Professional Documents

Culture Documents

Steel Bale

Steel Bale

Uploaded by

Risman YusufCopyright:

Available Formats

You might also like

- Lifting Lug Design Per ASME BTH-1Document8 pagesLifting Lug Design Per ASME BTH-1luis nunezNo ratings yet

- Splice Connection CHSDocument180 pagesSplice Connection CHSRaveendra Babu Cherukuri100% (2)

- Staircase Design To BS 8110-1:1997Document9 pagesStaircase Design To BS 8110-1:1997Gihan Chathuranga100% (9)

- Lifting Lugs Design Per ASME BTH-1-2005 PDFDocument2 pagesLifting Lugs Design Per ASME BTH-1-2005 PDFHernâniCruz100% (1)

- Anchor Bolt Reinforcement CheckDocument3 pagesAnchor Bolt Reinforcement CheckdantevariasNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Unbraced RC Circular Column Design - Sample Calculation (AS3600)Document4 pagesUnbraced RC Circular Column Design - Sample Calculation (AS3600)Tiam MarapeNo ratings yet

- Singly Reinforced Beam ExcelDocument3 pagesSingly Reinforced Beam ExcelVEERKUMAR100% (3)

- Design Steps For SRBDocument3 pagesDesign Steps For SRBKhajaNo ratings yet

- Beam Design DD2Document1 pageBeam Design DD2Emdadul HuqNo ratings yet

- Beam To Column Flange Connection-ASDDocument7 pagesBeam To Column Flange Connection-ASDAnonymous YDwBCtsNo ratings yet

- Strong Col Weak BeamDocument2 pagesStrong Col Weak BeamlaxmiNo ratings yet

- Strong Col Weak BeamDocument2 pagesStrong Col Weak BeamlaxmiNo ratings yet

- Design of Beam:528 Grade of Concrete: at Right EndDocument7 pagesDesign of Beam:528 Grade of Concrete: at Right EndSudip ShresthaNo ratings yet

- Perhitungan Untuk Mencari Alat Bantu AngkatDocument6 pagesPerhitungan Untuk Mencari Alat Bantu AngkatGame Just forNo ratings yet

- Mathcad - PART II Ceiling (ICU) 20200602 (Update) - 2Document418 pagesMathcad - PART II Ceiling (ICU) 20200602 (Update) - 2BQ HeNo ratings yet

- Crack WidthDocument2 pagesCrack Widthhabibur Rahman KhanNo ratings yet

- EQ2 4rth Floor ColumnDocument15 pagesEQ2 4rth Floor ColumnWilbert Carlo RachoNo ratings yet

- E Crane FoundationDocument1 pageE Crane FoundationPriodeep ChowdhuryNo ratings yet

- Two Way SlabDocument88 pagesTwo Way SlabSushil KumarNo ratings yet

- Cop Suoc2013Document36 pagesCop Suoc2013YUK LAM WONGNo ratings yet

- Problem 8 - Analysis of Eccentrically Loaded Column With Unknown C ValueDocument6 pagesProblem 8 - Analysis of Eccentrically Loaded Column With Unknown C ValueRey Joseph IglesiaNo ratings yet

- Analisis Balok Tulangan RangkapDocument3 pagesAnalisis Balok Tulangan Rangkapirgan.abdul.tkgd22No ratings yet

- Quantity Survey NotesDocument10 pagesQuantity Survey NotesSharath RMNo ratings yet

- Assignment 1Document12 pagesAssignment 1Suzan SalimNo ratings yet

- Technological Institute of The Philippines - Manila: SignatureDocument21 pagesTechnological Institute of The Philippines - Manila: SignaturePlatoon Nicart BejerNo ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AMahesh SuranaNo ratings yet

- Beam DesignDocument17 pagesBeam DesignmahaNo ratings yet

- Pile and Pile Cap DesignDocument14 pagesPile and Pile Cap Designshroud.3567No ratings yet

- Design of SplicingDocument13 pagesDesign of SplicingMc Tyler Reyes YuntingNo ratings yet

- DesignDocument34 pagesDesignAbhay SuwalNo ratings yet

- Design of ColumnsDocument3 pagesDesign of ColumnsAngelo AmarNo ratings yet

- Bolt Connection Design Based On NDS 2018: Input Data & Design SummaryDocument2 pagesBolt Connection Design Based On NDS 2018: Input Data & Design Summaryalejahrojas96No ratings yet

- Design of Pile CapDocument3 pagesDesign of Pile Capabhi aroteNo ratings yet

- This Is ItDocument33 pagesThis Is ItJames DerechoNo ratings yet

- Footing Subjected To Eccentric LoadingDocument5 pagesFooting Subjected To Eccentric LoadingPratik DhariwalNo ratings yet

- BEAM SampleDocument70 pagesBEAM SampleAira Joyce Salazar100% (1)

- Connection Design: C1-BP: ETABS 2016 16.2.1 License # 13GKCULR7HUKDLFDocument5 pagesConnection Design: C1-BP: ETABS 2016 16.2.1 License # 13GKCULR7HUKDLFjaicollaNo ratings yet

