Professional Documents

Culture Documents

검 사 증 명 서 Mill Test Certificate: EN10204 3.1/ISO 10474 3.1B

검 사 증 명 서 Mill Test Certificate: EN10204 3.1/ISO 10474 3.1B

Uploaded by

ClarkFedele27Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

검 사 증 명 서 Mill Test Certificate: EN10204 3.1/ISO 10474 3.1B

검 사 증 명 서 Mill Test Certificate: EN10204 3.1/ISO 10474 3.1B

Uploaded by

ClarkFedele27Copyright:

Available Formats

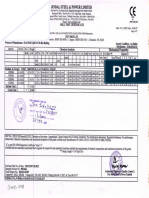

CERTIFICATE NO(성적서 번호)

DATE OF ISSUE(발행일자)

: E602905

: 2020-06-16

Page 1 of 2

검사증명서

CONTRACT(P/O) NO.(계약번호)

: MILL TEST CERTIFICATE

PR NO.(주문서번호)

: F200300325 EN10204 3.1/ISO 10474 3.1B

COMMODITY(제품명) : H.F.W. STEEL PIPE CUSTOMER(고객사): VAN LEEUWEN PIPE AND TUBE GULF FZE

SPECIFICATION(제품규격) : API 5L B M PSL2

Hydrostatic Tensile Properties(Gage Length : 2 inch) Hardness Test CVN Impact Test D.W.T Test( ℃)

TYPE Test Tensile Strength CVN Impact Test(0℃)

TOTAL Yield Y/R Max.

OF SIZE PCS WEIGHT Spec. E.L Shear Area(%)

LENGTH Base Weld Strength Rate Value Absorbed Energy(Joule) Shear

No. PIPE OUT-DIA×THICK×LENGTH HEAT No. Pressure Time ※2 Area

END (외경×두께×길이) ※2 MPa MPa MPa % % ※3 HV 1 2 3 avg (%) 1 2 avg

※3

Specimen

Min. 415 415 245 size 21 27

※1 (본) (KG) (M) PSI SEC

Max. 655 450 93 248 Criteria : In the case of 10×10)

1 EB BE 508 X 12.7 mm X 12.000 M 111 206,620 1,332 SU48862 1070 10 T 520 538 391 75 40 B 179 B-T90 10X10 161 149 155 155 95

T 527 538 397 75 41 H 192

W 176

2 EB BE 508 X 12.7 mm X 12.000 M 137 255,017 1,644 SU48863 1070 10 T 518 529 377 73 40 B 180 B-T90 10X10 143 137 139 140 95

T 525 529 394 75 42 H 182

W 179

3 EB BE 508 X 12.7 mm X 12.000 M 139 258,740 1,668 SU48864 1070 10 T 523 521 382 73 39 B 184 B-T90 10X10 148 149 151 149 95

T 529 520 400 76 40 H 193

W 175

4 EB BE 508 X 12.7 mm X 12.000 M 140 260,602 1,680 SU48865 1070 10 T 525 527 383 73 38 B 199 B-T90 10X10 115 114 111 113 95

T 533 523 392 74 39 H 182

W 185

Chemical Composition(%) 2 :×100 3 :×1000 4 :×10000 Zn-Coating Test HC-Test H.I.C Test Remark

Mn CEQ PCM Copper Sulfate Collapse

Spec. C Si P S Cu Ni Cr Mo V Ti Nb B Zn Coating Pressure CLR CTR CSR S.S.C.C ※1) Type of pipe end(관종) EB:ERW Black BE:Bevel End

※7 ※5 ※6 Test Test ※2) L: Longitudinal, T: Transverse

No. Heat No. 2 2 2 3 3 2 2 2 3 3 3 3 4 3 3 Time Result psi % % %

※4 ※3) B: Base, W: Weld Line, H: Heat Affected Zone

Min. ※4) H: Heat(Ladle) Analysis, P: Product Analysis

Max. 22 45 120 25 15 50 30 30 150 50 40 50 10 430 250 ※5) CEQ=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15 (If, C > 0.12)

1 SU48862 H 13 15 89 12 3 ※6) PCM=C+Si/30+(Mn+Cu+Cr)/20+Ni/60+Mo/15+V/10+5B (If, C ≤ 0.12)

P 14 14 87 13 4 1 1 2 2 2 1 9 5 288 189 ※7) For each reduction of 0.01% below the specified max.

for C, an increase of 0.05% above the specified max.

