Professional Documents

Culture Documents

By Michel Bruneau, Associate Member, ASCE ABSTRACT: Probabilistic System-Reliability Methods Have The Potential To Assist

By Michel Bruneau, Associate Member, ASCE ABSTRACT: Probabilistic System-Reliability Methods Have The Potential To Assist

Uploaded by

Eman SalehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

By Michel Bruneau, Associate Member, ASCE ABSTRACT: Probabilistic System-Reliability Methods Have The Potential To Assist

By Michel Bruneau, Associate Member, ASCE ABSTRACT: Probabilistic System-Reliability Methods Have The Potential To Assist

Uploaded by

Eman SalehCopyright:

Available Formats

EVALUATION O F SYSTEM-RELIABILITY M E T H O D S

FOR CABLE-STAYED BRIDGE DESIGN

By Michel Bruneau, 1 Associate Member, ASCE

ABSTRACT: Probabilistic system-reliability methods have the potential to assist

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

designers in better understanding the ultimate global behavior of bridges, thus

leading to more economical, rational, and reliable structures. Nonetheless, these

techniques are not currently broadly used in North American bridge engineering

practice. Using a sample cable-stayed bridge design, a study is conducted to assess

the practicability of system-reliability analytical methods to assist in the design of

cable-stayed bridges. Ductile and brittle cables are considered in series and mixed

system analyses, respectively. The sample bridge selected is found to be very re-

liable; the most likely failure mode identified is somewhat counterintuitive. More

importantly, considerable insight into global ultimate behavior is provided by these

analyses, and the effect of various design assumptions on global structural safety

can be assessed. Some obstacles to the transfer of system-reliability procedures to

the state of practice are identified.

INTRODUCTION

The theory of structural system reliability is well established; its funda-

mental analytical methods are comprehensively presented by many authors

(Ang and Tang 1984; Thoft-Christensen and Murotsu 1986; Melchers 1987;

Harr 1987). These powerful procedures allow the evaluation of the safety

of a total structural system as opposed to that of its constituent components,

although that global assessment invariably depends on the local ones.

Structural reliability methods, considering applied loads and resistance

of individual structural elements as random variables, have been used ex-

tensively for the development of limit states design (LSD) bridge codes,

including the Ontario Highway Bridge Design Code (1983) and the CSA

standard S6-M88 ("Design of" 1988). This implicitly reflects that design is

normally performed at the component level.

There may be instances, however, where structural system-reliability may

assist the designer in better understanding the ultimate global behavior of

a structure, which could lead to a more rational and economical final design.

Such benefits would be particularly expected for complex and highly re-

dundant structural systems. Nonetheless, these structural system-reliability

analytical techniques are apparently not broadly used in North American

bridge engineering practice. It is conjectured that the absence of those well-

established analytical procedures from the state of practice is attributable

to a deficient knowledge of system reliability theory by the designers' com-

munity, a poor data base of the needed pertinent information, and the lack

of incentives provided by traditional structural engineering approaches and

the associated competitiveness pressures.

Methods to rationally quantify structural redundancy in bridges, in a

system-reliability perspective, have been presented by some researchers

'Asst. Prof., Civ. Engrg. Dept., 161 Louis Pasteur, Univ. of Ottawa, Ottawa,

Ontario, Canada, K I N 6N5.

Note. Discussion open until September 1, 1992. T o extend the closing date one

month, a written request must be filed with the ASCE Manager of Journals. The

manuscript for this paper was submitted for review and possible publication o n

November 7, 1990. This paper is part of the Journal of Structural Engineering, Vol.

118, No. 4, April, 1992. ©ASCE, ISSN 0733-9445/92/0004-1106/$1.00 + $.15 per

page. Paper No. 872.

1106

J. Struct. Eng. 1992.118:1106-1120.

(Tharmabala and Nowak 1987; Frangopol and Nakib 1990). Some mathe-

matical models focusing on the study of bridge reliability have also been

proposed (Tharmabala and Nowak 1987), and used in combination with

results from load tests to improve system-reliability assessments of an ex-

isting steel truss bridge (Nowak and Tharmabala 1988). Such studies remain

few at this time.