- Composite Floor GirderDocument3 pagesComposite Floor GirderlucianduNo ratings yet

- 10.0 Base Plate & Anchor BoltDocument16 pages10.0 Base Plate & Anchor Boltkrishna kumar100% (1)

- 15-Cold Formed 2021Document35 pages15-Cold Formed 2021karim hassanNo ratings yet

- Design of Column: Axial Stress 0.1fckDocument22 pagesDesign of Column: Axial Stress 0.1fckSudip ShresthaNo ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AHayman AhmedNo ratings yet

- Sheet Metal Developed Length CalculationsDocument7 pagesSheet Metal Developed Length CalculationsOmkar PimpaleNo ratings yet

- Design of Machine Elements Assignment 2 Roll 07Document6 pagesDesign of Machine Elements Assignment 2 Roll 07Sharthak GhoshNo ratings yet

- Flexural Design Reinforced Concrete T Beams ACI 318 14Document19 pagesFlexural Design Reinforced Concrete T Beams ACI 318 14alufuq companyNo ratings yet

- Flexural Design Reinforced Concrete T Beams ACI 318 14Document19 pagesFlexural Design Reinforced Concrete T Beams ACI 318 14ahmadwehba2No ratings yet

- 4b-Design of Compression Member - Column Sept 2023Document40 pages4b-Design of Compression Member - Column Sept 2023saleh34534rf34No ratings yet

- To Do - DS - LRFD - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS - LRFD - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- Design of Slabs1Document8 pagesDesign of Slabs1Tonette AmorNo ratings yet

- Juvylen Final PlateDocument6 pagesJuvylen Final PlateEarl jan liboonNo ratings yet

- Nozzle Load As Per MegyesyDocument3 pagesNozzle Load As Per MegyesyamaNo ratings yet

- Footings Design - Isolated PadDocument12 pagesFootings Design - Isolated Padmaruthiinfra structuresNo ratings yet

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Document4 pagesMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiNo ratings yet

- Tension MemDocument19 pagesTension MemNick AvisNo ratings yet

- Ngasi Consulting Engineers: REF CalculationDocument18 pagesNgasi Consulting Engineers: REF CalculationUday UdmaleNo ratings yet

- SA LAB - Singly Reinforced BeamDocument8 pagesSA LAB - Singly Reinforced BeamAjayNo ratings yet

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- Analytic Geometry: Graphic Solutions Using Matlab LanguageFrom EverandAnalytic Geometry: Graphic Solutions Using Matlab LanguageNo ratings yet

- Assignment - Statistics MethodDocument3 pagesAssignment - Statistics MethodRisman YusufNo ratings yet

- Assignment - Statistics MethodDocument4 pagesAssignment - Statistics MethodRisman YusufNo ratings yet

- Laporan K3 Danau TempeDocument32 pagesLaporan K3 Danau TempeRisman YusufNo ratings yet

- Cals RismanDocument5 pagesCals RismanRisman YusufNo ratings yet

- Assignment - Advance Calculus II-1Document4 pagesAssignment - Advance Calculus II-1Risman YusufNo ratings yet

- No 2Document2 pagesNo 2Risman YusufNo ratings yet

- Risman Yusuf 2201801522 Ld43 Traffic Engineering Artificial Intelligence Enabled Iot: Traffic Congestion Reduction in Smart CitiesDocument4 pagesRisman Yusuf 2201801522 Ld43 Traffic Engineering Artificial Intelligence Enabled Iot: Traffic Congestion Reduction in Smart CitiesRisman YusufNo ratings yet

- BINUS University: Learning OutcomesDocument4 pagesBINUS University: Learning OutcomesRisman YusufNo ratings yet

- Risman Yusuf 2201801522 LD43 Traffic Engineering Assignment 2Document4 pagesRisman Yusuf 2201801522 LD43 Traffic Engineering Assignment 2Risman YusufNo ratings yet

- Risman Yusuf 2201801522 Lb43Document15 pagesRisman Yusuf 2201801522 Lb43Risman YusufNo ratings yet

- 20190824033713BN001638342 PDFDocument1 page20190824033713BN001638342 PDFRisman YusufNo ratings yet

- Team 3Document6 pagesTeam 3Risman YusufNo ratings yet

- Steel BarDocument4 pagesSteel BarRisman YusufNo ratings yet

- Shrinkage LimitDocument4 pagesShrinkage LimitRisman YusufNo ratings yet

- 20190824171419BN001669852 PDFDocument2 pages20190824171419BN001669852 PDFRisman YusufNo ratings yet

- Chapter XVDocument4 pagesChapter XVRisman YusufNo ratings yet

- 20190824033713BN001638342 PDFDocument1 page20190824033713BN001638342 PDFRisman YusufNo ratings yet

- 06 Andrews 1981Document19 pages06 Andrews 1981angelpoolafpc16No ratings yet

- BEP240SNc Tech Support3Document0 pagesBEP240SNc Tech Support3Pam EvansNo ratings yet

- Health Benefits of CucumbersDocument6 pagesHealth Benefits of Cucumbersver_at_workNo ratings yet

