Professional Documents

Culture Documents

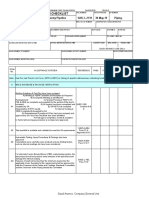

Saudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 Mech

Saudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 Mech

Uploaded by

junaidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 Mech

Saudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 Mech

Uploaded by

junaidCopyright:

Available Formats

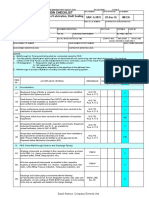

SAUDI ARAMCO ID/PIEU - 25-Apr-2017 - REV. 2018.02.00 (Standards Cutoff -February 28, 2018) Rev. 2018.02.

00 28-Feb-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM IPLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Documentation:

All agreed “Yes” items on the MCC Exception Item List shall have been

GI-2.710

A1 completed and approved by the Acceptance Committee members or their

Para. 4.1.1.3

representatives.

Saudi Aramco Test and Inspection Plan (SATIPs) & their applicable

GI-2.710

A2 checklists for field installation as detailed in SATIP-K-511-01 have been

Para. 4.1.1.2

verified to be complete and accepted.

All non-conformance reports and worksheets have been resolved to the GI-2.710

A3

satisfaction of Inspection Department. Para. 4.1.1.4

All log book entries have been resolved to the satisfaction of Inspection GI-2.710

A4

Department. Para. 4.1.1.4

All equipment fabrication documents, inspection record books, and

GI-2.710

A5 Equipment Instrument Schedules (EIS) are available for

Para. 4.1.1.6

review/Verification

All operation and Maintenance (O & M) manuals have been submitted to

the proponent for review four (4) weeks prior to Mechanical Completion GI-2.710

A6

Note: Process O&M manuals for facilities must be approved by the Para. 4.1.1.7

Proponent before Mechanical Completion (MC)

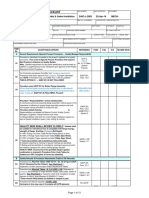

B P&ID Check/Walkthrough (Suction and Discharge Piping)

All piping components are installed in their respective locations as shown

P&ID #

B1 in the P&ID. (i.e.: piping, removable pipe spools, valves, vents, drains,

____________

spectacle plates, blinds, flange spacers, etc)

All in-line equipment & Instruments are installed in their respective

P&ID #

B2 locations as shown in the P&ID. (i.e.: Strainer, straightening vanes, flow

____________

meter, orifice fitting, Pressure Indicators, Temperature indicators, etc)

Colour coded Discharge and Suction piping are stenciled with the

following: SAES-L-350,

B3

a. Flow directional arrows and fluid service Sec. 20

b. Line designation number, size, class and specification

Identification are stenciled on major components such as but not limited

to : (Note: Identification shall follow Equipment identification number

designated on the P&ID)

a. Identification number for pumps

SAES-L-350,

B4 b. Strainer

Sec. 20

c. Flow element/flow meter

d. Control Valves

e. MOV's

f. Relief Valves

GI-2.710

Relief valves were calibrated, tagged and form 3099A was completed per

B5 Supplement 6

SATIP-J-600-01

Para 5.14a

Saudi Aramco: Company General Use

If pumps were used for flushing, verify that temporary packing were

GI-2.710

B6 installed if permanent packing or mechanical seal were not suitable for

Item 5.7 c

flushing.

Saudi Aramco: Company General Use

You might also like

- 05continuous Univariate Distributions, Vol. 1 PDFDocument769 pages05continuous Univariate Distributions, Vol. 1 PDFUsherAlexander0% (1)

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Miller v. AlabamaDocument62 pagesMiller v. AlabamaDoug MataconisNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul Hafeez SoomroNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAnonymous S9qBDVky100% (1)

- Saic e 2008Document4 pagesSaic e 2008usmanNo ratings yet

- SAIC-A-2013 Rev 0Document4 pagesSAIC-A-2013 Rev 0qazi12No ratings yet

- Saic F 2008Document4 pagesSaic F 2008usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeDocument7 pagesSaudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeAnonymous S9qBDVkyNo ratings yet

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- Saic-G - 2019Document2 pagesSaic-G - 2019SUNIL RAJPUTNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechDocument32 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Centrifugal Pumps SAIC-G-2002 29-Dec-16 MechAbdul Hafeez SoomroNo ratings yet

- Saic L 2002Document13 pagesSaic L 2002chidambaramNo ratings yet

- Saudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldDocument32 pagesSaudi Aramco Inspection Checklist: Pre-Welding Inspection (Shop & Field) of Plant Piping SAIC-W-2005 15-Dec-09 WeldIrshad Iqbal100% (2)