Cable-stayed bridges are perceived to be relatively safe under gravity

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

loads, as commented by Tang (1984) based on deterministic observations.

Nonetheless, system-reliability studies are essential to probabilistically quan-

tify this confidence. Such advanced analytical methods, which can lead to

more economical, rational, and reliable structures, should be of great in-

terest to designers. Since it is already recognized and anticipated that the

engineering efforts required for the design of cable-stayed bridges exceed

those required for more standard bridge configurations, other technical

barriers are currently preventing the integration of these methodologies into

state of practice. These must be identified.

The objective of this study is to assess the practicability of system-relia-

bility analytical methods to assist in the design of cable-stayed bridges. In

an attempt to meet this objective, a sample cable-stayed bridge is designed

by the writer, and system-reliability methods are applied to the resulting

design. The usefulness and practicability of the exercise is assessed. How-

ever, the conduct of a complete sensitivity analysis is beyond the scope of

the reported work.

It is noteworthy that this research simultaneously provides some rough

preliminary estimates of the structural safety index, (3, germane to cable-

stayed bridge design practice in North America, but the emphasis of this

limited investigation does not actually lie in an accurate determination of

this index.

DESCRIPTION OF SAMPLE CABLE-STAYED BRIDGE STUDIED

The bridge geometry (Fig. 1) is selected to be representative of a medium-

span cable-stayed bridge for which a single tower construction at midspan

is assumed possible. The total length of the bridge is 180 m. An increasing

number of short- and moderate-span cable-stayed bridges with only a few

cables are being constructed in North America.

For simplicity, the deck is selected to be a multispine steel box girder of

constant cross section, for which the plastic moment is attainable and large

inelastic deformations possible without undesirable local or global instability

effects. The central tower is chosen to actually consist of two towers of

uniform cross section, joined by a horizontal cross-beam immediately lo-

cated below the roadway, to form an H-shape in cross-elevation; full plas-

ticity can also be developed for this simple tower configuration.

30 m

25 m

6@30m

FIG. 1. Geometry of Sample Cable-Stayed Bridge Studied

1107

J. Struct. Eng. 1992.118:1106-1120.

Other particulars of that deterministic design are as follows.

8

The bridge is designed in compliance to the CAN3-S6-M78 ("Design

of" 1978) Canadian standard, a working stress design earlier edition of

the current CSA standard.

• The deck width is selected to accommodate two lanes of traffic, both

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

physically and as per the codified design model.

• Symmetry along the centerline of the roadway permits consideration of

only half of the total structure. All loads and properties herein are

specified accordingly.

• Uniform dead load is 45 kN/m.

• Uniform live load is 26 kN/m. This is representative of the Canadian

Standard Association (CSA) specified lane loading for a MS-250 truck

considering most unfavorable lateral placement of lane loading, impact

considerations, reduction for multiple lane loadings, and conversion,

for simplicity, of the point-load that CSA-S6-M78 specifies must be

simultaneously applied with the lane load, into an additional contri-

bution to the uniformly distributed load (UDL).

• The lane load model governs over the truck model for the current

design.

• Only the design of the major structural elements is performed in this

exercise.

• G40.21-M 350W steel is selected for the deck and tower with a resulting

allowable design stress of 210 MPa in both tension and compression.

In the final design, the sum of bending and axial stresses divided by

this allowable is 0.71 for the towers and 1.0 for the beams. More it-

erations to further optimize the tower design were not conducted. Re-

ductions in the provided tower strength, and concurrent increases in

tower flexibility, would also lead to increased girder strength demand

under unbalanced live loads, with little overall benefits.

• High-strength steel cables are selected with 2,250 MPa ultimate stress

capacity. The allowable stresses are determined using a factor of safety

of 3. Cables are prestressed to eliminate deflections due to dead loads

at the cable/deck attachment point. Wind loads, ice accretion, or other

loads on the cables are neglected in this design. For analysis purposes,

the cables are modeled as tension-only truss elements.

