Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

27 viewsThe Brewing Process: Malting

The Brewing Process: Malting

Uploaded by

Andrea CasillasThe brewing process involves 10 steps: 1) malting of barley grains, 2) milling the malt, 3) mashing to convert starches to sugars, 4) lautering to separate wort from grains, 5) boiling the wort to pasteurize and add hops, 6) clarifying the wort, 7) fermentation where yeast converts sugars to alcohol and carbon dioxide, 8) storage of young beer, 9) filtration to remove particles, and 10) filling containers. Making beer requires carefully controlling variables like temperature and concentration throughout the process to produce a good tasting final product.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Secret Magic Spells of The Romany GypsiesDocument28 pagesSecret Magic Spells of The Romany Gypsiesakenaton4089% (66)

- Beer Factory CASE STUDY ReportDocument7 pagesBeer Factory CASE STUDY ReportParas Khanal0% (1)

- Preparation of Beer and WineDocument27 pagesPreparation of Beer and WineSumit Nirmal100% (3)

- Intuitive Knowing As Spiritual ExperienceDocument237 pagesIntuitive Knowing As Spiritual ExperienceHugo Martin100% (1)

- Kerbstone Painting SpecsDocument3 pagesKerbstone Painting SpecsAbdullah Aboodi83% (6)

- History of The Brew:: WhouseDocument4 pagesHistory of The Brew:: WhousehiltonrtNo ratings yet

- Chen 382 FinalDocument9 pagesChen 382 Finalapi-240464495No ratings yet

- Beer ProductionDocument12 pagesBeer ProductionYonas Addam100% (1)

- Fermentation Process (Wine & Beer)Document39 pagesFermentation Process (Wine & Beer)Jannielle Joyce BoniaoNo ratings yet

- Brewing ProcessDocument1 pageBrewing ProcessMadanKarkiNo ratings yet

- Brewing ProcessDocument34 pagesBrewing ProcessDiana Mdm100% (1)

- How Beer Is Made in Industrial Brewing ProcessDocument7 pagesHow Beer Is Made in Industrial Brewing ProcessRey Danielle Taray NaveaNo ratings yet

- Winemaking ProcessDocument5 pagesWinemaking Processquachhuyentrangt66No ratings yet

- Maria Camila Forero Maria Camila Marin Angela Mugno Nicolas Vera Miguel Ruiz Maria Alejandra MuñozDocument39 pagesMaria Camila Forero Maria Camila Marin Angela Mugno Nicolas Vera Miguel Ruiz Maria Alejandra MuñozMaria Camila ForeroNo ratings yet

- Beer Processing: Adianto Jayaratana Jimmy Ongko Nico Andrianus. PDocument11 pagesBeer Processing: Adianto Jayaratana Jimmy Ongko Nico Andrianus. PNico AndrianusNo ratings yet

- Mapúa University: Beer ManufacturingDocument11 pagesMapúa University: Beer ManufacturingChesterJerichoRamosNo ratings yet

- Beer - Types, Production & SpoilageDocument17 pagesBeer - Types, Production & SpoilagePallaviNo ratings yet

- Manufacturing Process of BeerDocument43 pagesManufacturing Process of Beerabhys_raghuNo ratings yet

- Beer ProductionDocument8 pagesBeer ProductionArush SidanaNo ratings yet

- Beverage Purchasing ControlDocument54 pagesBeverage Purchasing ControlRonald ArzagaNo ratings yet

- The Illustrated Guide to Brewing Beer: A Comprehensive Handboook of Beginning Home BrewingFrom EverandThe Illustrated Guide to Brewing Beer: A Comprehensive Handboook of Beginning Home BrewingNo ratings yet

- Edward, Michael - Production of Wine Beer Spirits and LiquersDocument179 pagesEdward, Michael - Production of Wine Beer Spirits and LiquersGabriel Reyes SahagúnNo ratings yet

- The Homebrewer's Handbook: An Illustrated Beginner?s GuideFrom EverandThe Homebrewer's Handbook: An Illustrated Beginner?s GuideNo ratings yet

- Beer 101Document11 pagesBeer 101MadanKarkiNo ratings yet

- Material Balance - Craft BeerDocument7 pagesMaterial Balance - Craft BeerScribdTranslationsNo ratings yet