P 14 14 86 12 3 1 1 2 2 2 1 9 5 286 188

for Mn is permissible, up to a max. of 1.65%

2 SU48863 H 14 15 91 10 3

※ Heat Treatment Temperature: Min 1050℃

P 14 14 88 10 4 1 1 2 2 2 1 9 5 297 197 ※ Tensile test : Strip specimen(1T180, Width : 38.1mm)

P 14 14 88 10 4 1 1 2 2 2 1 9 4 294 194 ※ SPEC YEAR - API 5L 46th Edition(2018)

3 SU48864 H 14 16 92 11 3 ※ This material has been fully killed and made by basic oxygen process

P 14 15 89 11 3 1 1 2 3 2 1 10 4 293 192 (TMCP)

※ Hardness to NACE MR0175(2013ED) / ISO 15156 : Max.248Hv

P 13 15 89 11 3 1 1 2 3 2 1 10 4 289 188

※ Metallographic Test : GOOD

4 SU48865 H 14 16 91 12 3

※ API 5L Annex.E(N.D.E) : O.D<6":ECT(1.6mm hole), O.D>6":UT(3.2mm

P 14 15 87 12 5 1 1 2 2 2 1 10 4 288 190 hole)

P 14 15 88 12 5 1 1 2 3 2 1 11 5 293 194 ※ HR coil manufactured by : POSCO(KOREA)

Non-Destructive Test Flattening / Residual Magnetism

Heat Treatment Visual & Dimension

(U.T) Bending Test (Gauss)

GOOD GOOD GOOD GOOD GOOD

본 제품은 관련 규격에 합격되었음을 보증합니다.

This material has been manufactured, sampled, tested and inspected in accordance with the specification and has been found to meet the requirements.

* 본 검사증명서에 명기된 규격용도외 사용시 안전상 문제가 발생할 수 있으며, 검사증명서 위.변조시 사문서 위조로 불이익을 당하실 수 있습니다.

SURVEYOR QA Manager

* 본 검사증명서는 원본인 전자문서(전자서명 정보 포함)로부터 출력된 사본입니다. 전자문서의 내용은 현대제철 고객포탈에서 확인하실 수 있습니다.(http://sm.hyundai-steel.com/cs/cm/login.jsp)

* This Mill Test Certificate is a copy that has been printed from original electronic document(with digital signing).

You are able to check an original electronic document at hyundaisteel's customer portal.( http://sm.hyundai-steel.com/cs/cm/login.jsp) * QRcode scanner App : 'QReal'

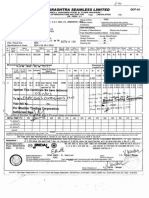

CERTIFICATE NO(성적서 번호)

DATE OF ISSUE(발행일자)

: E602905

: 2020-06-16

Page 2 of 2

검사증명서

CONTRACT(P/O) NO.(계약번호)

: MILL TEST CERTIFICATE

PR NO.(주문서번호)

: F200300325 EN10204 3.1/ISO 10474 3.1B

COMMODITY(제품명) : H.F.W. STEEL PIPE CUSTOMER(고객사): VAN LEEUWEN PIPE AND TUBE GULF FZE

SPECIFICATION(제품규격) : API 5L B M PSL2

Hydrostatic Tensile Properties(Gage Length : 2 inch) Hardness Test CVN Impact Test D.W.T Test( ℃)

TYPE Test Tensile Strength CVN Impact Test(0℃)

TOTAL Yield Y/R Max.

