagesBuilding Cost Guide: Building Type Estimated Valuezain ulabdeenNo ratings yet

- Contractor Mix Design Guidelines: Oregon Department of TransportationDocument17 pagesContractor Mix Design Guidelines: Oregon Department of TransportationKasun UdaraNo ratings yet

- Tarh Rosazi Forodgah PDFDocument172 pagesTarh Rosazi Forodgah PDFKasun UdaraNo ratings yet

- Flexible Pavements of Ohio: Technical BulletinDocument4 pagesFlexible Pavements of Ohio: Technical BulletinKasun UdaraNo ratings yet

- Method Statement For The Arrangement of Pilot Road at Ch. 4+300 4+400 GPAR (Add Sub)Document5 pagesMethod Statement For The Arrangement of Pilot Road at Ch. 4+300 4+400 GPAR (Add Sub)Kasun UdaraNo ratings yet

- Highway Schedule of Rates - 2008 Basic Rates - Colombo: Item No Description Unit Rate RsDocument6 pagesHighway Schedule of Rates - 2008 Basic Rates - Colombo: Item No Description Unit Rate RsKasun UdaraNo ratings yet

- Highway Engineering Exchange Program Strategic Plan - 2006: HEEP Mission StatementDocument3 pagesHighway Engineering Exchange Program Strategic Plan - 2006: HEEP Mission StatementKasun UdaraNo ratings yet

- Method Statement For The Preparation of The Ground For Installation of Right of Way Fence at Marshy AreasDocument3 pagesMethod Statement For The Preparation of The Ground For Installation of Right of Way Fence at Marshy AreasKasun UdaraNo ratings yet

- Amit Kumar 2Document52 pagesAmit Kumar 2ravi singhNo ratings yet

- Steel Frame Construction Limited Architects, Planners, Engineers. Proforma InvoiceDocument4 pagesSteel Frame Construction Limited Architects, Planners, Engineers. Proforma Invoicetambulira edrineNo ratings yet

- Jss 1 Basic Technology Week 4 - 10Document9 pagesJss 1 Basic Technology Week 4 - 10Victory OjugbaNo ratings yet

- GFRP Roofing - CADocument16 pagesGFRP Roofing - CAEngineering ACPNo ratings yet

- DOWs THEORYDocument4 pagesDOWs THEORYHemant SinghNo ratings yet

- Product Range & Specifications: Pre-Stressed Hollow Core SlabsDocument2 pagesProduct Range & Specifications: Pre-Stressed Hollow Core Slabskhajarasool786No ratings yet

- Unit-Iv: The Sourcing DecisionsDocument31 pagesUnit-Iv: The Sourcing DecisionsGangadhara Rao100% (1)

- CSB0028Document2 pagesCSB0028chinnaNo ratings yet

- Earthquake Resistant Design of A Building Using Shear WallDocument7 pagesEarthquake Resistant Design of A Building Using Shear Wallnithya kjNo ratings yet

- Simplified Structural Analysis of Retaining Walls On Stepped FootingsDocument15 pagesSimplified Structural Analysis of Retaining Walls On Stepped Footingsalvaro sangurimaNo ratings yet

- Volume Ii: Specifications (Wall Cladding) : Issue: FINAL, 14th FEB 2013Document10 pagesVolume Ii: Specifications (Wall Cladding) : Issue: FINAL, 14th FEB 2013Ahmad SaadeldinNo ratings yet

- Erection Girder - PPTX (Autosaved)Document31 pagesErection Girder - PPTX (Autosaved)Aulia Noval Hersyahputra100% (1)

- MS - Casting of I Beam - Double Track - UEDocument9 pagesMS - Casting of I Beam - Double Track - UEMAYMODERN STEELNo ratings yet

- Faculty of Architecture and Planning, AKTU, Lucknow: Research AssignmentDocument12 pagesFaculty of Architecture and Planning, AKTU, Lucknow: Research AssignmentVikash KumarNo ratings yet

- Sheet Pile Wall IntroductionDocument19 pagesSheet Pile Wall IntroductionSâu HeoNo ratings yet

- Supply Chain Management (3rd Edition)Document24 pagesSupply Chain Management (3rd Edition)CeceNo ratings yet

- Design and Analysis of Pre-Engineered Building With Subjected To Seismic Loads Using E-TabsDocument4 pagesDesign and Analysis of Pre-Engineered Building With Subjected To Seismic Loads Using E-TabsFaisal AminNo ratings yet

- Performance Evaluation of Waste PlasticDocument6 pagesPerformance Evaluation of Waste PlasticVijayakrishna SingamsettiNo ratings yet

- Structural Engineering For SolarDocument9 pagesStructural Engineering For SolarO'Donnell & NaccaratoNo ratings yet

- National Institute of Fashion Technology, New DelhiDocument8 pagesNational Institute of Fashion Technology, New DelhiHimangi VermaNo ratings yet

- TOS III Chapter V Design of Steel Structures. A.PropertiesDocument4 pagesTOS III Chapter V Design of Steel Structures. A.PropertiesShyam WanaskarNo ratings yet

- ACO Bridge Drain GullyDocument5 pagesACO Bridge Drain GullyValiNo ratings yet

- Bursting Reinforcement DesignDocument4 pagesBursting Reinforcement Designvenkatd123603No ratings yet

- Agitator Supply List Till: 06-05-2019: SL No Client Tank Size KW Sot No Remarks DIA (M) HT (M)Document43 pagesAgitator Supply List Till: 06-05-2019: SL No Client Tank Size KW Sot No Remarks DIA (M) HT (M)hari prasadNo ratings yet

- Course Outline For Reinforced Concrete IDocument2 pagesCourse Outline For Reinforced Concrete ITefera TemesgenNo ratings yet

- SCAFFOLD CALCULATION Rev.003Document3 pagesSCAFFOLD CALCULATION Rev.003Andy IrawanNo ratings yet

- SL No Description of Work Status Remark: A Pre Construction Site Works Concerned CE/SE/EEDocument6 pagesSL No Description of Work Status Remark: A Pre Construction Site Works Concerned CE/SE/EERadhakrishna KPNo ratings yet