• The deck is connected at the tower such that it is restrained against

longitudinal movements, but free to rotate.

• P-A and nonlinear geometric effects for this design are very small; thus,

they are neglected in both the original design and subsequent reliability

analyses.

• Shear lag effects are not significant for the selected multispine double

box-girder cross section of the deck, and have been neglected.

• No composite action is assumed to exist between the concrete deck and

steel box girders.

• No efforts are made to optimize the design beyond the efficient design

of individual structural elements.

A commercial linear-elastic structural analysis program (Wilson and Ha-

bibullah 1989) is used to assist in the design of the structure. Some properties

of the resulting half-structure are presented in Table 1. A detailed pres-

1108

J. Struct. Eng. 1992.118:1106-1120.

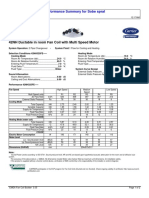

TABLE 1. Numerical Values of Random Variables

Deterministic Distribution a standard GOV

Item value type u, (mean) deviation = (X/CT

(D (2) (3) (4) (5) (6)

FY tower and deck 350 MPa Normal 367.5 MPa 36.75 MPa 0.10

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

FU C a b l e s ( = F r nominal) 2,250 MPa Normal 2,363 MPa 236.3 MPa 0.10

Cable area (A) 6,500 mm2 Normal 6,500 mm2 10,000 mm2 0.05

Deck area (A) 200,000 mm 2

Normal 200,000 mm2 10,000 mm2 0.05

Tower area (A) 250,000 mm2 Normal 250,000 mm2 12,500 mm2 0.05

Plastic modulus deck (Z) 0.0682 m3 Normal 0.0682 m3 0.00341 m3 0.05

Plastic modulus tower (Z) 0.219 m3 Normal 0.219 m3 0.0109 m3 0.05

Dead load io0 45 kN/m Normal 47.25 kN/m 4.73 kN/m 0.10

Live load o)L 26 kN/m Normal 32.7 kN/m 4.27 kN/m 0.13

entation of additional parameters considered or resulting from the static

design is beyond the scope of this paper.

RELIABILITY ANALYSIS

Random Variables

Sectional properties (A,Z), material yield stress (FY), and applied, uni-

formly distributed dead and live loads (wD and wL, respectively) are chosen

as the random variables of interest for this study. Plastic capacities are direct

functions of those variables.

The probability distributions and statistical moments of common struc-

tural engineering random variables presented by Ellingwood (1983) and

Ellingwood et al. (1980) are deemed appropriate for this study; nonetheless,

bridge live loads are not covered by those documents and require a separate

assessment. The results of studies by Agarwal and Wolkowicz (1976), Buck-

land and Sexsmith (1981), Foster et al. (1981), and Harman and Davenport

(1979) are considered to define the live-load random parameters.

In the survey of individual truck weights, conducted by the Ontario Min-

istry of Transportation and Communication (MTC), and reported by Agar-

wal and Wolkowicz (1976), a superposition of three normal curves was found

to best fit the curve of collected data (Foster et al. 1981). The mean and

standard deviation from the normal curve fitting the zone of heaviest trucks

are 480 kN and 62.7 kN, respectively.

For the spans under consideration herein, a uniformly distributed live

load governs design. The uniform lane load model selected for this reliability

analysis is that suggested by Harman and Davenport (1979). It has been

derived recognizing that live load, which must simulate accurately the effects

of multiple trucks on a bridge, depends mainly on the random weight of

each truck, the random sequence of truck along spans, the aspect of influ-

ence lines on which it is acting, the random distance between truck queuing,

and may be dependant of traffic-jam loading.