- SciencefactsbeerDocument43 pagesSciencefactsbeershakanguvuNo ratings yet

- Kyambogo University: Faculty of Science Department of Chemistry Microbiology AssignmentDocument5 pagesKyambogo University: Faculty of Science Department of Chemistry Microbiology AssignmentNkugwa Mark WilliamNo ratings yet

- What Is BeerDocument5 pagesWhat Is BeerTeten GunawanNo ratings yet

- Brewing ProcessDocument9 pagesBrewing ProcessDavid MuneneNo ratings yet

- Bar and LiquorDocument8 pagesBar and LiquorEkoh EnduranceNo ratings yet

- The Beginner's Guide to Beer Brewing: Fundamentals Of Beer BrewingFrom EverandThe Beginner's Guide to Beer Brewing: Fundamentals Of Beer BrewingNo ratings yet

- Sefinew Asaye MeleeseDocument42 pagesSefinew Asaye MeleeseabrhshNo ratings yet

- Beer Notes 1Document9 pagesBeer Notes 1shreeya guptaNo ratings yet

- 3 BeerDocument16 pages3 BeerJatin Kumar SinghNo ratings yet

- How Beer Works: Main Home FoodDocument16 pagesHow Beer Works: Main Home FoodNeelajit ChandraNo ratings yet

- Beer Management: Technological University of The Philippines - TaguigDocument5 pagesBeer Management: Technological University of The Philippines - TaguigTyron FrancisNo ratings yet

- Bar ManualDocument45 pagesBar Manualbagus wiraNo ratings yet

- Beer - Ingredients: Water. Beer Is Approximately 90 Percent Water. Not All Water Is IdealDocument8 pagesBeer - Ingredients: Water. Beer Is Approximately 90 Percent Water. Not All Water Is IdealFarhaan MohammedNo ratings yet

- BeerDocument22 pagesBeeraregawi zemchealNo ratings yet

- Objective: To Study The Ever Popular Beverage With Emphasis OnDocument28 pagesObjective: To Study The Ever Popular Beverage With Emphasis OnPrashant100% (1)

- Heineken in Vietnam CaseDocument21 pagesHeineken in Vietnam CaseHiền Trần100% (1)

- Micro Brewing Guide EnglishDocument27 pagesMicro Brewing Guide EnglishZamir HadesNo ratings yet

- Preparation of Blueberry Craft BeerDocument15 pagesPreparation of Blueberry Craft BeerScribdTranslationsNo ratings yet

- Beer ManufacturingDocument23 pagesBeer ManufacturingDivya AggarwalNo ratings yet

- By, Kunjal Patel, M.sc. Microbiology .Document30 pagesBy, Kunjal Patel, M.sc. Microbiology .gaurangHpatelNo ratings yet

- Beer ProductionDocument20 pagesBeer ProductionEduardo AmezcuaNo ratings yet

- BCH 412 Note Beer-1Document10 pagesBCH 412 Note Beer-1ezekielolami01No ratings yet

- Product DescriptionDocument3 pagesProduct DescriptionMaj FernandezNo ratings yet

- How To Brew Your Own BeerDocument6 pagesHow To Brew Your Own BeerJohan RiosNo ratings yet

- ACE2056 Group 4 BrewLab Report - 1Document5 pagesACE2056 Group 4 BrewLab Report - 1Loan Kim VuongNo ratings yet

- Term Paper Presentation On FermentationDocument11 pagesTerm Paper Presentation On FermentationOluwagbenga ElijahNo ratings yet

- Organic Chemistry Lab WinemakingDocument8 pagesOrganic Chemistry Lab WinemakingChelsie NicoleNo ratings yet

- PTK DraftDocument3 pagesPTK Draftjonathantjioe123No ratings yet

- Solibra Abidjan Lemonaderies and Ice Cream Company Soliglace Brasserie Artois International Brewery and Coolers A Subsidiary of The Castel GroupDocument4 pagesSolibra Abidjan Lemonaderies and Ice Cream Company Soliglace Brasserie Artois International Brewery and Coolers A Subsidiary of The Castel GroupJoel Henry KablanNo ratings yet

- Notes For Beer Mash & Chill Proofing, Molecular Markers Notes SummaryDocument24 pagesNotes For Beer Mash & Chill Proofing, Molecular Markers Notes SummaryANUPAM SINGLA0% (1)