- Waterfall ModelDocument3 pagesWaterfall Modelparthu1710No ratings yet

- 2nd Chapter RM-IDocument21 pages2nd Chapter RM-IHajra KhanNo ratings yet

- Fondu PDFDocument2 pagesFondu PDFRaghda Jammoul100% (1)

- CQR User Manual-3 PDFDocument98 pagesCQR User Manual-3 PDFJoe GellatlyNo ratings yet

- Warhammer 40k - Codex - Errata - Dark Angels Q&A v2.0Document2 pagesWarhammer 40k - Codex - Errata - Dark Angels Q&A v2.0Jakub KalembaNo ratings yet

- CB Insights - Most Promising StartupsDocument122 pagesCB Insights - Most Promising StartupsRazvan CosmaNo ratings yet

- Carta Organisasi PibgDocument1 pageCarta Organisasi PibgNasha FatehaNo ratings yet

- InkaTAC-Amomax Lista de Precios 2020 Set.Document9 pagesInkaTAC-Amomax Lista de Precios 2020 Set.christopher carhuamacaNo ratings yet

- Fin358 Individual Assignment Nur Hazani 2020818012Document12 pagesFin358 Individual Assignment Nur Hazani 2020818012nur hazaniNo ratings yet

- Operator's Manual: Short-Reach Specification Machine (For Digging Operation) (S-SR120-B)Document88 pagesOperator's Manual: Short-Reach Specification Machine (For Digging Operation) (S-SR120-B)TommyNo ratings yet

- STARBOOKS Named As Priority Program For 2018: Press ReleaseDocument2 pagesSTARBOOKS Named As Priority Program For 2018: Press ReleaseArnoNo ratings yet

- 1st Year Chemistry Practical 1 - Stoichiometry in SolutionDocument5 pages1st Year Chemistry Practical 1 - Stoichiometry in SolutionNoel SimpasaNo ratings yet

- Nursing Home Private Hospital / ICU Nursing Chart: 6 HR 18 HRDocument2 pagesNursing Home Private Hospital / ICU Nursing Chart: 6 HR 18 HRdavidNo ratings yet

- AdventureTime BoardGame RULEBOOK DefinitivoDocument33 pagesAdventureTime BoardGame RULEBOOK DefinitivoesacosaNo ratings yet

- Be5024 0 1Document6 pagesBe5024 0 1Victor SanchezNo ratings yet

- Din 6885Document1 pageDin 6885Riadini Anis Hade50% (2)

- Caltech - PG Program in Cloud ComputingDocument22 pagesCaltech - PG Program in Cloud ComputingkaperumaNo ratings yet

- R BalajiDocument81 pagesR BalajiBalaji radhakrishnanNo ratings yet

- Topic 9 - Forum Question 1. Explain The Meaning of Communication and Describe What Is Non-Verbal CommunicationDocument3 pagesTopic 9 - Forum Question 1. Explain The Meaning of Communication and Describe What Is Non-Verbal CommunicationHadi azfar channelNo ratings yet

- Teacher Answer Key What Is My Adaptation WorksheetsDocument2 pagesTeacher Answer Key What Is My Adaptation Worksheetssteffielisa12No ratings yet

- Ab PomDocument2 pagesAb PomErica CalzadaNo ratings yet

- The Management EnvironmentDocument28 pagesThe Management EnvironmentRashid Al-MansouriNo ratings yet

- Destrezas Distribuidas Por ParcialesDocument6 pagesDestrezas Distribuidas Por ParcialesAmy Del Cisne Hernandez ChiribogaNo ratings yet

- Point of View SortDocument1 pagePoint of View Sortapi-407328150No ratings yet

- Powder CoatingsDocument30 pagesPowder Coatingsferdlh9No ratings yet

- Quarter by Numbers: Global HighlightsDocument37 pagesQuarter by Numbers: Global HighlightsAndreaNo ratings yet

- Sequence 02 All LessonsDocument14 pagesSequence 02 All Lessonstutor16100% (1)

Steel Bale

Steel Bale

Uploaded by

Risman YusufOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Bale

Steel Bale

Uploaded by

Risman YusufCopyright:

Available Formats

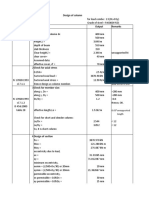

NAMA : Muhaimin Iqbal

NIM : 2201842384

KELAS : LB43

LECTURE : Jonathan Togi H. Sidabutar, S,T.,M.T

MID TERM EXAM

THEORY AND DESIGN OF STEEL STRUCTURES

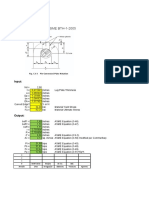

1. Select 30-Foot-Long W12 Tension Member To Resist A Dead Load Of 150 Kip And A Live Load

Of XYZ Kip. A992 Steel Is Used. Two Lines Of 3/4 Inch Diameter Bolt Are Used (4 Bolts Each

Line). For The Purpose Of This Problem, You May Ignore Block Shear Rupture. (XYZ = The Last

