Professional Documents

Culture Documents

Report PDF

Report PDF

Uploaded by

MORESAGAR0 ratings0% found this document useful (0 votes)

17 views12 pagesOriginal Title

REPORT.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

17 views12 pagesReport PDF

Report PDF

Uploaded by

MORESAGARCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 12

DESIGN

ENGINEERING

BLADELESS TURBINE

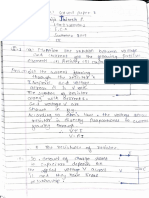

Abstract

The primary objective is to perform an experimental

analysis of bladeless turbine. It is an unconventional

turbine that uses fluid/air properties such as

boundary layer and adhesion of fluid on series of

smooth discs keyed to a shaft Resistance to fluid/

air flow between the disc plates results in energy

transfer to the shaft. This turbine can be used for

small scale industry to develop power with high

efficiency than conventional one. Thus an analysis of

the performance and efficiency of bladeless turbine

Is to be carried out.

Introduction of Bladeless Turbine

Tesla turbine, a bladeless turbine, was patented by the famous scientist Nikola

Tesla (1856-1943) in 1913. Up to now, a major stumbling block in its commercial

use has been its low efficiency and certain other operational difficulties. However,

there has been a resurgence of research interest in this type of turbines because

they have several advantages (as explained below) and hence may be

appropriately developed and used in certain niche application areas.

The Tesla turbine is also known as disc turbine because the rotor of this turbine

is formed by a series of flat, parallel, co-rotating discs, which are closely spaced

and attached to a central shaft. The working fluid is injected nearly tangentially

to the rotor by means of inlet nozzle. The injected fluid, which passes through the

narrow gaps between the discs, approaches spirally towards the exhaust port

located at the centre of each disc. The viscous drag force, produced due to the

relative velocity between the rotor and the working fluid, causes the rotor to

rotate. There is a housing surrounding the rotor, with a small radial and axial

clearance.

car mnswrsonice

In physics and fluid mechanics, a boundary layer is

the layer of fluid in the immediate vicinity of

a surface where the effects of viscosity are

significant. In the Earth's atmosphere,

the atmospheric boundary layer is the air layer near

the ground affected by diurnal heat, moisture or

momentum transfer to or from the surface. On

an aircraft wing the boundary layer is the part of the

flow close to the wing, where viscous forces distort

the surrounding non-viscous flow

Different types of Boundary Layer Flow

There are two different types of boundary layer flow

listed below.

1)Laminar Boundary Layer Flow

The laminar boundary is a very smooth flow, while the

turbulent boundary layer contains swirls or "eddies."

The laminar flow creates less skin friction drag than

the turbulent flow, but is less stable. Boundary layer

flow over a wing surface begins as a smooth laminar

flow. As the flow continues back from the leading edge,

the laminar boundary layer increases in thickness.

2) Turbulent Boundary Layer Flow

- At some distance back from the leading edge,

the smooth laminar flow breaks down and

transitions to a turbulent flow. From a drag

standpoint, it is advisable to have the transition

from laminar to turbulent flow as far aft on the

wing as possible, or have a large amount of the

wing surface within the laminar portion of the

boundary layer. The low energy laminar flow,

however, tends to break down more suddenly

than the turbulent layer.

Corrosion and cavitation is less.

Simple in construction.

Pollution free.

Low cost to produce and maintain.

Lower design and production costs than standard turbines, jet

engines and pumps.

As it is bladeless, it is not require to design the blade geometry.

High-speed.

This type of equipment can be operated at a wide range of

working medium parameters without any danger and malfunction.

It is not so sensitive to a partially polluted working

medium, since the fluid flow is parallel to disks, so it can

be operated with saturated steam.

It can be used in reverse direction.

Improved reliability, resistance to erosion due to

cavitation when steam quality is poor.

A cost-effective, elegant, clean/ green and robust

solution to compressor power prob.

+ Applied to various low torque operation.

: Applied to small scale industry.

* Geothermal applications.

* Chemical, oi] & petrochemical processing.

+ Pulp & paper manufacturing.

+ Waste water treatment &disposal applications.

+ Mining & environmental clean-up.

+ The Bladeless turbine is selected over traditional blade

turbines due to its high efficiency under pressure and the

ability to make it compact in size.

+ And also reduce noise derived from the operation of an engine

+ Study and analysis of this bladeless turbine

come to conclusion that Number of discs,

spacing between discs and surface finish of

discs affects the performance of turbine

significantly .This work was carried out to study

performance of disc turbine operating on water

medium, however previous studies and

experimentation carried out with air and steam

medium.

THANK YOU

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Nctacsatja Jainesh P.: 1ca) O Mehtion He E Lcton - Hetuueen Volr ItageDocument19 pagesNctacsatja Jainesh P.: 1ca) O Mehtion He E Lcton - Hetuueen Volr ItageMORESAGARNo ratings yet

- Ghanchi Mukim Anvar 190230109019 Electrical Engineering: Name Enrollment No BranchDocument45 pagesGhanchi Mukim Anvar 190230109019 Electrical Engineering: Name Enrollment No BranchMORESAGARNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityMORESAGARNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityMORESAGARNo ratings yet

- A Course in Spoken English PDFDocument145 pagesA Course in Spoken English PDFMORESAGARNo ratings yet

- CpuDocument3 pagesCpuMORESAGARNo ratings yet

- CpuDocument3 pagesCpuMORESAGARNo ratings yet