- SAIC-G-2022 Rev 2Document25 pagesSAIC-G-2022 Rev 2faisal hussainNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistHesham HelalNo ratings yet

- Saudi Aramco Inspection Checklist 6232Document19 pagesSaudi Aramco Inspection Checklist 6232Munir Choudary100% (1)

- SAIC-L-2094 Rev 7Document18 pagesSAIC-L-2094 Rev 7Jaseel KanhirathingalNo ratings yet

- Saic P 3002Document1 pageSaic P 3002aneeshjokay0% (1)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Relief Valves SAIC-J-2006 24-Jul-18 MechDocument5 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Relief Valves SAIC-J-2006 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistjunaidNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistshahzadaNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 Mechkarthi51289No ratings yet

- Saic H 2060Document11 pagesSaic H 2060jerinNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistnadeem shaikhNo ratings yet

- Saic M 1067Document2 pagesSaic M 1067mathew.genesis.inspNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Field Applied Internal Coatings & Repairs SAIC-H-2057Document3 pagesSaudi Aramco Inspection Checklist: Review Procedure - Field Applied Internal Coatings & Repairs SAIC-H-2057Allan LindoNo ratings yet

- Saudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldDocument19 pagesSaudi Aramco Inspection Checklist: Post Weld Heat Treatment (PWHT) For On-Plot Piping SAIC-W-2004 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocument12 pagesSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- Saudi Aramco Inspection ChecklistDocument12 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- SATR-D-2003 Vessel Closure Inspection CertificateDocument1 pageSATR-D-2003 Vessel Closure Inspection CertificateAnonymous S9qBDVkyNo ratings yet

- SAIC-L-2092 Rev 7Document12 pagesSAIC-L-2092 Rev 7Jaseel KanhirathingalNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection Checklist: Completion of Form 3099A SAIC-J-2010 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Completion of Form 3099A SAIC-J-2010 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Relief Valve Authorization SAIC-J-2005 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Review of Relief Valve Authorization SAIC-J-2005 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 29-Dec-16 MechAbdul HafeezNo ratings yet

- Saudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 MechDocument5 pagesSaudi Aramco Inspection Checklist: Foam Generating Equipment - Installation Insp & Testing SAIC-B-2014 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saic L 2139Document9 pagesSaic L 2139Kumar RNo ratings yet

- SAIC-P-3602 Rev 3Document3 pagesSAIC-P-3602 Rev 3DipuNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- SAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FDocument8 pagesSAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FKirubhakarPooranamNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- SAIC-P-3627 Rev 3Document13 pagesSAIC-P-3627 Rev 3Leonil Ibañez BiñanNo ratings yet

- SAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinDocument2 pagesSAIC-L-2038 Rev 7 - Final Inspection For Release of Fabricated PipinLipika GayenNo ratings yet

- Saic B 4001Document2 pagesSaic B 4001usmanNo ratings yet

- Saudi Aramco Inspection Checklist: Piping / Equipment Internal Cleaning InspectionDocument4 pagesSaudi Aramco Inspection Checklist: Piping / Equipment Internal Cleaning InspectionDilshad Ahemad100% (1)

- SAIC-A-2001 - Review Procedure - Pressure Testing (All Applications)Document13 pagesSAIC-A-2001 - Review Procedure - Pressure Testing (All Applications)walidNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 PipingDocument15 pagesSaudi Aramco Inspection Checklist: Review Procedure - Post Test Reinstatement & Checklist SAIC-A-2006 30-Apr-13 Pipingpookkoya thangalNo ratings yet

- Sac Inspection Checklist: Piping-Review of Positive Material Identification Program and Testing ProcedureDocument2 pagesSac Inspection Checklist: Piping-Review of Positive Material Identification Program and Testing Procedurehusnain aliNo ratings yet

- SAIC-L-2002 Rev 6Document13 pagesSAIC-L-2002 Rev 6biplabpal2009No ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- Saudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldAbdul Khaleem KhanNo ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechDocument6 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritNo ratings yet

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Document6 pagesSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNo ratings yet

- Wiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsFrom EverandWiley Practitioner's Guide to GAAS 2016: Covering all SASs, SSAEs, SSARSs, PCAOB Auditing Standards, and InterpretationsNo ratings yet