3 Digits Of NIM)

XYZ = 384

GIVEN DATA

Member Details

Grade of Steel, A992

Length of member, I = 30 ft

Connection Details

3

Diameter of bolt, db = 4 in

Factored load

Service Dead Load, D = 150 kips

Service Live Load, L = 384 kips

CALCULATIONS

Grade of Steel, A 992

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

Yield stress, Fy = 50 ksi AISC Table 2-4 P.2-48

Ultimate stress Fu = 65 ksi AISC Table 2-4 P.2-48

3

Diameter of bolt hole, db = 4 in

1

dh = db + in

8

3 1

dh = 4 in + 8 in

= 0.875 in

Factored load, Pu (Com1) = 1.4 (D)

= 210 kips

Pu (Com2) = 1.2 (D) + 1.6 (L)

= 1.2 (150) + 1.6 (384)

= 794.4 kips

take the biggest factored load, Pu = 794.4 kips

Yielding in the gross section

Design strength of gross section is obtained as:

𝑃𝑢

Agmin = 0.9 𝐹𝑦

min{ }

(0.75)2 𝐹𝑢

Pu

= (0.75)2𝐹𝑢

794.4

= (0.75)2×65

794.4

=

36.5625

= 21.727 in 2

L

Calctulation rmin rmin = 300

30 ft

rmin = 300

30 ft = 360 in

360 in

=

300

= 1.2 in

Therefore, required Agmin = 21.727 in 2

rmin = 1.2 in

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

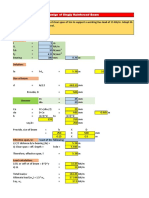

Determine W -Shape

Furthermore, the W12 x 79 profile test based on AISC Table 1-1 P.1-24 is close to the minimum area(up),

with Agmin = 21.727 in 2 & rmin = 1.2 in

Profil : Select W 12×79 AISC Table 5-1 P.5-11

GIVEN DATA

Member Details

Grede of steel = A 992

Selected member, = W 12×79

Gross area of section, Ag = 23.2 in 2 AISC Table 1-1 P.1-24

Thickness of flange, tf = 0.735 in AISC Table 1-1 P.1-24

Width of flange, bf = 12.1 in AISC Table 1-1 P.1-24

Depth of section, d = 12.4 in AISC Table 1-1 P.1-24

Radius of gyration, ry = 3.05 in AISC Table 6-1 P.6-80

Length of member, I = 30 ft

Connection Details

Member connected to web/two flanges = two flanges

3

Diameter of bolt, db = 4 in

Number of bolts across a section, n =4

Number of bolts in line, m =4

Pitch of the bolts, s = 3 in

End Distance, = 2 in

Edge distance, = 1.5 in

Distance of centeroid from edge 𝑥̅ = 1.06 in (WT6×39.5) AISC Table 1 – 8 P.1-65

𝑥̅ is the distance from the centroid of the area connected to the plane of connection - For this case x is

equal to the distance of centroid of the angle from the edge.

CALCULATIONS

For grade of steel A 992

Yield stress, Fy = 50 ksi

Ultimate stress, Fu = 65 ksi

3 1

Diameter of bolt hole, dh = 4 in + 8 in

= 0.875 in

DESIGN STRENGTH

Yielding in the gross section

Design strength of gross section is obtained as:

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

Øt Pn = Øt × Fy × Ag

= 0.9 × 50 × 23.2

Terms ; Øt Pn gross section > Pu

= 1044 kips > 794.4 kips …… {OK}

Fracture in the net section

Net area, An = Ag – n × (dh × tf)

An = Ag – (no. of holes) × (diameter of hole) × (thickness of flange)

= 23.2 – 4 × 0.875 × 0.735

= 20.6275 in 2

Length of connection in the direction of loading,

L = 9 in

Since the member is connected to two flanges, Alternative value of U

𝑥̅

Shear lag Factor, U2 = 1 - 𝐿 ……..case2 AISC Table D3.1 P.16.1-28

1.06

=1-

9

= 0.882

bf = 12.1 in

2

d = 3×12.4

= 8.267

2

bf ≥ 3 𝑑, then U7 = 0.9………case7 AISC Table D3.1 P.16.1-28

Effective area, Ae = U × An

= 0.9 × 20.6275

= 18.56475 in 2

Design strength of net section is obtained as:

Øt Pn = Øt × Fu × Ae

= 0.75 × 65 × 18.56475

= 905.03 kips

Thus, design strength of the member is the smallest of the two values, that is

Øt Pn = 905.03 kips > Pu = 794.4 ……………{OK}

Hence, SAFE

Slenderness ratio, I/ry = 30 × 12 / 3.05

= 118 < 300 ………….. {OK}

Hence, SAFE

Conclusion

Based on the verifivation gross section yielding & net section fracture, W12X79 is adequate

It can be concluded that the W12 x 79 steel profile can be used.