According to this model, the corresponding magnitude of the mean max-

imum 50-year uniform lane live load, q, is obtained by spreading the weight

of the mean heaviest truck load over a length of 18.3 m, and multiplying it

by a factor, K, which accounts for the effect of rare occurrence of multiple

truck presence in a given lane on long spans. The value of K depends on

the span; for a length of 90 m, it is 0.6. Thus, for the case at hand

1109

J. Struct. Eng. 1992.118:1106-1120.

( 480 k N \

,° „

18.3 m /

= 0.6 x (26.2 kN/m) = 15.7 kN/m (1)

over the length and for each lane of the bridge. The reader is referred to

the aforementioned papers if additional probabilistic information on this

topic is sought.

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

Finally, q is multiplied by the same factors previously used during the

design phase to take into account the most unfavorable lateral placement

of lane loading, impact considerations, and reduction for multiple lane load-

ing, to obtain the resulting mean 50-year maximum value of the uniformly

distributed live-load value, wL = 32.7 kN/m. This load is applied over

whatever length necessary to produce the most critical effect. Using the

coefficient of variation (COV) measured in MTC's survey, the correspond-

ing standard deviation is 4.27 kN/m.

Table 1 summarizes the resulting values calculated for the selected random

variables. Not surprisingly, mean values do not necessarily equal the spec-

ified or calculated deterministic values. Also, for simplicity in this study,

uncertainties associated with the structural analysis and with the design

equations for resistance have been neglected.

It is noteworthy that traffic live-load characteristics and model definitions

used in many countries, states, or provinces vary substantially. In a cable-

stayed bridge, the bending moments in the deck and towers under permanent

loads are held to a minimum by cable adjustments, and consequently, live

load has a more considerable effect in this kind of structure. Therefore,

special care must be taken before extrapolating the findings of this study in

an international perspective.

Ductile Cable Systems—Series System Analysis

When all structural components, including the cables, are ductile, struc-

tural system failure will occur by formation of a collapse plastic mechanism.

The performance functions can be directly obtained from the virtual work

expressions describing the failure plastic mechanisms. The identification of

these mechanisms, along with plastic-hinge locations and corresponding

plastic capacities, is involved, but once this is accomplished, the determi-

nation of the structural system reliability simply consists of identifying, in

a probabilistic sense, the weakest mechanism, much like series system anal-

ysis.

Effects of Axial Loads

Both deck and tower behave as beam-column components. The signifi-

cance of axial force on plastic capacities must therefore be assessed. From

simple plastic analysis theory and assuming that the neutral axis at ultimate

stays within the webs of an hollow rectangular section, the well-known axial

bending interaction curve is defined as:

— = 1 - (lL\2-¥-

(2)

MP \pP) AwZx

where M = the applied moment; MP = the plastic moment capacity in the

absence of axial loads; P = the applied axial force; PP = the plastic axial

force capacity in the absence of applied moment; A = the cross-sectional

area; w = the sum of the web thicknesses; and Zx = the plastic modulus

around the axis of bending.

1110

J. Struct. Eng. 1992.118:1106-1120.

For the bridge's deck, reductions in plastic moments due to axial force

are neglected in the formulation of performance functions since bending

moment effects are found to be largely dominant. Deterministic evaluations

of the maximum reductions of Mp at ultimate are found to be at worst 5%

in this case.

For the tower, except for the formulation of one pure axial force per-

formance function (compression failure) under maximum balanced loads,

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

bending is a dominant factor in spite of the large axial forces, and simpler

plastic capacity expressions ignoring the bending/axial interaction curve are

again found to be acceptable.