- Decoction MashingDocument4 pagesDecoction MashingBaldev SinghNo ratings yet

- Introduction: For The Love of VodkaDocument8 pagesIntroduction: For The Love of VodkaAdam GhahramaniNo ratings yet

- Seminar BeerDocument16 pagesSeminar BeerKshitij DushingNo ratings yet

- Traditional Biotechnology Red Team Group 2 OfficialDocument74 pagesTraditional Biotechnology Red Team Group 2 OfficialJun RaselNo ratings yet

- The Main Fermentation in the Beer Brewing Process - Selected QuestionsFrom EverandThe Main Fermentation in the Beer Brewing Process - Selected QuestionsRating: 5 out of 5 stars5/5 (1)

- Workshop Based On: Vodka DistilledDocument18 pagesWorkshop Based On: Vodka DistilledAdam GhahramaniNo ratings yet

- Global Sale of Laptop and Desktop Computers Over The Past Ten YearsDocument1 pageGlobal Sale of Laptop and Desktop Computers Over The Past Ten YearsAndrea CasillasNo ratings yet

- Questionsaboutthe Ideas Ofthe Passage - : Skill 1: Answer Main Idea Questions CorrectlyDocument4 pagesQuestionsaboutthe Ideas Ofthe Passage - : Skill 1: Answer Main Idea Questions CorrectlyAndrea CasillasNo ratings yet

- Are Used To State Additional Information About The Noun in The SentenceDocument1 pageAre Used To State Additional Information About The Noun in The SentenceAndrea CasillasNo ratings yet

- Renewable Energy: Author: Andrea Isabel Casillas HernándezDocument2 pagesRenewable Energy: Author: Andrea Isabel Casillas HernándezAndrea CasillasNo ratings yet

- Biogas:Converting Waste To Energy: Author: Andrea Isabel Casillas HernándezDocument2 pagesBiogas:Converting Waste To Energy: Author: Andrea Isabel Casillas HernándezAndrea CasillasNo ratings yet

- EoE Programme AgendaDocument9 pagesEoE Programme AgendathegpcgroupNo ratings yet

- Week 4 - Stadelman-Cohen & Hillman (2014)Document22 pagesWeek 4 - Stadelman-Cohen & Hillman (2014)kehanNo ratings yet

- 3139BCE-Cannot The Year of Mahabharata War!Document5 pages3139BCE-Cannot The Year of Mahabharata War!KrishenKaulNo ratings yet

- GEO L9 Physiography India Part 1Document72 pagesGEO L9 Physiography India Part 1Sambasivarao PerumallaNo ratings yet

- Posture ClassDocument56 pagesPosture Classnarainder kumarNo ratings yet

- Sop BM RHF Oprn ProcedureDocument2 pagesSop BM RHF Oprn ProcedurewrbmrhfispNo ratings yet

- Industrial Training Report of A & A Telecom Engineering PVT LTDDocument69 pagesIndustrial Training Report of A & A Telecom Engineering PVT LTDHasithaGanepola100% (4)

- Ovine Pulmonary Adenocarcinoma: (Adenomatosis)Document6 pagesOvine Pulmonary Adenocarcinoma: (Adenomatosis)WormInchNo ratings yet

- Medsurg Fbao EndtermDocument6 pagesMedsurg Fbao EndtermNevea CariñoNo ratings yet

- Tec Specific CESSNA 172-R QuestionsDocument5 pagesTec Specific CESSNA 172-R QuestionsShaurya KhuranaNo ratings yet

- 02 000378Document477 pages02 000378JimNo ratings yet

- Physical Explanation - General SemiconductorsDocument3 pagesPhysical Explanation - General SemiconductorsNarayanan RamanathanNo ratings yet

- English Pre Aarambh Checklist 35 by Nimisha Mam 10th April 2024Document13 pagesEnglish Pre Aarambh Checklist 35 by Nimisha Mam 10th April 2024maazkinnatNo ratings yet

- Hampton Frames 2014 CatalogueDocument32 pagesHampton Frames 2014 CataloguehamptonframesNo ratings yet

- BTCDocument30 pagesBTCshajib_sustNo ratings yet

- Waves Solved QuestionsDocument27 pagesWaves Solved Questionscolorado wildernessNo ratings yet

- Islamiat Notes by Roshan Wadwani PDFDocument151 pagesIslamiat Notes by Roshan Wadwani PDFJaffar Mastoi100% (1)