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

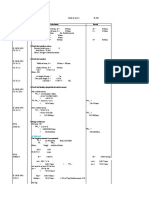

2. Determine The Capacity Of Bearing-Type Connection And Check If The Connection Meets Layout

Requirement

• 1 inch diameter Group A-X bolts

• A572 Gr.50 plate

Fu = 65 ksi AISC Table 2-4 P.2-48

Fy = 50 ksi AISC Table 2-4 P.2-48

• 13” x 1/2” plate

Diameter of bolt hole

db = 1 in

1

dh = 1 in + 16 in

= 1.0625 in

Bolt shear capacity (1 bolt) 1 in diameter group A – X bolts (single)

Ørn = 40 kips/bolt AISC Table 7-1 P.7-22

Required Number of bolts

n bolt = 12 → 4 external

8 internal

Ørn = 12 bolt × 40 kips/bolt

= 480 kips

Bolt Spacing requirement

Spacing, Sused = 3 in

2

Smin = 2 × × db

3

2

=2×3×1

= 2.667 in

Spreferred = 3 × db

=3×1

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

= 3 in

Syarat :

Smin < Sused

2.677 < 3…….{OK}, adequate

Sused = 3 in

Edge Distance requirement

1

If, Bolt diameter = 1 in → min edge distance = 1 AISC Table J3.4 P.16.1-123

4

Leused = 3 in

Syarat :

Lemin < Leused

1

1 < 3 …..{OK} adequate

4

Leused = 3 in

Bolt Bearing Capacity

Spacing, S = 3 in

Edge distance le = 3 in

Thicknes of pplate t = 0.5 in

db = 1 in

dh = 1.0625 in

Fu = 65 ksi

2db = 2 × db

=2×1

= 2 in

𝑑ℎ

lce = le - 2

1.0625

=3- 2

= 2.46875 in

lci = s – dh

= 3 - 1.0625

= 1.9375 in

a. Eksternal → nbolt = 4

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

𝑖𝑐𝑒

rne = 1.2 × t × Fu × min {2𝑑𝑏 }

= 1.2 × t × Fu × 2db

= 1.2 × 0.5 × 65 × 2 (1)

= 78 kips / bolt

b. Internal → nbolt = 8

𝑖𝑐𝑖

rni = 1.2 × t × Fu × min {2𝑑𝑏 }

= 1.2 × t × Fu × lci

= 1.2 × 0.5 × 65 × 1.9375

= 75.5625 kips / bolt

Rn = (rne × 4) + (rni × 8)

= (78 × 4) + (75.5625 × 8)

= 916.5 kips

Design Capacity of Plat

For 12 number bolts

ØRn = 0.75 × Rn

= 0.75 × 916.5

= 687.375 kips

ØRn = 687.375 > 480 kips …OK

Conclusion

Bolt shear capacity = 480 kips

Bolt bearing capacity = 687.375

Bolt Design capacity

ØRn = 480 kips

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

3. Design fillet weld to resist a service dead load and live load of XY kip and 30 kip, respectively. (XY

= the last two digits of NIM)

XY = 84

• A36 steel and E70 electrodes are used → Fexx = 70 ksi

• Assume the capacity of the gusset plate to be adequate

Answer :

Knows

Service dead load, D = 84 kips

Service live load, L = 30 kips

Factor Loaded

Dead load, D = 84 kips

Live load, L = 30 kips

Factored Design load, Pu = 1.2 D + 1.6 L

= 1.2 (84) + 1.6 (30)

= 148.8 kips

Weld Limits

3

Effective thickness, t = 8 in

t = 0.375 in

3

Min. size fillet weld, amin = 16 in AISC Table J2.4 P.16.1-111

= 0.1875 in

1

Min. size fillet weld, amax =t-

16

3 1

= 8 - 16

= 0.3125 in

Fillet weld Used, aused = 0.3125 in → take the greatest value

Compute the capacity of 1 in weld

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

aused = 0.3125 in

Electrode strength FEXX = 70 ksi AISC Table 8-3 P.8-65

Lw = 1 in

t = 0.375 in

For Grade of Steel, A36 AISC Table 2-4 P.2-48

Yield Stress Fy = 36

Ultimate stress Fu = 58 until 80 ksi → (assumption : 70 ksi)

Agv = Anv = Lw × t

= 1 in × 0.375 in

= 0.375 in2

Weld metal capacity

Ørn = 0.75 × (0.6 × FEXX) × (0.707 × a × Lw)

= 0.75 × (0.6 × 70) × (0.707 × 0.3125 × 1)

= 6.9593 kips for 1 in of weld

Base metal capacity

Yielding

Ørn = 1 × (0.6 × Fy) × Agv

= 1 × (0.6 × 36) × 0.375

= 8.1 kips for 1 inch of weld

Fracture

Ørn = 0.75 × (0.6 × Fu) × Anv

= 0.75 × (0.6 × 70) × 0.375

= 11.8125 kips for 1 inch of weld

Take the smallest value, then the design strength of the 1 inch weld connection

The design strength of the 1 inch weld connection Ørn = 6.9593 kips

Length of required

𝑃𝑢

Total length weld, Lw req = Ørn

148.8

= 6.9593

= 21.38

Lw req = 22 in

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

Sketch

(22 in – 6 in )

