Professional Documents

Culture Documents

ECA GMP For Vaccines Manufacturers

ECA GMP For Vaccines Manufacturers

Uploaded by

Antonio MoncayoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ECA GMP For Vaccines Manufacturers

ECA GMP For Vaccines Manufacturers

Uploaded by

Antonio MoncayoCopyright:

Available Formats

GMP Certification Programme

Certified Biotech Manager

Speakers

GMP for Vaccine

Dr Robert Eskes

Manufacturers

Novartis Technical Operations

24/25 November 2020 | Barcelona, Spain

Mag. Petra Falb

AGES - Austrian Agency for Health

and Food Safety

Dr Andreas Neubert

IDT Biologika

Dr Volker Öppling

PEI, German Federal Institut for

Vaccines and Biomedicines

Current Regulatory Requirements and Practical Implementation

Robert Schwarz Highlights

FH Campus Vienna

Th

ree Case Studies:

1. Concept of Multipurpose Vaccine Production Facility

2. Design, Construction and Qualification of a New

Production Line

3. GMP Development and Manufacturing of Recombinant Viral

Dr Jörg Weyermann Vaccines for Clinical Trials

GlaxoSmithKline Peculiarities of Viral and Bacterial Vaccines

GMP Issues for Upstream and Downstream Processing

Staff Safety

With Case Studies on New Manufacturing

Buildings and Validation of Fogging/Gassing

Systems

Programme

Objective Target Audience

The development and production of vaccines makes high de- The course is designed for personnel of pharmaceutical

mands on the manufacturing pharmaceutical industry. The spe- industries, their suppliers and regulatory bodies who

cial requirements on handling and safety with live organisms ne- are responsible for quality control and/or quality

cessitate measures which exceed the requirements of classic assurance in vaccine/biopharmaceutical production,

pharmaceutical manufacturing. manage the vaccine production,

establish the operator protection,

Topics like the enhanced risk of cross-contaminations, audit vaccine manufacturers,

questions about individual safety of staff and the issues of clean- design or operate vaccine production sites.

ing and disinfection of rooms and equipment concern a vaccine

manufacturer in a considerable scale.

Programme

Specifically the demands of the necessary bio safety classes

with negative pressure of rooms versus that of aseptic process- GMP for Vaccines: What are the Issues?

ing with positive pressure requires a well thought- out design of

vaccine facilities. Differences between vaccines and conventional products

Inactivated and live vaccines

Also, the safety of environment and waste disposal should re- Control of vaccine strains and cell lines

ceive proper attention already in the design phase. But the dedi- Risk of (cross-)contamination

cated requirements on staff safety are also a challenge in vaccine (Bio)safety issues

manufacturing.

The Peculiarities of Bacterial Vaccines

This Course will give you the possibility to see the theoretical

background as well as the practical implementation of GMP re- Types of vaccines available

quirements in the vaccine production. A combination of theoret- Manufacturing of classical/modern bacterial vaccines

ical requirements and practical case studies is the best way to Challenges in manufacturing (quality/regulatory issues)

learn this. New technologies and products

Speakers from regulatory bodies, consulting and practising ex- The Peculiarities of Viral Vaccines

perts will give you the chance to get to know the different views

and you will have ample opportunity to discuss with speakers From viral seeds to finished products

and other participants about specific issues. Requirements for raw and starting materials

Efficient process and product control

Background Setting specifications adequately

Appropriate tests and assays for product release

“Vaccines are expected to be very safe” is one of the headlines in Stability testing

the presentation of the CBER “Vaccine safety team”. At the same Viral safety aspects

time, new vaccines are needed for diseases for which currently TSE compliance

no vaccine is available, and production technologies need im- How to deal with OOS results?

provement to deal with the shortage of certain types of vac- Requirements for early and late clinical trial phases

cines. This has led to the emergence of new technologies. One of

the important questions from the authorities however is “How cGMP Issues for Upstream Processing

safe are the new technologies”. The FDA has issued a draft guide-

line on new cell substrates for vaccine manufacturing to detail General GMP concerns for upstream processing

requirements in this area. Raw materials and media preparation

Cell culture

In the development of new technologies for the pharmaceutical Virus culture

and biopharmaceutical production of vaccines again the ques- Inactivation of microorganisms

tion of GMP compliance and safety is emphasised.