OF SIZE PCS WEIGHT Spec. E.L Shear Area(%)

LENGTH Base Weld Strength Rate Value Absorbed Energy(Joule) Shear

No. PIPE OUT-DIA×THICK×LENGTH HEAT No. Pressure Time ※2 Area

END (외경×두께×길이) ※2 MPa MPa MPa % % ※3 HV 1 2 3 avg (%) 1 2 avg

※3

Specimen

Min. 415 415 245 size 21 27

※1 (본) (KG) (M) PSI SEC

Max. 655 450 93 248 Criteria : In the case of 10×10)

5 EB BE 508 X 12.7 mm X 12.000 M 126 234,541 1,512 SU48866 1070 10 T 518 525 378 73 39 B 189 B-T90 10X10 113 105 107 108 95

T 522 525 398 76 39 H 183

W 176

6 EB BE 508 X 12.7 mm X 12.000 M 126 234,541 1,512 SU48867 1070 10 T 527 521 394 75 38 B 189 B-T90 10X10 129 126 129 128 95

T 529 519 399 75 38 H 197

W 189

7 EB BE 508 X 12.7 mm X 12.000 M 44 81,904 528 SU48869 1070 10 T 528 533 386 73 38 B 193 B-T90 10X10 92 101 102 98 95

H 179

W 178

TOTAL 823 1,531,965 9,876

Chemical Composition(%) 2 :×100 3 :×1000 4 :×10000 Zn-Coating Test HC-Test H.I.C Test Remark

Mn CEQ PCM Copper Sulfate Collapse

Spec. C Si P S Cu Ni Cr Mo V Ti Nb B Zn Coating Pressure CLR CTR CSR S.S.C.C ※1) Type of pipe end(관종) EB:ERW Black BE:Bevel End

※7 ※5 ※6 Test Test ※2) L: Longitudinal, T: Transverse

No. Heat No. 2 2 2 3 3 2 2 2 3 3 3 3 4 3 3 Time Result psi % % %

※4 ※3) B: Base, W: Weld Line, H: Heat Affected Zone

Min. ※4) H: Heat(Ladle) Analysis, P: Product Analysis

Max. 22 45 120 25 15 50 30 30 150 50 40 50 10 430 250 ※5) CEQ=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15 (If, C > 0.12)

5 SU48866 H 14 15 89 12 4 ※6) PCM=C+Si/30+(Mn+Cu+Cr)/20+Ni/60+Mo/15+V/10+5B (If, C ≤ 0.12)

P 14 15 88 12 5 1 1 2 3 2 1 10 4 291 191 ※7) For each reduction of 0.01% below the specified max.

for C, an increase of 0.05% above the specified max.

P 14 15 88 11 4 1 1 2 3 2 1 11 3 290 190

for Mn is permissible, up to a max. of 1.65%

6 SU48867 H 14 15 90 11 4

※ Heat Treatment Temperature: Min 1050℃

P 14 15 90 12 5 2 1 2 2 2 1 11 3 292 190 ※ Tensile test : Strip specimen(1T180, Width : 38.1mm)

P 13 15 90 12 5 2 1 2 2 2 1 11 3 290 188 ※ SPEC YEAR - API 5L 46th Edition(2018)

7 SU48869 H 13 15 91 12 4 ※ This material has been fully killed and made by basic oxygen process

P 13 15 89 12 5 2 1 2 2 2 1 9 4 288 186 (TMCP)

※ Hardness to NACE MR0175(2013ED) / ISO 15156 : Max.248Hv

P 13 15 90 12 5 2 1 2 2 2 1 10 3 291 188

※ Metallographic Test : GOOD

※ API 5L Annex.E(N.D.E) : O.D<6":ECT(1.6mm hole), O.D>6":UT(3.2mm

hole)

※ HR coil manufactured by : POSCO(KOREA)

Non-Destructive Test Flattening / Residual Magnetism

Heat Treatment Visual & Dimension

(U.T) Bending Test (Gauss)

GOOD GOOD GOOD GOOD GOOD

본 제품은 관련 규격에 합격되었음을 보증합니다.