8“→

2

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

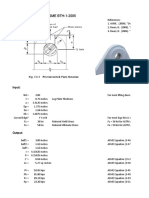

TABLE ANSWER NO 1

AISC Table 2-4 P.2-48

AISC Table 5-1 P.5-11

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

AISC Table 1-1 P.1-24

AISC Table 6-1 P.6-80

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

AISC Table 1 – 8 P.1-65

AISC Table D3.1 P.16.1-28

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

TABLE ANSWER NO 2

A572 Gr.50 → AISC Table 2-4 P.2-48

AISC Table 7-1 P.7-22

AISC Table J3.4 P.16.1-123

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

TABLE ANSWER NO 3

AISC Table 2-4 P.2-48 → Grade Steel A36

AISC Table J2.4 P.16.1-111

AISC Table 8-3 P.8-65

MUHAIMIN IQBAL – 2201842384 – LB43

MID TERM EXAM - THEORY AND DESIGN OF STEEL STRUCTURES

You might also like

- Lifting Lug Design Per ASME BTH-1Document8 pagesLifting Lug Design Per ASME BTH-1luis nunezNo ratings yet

- Splice Connection CHSDocument180 pagesSplice Connection CHSRaveendra Babu Cherukuri100% (2)

- Staircase Design To BS 8110-1:1997Document9 pagesStaircase Design To BS 8110-1:1997Gihan Chathuranga100% (9)

- Lifting Lugs Design Per ASME BTH-1-2005 PDFDocument2 pagesLifting Lugs Design Per ASME BTH-1-2005 PDFHernâniCruz100% (1)

- Anchor Bolt Reinforcement CheckDocument3 pagesAnchor Bolt Reinforcement CheckdantevariasNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Unbraced RC Circular Column Design - Sample Calculation (AS3600)Document4 pagesUnbraced RC Circular Column Design - Sample Calculation (AS3600)Tiam MarapeNo ratings yet

- Singly Reinforced Beam ExcelDocument3 pagesSingly Reinforced Beam ExcelVEERKUMAR100% (3)

- Design Steps For SRBDocument3 pagesDesign Steps For SRBKhajaNo ratings yet

- Beam Design DD2Document1 pageBeam Design DD2Emdadul HuqNo ratings yet

- Beam To Column Flange Connection-ASDDocument7 pagesBeam To Column Flange Connection-ASDAnonymous YDwBCtsNo ratings yet

- Strong Col Weak BeamDocument2 pagesStrong Col Weak BeamlaxmiNo ratings yet

- Strong Col Weak BeamDocument2 pagesStrong Col Weak BeamlaxmiNo ratings yet

- Design of Beam:528 Grade of Concrete: at Right EndDocument7 pagesDesign of Beam:528 Grade of Concrete: at Right EndSudip ShresthaNo ratings yet

- Perhitungan Untuk Mencari Alat Bantu AngkatDocument6 pagesPerhitungan Untuk Mencari Alat Bantu AngkatGame Just forNo ratings yet

- Mathcad - PART II Ceiling (ICU) 20200602 (Update) - 2Document418 pagesMathcad - PART II Ceiling (ICU) 20200602 (Update) - 2BQ HeNo ratings yet

- Crack WidthDocument2 pagesCrack Widthhabibur Rahman KhanNo ratings yet

- EQ2 4rth Floor ColumnDocument15 pagesEQ2 4rth Floor ColumnWilbert Carlo RachoNo ratings yet

- E Crane FoundationDocument1 pageE Crane FoundationPriodeep ChowdhuryNo ratings yet

- Two Way SlabDocument88 pagesTwo Way SlabSushil KumarNo ratings yet

- Cop Suoc2013Document36 pagesCop Suoc2013YUK LAM WONGNo ratings yet

- Problem 8 - Analysis of Eccentrically Loaded Column With Unknown C ValueDocument6 pagesProblem 8 - Analysis of Eccentrically Loaded Column With Unknown C ValueRey Joseph IglesiaNo ratings yet

- Analisis Balok Tulangan RangkapDocument3 pagesAnalisis Balok Tulangan Rangkapirgan.abdul.tkgd22No ratings yet

- Quantity Survey NotesDocument10 pagesQuantity Survey NotesSharath RMNo ratings yet

- Assignment 1Document12 pagesAssignment 1Suzan SalimNo ratings yet

- Technological Institute of The Philippines - Manila: SignatureDocument21 pagesTechnological Institute of The Philippines - Manila: SignaturePlatoon Nicart BejerNo ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AMahesh SuranaNo ratings yet

- Beam DesignDocument17 pagesBeam DesignmahaNo ratings yet

- Pile and Pile Cap DesignDocument14 pagesPile and Pile Cap Designshroud.3567No ratings yet

- Design of SplicingDocument13 pagesDesign of SplicingMc Tyler Reyes YuntingNo ratings yet

- DesignDocument34 pagesDesignAbhay SuwalNo ratings yet

- Design of ColumnsDocument3 pagesDesign of ColumnsAngelo AmarNo ratings yet

- Bolt Connection Design Based On NDS 2018: Input Data & Design SummaryDocument2 pagesBolt Connection Design Based On NDS 2018: Input Data & Design Summaryalejahrojas96No ratings yet