- Philippines' Country Profile : Tag-Ulan, The Rainy Season From June To November and Tag-Lamig, The Cool Dry Season FromDocument34 pagesPhilippines' Country Profile : Tag-Ulan, The Rainy Season From June To November and Tag-Lamig, The Cool Dry Season FromEugene Evan Endaya UyNo ratings yet

- General Chemistry 1: Quarter 2 - Module 4 Polymers & BiomoleculesDocument22 pagesGeneral Chemistry 1: Quarter 2 - Module 4 Polymers & BiomoleculesKaren de los ReyesNo ratings yet

- Report On Reuse of Abandoned Quarries and Mine Pits in KeralaDocument90 pagesReport On Reuse of Abandoned Quarries and Mine Pits in KeralaDrThrivikramji Kyth100% (10)

- Datasheet S7-300Document124 pagesDatasheet S7-300mar3a3p3rez-22No ratings yet

- Sesiones de Technical EnglishDocument90 pagesSesiones de Technical EnglishBill Klinthon Chiara100% (1)

- Test Bank For Entrepreneurship Theory Process and Practice 10th Edition by KuratkoDocument36 pagesTest Bank For Entrepreneurship Theory Process and Practice 10th Edition by Kuratkosanityenhanceqould1100% (54)

- Girder - Arrangement 04 08 2023Document9 pagesGirder - Arrangement 04 08 2023sanyogitasawant5No ratings yet

- High Voltage Switching Operations: The Next StepDocument2 pagesHigh Voltage Switching Operations: The Next Steplenon chidzivaNo ratings yet

- Formulation - of - Corrosion - Inhibitors-Yun Chen and Wenzhong Yang 23 PAGESDocument23 pagesFormulation - of - Corrosion - Inhibitors-Yun Chen and Wenzhong Yang 23 PAGESChoice Organo100% (4)

- Monash Sustainability Institute - Annual Activity Report 2013Document76 pagesMonash Sustainability Institute - Annual Activity Report 2013Monash Sustainability InstituteNo ratings yet

The Brewing Process: Malting

The Brewing Process: Malting

Uploaded by

Andrea Casillas0 ratings0% found this document useful (0 votes)

27 views2 pagesThe brewing process involves 10 steps: 1) malting of barley grains, 2) milling the malt, 3) mashing to convert starches to sugars, 4) lautering to separate wort from grains, 5) boiling the wort to pasteurize and add hops, 6) clarifying the wort, 7) fermentation where yeast converts sugars to alcohol and carbon dioxide, 8) storage of young beer, 9) filtration to remove particles, and 10) filling containers. Making beer requires carefully controlling variables like temperature and concentration throughout the process to produce a good tasting final product.

Original Description:

Original Title

Assigment 3

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe brewing process involves 10 steps: 1) malting of barley grains, 2) milling the malt, 3) mashing to convert starches to sugars, 4) lautering to separate wort from grains, 5) boiling the wort to pasteurize and add hops, 6) clarifying the wort, 7) fermentation where yeast converts sugars to alcohol and carbon dioxide, 8) storage of young beer, 9) filtration to remove particles, and 10) filling containers. Making beer requires carefully controlling variables like temperature and concentration throughout the process to produce a good tasting final product.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

27 views2 pagesThe Brewing Process: Malting

The Brewing Process: Malting

Uploaded by

Andrea CasillasThe brewing process involves 10 steps: 1) malting of barley grains, 2) milling the malt, 3) mashing to convert starches to sugars, 4) lautering to separate wort from grains, 5) boiling the wort to pasteurize and add hops, 6) clarifying the wort, 7) fermentation where yeast converts sugars to alcohol and carbon dioxide, 8) storage of young beer, 9) filtration to remove particles, and 10) filling containers. Making beer requires carefully controlling variables like temperature and concentration throughout the process to produce a good tasting final product.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

The Brewing Process

Author: Andrea Isabel Casillas Hernández

Introduction

Surely you have enjoyed a cold beer in the company of good friends, and if not, at least you are certain

what beer is. But have you ever started to think about the steps to make a beer? The entire process to

make a beer is known in many countries as The Brewing Process.

“Brewing” is the practice of regulating the interactions between water, starch, yeast, and hops so that

the final result is what is called beer. Beer is the most generally consumed alcoholic beverage in the

world, also is the third most popular drink overall after water and tea.