Probabilistic Failure Plastic Analysis

The first-order second-moment (FOSM) method (in which two measures,

the mean value and the standard deviation of probability density functions,

are considered) was used for this study (Special Publication 1981; Ellingwood

et al. 1980; Nowak and Lind 1979). This method uses a linear approximation

of the performance functions at the most likely failure point. Reliability is

measured by a safety index, 3, which can be translated into notional prob-

abilities of failure, pf, according to the relationship:

P/=*(-P) (3)

where <!>( •) = the standard normal cumulative probability, available in most

mathematical handbooks. Alternatively, the following closed-form equation

(MacGregor 1976) can be used to relate (3 and F^for very small probabilities

of failure:

pf = 460 e" 43 P (4)

Conceptually, a performance function, Z, is expressed as the difference

of the structural resistance, R, and effect of the applied loads, S, random

variables. Failure occurs ii Z = R — S < 0. The safety index is related to

the mean and the standard deviation of the performance function, by the

following ratio:

P = ^ (5)

Actual failure functions for structural components or systems must include

the effect of various loads and resistances, the latter dependant on different

material strengths and geometry, each with its own probability curve. A

generalized formulation of the limit state failure equation, or performance

function, can be written as:

Z(x[,x'2, . . .,x'n) = 0 (6)

where x\ = a set of uncorrelated reduced variates

x[ = {—-^j i = 1, 2, . . ., n (7)

where x\ = the basic random variables; and \LXI and <sxi = their respective

means and standard deviations.

The performance function can be visualized as a multidimensional surface

in an n-dimension space, where p is the minimum distance from the origin

1111

J. Struct. Eng. 1992.118:1106-1120.

to that failure surface. The solution of the structural reliability problem

essentially consists in finding the coordinates x[ * of that point on that surface,

for which

x'* = -af p i = 1, 2, . . ., n (8)

and where the direction cosines, af, perpendicular to the failure surface,

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

are:

W/*

a? = 2 (9)

y? w)*

As the pertinent point of tangency on the failure surface is initially un-

known, a numerical iteration strategy must be implemented to achieve

convergence for any nonlinear performance function and probability di-

tribution. An existing computer program, developed to perform these

structural-reliability operations, is used in this study (Liu et al. 1989).

Fourteen different plastic collapse mechanisms are considered in the for-

mulation of performance functions. These functions are tabulated in Table

2, and corresponding failure mechanisms are illustrated in Fig. 2. The pro-

gram considers all these performance functions, as well as the numerical

values and type of probability distributions of the related random variables,

and calculates their individual first-order probabilities and safety indices.

Four different sets of numerical values for the key random variables are

considered. In each case, mean and standard deviations of all variables

listed in Table 1 have been used, unless indicated otherwise for some specific

TABLE 2. Performance Functions Considered for Series System Analysis

Z,(X) = Cj Mp Deck + C 2 MP Tower + C3 u>L + C4 cop + C5 TP Cable + C6 PP Tower

i C, c2 c3 Q c5 Ce

(1) (2) (3) (4) (5) (6) (7)

1 1.0 — -56.25 -56.25 — —

2 1.0 — -75.0 -75.0 — —

3 3.0 — -900.0 -900.0 13.42 —

4 4.0 — -900.0 -900.0 13.42 —

5 3.0 — -2,025.0 -2,025.0 26.82 —

6 3.0 0.928 -900.0 -900.0 12.44 —

7 4.5 0.928 -900.0 + 450.0 — —

8 2.0 0.464 -1,350.0 -1,350.0 18.66 —

9 3.0 0.464 -1,350.0 — — —

10 4.0 2.782 -900.0 -900.0 12.44 —

11 4.5 4.172 -900.0 + 450.0 — —

12 6.0 0.695 -1,350.0 — 34.22 —

13 3.0 0.253 -1,350.0 — 9.05 —

14 — — -154.0 -154.0 — 1.0

—

N O t e : MP D e c k — -^Deck **y Decki MP Tower *™ ^Towcr *'Y Toweri ^ P Cable -^Cable ** U Cable)

Pp Tower - ^Tower Fy Towerl compatible units are kN and meter.