- Design of Pile CapDocument3 pagesDesign of Pile Capabhi aroteNo ratings yet

- This Is ItDocument33 pagesThis Is ItJames DerechoNo ratings yet

- Footing Subjected To Eccentric LoadingDocument5 pagesFooting Subjected To Eccentric LoadingPratik DhariwalNo ratings yet

- BEAM SampleDocument70 pagesBEAM SampleAira Joyce Salazar100% (1)

- Connection Design: C1-BP: ETABS 2016 16.2.1 License # 13GKCULR7HUKDLFDocument5 pagesConnection Design: C1-BP: ETABS 2016 16.2.1 License # 13GKCULR7HUKDLFjaicollaNo ratings yet

- Composite Floor GirderDocument3 pagesComposite Floor GirderlucianduNo ratings yet

- 10.0 Base Plate & Anchor BoltDocument16 pages10.0 Base Plate & Anchor Boltkrishna kumar100% (1)

- 15-Cold Formed 2021Document35 pages15-Cold Formed 2021karim hassanNo ratings yet

- Design of Column: Axial Stress 0.1fckDocument22 pagesDesign of Column: Axial Stress 0.1fckSudip ShresthaNo ratings yet

- Geometry Materials: AASHTO Standard Specification, Division 1ADocument5 pagesGeometry Materials: AASHTO Standard Specification, Division 1AHayman AhmedNo ratings yet

- Sheet Metal Developed Length CalculationsDocument7 pagesSheet Metal Developed Length CalculationsOmkar PimpaleNo ratings yet

- Design of Machine Elements Assignment 2 Roll 07Document6 pagesDesign of Machine Elements Assignment 2 Roll 07Sharthak GhoshNo ratings yet

- Flexural Design Reinforced Concrete T Beams ACI 318 14Document19 pagesFlexural Design Reinforced Concrete T Beams ACI 318 14alufuq companyNo ratings yet

- Flexural Design Reinforced Concrete T Beams ACI 318 14Document19 pagesFlexural Design Reinforced Concrete T Beams ACI 318 14ahmadwehba2No ratings yet

- 4b-Design of Compression Member - Column Sept 2023Document40 pages4b-Design of Compression Member - Column Sept 2023saleh34534rf34No ratings yet

- To Do - DS - LRFD - Supporting Beam - W8X18 - W8X18Document15 pagesTo Do - DS - LRFD - Supporting Beam - W8X18 - W8X18amitNo ratings yet

- Design of Slabs1Document8 pagesDesign of Slabs1Tonette AmorNo ratings yet

- Juvylen Final PlateDocument6 pagesJuvylen Final PlateEarl jan liboonNo ratings yet

- Nozzle Load As Per MegyesyDocument3 pagesNozzle Load As Per MegyesyamaNo ratings yet

- Footings Design - Isolated PadDocument12 pagesFootings Design - Isolated Padmaruthiinfra structuresNo ratings yet

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Document4 pagesMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiNo ratings yet

- Tension MemDocument19 pagesTension MemNick AvisNo ratings yet

- Ngasi Consulting Engineers: REF CalculationDocument18 pagesNgasi Consulting Engineers: REF CalculationUday UdmaleNo ratings yet

- SA LAB - Singly Reinforced BeamDocument8 pagesSA LAB - Singly Reinforced BeamAjayNo ratings yet

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- Analytic Geometry: Graphic Solutions Using Matlab LanguageFrom EverandAnalytic Geometry: Graphic Solutions Using Matlab LanguageNo ratings yet

- Assignment - Statistics MethodDocument3 pagesAssignment - Statistics MethodRisman YusufNo ratings yet

- Assignment - Statistics MethodDocument4 pagesAssignment - Statistics MethodRisman YusufNo ratings yet

- Laporan K3 Danau TempeDocument32 pagesLaporan K3 Danau TempeRisman YusufNo ratings yet

- Cals RismanDocument5 pagesCals RismanRisman YusufNo ratings yet

- Assignment - Advance Calculus II-1Document4 pagesAssignment - Advance Calculus II-1Risman YusufNo ratings yet

- No 2Document2 pagesNo 2Risman YusufNo ratings yet

- Risman Yusuf 2201801522 Ld43 Traffic Engineering Artificial Intelligence Enabled Iot: Traffic Congestion Reduction in Smart CitiesDocument4 pagesRisman Yusuf 2201801522 Ld43 Traffic Engineering Artificial Intelligence Enabled Iot: Traffic Congestion Reduction in Smart CitiesRisman YusufNo ratings yet

- BINUS University: Learning OutcomesDocument4 pagesBINUS University: Learning OutcomesRisman YusufNo ratings yet

- Risman Yusuf 2201801522 LD43 Traffic Engineering Assignment 2Document4 pagesRisman Yusuf 2201801522 LD43 Traffic Engineering Assignment 2Risman YusufNo ratings yet

- Risman Yusuf 2201801522 Lb43Document15 pagesRisman Yusuf 2201801522 Lb43Risman YusufNo ratings yet