Development

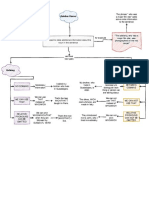

In the beer-making process, various ingredients are mixed, processed, and sometimes the structure of

the raw materials is altered. The brewing process is made up of ten production steps from the fresh

barley to the finished beer. Let is it see what these steps are and why making beer is considered an art.

1. Malting. This is the first step of the brewing process. Firstly, the fresh barley gets soaked in

water to germinate. This partial germination makes for easier conversion of the grain’s

starches into malt sugars.

2. Milling. The finished malt is milled, similar to the making of flour, so that it dissolves better in

water.

3. Mashing. Once milling is complete, mashing beings. The milled malt is mixed with water in the

mash tun – mashing-in. The mash will take between 30-120 min, the time depends of the

temperature and type of enzyme working.

4. Lautering. In this step, the mash is filtered in the lauter tun as the husks sink and the wort is

separated from the solid substances (spent grains).

5. Boiling. The process of boiling the wort is responsible for two main things:

Pasteurize the wort

Add hops or other flavors such as ginger or molasses.

6. Wort Clarification. Here the wort is fed into the whirlpool and starts to rotate. Hop particles

that have not dissolved, and proteins forms a cone in the middle of the container, and the

clear wort can be tapped off at the side.

7. Fermentation. This step takes place in a fermentation tank where special brewing yeast is

added. In the next 4-6 days, yeast turns the malt sugar into alcohol and carbon dioxide. This is

where the reaction to beer occurs:

C6H12O6 2C2H5OH + 2CO2

8. Storage. Young beer is stored anything from three weeks to three months in a storage tank at

between 1 and 2° Celsius, then the beer becomes clear and acquires its characteristic colour.

9. Filtration. The beer is filtered to separate all the particles that have been sedimented in the

fermentation.

10. Filling. The beer is filled using counter pressure to prevent any carbon dioxide from escaping.

Barrels are filled directly in our brewery.

Conclusion

In conclusion, I would like to emphasize that beer is a very consumed drink all over the world. Making

beer is not as simple as it seems, it is necessary to control many variables such as temperature and

concentration, so that finally you can have a beer that tastes and smells good. All steps are important

in the brewing process, if any goes wrong, it could seriously affect the final result of the beer.

References

Beer brewing: the brewing process | Braeu am Berg. (2016). Retrieved 14 November 2020, from

https://www.braeuamberg.at/en/brewing-process/

Trosset, F. (2018). The Brewing Process — Aslan Brewing Co. Retrieved 14 November 2020, from

https://aslanbrewing.com/thebrewingprocess

Morales, M. (2018). Chemical reactions in beer. Revista De Química, (2518-2803). Retrieved from

http://revistas.pucp.edu.pe/quimica

You might also like

- Secret Magic Spells of The Romany GypsiesDocument28 pagesSecret Magic Spells of The Romany Gypsiesakenaton4089% (66)

- Beer Factory CASE STUDY ReportDocument7 pagesBeer Factory CASE STUDY ReportParas Khanal0% (1)

- Preparation of Beer and WineDocument27 pagesPreparation of Beer and WineSumit Nirmal100% (3)

- Intuitive Knowing As Spiritual ExperienceDocument237 pagesIntuitive Knowing As Spiritual ExperienceHugo Martin100% (1)

- Kerbstone Painting SpecsDocument3 pagesKerbstone Painting SpecsAbdullah Aboodi83% (6)

- History of The Brew:: WhouseDocument4 pagesHistory of The Brew:: WhousehiltonrtNo ratings yet

- Chen 382 FinalDocument9 pagesChen 382 Finalapi-240464495No ratings yet

- Beer ProductionDocument12 pagesBeer ProductionYonas Addam100% (1)

- Fermentation Process (Wine & Beer)Document39 pagesFermentation Process (Wine & Beer)Jannielle Joyce BoniaoNo ratings yet

- Brewing ProcessDocument1 pageBrewing ProcessMadanKarkiNo ratings yet

- Brewing ProcessDocument34 pagesBrewing ProcessDiana Mdm100% (1)

- How Beer Is Made in Industrial Brewing ProcessDocument7 pagesHow Beer Is Made in Industrial Brewing ProcessRey Danielle Taray NaveaNo ratings yet