1112

J. Struct. Eng. 1992.118:1106-1120.

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

FIG. 2. Plastic Collapse Mechanisms Considered in Formulation of Performance

Functions—Live Load Only Applied to Portion of Span Producing Positive Work

when Undergoing Plastic Mechanism Action ('Indicates Cable Yielding; Broken

Line Symbolizes Plastic Compression Failure of Tower for Case 14, or Cables in

Compression, i.e., Not Contributing, for All Other Cases)

TABLE 3. Values of Random Variables Modified in Cases 1 - 4 of This System-

Reliability Study; H- and <x are Mean and Standard Deviations Symbols

Case 3

Item Case 1 Case 2 (actual design) Case 4

(1) (2) (3) (4) (5)

Dead load (j, (kN/m) 45.0 45.0 47.25 47.25

Dead load u (kN/m) 0.0 0,0 4.73 4.73

Live load (j, (kN/m) 26.0 26.0 32.7 32.7

Live load <r (kN/m) 0.0 0.0 4.27 4.27

Cable area (m2) 0.0065 0.0044 0.0065 0.0044

variables in Table 3. In the first two sets (cases 1 and 2), the mean dead

loads and live loads are equal to the specified deterministic design values,

and the respective standard deviations null. This is used to provide bench-

marks where the variability of the loads has been eliminated, the measure

of the safety index being only dependant on the random variables related

to material properties and geometry. In the last two sets (cases 3 and 4),

the probabilistic system-reliability evaluations proceed using the actual val-

ues of the live- and dead-load random variables derived in a previous section.

While cases 1 and 3 provide probabilistic assessments of the original design

and the relative effects of loads variability, cases. 2 and 4 are included to

roughly assess the potential consequences on this bridge's system reliability

of a reduction in the cable safety factor, from 3 to 2, as modeled by a 33%

1113

J. Struct. Eng. 1992.118:1106-1120.

reduction in the area of all cables. It is acknowledged that this reduction

of safety factor would be of large consequence on the safety index, (3, of

the cable element alone, but its influence on system reliability remains to

be investigated. Nonetheless, the reduction in area is implemented only

parametrically in the reliability analysis; the original structural configuration

is unchanged.

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

Analysis of Results

Results for the 14 previously described performance functions are pre-

sented in Table 4. Failure modes are ranked in order of increasing safety

index, i.e., from the highest probabilities of failure to the lowest. A large

number of observations on those findings is following.

• In all cases, the first failure mode does not include any cable failure;

it involves overall rocking of the superstructure by plastic hinging in

the deck and in the tower just above the deck, in spite of the presumed

conservative tower design. This mode of structural system failure is

somewhat counterintuitive, and could have been overlooked if not for

this system-reliability analysis. In fact, increases in cable strength would

not improve the system reliability of that bridge.

• Variation of the safety factor of cables has a greater impact on the

remaining noncritical failure modes and their relative ranking. Failure

modes involving cable failure(s) are identified in Table 4.

• Although changes in the ranking of the various plastic collapse mech-

anisms are modest when comparing the relative effects of loads varia-

bility (e.g., cases 1 versus case 3), this could be of profound significance

if a capacity design philosophy is sought by strengthening portions of

the structure to either delay or prevent some undesirable failure modes.

While consequences of strengthening the tower, or other parts of the

TABLE 4. Safety Indices for All Structural System Plastic Collapse Mechanisms

Case 1 Case 2 Case 3 Case 4

Failure Safety Failure Safety Failure Safety Failure Safety

mode index mode index mode index mode index

(1) (2) (3) (4) (5) (6) (7) (8)

9 6.83 9 6.83 9 5.32 9 5.32

2 7.83 5a 7.02 5" 7.32 5a 5.70

a

5 8.13 2 7.82 2 7.40 8a 7.27

1 8.38 1 8.38 1 8.08 2 7.40

14 8.81 8a 8.57 8a 8.46 1 8.08

8a 9.24 14 8.81 14 8.61 3" 8.19

7 9.83 3a 9.36 3a 9.14 14 8.61

3a 9.84 7 9.83 7 9.31 4 a

9.01

11 9.93 11 9.93 11 9.77 7 9.31

4 a

10.49 4 a

10.09 4 a 9.82 13 9.74

6a 11.37 6a 10.72 13 10.61 11 9.77

13 11.79 10a 11.00 6a 10.72 6a 9.84

a

10 11.93 13 11.43 10a 11.57 10" 10.62

12a 12.27 12a 12.74 12a 12.06 12a 12.42

'Plastic collapse mechanism involving cable failure(s).