Containment, Biological Safety and Product

Furthermore, with the Quality Initiative for the 21st Century Protection

from the FDA new guidelines have been issued, which have an

impact not just on the conventional pharmaceutical industry but Containment, product safety versus environmental safety

also on vaccine manufacturers. Risk management and quality in Primary containment and additional measures

design are essential in the implementation of new technologies Negative pressure areas in aseptic manufacturing

and the introduction of new vaccines. Ensuring the expected Decontamination of facilities

safety is one of the greatest challenges of all vaccine producers. Personnel as critical component in containment

GMP for Vaccine Manufacturers | 24/25 November 2020, Barcelona, Spain

Speakers

Decontamination, Virus Inactivation and Virus Speakers

Removal Techniques

Dr Robert Eskes, Novartis Technical Operations,

Decontamination of surfaces Austria

Validation of decontamination procedures Currently Robert Eskes is Head MS&T Unterach /Novartis Tech-

Virus inactivation: principles and methods nical Operations – Aseptics at EBEWE Pharma in Unterach, Aus-

Virus removal methods tria. From 2014 to 2016 he was Quality Assurance head for Third

GMP issues on virus inactivation and virus removal Party Manufacturing at GSK Vaccines,. Before that, he held posi-

techniques tions as Quality Assurance head at Novartis Vaccines and as Val-

idation manager at CSL-Behring GmbH.

Validation of a Decontamination System for Produc-

tion Equipment, Process Devices and Cleanrooms Petra Falb, AGES - Austrian Agency for Health and

Food Safety

Different gassing systems Petra Falb studied at Veterinary University Vienna, (Austria).

System qualification From 1998 to 2001 she worked as scientist at the Institute for

Validation of a dry fog detergent Virology and later at the Institute for pathology. 2001-2003 she

was self employed as veterinary surgeon. In 2003 she joined the

Case Study: Concept of Multipurpose AGES with responsibilities in quality assessment of human and

Vaccine Production Facility veterinary vaccines (national, decentralised and centralized pro-

cedures). Until 2016 her focus was on viral vaccines. In 2017, she

Practical issues with flow of material, personnel and took over new responsibilities for veterinary vaccines.

waste material

Clean room qualification Dr Volker Öppling, Paul Ehrlich Institut, Germany

Segregation of cell preparation, virus production and After study of Veterinary Medicine and his PhD he got appoint-

downstream processing ment for specialist of Veterinary Microbiology. 1990-2007 he

Change over procedures for manufacturing campaigns was responsible for human bacterial (especially polysaccharide

based) and fungal vaccines in the Department “Human Bacterial

Issues of Staff Safety Vaccines” at the Paul-Ehrlich-Institut. Currently he is head of

section “Microbiological Vaccines” (all bacterial, fungal and par-

Requirements and Guidelines asitic vaccines). Main responsibilities are: assessment of mar-

Differences vaccines products and plasma products keting authorisation applications (quality, preclinic and clinic),

Use of S3 coveralls batch release, assessment of clinical trial applications, provision

Environmental health and safety challenges of regulatory and scientific advise, managing of regulatory af-

Examples from daily business fairs issues.

Case Study: Design, Construction and Dr Andreas Neubert, IDT Biologika, Germany

Qualification of a New Production Line Andreas Neubert completed his study of veterinary medicine

with graduation. He works since several years in different posi-

Requirements of design tions at IDT and is currently head of production there.

Issues of construction

Qualification challenges Robert Schwarz, FH Campus Vienna, Austria

Robert Schwarz studied biotechnology and quality manage-

cGMP Issues for Downstream Processing ment. He joined Baxter in 2001 as coordinator of environmental

monitoring. From 2005 he was validation specialist responsible

General GMP concerns for downstream processing for equipment qualification, sterilisation validation and cleaning

(Ultra)filtration techniques validation. Since 2010 he is university lecturer in the field of bio-

(Ultra)centrifugation techniques tech at the University of Applied Sciences in Vienna.