- Winemaking ProcessDocument5 pagesWinemaking Processquachhuyentrangt66No ratings yet

- Maria Camila Forero Maria Camila Marin Angela Mugno Nicolas Vera Miguel Ruiz Maria Alejandra MuñozDocument39 pagesMaria Camila Forero Maria Camila Marin Angela Mugno Nicolas Vera Miguel Ruiz Maria Alejandra MuñozMaria Camila ForeroNo ratings yet

- Beer Processing: Adianto Jayaratana Jimmy Ongko Nico Andrianus. PDocument11 pagesBeer Processing: Adianto Jayaratana Jimmy Ongko Nico Andrianus. PNico AndrianusNo ratings yet

- Mapúa University: Beer ManufacturingDocument11 pagesMapúa University: Beer ManufacturingChesterJerichoRamosNo ratings yet

- Beer - Types, Production & SpoilageDocument17 pagesBeer - Types, Production & SpoilagePallaviNo ratings yet

- Manufacturing Process of BeerDocument43 pagesManufacturing Process of Beerabhys_raghuNo ratings yet

- Beer ProductionDocument8 pagesBeer ProductionArush SidanaNo ratings yet

- Beverage Purchasing ControlDocument54 pagesBeverage Purchasing ControlRonald ArzagaNo ratings yet

- The Illustrated Guide to Brewing Beer: A Comprehensive Handboook of Beginning Home BrewingFrom EverandThe Illustrated Guide to Brewing Beer: A Comprehensive Handboook of Beginning Home BrewingNo ratings yet

- Edward, Michael - Production of Wine Beer Spirits and LiquersDocument179 pagesEdward, Michael - Production of Wine Beer Spirits and LiquersGabriel Reyes SahagúnNo ratings yet

- The Homebrewer's Handbook: An Illustrated Beginner?s GuideFrom EverandThe Homebrewer's Handbook: An Illustrated Beginner?s GuideNo ratings yet

- Beer 101Document11 pagesBeer 101MadanKarkiNo ratings yet

- Material Balance - Craft BeerDocument7 pagesMaterial Balance - Craft BeerScribdTranslationsNo ratings yet

- SciencefactsbeerDocument43 pagesSciencefactsbeershakanguvuNo ratings yet

- Kyambogo University: Faculty of Science Department of Chemistry Microbiology AssignmentDocument5 pagesKyambogo University: Faculty of Science Department of Chemistry Microbiology AssignmentNkugwa Mark WilliamNo ratings yet

- What Is BeerDocument5 pagesWhat Is BeerTeten GunawanNo ratings yet

- Brewing ProcessDocument9 pagesBrewing ProcessDavid MuneneNo ratings yet

- Bar and LiquorDocument8 pagesBar and LiquorEkoh EnduranceNo ratings yet

- The Beginner's Guide to Beer Brewing: Fundamentals Of Beer BrewingFrom EverandThe Beginner's Guide to Beer Brewing: Fundamentals Of Beer BrewingNo ratings yet

- Sefinew Asaye MeleeseDocument42 pagesSefinew Asaye MeleeseabrhshNo ratings yet

- Beer Notes 1Document9 pagesBeer Notes 1shreeya guptaNo ratings yet

- 3 BeerDocument16 pages3 BeerJatin Kumar SinghNo ratings yet

- How Beer Works: Main Home FoodDocument16 pagesHow Beer Works: Main Home FoodNeelajit ChandraNo ratings yet

- Beer Management: Technological University of The Philippines - TaguigDocument5 pagesBeer Management: Technological University of The Philippines - TaguigTyron FrancisNo ratings yet

- Bar ManualDocument45 pagesBar Manualbagus wiraNo ratings yet

- Beer - Ingredients: Water. Beer Is Approximately 90 Percent Water. Not All Water Is IdealDocument8 pagesBeer - Ingredients: Water. Beer Is Approximately 90 Percent Water. Not All Water Is IdealFarhaan MohammedNo ratings yet

- BeerDocument22 pagesBeeraregawi zemchealNo ratings yet

- Objective: To Study The Ever Popular Beverage With Emphasis OnDocument28 pagesObjective: To Study The Ever Popular Beverage With Emphasis OnPrashant100% (1)

- Heineken in Vietnam CaseDocument21 pagesHeineken in Vietnam CaseHiền Trần100% (1)