This material has been manufactured, sampled, tested and inspected in accordance with the specification and has been found to meet the requirements.

* 본 검사증명서에 명기된 규격용도외 사용시 안전상 문제가 발생할 수 있으며, 검사증명서 위.변조시 사문서 위조로 불이익을 당하실 수 있습니다.

SURVEYOR QA Manager

* 본 검사증명서는 원본인 전자문서(전자서명 정보 포함)로부터 출력된 사본입니다. 전자문서의 내용은 현대제철 고객포탈에서 확인하실 수 있습니다.(http://sm.hyundai-steel.com/cs/cm/login.jsp)

* This Mill Test Certificate is a copy that has been printed from original electronic document(with digital signing).

You are able to check an original electronic document at hyundaisteel's customer portal.( http://sm.hyundai-steel.com/cs/cm/login.jsp) * QRcode scanner App : 'QReal'

You might also like

- 9.1 Corporate Profile: SchlumbergerDocument5 pages9.1 Corporate Profile: SchlumbergerClarkFedele27No ratings yet

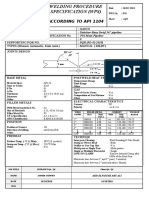

- Welding Procedure Specification (WPS) : According To Api 1104Document1 pageWelding Procedure Specification (WPS) : According To Api 1104Maged Lotfy Abdel-aal100% (1)

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema NandhNo ratings yet

- Flange 10 & 12 InchDocument2 pagesFlange 10 & 12 InchreniNo ratings yet

- TubacexDocument1 pageTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Document2 pagesMill'S Test Certificate ACC. TO EN 10204 / 3.1Durulsan MakinaNo ratings yet

- 1.20mm T.C - Mehta SteelsDocument1 page1.20mm T.C - Mehta SteelsRonak FireNo ratings yet

- 16 MM MS Plate 355 JR - India-MTCDocument1 page16 MM MS Plate 355 JR - India-MTCQc QatarNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- Cert ACERO INOX 316L PDFDocument1 pageCert ACERO INOX 316L PDFCarlos RomeroNo ratings yet

- Valve Inspection and Test PlanDocument1 pageValve Inspection and Test PlanClarkFedele27100% (1)

- Technical Submittal - PF-K & Er-VDocument50 pagesTechnical Submittal - PF-K & Er-VClarkFedele27No ratings yet

- AASHTODocument39 pagesAASHTOResearcher50% (2)

- Raw Material MTC - API 5L GR B PSL 2Document3 pagesRaw Material MTC - API 5L GR B PSL 2ClarkFedele27No ratings yet

- MTC 17 4PH Al20201127a174Document1 pageMTC 17 4PH Al20201127a174Ajeng PratiwiNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- Certificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Document1 pageCertificado Tubo 1.1-2 AC SC SCH 80 X 5.8-1Raul Esteban Jaimes GalvisNo ratings yet

- Material Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical PropertiesDocument4 pagesMaterial Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical PropertiesŠâįf ÄhmāđNo ratings yet

- ASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Document1 pageASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Omar Bautista Díaz100% (1)

- MTC - Rel-01 (Rev.00)Document16 pagesMTC - Rel-01 (Rev.00)Alam MD SazidNo ratings yet

- MTC 5Document1 pageMTC 5Muthazhagan SaravananNo ratings yet

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan Ortega100% (1)

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- No. A-14-401751 Rev 00Document3 pagesNo. A-14-401751 Rev 00Adrian CeplinschiNo ratings yet