Sterile filtration and aseptic processing

Dr Joerg Weyermann, GlaxoSmithKline, Germany

Case Study: GMP Development and Joerg Weyermann is head Head Quality Assurance at GSK, for-

Manufacturing of Recombinant Viral Vaccines mer Novartis Vaccines and Diagnostics GmbH. Until 2009 he

for Clinical Trials was the Head Quality Operations for Sandoz Industrial Products

GmbH. Before that he was Head Quality Control at Sandoz.

Regulatory expectations for vaccine batches for phase

1/2/3 clinical trials

Development vs. validation

Regulatory expectations for implementation of analytical

methods – qualification and validation

Contract manufacturing of IMPDs

GMP for Vaccine Manufacturers | 24/25 November 2020, Barcelona, Spain

If the bill-to-address deviates from the specifica- Reservation Form (Please complete in full)

tions on the right, please fill out here:

GMP for Vaccine Manufacturers, 24/25 November 2020, Barcelona, Spain

____________________________________

____________________________________

Title, first name, surname

____________________________________

____________________________________ Department Company

Important: Please indicate your company’s VAT ID Number Purchase Order Number, if applicable

CONCEPT HEIDELBERG

P.O. Box 101764 City ZIP Code Country

Fax +49 (0) 62 21/84 44 34

Phone / Fax

D-69007 Heidelberg

GERMANY

E-Mail (Please fill in)

General terms and conditions or speakers without notice or to cancel an event. cellation or non-appearance. If you cannot take part, you have to inform us in Privacy Policy: By registering for this event, I accept the processing of my Perso-

If you cannot attend the conference you have two options: If the event must be cancelled, registrants will be notified as soon as possible writing. The cancellation fee will then be calculated according to the point of nal Data. Concept Heidelberg will use my data for the processing of this order,

1. We are happy to welcome a substitute colleague at any time. and will receive a full refund of fees paid. CONCEPT HEIDELBERGwill not be re- time at which we receive your message. for which I hereby declare to agree that my personal data is stored and pro-

2. If you have to cancel entirely we must charge the following processing fees: sponsible for discount airfare penalties or other costs incurred due to a cancel- In case you do not appear at the event without having informed us, you will have cessed. Concept Heidelberg will only send me information in relation with this

- Cancellation until 2 weeks prior to the conference 10 %, lation. to pay the full registration fee, even if you have not made the payment yet. Only order or similar ones. My personal data will not be disclosed to third parties (see

- Cancellation until 1 weeks prior to the conference 50 % Terms of payment: Payable without deductions within 10 days after receipt of after we have received your payment, you are entitled to participate in the con- also the privacy policy at http://www.gmp-compliance.org/eca_privacy.html). I

- Cancellation within 1 week prior to the conference 100 %. invoice. ference (receipt of payment will not be confirmed)! (As of January 2012). note that I can ask for the modification, correction or deletion of my data at any

CONCEPT HEIDELBERG reserves the right to change the materials, instructors,

# Important: This is a binding registration and above fees are due in case of can- German law shall apply. Court of jurisdiction is Heidelberg. time via the contact form on this website.

Date

Venue

Registration

P.O.Box 10 17 64

Social Event

VAT is reclaimable.

Barcelo Sants Hotel

Accommodation

ECA Members € 1,590

Pl. Països Catalans, s/n

APIC Members € 1,690

CONCEPT HEIDELBERG

08014 Barcelona, Spain

Fax +49(0)62 21/84 44 34

organisation of this event.

Non-ECA Members € 1,790

Phone +34 93 503 53 00

www.gmp-compliance.org.

+49(0)62 21/84 44 10, or at

+49(0)62 21/84 44 22, or at

Phone +49(0)62 21/84 44-0

Conference language

69007 Heidelberg, Germany

info@concept-heidelberg.de

www.concept-heidelberg.de

EU GMP Inspectorates € 895

Email sants@barcelo.com

bach@concept-heidelberg.de.

organisation etc. please contact:

message. Or you register online at

Organisation and Contact

schroeder@concept-heidelberg.de.

companies in a relaxed atmosphere.