- Codification of Statements on Auditing Standards: Numbers 122 to 133, January 2018From EverandCodification of Statements on Auditing Standards: Numbers 122 to 133, January 2018No ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection ChecklistjunaidNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistjunaidNo ratings yet

- Saudi Aramco Inspection Checklist: Hood Installation SAIC-K-4036 25-Apr-18 HvacDocument3 pagesSaudi Aramco Inspection Checklist: Hood Installation SAIC-K-4036 25-Apr-18 HvacjunaidNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistjunaidNo ratings yet

- Learning Quran With Reference: By: Saim ShahariarDocument22 pagesLearning Quran With Reference: By: Saim ShahariarJohn PlayerNo ratings yet

- Esther Mead Resume 2020 EducationDocument2 pagesEsther Mead Resume 2020 Educationapi-285157849No ratings yet

- BDS VAM®+TOP+Casing Regular 9.625 47.00 RegularDocument1 pageBDS VAM®+TOP+Casing Regular 9.625 47.00 RegularFajar PutraNo ratings yet

- Pre Oral DefenseDocument2 pagesPre Oral Defensevj hernandezNo ratings yet

- Script Logic TutorialDocument6 pagesScript Logic TutorialRakesh KumarNo ratings yet

- Ateneo de Manila University: RD STDocument3 pagesAteneo de Manila University: RD STMichelle FelloneNo ratings yet

- Act No 3083 and CA 327Document1 pageAct No 3083 and CA 327FJ Valerio - LumioNo ratings yet

- JewellersDocument33 pagesJewellersPrashant shamarao YadavNo ratings yet

- Using AnsysDocument27 pagesUsing AnsysAboalmaaliNo ratings yet

- TB6600 Toshiba Datasheet PDFDocument8 pagesTB6600 Toshiba Datasheet PDFArmin SelimovicNo ratings yet

- Manoj Kumar StatementDocument19 pagesManoj Kumar StatementramamodupuNo ratings yet

- Gingival Depigmentation - Case SeriesDocument6 pagesGingival Depigmentation - Case SeriesDr.Niveditha SNo ratings yet

- Psna College of Engineering and Technology, Dindigul Department of Mechanical Engineering Assignment - I Class - Cse - D ConicsDocument1 pagePsna College of Engineering and Technology, Dindigul Department of Mechanical Engineering Assignment - I Class - Cse - D Conicsbalusharma1212No ratings yet

- Abonesh Tesfaye Agri. Economics - Jan. 2007Document246 pagesAbonesh Tesfaye Agri. Economics - Jan. 2007Rafez JoneNo ratings yet

- Curriculum DevelopmentDocument20 pagesCurriculum DevelopmentCathlyn Jane LorenzoNo ratings yet

- Chinar Public School Class-9 Social Science Sample Paper: General InstructionsDocument10 pagesChinar Public School Class-9 Social Science Sample Paper: General InstructionsLakshit ChoudharyNo ratings yet

- Q2 Tle Reviewer PDFDocument6 pagesQ2 Tle Reviewer PDFFire RobloxNo ratings yet

- SECTION 15830 FansDocument6 pagesSECTION 15830 FansfatREVITNo ratings yet

- Make Up Sentences: 1. Circle The Right ItemDocument4 pagesMake Up Sentences: 1. Circle The Right ItemNatalieNo ratings yet

- Sabine Pass Approval Order, DOEDocument50 pagesSabine Pass Approval Order, DOEcprofitaNo ratings yet

- Phil 107 Fall 2013 Moore-2Document6 pagesPhil 107 Fall 2013 Moore-2Austin McEverNo ratings yet

- Maths Test Report 19 Feb 2024 To 09 Apr 2024 50 TestsDocument4 pagesMaths Test Report 19 Feb 2024 To 09 Apr 2024 50 TestsBat SenjiNo ratings yet

- GFH 44Document9 pagesGFH 44Marie MedinaNo ratings yet

- CRM Assignment 2Document11 pagesCRM Assignment 2Arneet SarnaNo ratings yet

- Argumentative Essay Outline: Hook Thesis StatementDocument2 pagesArgumentative Essay Outline: Hook Thesis StatementHafizah NORHAFIZAH BINTI SYOFIYAN100% (1)

- Computer System ServicingDocument54 pagesComputer System ServicingCABADONGA, Justin M.No ratings yet

- Edenham Newsletter No17 21 July 2017Document6 pagesEdenham Newsletter No17 21 July 2017mattwebbeNo ratings yet

- Alumni LetterDocument2 pagesAlumni LetterTubban JAy-AReNo ratings yet