- Micro Brewing Guide EnglishDocument27 pagesMicro Brewing Guide EnglishZamir HadesNo ratings yet

- Preparation of Blueberry Craft BeerDocument15 pagesPreparation of Blueberry Craft BeerScribdTranslationsNo ratings yet

- Beer ManufacturingDocument23 pagesBeer ManufacturingDivya AggarwalNo ratings yet

- By, Kunjal Patel, M.sc. Microbiology .Document30 pagesBy, Kunjal Patel, M.sc. Microbiology .gaurangHpatelNo ratings yet

- Beer ProductionDocument20 pagesBeer ProductionEduardo AmezcuaNo ratings yet

- BCH 412 Note Beer-1Document10 pagesBCH 412 Note Beer-1ezekielolami01No ratings yet

- Product DescriptionDocument3 pagesProduct DescriptionMaj FernandezNo ratings yet

- How To Brew Your Own BeerDocument6 pagesHow To Brew Your Own BeerJohan RiosNo ratings yet

- ACE2056 Group 4 BrewLab Report - 1Document5 pagesACE2056 Group 4 BrewLab Report - 1Loan Kim VuongNo ratings yet

- Term Paper Presentation On FermentationDocument11 pagesTerm Paper Presentation On FermentationOluwagbenga ElijahNo ratings yet

- Organic Chemistry Lab WinemakingDocument8 pagesOrganic Chemistry Lab WinemakingChelsie NicoleNo ratings yet

- PTK DraftDocument3 pagesPTK Draftjonathantjioe123No ratings yet

- Solibra Abidjan Lemonaderies and Ice Cream Company Soliglace Brasserie Artois International Brewery and Coolers A Subsidiary of The Castel GroupDocument4 pagesSolibra Abidjan Lemonaderies and Ice Cream Company Soliglace Brasserie Artois International Brewery and Coolers A Subsidiary of The Castel GroupJoel Henry KablanNo ratings yet

- Notes For Beer Mash & Chill Proofing, Molecular Markers Notes SummaryDocument24 pagesNotes For Beer Mash & Chill Proofing, Molecular Markers Notes SummaryANUPAM SINGLA0% (1)

- Decoction MashingDocument4 pagesDecoction MashingBaldev SinghNo ratings yet

- Introduction: For The Love of VodkaDocument8 pagesIntroduction: For The Love of VodkaAdam GhahramaniNo ratings yet

- Seminar BeerDocument16 pagesSeminar BeerKshitij DushingNo ratings yet

- Traditional Biotechnology Red Team Group 2 OfficialDocument74 pagesTraditional Biotechnology Red Team Group 2 OfficialJun RaselNo ratings yet

- The Main Fermentation in the Beer Brewing Process - Selected QuestionsFrom EverandThe Main Fermentation in the Beer Brewing Process - Selected QuestionsRating: 5 out of 5 stars5/5 (1)

- Workshop Based On: Vodka DistilledDocument18 pagesWorkshop Based On: Vodka DistilledAdam GhahramaniNo ratings yet

- Global Sale of Laptop and Desktop Computers Over The Past Ten YearsDocument1 pageGlobal Sale of Laptop and Desktop Computers Over The Past Ten YearsAndrea CasillasNo ratings yet

- Questionsaboutthe Ideas Ofthe Passage - : Skill 1: Answer Main Idea Questions CorrectlyDocument4 pagesQuestionsaboutthe Ideas Ofthe Passage - : Skill 1: Answer Main Idea Questions CorrectlyAndrea CasillasNo ratings yet

- Are Used To State Additional Information About The Noun in The SentenceDocument1 pageAre Used To State Additional Information About The Noun in The SentenceAndrea CasillasNo ratings yet

- Renewable Energy: Author: Andrea Isabel Casillas HernándezDocument2 pagesRenewable Energy: Author: Andrea Isabel Casillas HernándezAndrea CasillasNo ratings yet

- Biogas:Converting Waste To Energy: Author: Andrea Isabel Casillas HernándezDocument2 pagesBiogas:Converting Waste To Energy: Author: Andrea Isabel Casillas HernándezAndrea CasillasNo ratings yet

- EoE Programme AgendaDocument9 pagesEoE Programme AgendathegpcgroupNo ratings yet