Fees (per delegate, plus VAT)

(Registration and coffee 09.00 h – 9.30 h)

Ms Nicole Bach (Organisation Manager) at

For questions regarding reservation, hotel,

the hotel. Early reservation is recommended.

Mr Axel H. Schroeder (Operations Director) at

Tuesday, 24 November 2020, 09.30 h – 18.00 h

The official conference language will be English.

ECA has entrusted Concept Heidelberg with the

For questions regarding content please contact:

Wednesday, 25 November 2020., 08.30 h – 17.00 h

conference. Reservation should be made directly with

social event. This is an excellent

rooms in the conference hotel. You will receive a room

In the evening of the first course

day, you are cordially invited to a

ences with colleagues from other

opportunity to share your experi-

reservation form/POG when you have registered for the

CONCEPT HEIDELBERG has reserved a limited number of

on the first day, lunch on both days and all refreshments.

Via the attached reservation form, by e-mail or by fax

The conference fee is payable in advance after receipt of

invoice and includes conference documentation, dinner

WA/03022020

You might also like

- Modern Data Warehouse ProposalDocument3 pagesModern Data Warehouse ProposalJuan Pablo GaricoitsNo ratings yet

- Michael Tonry - Punishing Race - A Continuing American Dilemma (2011, Oxford University Press)Document221 pagesMichael Tonry - Punishing Race - A Continuing American Dilemma (2011, Oxford University Press)Par PoundzNo ratings yet

- FPE30806 Exam Excel File 2020Document18 pagesFPE30806 Exam Excel File 2020Antonio MoncayoNo ratings yet

- Current and Future Challenges in Quality Assurance in Mo - 2021 - Clinica ChimicDocument8 pagesCurrent and Future Challenges in Quality Assurance in Mo - 2021 - Clinica ChimicAns Barrung100% (1)

- GEA-The Reality of Continuous Pharmaceutical Manufacturing Conference - Hosted by GEA, Siemens & Perceptive EngineeringDocument4 pagesGEA-The Reality of Continuous Pharmaceutical Manufacturing Conference - Hosted by GEA, Siemens & Perceptive Engineeringraju1559405No ratings yet

- 00 QCIssueswithVaccinesDocument13 pages00 QCIssueswithVaccinesLuhur DianNo ratings yet

- Success at Speed-EbookDocument34 pagesSuccess at Speed-EbookbioNo ratings yet

- Gen Viralsafety2018Document36 pagesGen Viralsafety2018Mahammad SadiqueNo ratings yet

- Pharma Ebook PDF 1697438871Document33 pagesPharma Ebook PDF 1697438871intan nurulNo ratings yet

- ECA-Annex2 - GMP-Compliance-Biopharmaceuticals PDFDocument4 pagesECA-Annex2 - GMP-Compliance-Biopharmaceuticals PDFSung-KooNo ratings yet

- Virus FiltrationDocument5 pagesVirus FiltrationchauhangeminiNo ratings yet

- Oncology Product Manufacturing in Non-Dedicated AreaDocument2 pagesOncology Product Manufacturing in Non-Dedicated Areasameh qanadilo100% (1)

- C - PALL - 303PA BioDocument15 pagesC - PALL - 303PA Biocarlos tNo ratings yet

- ECA Microbiology Non MicrobiologistsDocument4 pagesECA Microbiology Non MicrobiologistsKhushbu RathodNo ratings yet

- New Challenges For Biopharmaceutical Process DevelopmentDocument4 pagesNew Challenges For Biopharmaceutical Process DevelopmentAmgad_SNo ratings yet

- Designing A Facility With Both Good Manufacturing Practice (GMP) and Biosafety in Mind: Synergies and ConflictsDocument10 pagesDesigning A Facility With Both Good Manufacturing Practice (GMP) and Biosafety in Mind: Synergies and ConflictsAhmad ALayeshNo ratings yet

- Design and Optimization of A Large Scale Biopharmaceutical Facility Using Process Simulation and Scheduling ToolsDocument9 pagesDesign and Optimization of A Large Scale Biopharmaceutical Facility Using Process Simulation and Scheduling ToolsIRFAN AHANGERNo ratings yet