- DMR-223 0001Document2 pagesDMR-223 0001Avishek GuptaNo ratings yet

- MTC Item # 01Document18 pagesMTC Item # 01ClarkFedele27No ratings yet

- 1 MTCDocument2 pages1 MTCRazvan CristeaNo ratings yet

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- Red DN80 50 50936Document1 pageRed DN80 50 50936slimane AIT-IDIRNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- MTC - Oufo (Argentina) - 16Document1 pageMTC - Oufo (Argentina) - 16Aceros DessolNo ratings yet

- Ribo TC 324 (00000003)Document1 pageRibo TC 324 (00000003)Vinay YadavNo ratings yet

- Outokumpu: Si MN P S CR NiDocument3 pagesOutokumpu: Si MN P S CR NiDarkedgeNo ratings yet

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdDocument1 pageTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocNo ratings yet

- Page 1 of 1: Test Certificate No. 0000141878Document1 pagePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNo ratings yet

- Fittings ThrededDocument2 pagesFittings ThrededreniNo ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- Wenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicateDocument1 pageWenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicatePerumal Govindan100% (1)

- TC No-1451Document1 pageTC No-1451Structures ProductionNo ratings yet

- Mgoha : ' "Xsjjl8Document1 pageMgoha : ' "Xsjjl8PetroPower OilandgasNo ratings yet

- Vedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKDocument23 pagesVedanta Limited Cairn Oil & Gas: Integrated Field Plan Execution Services in Satellite Fields in Rj-On 90/1 BLOCKPRAKASH PANDEYNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- Commented - 8' PIPE TCDocument1 pageCommented - 8' PIPE TCAqib Khan VCSPNo ratings yet

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- MFF Spect. Blind 6 CL 150Document1 pageMFF Spect. Blind 6 CL 150Mohamed RaafatNo ratings yet

- Abnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Document1 pageAbnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Mohamed RaafatNo ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 2.5 MM 1250....Document1 page2.5 MM 1250....Balaji Defence100% (1)

- JSW Steel MTCDocument5 pagesJSW Steel MTCNelson 2428No ratings yet

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- MTC PDFDocument170 pagesMTC PDFShoukat Zaki0% (2)

- Jyoti Steel Industries: Test Certificate As Per en 10204-3.1Document1 pageJyoti Steel Industries: Test Certificate As Per en 10204-3.1Gagat GongatNo ratings yet

- Rajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1Document1 pageRajendra Ferromet Pvt. LTD.: Material Test Certificate According To en 10204:2004 / 3.1qualityNo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- Test Certificate: CM/L-NO:5530357Document10 pagesTest Certificate: CM/L-NO:5530357TARUNKUMARNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- Mill Test Reports 19mm 26mmDocument2 pagesMill Test Reports 19mm 26mmkayshephNo ratings yet

- MTC Annexure (6 Inch)Document16 pagesMTC Annexure (6 Inch)maheshNo ratings yet

- 08.05.2019 Npu 400Document2 pages08.05.2019 Npu 400Yasin BaturNo ratings yet

- Engineering Materials: Important NotesDocument1 pageEngineering Materials: Important NotesMiftahul IslamNo ratings yet

- Valve GADDocument2 pagesValve GADClarkFedele27No ratings yet

- APS Business ReferencesDocument3 pagesAPS Business ReferencesClarkFedele27No ratings yet

- 18B. Protegol UR 32.55R Data SheetDocument3 pages18B. Protegol UR 32.55R Data SheetClarkFedele27No ratings yet

- Non Destructive Testing FacilityDocument158 pagesNon Destructive Testing FacilityClarkFedele27No ratings yet

- Sutech Valves - Product RangeDocument5 pagesSutech Valves - Product RangeClarkFedele27No ratings yet

- Wedding Song ChordsDocument13 pagesWedding Song ChordsClarkFedele27No ratings yet

- Product Data: Carboguard 190 HDocument2 pagesProduct Data: Carboguard 190 HClarkFedele27100% (1)