- Week 4 - Stadelman-Cohen & Hillman (2014)Document22 pagesWeek 4 - Stadelman-Cohen & Hillman (2014)kehanNo ratings yet

- 3139BCE-Cannot The Year of Mahabharata War!Document5 pages3139BCE-Cannot The Year of Mahabharata War!KrishenKaulNo ratings yet

- GEO L9 Physiography India Part 1Document72 pagesGEO L9 Physiography India Part 1Sambasivarao PerumallaNo ratings yet

- Posture ClassDocument56 pagesPosture Classnarainder kumarNo ratings yet

- Sop BM RHF Oprn ProcedureDocument2 pagesSop BM RHF Oprn ProcedurewrbmrhfispNo ratings yet

- Industrial Training Report of A & A Telecom Engineering PVT LTDDocument69 pagesIndustrial Training Report of A & A Telecom Engineering PVT LTDHasithaGanepola100% (4)

- Ovine Pulmonary Adenocarcinoma: (Adenomatosis)Document6 pagesOvine Pulmonary Adenocarcinoma: (Adenomatosis)WormInchNo ratings yet

- Medsurg Fbao EndtermDocument6 pagesMedsurg Fbao EndtermNevea CariñoNo ratings yet

- Tec Specific CESSNA 172-R QuestionsDocument5 pagesTec Specific CESSNA 172-R QuestionsShaurya KhuranaNo ratings yet

- 02 000378Document477 pages02 000378JimNo ratings yet

- Physical Explanation - General SemiconductorsDocument3 pagesPhysical Explanation - General SemiconductorsNarayanan RamanathanNo ratings yet

- English Pre Aarambh Checklist 35 by Nimisha Mam 10th April 2024Document13 pagesEnglish Pre Aarambh Checklist 35 by Nimisha Mam 10th April 2024maazkinnatNo ratings yet

- Hampton Frames 2014 CatalogueDocument32 pagesHampton Frames 2014 CataloguehamptonframesNo ratings yet

- BTCDocument30 pagesBTCshajib_sustNo ratings yet

- Waves Solved QuestionsDocument27 pagesWaves Solved Questionscolorado wildernessNo ratings yet

- Islamiat Notes by Roshan Wadwani PDFDocument151 pagesIslamiat Notes by Roshan Wadwani PDFJaffar Mastoi100% (1)

- Philippines' Country Profile : Tag-Ulan, The Rainy Season From June To November and Tag-Lamig, The Cool Dry Season FromDocument34 pagesPhilippines' Country Profile : Tag-Ulan, The Rainy Season From June To November and Tag-Lamig, The Cool Dry Season FromEugene Evan Endaya UyNo ratings yet

- General Chemistry 1: Quarter 2 - Module 4 Polymers & BiomoleculesDocument22 pagesGeneral Chemistry 1: Quarter 2 - Module 4 Polymers & BiomoleculesKaren de los ReyesNo ratings yet

- Report On Reuse of Abandoned Quarries and Mine Pits in KeralaDocument90 pagesReport On Reuse of Abandoned Quarries and Mine Pits in KeralaDrThrivikramji Kyth100% (10)

- Datasheet S7-300Document124 pagesDatasheet S7-300mar3a3p3rez-22No ratings yet

- Sesiones de Technical EnglishDocument90 pagesSesiones de Technical EnglishBill Klinthon Chiara100% (1)

- Test Bank For Entrepreneurship Theory Process and Practice 10th Edition by KuratkoDocument36 pagesTest Bank For Entrepreneurship Theory Process and Practice 10th Edition by Kuratkosanityenhanceqould1100% (54)

- Girder - Arrangement 04 08 2023Document9 pagesGirder - Arrangement 04 08 2023sanyogitasawant5No ratings yet

- High Voltage Switching Operations: The Next StepDocument2 pagesHigh Voltage Switching Operations: The Next Steplenon chidzivaNo ratings yet

- Formulation - of - Corrosion - Inhibitors-Yun Chen and Wenzhong Yang 23 PAGESDocument23 pagesFormulation - of - Corrosion - Inhibitors-Yun Chen and Wenzhong Yang 23 PAGESChoice Organo100% (4)

- Monash Sustainability Institute - Annual Activity Report 2013Document76 pagesMonash Sustainability Institute - Annual Activity Report 2013Monash Sustainability InstituteNo ratings yet