- Re-Imagining Vaccine Manufacturing: DCVMN Agm 2020Document19 pagesRe-Imagining Vaccine Manufacturing: DCVMN Agm 2020Bulent InanNo ratings yet

- Chapter 17 Vaccine Scaleup and Manufacturing 2007Document8 pagesChapter 17 Vaccine Scaleup and Manufacturing 2007Don GersonNo ratings yet

- The Vaccine IndustryDocument8 pagesThe Vaccine IndustryAlejandro MotoliníaNo ratings yet

- Essential Microbiology For GXP Compliance PDFDocument117 pagesEssential Microbiology For GXP Compliance PDFRaj Kishore100% (2)

- Env Monitoring Clean Rooms DraftDocument37 pagesEnv Monitoring Clean Rooms DraftKrischaireddy AnnapureddyNo ratings yet

- Covid-19 Vaccine Development: Executive SummaryDocument13 pagesCovid-19 Vaccine Development: Executive SummaryNasir AbdulraheemNo ratings yet

- TP0602 0505Document8 pagesTP0602 0505nsk79in@gmail.comNo ratings yet

- Microbiological & Toxicological Quality and Safety of Medical DevicesDocument4 pagesMicrobiological & Toxicological Quality and Safety of Medical DevicesJeevanend ArumugamNo ratings yet

- Microbiology and Sterility Assurance Book (2011)Document1 pageMicrobiology and Sterility Assurance Book (2011)Tim Sandle100% (1)

- ECA Pre Filled Syringes PC2023Document6 pagesECA Pre Filled Syringes PC2023مريم السراقبيNo ratings yet

- Bioreactor Concepts For Cell Culture-Based Viral Vaccine ProductionDocument15 pagesBioreactor Concepts For Cell Culture-Based Viral Vaccine ProductionJohn Lloyd GenerosoNo ratings yet

- Safety Management in A Chemical Plant: Oberholt andDocument8 pagesSafety Management in A Chemical Plant: Oberholt andShivraj KolambekarNo ratings yet

- Designing A Facility With Both GMP and Biosafety in MindDocument10 pagesDesigning A Facility With Both GMP and Biosafety in MindLemlogNo ratings yet

- 2010 Article 9503 PDFDocument3 pages2010 Article 9503 PDFlalooprasad15No ratings yet

- Multi Attribute Method Implementation Using A High Resolution Mass Spectrometry PlatformDocument22 pagesMulti Attribute Method Implementation Using A High Resolution Mass Spectrometry Platformyun baiNo ratings yet

- Article 22567Document9 pagesArticle 22567Ravi KanthNo ratings yet

- CPC Cell Gene Therapies - White PaperDocument13 pagesCPC Cell Gene Therapies - White PaperJosh WhiteNo ratings yet

- 5 Essentials Molecular Development Ebook CY38640 30aug23 EBDocument11 pages5 Essentials Molecular Development Ebook CY38640 30aug23 EBMuzna HashmiNo ratings yet

- An Audit Approach To Address Microbial C PDFDocument39 pagesAn Audit Approach To Address Microbial C PDFOmar Faruq100% (1)

- Validation 100908Document84 pagesValidation 100908AshokPokiriNo ratings yet

- Aseptic ProcessingDocument13 pagesAseptic Processingnsk79in@gmail.comNo ratings yet

- OverviewsldDocument21 pagesOverviewsldNguyễn Hà MyNo ratings yet

- 00 - Virus Filtration CourseDocument8 pages00 - Virus Filtration CoursechauhangeminiNo ratings yet

- Cases Study of Microbiological Contamination2011Document8 pagesCases Study of Microbiological Contamination2011Cristina Croitoru0% (1)

- A Methodology For Knowledge Management in Biopharmacuetical ProductionDocument5 pagesA Methodology For Knowledge Management in Biopharmacuetical ProductionNgoc Sang HuynhNo ratings yet

- Good Manufacturing Practice GMP Guidelines Eudralex Volume 4Document12 pagesGood Manufacturing Practice GMP Guidelines Eudralex Volume 4Editor IJTSRDNo ratings yet

- Pharmaceutical Process Validation ThesisDocument8 pagesPharmaceutical Process Validation Thesisafkogftet100% (1)