- Copon EA 4-2217 Data SheetDocument2 pagesCopon EA 4-2217 Data SheetClarkFedele27No ratings yet

- Carbothane 134Document2 pagesCarbothane 134ClarkFedele27No ratings yet

- Carbozinc 11: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11: Selection & Specification Data Substrates & Surface PreparationClarkFedele27No ratings yet

- CatalogueDocument2 pagesCatalogueClarkFedele27No ratings yet

- Venting Requirement - API 2000 5th EditionDocument1 pageVenting Requirement - API 2000 5th EditionClarkFedele27No ratings yet

- APS - New Capability StatementDocument12 pagesAPS - New Capability StatementClarkFedele27No ratings yet

- Avery Hardoll Whittaker Controls 4 Inch Self Sealing Ind CouplingsDocument2 pagesAvery Hardoll Whittaker Controls 4 Inch Self Sealing Ind CouplingsClarkFedele27No ratings yet

- 24 150 8811 DTR.L Go.aDocument1 page24 150 8811 DTR.L Go.aClarkFedele27No ratings yet

- 24 150 8811 DTR.L Ma.g Fa14Document1 page24 150 8811 DTR.L Ma.g Fa14ClarkFedele27No ratings yet

- Cameron: Valves & Measurement General Arrangement 4"-150 CL, MODEL 211, 201 HO Safety Bleed/DtrDocument1 pageCameron: Valves & Measurement General Arrangement 4"-150 CL, MODEL 211, 201 HO Safety Bleed/DtrClarkFedele27No ratings yet

- 20 150 8811 DTR.L Ma.g Fa14Document1 page20 150 8811 DTR.L Ma.g Fa14ClarkFedele27No ratings yet

- 16 150 8811 DTR.L Ma.g Fa14 - Rev02Document1 page16 150 8811 DTR.L Ma.g Fa14 - Rev02ClarkFedele27No ratings yet

- 04 150 211 DTR.L Mat Fa10Document1 page04 150 211 DTR.L Mat Fa10ClarkFedele27No ratings yet

- Ace 00480 01001 R5Document2 pagesAce 00480 01001 R5ClarkFedele27No ratings yet

- Orbit Facility ProfileDocument23 pagesOrbit Facility ProfileClarkFedele27No ratings yet

- Brochure Alfa 2019Document15 pagesBrochure Alfa 2019ClarkFedele27No ratings yet

- PO Box 4038, Doha, Qatar Telephone (+974) 4407 6000 / 4460 0099 /4407 6444 Fax: (+974) 4407 6498Document12 pagesPO Box 4038, Doha, Qatar Telephone (+974) 4407 6000 / 4460 0099 /4407 6444 Fax: (+974) 4407 6498ClarkFedele27No ratings yet

- Ace 02380 001 R8 PDFDocument1 pageAce 02380 001 R8 PDFClarkFedele27No ratings yet

- ALFA Monolithic Isolation Joint Brochure - FinalDocument4 pagesALFA Monolithic Isolation Joint Brochure - FinalClarkFedele27No ratings yet

- MPS No 89 Rev 0 Grade BR PSL 2Document7 pagesMPS No 89 Rev 0 Grade BR PSL 2ClarkFedele27No ratings yet

- Membrane StructuresDocument51 pagesMembrane Structuresimalzeolandicho100% (1)

- Building Construction Costs Handbook 2019-2020Document89 pagesBuilding Construction Costs Handbook 2019-2020Rotich philipNo ratings yet

- 37 Mohammed Falalu HamzaDocument10 pages37 Mohammed Falalu HamzatridaysNo ratings yet

- Design Considerations For Multi-Story Podium ProjectsDocument89 pagesDesign Considerations For Multi-Story Podium ProjectsDavid GoshadzeNo ratings yet

- Class 10 Chemistry Model Paper 1 Solution FDocument11 pagesClass 10 Chemistry Model Paper 1 Solution Ffbk28177No ratings yet