- 20190824033713BN001638342 PDFDocument1 page20190824033713BN001638342 PDFRisman YusufNo ratings yet

- Team 3Document6 pagesTeam 3Risman YusufNo ratings yet

- Steel BarDocument4 pagesSteel BarRisman YusufNo ratings yet

- Shrinkage LimitDocument4 pagesShrinkage LimitRisman YusufNo ratings yet

- 20190824171419BN001669852 PDFDocument2 pages20190824171419BN001669852 PDFRisman YusufNo ratings yet

- Chapter XVDocument4 pagesChapter XVRisman YusufNo ratings yet

- 20190824033713BN001638342 PDFDocument1 page20190824033713BN001638342 PDFRisman YusufNo ratings yet

- 06 Andrews 1981Document19 pages06 Andrews 1981angelpoolafpc16No ratings yet

- BEP240SNc Tech Support3Document0 pagesBEP240SNc Tech Support3Pam EvansNo ratings yet

- Health Benefits of CucumbersDocument6 pagesHealth Benefits of Cucumbersver_at_workNo ratings yet

- Waterfall ModelDocument3 pagesWaterfall Modelparthu1710No ratings yet

- 2nd Chapter RM-IDocument21 pages2nd Chapter RM-IHajra KhanNo ratings yet

- Fondu PDFDocument2 pagesFondu PDFRaghda Jammoul100% (1)

- CQR User Manual-3 PDFDocument98 pagesCQR User Manual-3 PDFJoe GellatlyNo ratings yet

- Warhammer 40k - Codex - Errata - Dark Angels Q&A v2.0Document2 pagesWarhammer 40k - Codex - Errata - Dark Angels Q&A v2.0Jakub KalembaNo ratings yet

- CB Insights - Most Promising StartupsDocument122 pagesCB Insights - Most Promising StartupsRazvan CosmaNo ratings yet

- Carta Organisasi PibgDocument1 pageCarta Organisasi PibgNasha FatehaNo ratings yet

- InkaTAC-Amomax Lista de Precios 2020 Set.Document9 pagesInkaTAC-Amomax Lista de Precios 2020 Set.christopher carhuamacaNo ratings yet

- Fin358 Individual Assignment Nur Hazani 2020818012Document12 pagesFin358 Individual Assignment Nur Hazani 2020818012nur hazaniNo ratings yet

- Operator's Manual: Short-Reach Specification Machine (For Digging Operation) (S-SR120-B)Document88 pagesOperator's Manual: Short-Reach Specification Machine (For Digging Operation) (S-SR120-B)TommyNo ratings yet

- STARBOOKS Named As Priority Program For 2018: Press ReleaseDocument2 pagesSTARBOOKS Named As Priority Program For 2018: Press ReleaseArnoNo ratings yet

- 1st Year Chemistry Practical 1 - Stoichiometry in SolutionDocument5 pages1st Year Chemistry Practical 1 - Stoichiometry in SolutionNoel SimpasaNo ratings yet

- Nursing Home Private Hospital / ICU Nursing Chart: 6 HR 18 HRDocument2 pagesNursing Home Private Hospital / ICU Nursing Chart: 6 HR 18 HRdavidNo ratings yet

- AdventureTime BoardGame RULEBOOK DefinitivoDocument33 pagesAdventureTime BoardGame RULEBOOK DefinitivoesacosaNo ratings yet

- Be5024 0 1Document6 pagesBe5024 0 1Victor SanchezNo ratings yet

- Din 6885Document1 pageDin 6885Riadini Anis Hade50% (2)

- Caltech - PG Program in Cloud ComputingDocument22 pagesCaltech - PG Program in Cloud ComputingkaperumaNo ratings yet

- R BalajiDocument81 pagesR BalajiBalaji radhakrishnanNo ratings yet

- Topic 9 - Forum Question 1. Explain The Meaning of Communication and Describe What Is Non-Verbal CommunicationDocument3 pagesTopic 9 - Forum Question 1. Explain The Meaning of Communication and Describe What Is Non-Verbal CommunicationHadi azfar channelNo ratings yet

- Teacher Answer Key What Is My Adaptation WorksheetsDocument2 pagesTeacher Answer Key What Is My Adaptation Worksheetssteffielisa12No ratings yet

- Ab PomDocument2 pagesAb PomErica CalzadaNo ratings yet

- The Management EnvironmentDocument28 pagesThe Management EnvironmentRashid Al-MansouriNo ratings yet

- Destrezas Distribuidas Por ParcialesDocument6 pagesDestrezas Distribuidas Por ParcialesAmy Del Cisne Hernandez ChiribogaNo ratings yet

- Point of View SortDocument1 pagePoint of View Sortapi-407328150No ratings yet

- Powder CoatingsDocument30 pagesPowder Coatingsferdlh9No ratings yet

- Quarter by Numbers: Global HighlightsDocument37 pagesQuarter by Numbers: Global HighlightsAndreaNo ratings yet

- Sequence 02 All LessonsDocument14 pagesSequence 02 All Lessonstutor16100% (1)