- Biopharmaceutical Process DevelopmentDocument21 pagesBiopharmaceutical Process Developmentcarlos tNo ratings yet

- Standards For Quality VaccinesDocument4 pagesStandards For Quality VaccinesauiiiNo ratings yet

- Stage Gating Criteria Tables 2021Document39 pagesStage Gating Criteria Tables 2021bilou hertNo ratings yet

- ECA Contamination Control+WSDocument6 pagesECA Contamination Control+WSBiopharma GuruNo ratings yet

- Annex 2: © World Health Organization WHO Technical Report Series, No. 926, 2004Document25 pagesAnnex 2: © World Health Organization WHO Technical Report Series, No. 926, 2004Iqbal RahmansyahNo ratings yet

- Viral Vector Production Process Intensification: Analytics, Automation, In-Line Testing and MoreDocument16 pagesViral Vector Production Process Intensification: Analytics, Automation, In-Line Testing and MoreAtrocitus RedNo ratings yet

- ECA Contamination ControlDocument6 pagesECA Contamination ControlSathish KumarNo ratings yet

- International Journal of Food Microbiology: Jeanne-Marie Membré, Ronald J.W. LambertDocument6 pagesInternational Journal of Food Microbiology: Jeanne-Marie Membré, Ronald J.W. LambertLu SolarteNo ratings yet

- Annex 2: WHO Good Manufacturing Practices For Biological ProductsDocument38 pagesAnnex 2: WHO Good Manufacturing Practices For Biological ProductsrdasarathNo ratings yet

- Validation-Of - Microbiological-Control-MeasuresDocument40 pagesValidation-Of - Microbiological-Control-MeasuressomnitNo ratings yet

- Biomanufacturing ProcessesDocument9 pagesBiomanufacturing Processesalvin bautistaNo ratings yet

- Apr MicrobialidentificationDocument82 pagesApr MicrobialidentificationAntónio FerreiraNo ratings yet

- tmp8EF1 TMPDocument11 pagestmp8EF1 TMPFrontiersNo ratings yet

- Reference Article 5C 2018Document15 pagesReference Article 5C 2018Disaver YoyoyNo ratings yet

- Microbial Testing in Support of Aseptic ProcessingDocument6 pagesMicrobial Testing in Support of Aseptic ProcessingmeghanalandeNo ratings yet

- Introduction to Biologic and Biosimilar Product Development and AnalysisFrom EverandIntroduction to Biologic and Biosimilar Product Development and AnalysisNo ratings yet

- Grupos4 4158 2794143 FrutasyvegetalesDocument4 pagesGrupos4 4158 2794143 FrutasyvegetalesAntonio MoncayoNo ratings yet

- Grupos8 8949 2794331 Tarea1 ProceFrutasVegetalesDocument3 pagesGrupos8 8949 2794331 Tarea1 ProceFrutasVegetalesAntonio MoncayoNo ratings yet

- Exercise 0.4 Dried Potato SlicesDocument25 pagesExercise 0.4 Dried Potato SlicesAntonio MoncayoNo ratings yet

- Formula Sheet Mass and Energy BalancesDocument3 pagesFormula Sheet Mass and Energy BalancesAntonio MoncayoNo ratings yet

- Grupos4 - 4158 - 2794142 - Frutas y VerdurasDocument2 pagesGrupos4 - 4158 - 2794142 - Frutas y VerdurasAntonio MoncayoNo ratings yet

- BPE35306 - Microalgae Biotechnology - Practical Manual 2020 - OnlineDocument16 pagesBPE35306 - Microalgae Biotechnology - Practical Manual 2020 - OnlineAntonio MoncayoNo ratings yet

- Picochlorum Repeated Batch Growth Algaemist Panel PBR Day-Night Cycle - 1 - MinDocument110 pagesPicochlorum Repeated Batch Growth Algaemist Panel PBR Day-Night Cycle - 1 - MinAntonio MoncayoNo ratings yet

- Mass and Energy Balances - Background InformationDocument12 pagesMass and Energy Balances - Background InformationAntonio MoncayoNo ratings yet