- Making Stones in Alchemy-Hauck PDFDocument3 pagesMaking Stones in Alchemy-Hauck PDFNeilNo ratings yet

- International Catalogue 2019Document324 pagesInternational Catalogue 2019ag22klaNo ratings yet

- FMMQ - Assignment 2Document7 pagesFMMQ - Assignment 2Paras MangleNo ratings yet

- Weberfloor 514 SL TDS SelflevelDocument3 pagesWeberfloor 514 SL TDS SelflevelMusab yassinNo ratings yet

- 05 Aramco Approved Coating SystemDocument3 pages05 Aramco Approved Coating SystemRyanNo ratings yet

- CompositeDocument24 pagesCompositeKartik SharmaNo ratings yet

- Acoustic Doors - Hinged Wooden AcoustVVic Door - Acoustic Wooden Door - Sound Proof Doors by Ecotone AcousticsDocument5 pagesAcoustic Doors - Hinged Wooden AcoustVVic Door - Acoustic Wooden Door - Sound Proof Doors by Ecotone AcousticsEdifice Placement SolutionsNo ratings yet

- 2019-08-25 Rated Boq - InteriorDocument2 pages2019-08-25 Rated Boq - Interiorstudiopy0% (1)

- Property TablesDocument33 pagesProperty Tablesapi-543054399No ratings yet

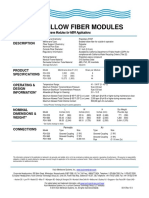

- Datasheet - PURON MBR Modules PSH330 PSH660 PSH1800 Rev 15-3 PDFDocument1 pageDatasheet - PURON MBR Modules PSH330 PSH660 PSH1800 Rev 15-3 PDFAlok singhNo ratings yet

- SPECTITE Inc Cat1Document12 pagesSPECTITE Inc Cat1Abraham100% (1)

- SFG FULL FormDocument3 pagesSFG FULL FormMohammed Tanjil Morshed remonNo ratings yet

- New Simplified Chemistry Class 8 ICSE Solution1Document10 pagesNew Simplified Chemistry Class 8 ICSE Solution1Aalana MachadoNo ratings yet

- Partial Replacement of Cement With Marbl PDFDocument3 pagesPartial Replacement of Cement With Marbl PDFamish rajNo ratings yet

- Industrial Training Report of Panshul JamwalDocument31 pagesIndustrial Training Report of Panshul Jamwalपाँशुल जम्वाल राजपूतNo ratings yet

- Sunepoxy PaintDocument1 pageSunepoxy PaintAiyaz BhatiNo ratings yet

- 3 of 3 Worksheet Class Viii Science L-6combustion and FlameDocument4 pages3 of 3 Worksheet Class Viii Science L-6combustion and FlameRekha kumariNo ratings yet

- Manufacturing Processes & Production TechniquesDocument3 pagesManufacturing Processes & Production TechniquesQwer QwerNo ratings yet

- b2dd7155a726e1676b9bde8c30b698cdDocument133 pagesb2dd7155a726e1676b9bde8c30b698cdvirender ohriNo ratings yet

- CH301 Worksheet 9 (Answer Key) Rank The Following Solution Properties (From Lowest To Highest) : C H, H O, CH, NHDocument2 pagesCH301 Worksheet 9 (Answer Key) Rank The Following Solution Properties (From Lowest To Highest) : C H, H O, CH, NHJohn BartolomeNo ratings yet

- MOM Menara-JO 21 SeptemberDocument3 pagesMOM Menara-JO 21 SeptemberAmaliahAisyahRakhmiNo ratings yet

- International Standard CodesDocument6 pagesInternational Standard CodesMubashar Islam JadoonNo ratings yet

- Tubing Capacities DisplacementsDocument2 pagesTubing Capacities DisplacementsIkki Ventrue-100% (1)