- Chlorella Repeated Batch Growth Algaemist Panel PBR Day-Night Cycle - 1 - MinDocument110 pagesChlorella Repeated Batch Growth Algaemist Panel PBR Day-Night Cycle - 1 - MinAntonio MoncayoNo ratings yet

- FPE20306-2019 - Chapter 1 - Food Material Properties - TheoryDocument17 pagesFPE20306-2019 - Chapter 1 - Food Material Properties - TheoryAntonio MoncayoNo ratings yet

- FPE20306-2019 - Chapter 3 - Evaporation - TheoryDocument18 pagesFPE20306-2019 - Chapter 3 - Evaporation - TheoryAntonio MoncayoNo ratings yet

- Exercise 5.3 - Spray Dryer I (2020)Document36 pagesExercise 5.3 - Spray Dryer I (2020)Antonio MoncayoNo ratings yet

- Exercise 0.3 Evaporation of Fresh Orange JuiceDocument16 pagesExercise 0.3 Evaporation of Fresh Orange JuiceAntonio MoncayoNo ratings yet

- Exercise 0.2 Centrifuging Whole MilkDocument32 pagesExercise 0.2 Centrifuging Whole MilkAntonio MoncayoNo ratings yet

- Exercise 0.5 UltrafiltrationDocument67 pagesExercise 0.5 UltrafiltrationAntonio MoncayoNo ratings yet

- Composition Reduction Dry Milling CornDocument10 pagesComposition Reduction Dry Milling CornAntonio MoncayoNo ratings yet

- 1.1 Effect of Ingredients and Processing Parameters On Pellet QualityDocument8 pages1.1 Effect of Ingredients and Processing Parameters On Pellet QualityAntonio MoncayoNo ratings yet

- Monca001 Paper4 Resit02 2021Document1 pageMonca001 Paper4 Resit02 2021Antonio MoncayoNo ratings yet

- 2020 Superheated Steam Drying v1Document1 page2020 Superheated Steam Drying v1Antonio MoncayoNo ratings yet

- 0.2 Thermal Characterization and Phase Beahvior of CornstarchDocument7 pages0.2 Thermal Characterization and Phase Beahvior of CornstarchAntonio MoncayoNo ratings yet

- Evaluation Hammer Mill MaizeDocument25 pagesEvaluation Hammer Mill MaizeAntonio MoncayoNo ratings yet

- Workassignment BPE IA Tjalma FinalDocument4 pagesWorkassignment BPE IA Tjalma FinalAntonio MoncayoNo ratings yet

- Monca001 Paper1 Resit02 2021Document1 pageMonca001 Paper1 Resit02 2021Antonio MoncayoNo ratings yet

- Work Assignment BPE Antonio Moncayo v2Document3 pagesWork Assignment BPE Antonio Moncayo v2Antonio MoncayoNo ratings yet

- Reflection Report - AMDocument2 pagesReflection Report - AMAntonio MoncayoNo ratings yet

- Work assignment-thesisBPE-Wimar R v02Document3 pagesWork assignment-thesisBPE-Wimar R v02Antonio MoncayoNo ratings yet

- Results Draft 1 Antonio Moncayo - RCDocument11 pagesResults Draft 1 Antonio Moncayo - RCAntonio MoncayoNo ratings yet

- WA - Ana Sofia Camacho FinalDocument3 pagesWA - Ana Sofia Camacho FinalAntonio MoncayoNo ratings yet

- Rafael 3Document7 pagesRafael 3Antonio MoncayoNo ratings yet

- Selection of A Premier in Nunavut and Related IssuesDocument93 pagesSelection of A Premier in Nunavut and Related IssuesNunatsiaqNewsNo ratings yet

- 5e - Ley Lines & Nexuses 1.0Document21 pages5e - Ley Lines & Nexuses 1.0Russo BrOficialNo ratings yet

- Position Department Annual Salary LocationDocument2 pagesPosition Department Annual Salary LocationdasdasNo ratings yet

- Exercise 5. Measuring Carbon Dioxide Production in Animals PDFDocument3 pagesExercise 5. Measuring Carbon Dioxide Production in Animals PDFJM MelecioNo ratings yet

- Filler Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysDocument8 pagesFiller Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysimreNo ratings yet

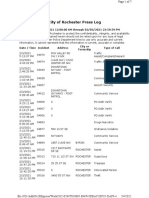

- RPD Daily Incident Report 2/3/21Document7 pagesRPD Daily Incident Report 2/3/21inforumdocsNo ratings yet

- Setting MikrotikDocument10 pagesSetting MikrotikLambace KecciNo ratings yet

- UGC NTA NET History December 2019 Previous Paper Questions: ExamraceDocument2 pagesUGC NTA NET History December 2019 Previous Paper Questions: ExamracesantonaNo ratings yet

- Spheres of Might 5eDocument144 pagesSpheres of Might 5eSlava Granlund100% (1)

- DocxDocument3 pagesDocxFarah Farah100% (1)

- For The Full Essay Please WHATSAPP 010-2504287: Assignment / TugasanDocument16 pagesFor The Full Essay Please WHATSAPP 010-2504287: Assignment / TugasanSimon RajNo ratings yet

- Nurses Bill of RightsDocument1 pageNurses Bill of RightsFlauros Ryu Jabien100% (1)

- The Giant and The RockDocument6 pagesThe Giant and The RockVangie SalvacionNo ratings yet

- Ethical Considerations When Conducting ResearchDocument3 pagesEthical Considerations When Conducting ResearchRegine A. UmbaadNo ratings yet

- Test Bank For Biology The Unity and Diversity of Life 14Th Edition by Starr Taggart and Evers Isbn 1305073959 978130507395 Full Chapter PDFDocument36 pagesTest Bank For Biology The Unity and Diversity of Life 14Th Edition by Starr Taggart and Evers Isbn 1305073959 978130507395 Full Chapter PDFjoan.derrick732100% (10)

- APT1001.A2.01E.V1.0 - Preparation For Debug Kit SetupDocument2 pagesAPT1001.A2.01E.V1.0 - Preparation For Debug Kit SetupСергей КаревNo ratings yet

- From Demon To Deity Kang Wang in Thirteenth-Century Jizhou and BeyondDocument31 pagesFrom Demon To Deity Kang Wang in Thirteenth-Century Jizhou and BeyondLiping ZhuNo ratings yet

- MGT 101 Introduction To Management Caryl Andrea A. Tinae Group No. 2 Groups and Teams October 30, 2015Document2 pagesMGT 101 Introduction To Management Caryl Andrea A. Tinae Group No. 2 Groups and Teams October 30, 2015meriiNo ratings yet

- Kodaks Nos 1A and 3 Series IIIDocument78 pagesKodaks Nos 1A and 3 Series IIIFalcoNo ratings yet

- About Mind Spo!s: People Also AskDocument1 pageAbout Mind Spo!s: People Also AskMichael FernandoNo ratings yet

- English Hots 1Document69 pagesEnglish Hots 1Aswin Shriram UmaThiagarajanNo ratings yet

- A Market Survey BL AgroDocument81 pagesA Market Survey BL AgrogoswamiphotostatNo ratings yet

- The Emotional Tone Scale - Read "The Hubbard Chart of Human EvaluationDocument1 pageThe Emotional Tone Scale - Read "The Hubbard Chart of Human EvaluationErnesto Salomon Jaldín MendezNo ratings yet

- Engr. Frederick B. Garcia: Proposed 3-Storey ResidenceDocument1 pageEngr. Frederick B. Garcia: Proposed 3-Storey Residencesam nacionNo ratings yet

- 03 Preliminary PagesDocument12 pages03 Preliminary PagesBillie Jan Louie JardinNo ratings yet

- Mike Millmore - CHP 7. Strategic Human Resource Planning The Weakest LinkDocument40 pagesMike Millmore - CHP 7. Strategic Human Resource Planning The Weakest LinkAndyHNo ratings yet

- Kerala Agricultural University: Main Campus, Vellanikkara, Thrissur - 680 656, KeralaDocument3 pagesKerala Agricultural University: Main Campus, Vellanikkara, Thrissur - 680 656, KeralaAyyoobNo ratings yet

- Learning Skill For 21ST CenturyDocument16 pagesLearning Skill For 21ST CenturyKSSNo ratings yet