1114

J. Struct. Eng. 1992.118:1106-1120.

bridge, on the global safety can be inferred from the results tabulated

in Table 4, a redesign under any changed conditions would be man-

datory to validate such deductions. However, the superiority of the

probabilistic evaluation, over the deterministic one, lies largely in the

capacity to calculate credible safety indices.

In spite of the limited redundancy of this structure as compared with

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

that of large cable-stayed bridges, safety indices for the structure as a

whole are considerably larger than that of individual structural com-

ponents.

The critical p is 5.32. A conservative original design may be partly

accountable for this high level of safety. Most other plastic-collapse

mechanisms, with safety indices above 6, are highly unlikely to occur.

It is noteworthy that the interaction of bending and axial loads is partly

instrumental to the high structural system reliability calculated. While

the performance functions are developed from plastic collapse mech-

anisms in which the reduction in plastic moments due to the presence

of axial force is negligible, the bridge is designed using working stress

philosophy in which the axial effect is weighted with the same impor-

tance as the bending effect; the difference between the axial-bending

elastic and inelastic interaction curves is considerable. In addition, the

previously mentioned conservative tower design also contributes to the

high overall reliability.

The substantial insight into the ultimate behavior of the structure pro-

vided by these analyses can be used advantageously to prevent unde-

sirable failure modes. A capacity design philosophy could be imple-

mented such that a local noncollapse failure mechanism would develop

at a higher probability of failure than the first structural system-failure

mode, thus warning of structural distress locally without endangering

the structure globally. Stringers or other local deck components could

be designed to a lower safety index to serve for that purpose. In other

words, by providing an upper bound on the strength of local structural

components (relatively to that of other key structural elements), easily

repairable local failure modes could be ensured to be more probable

than the first global structural failure mode whose occurrence would be

of dramatic consequences.

The determination of the performance functions for this simple structure

is a lengthy exercise. The lack of computerized assistance in this task

may preclude the applicability of system-reliability to more complex

multi-cable/multi-tower bridges.

Finally, the large safety factors traditionally used in the design of in-

dividual cables are also intended to provide protection against a number

of factors which are difficult to quantify by system-reliability studies at

this time. Corrosion at the cable anchorage is one of these problems,

especially for bridges that remain un-maintained for years (the author

has inspected structures where severe corrosion affected more than a

third of the original cable effective area). Fatigue, loss of prestress due

to anchorage slippage, stress relaxation, and dynamic effects are some

of the other problems anticipated by designers, leading to generous

allocation of safety factors in cable design: It is noteworthy that there

is no standard practice in this regard, and that some designers will

1115

J. Struct. Eng. 1992.118:1106-1120.

instead affix safety factors of different magnitudes to various aspect of

behavior to protect against unsatisfactory performance.

Brittle Cables—Mixed System Analysis

Cables used in bridges often cannot be considered ductile, contrary to

the assumption adopted in a previous section. In some cases, the nonlinear

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

inelastic behavior, which may occur due to compaction of the strand, will

be eliminated by prestretching operations performed by the manufacturer

to linearize the behavior up to a very high resistance. In spite of this, while

the stress-strain diagram of cable steel does show a genuine plastic plateau,

the elongation at rupture is considerably smaller than for mild steel (Gimsing

1983). In fact, the plastic strains of the cable steel may not be sufficient to

allow the attainment of the plastic collapse mechanisms previously consid-

ered. Thus, the study of the bridge as a mixed system, where cables are

brittle but the rest of the structure is ductile, is necessary.

Analysis

For this mixed systems, an event tree approach is adopted. This meth-

odology is well described by Ang and Tang (1984), Thoft-Christensen and

Murotsu (1986), and others. Points of possible component failures for the

chosen simple bridge structure are identified in Fig. 3. Points A - E identify

regions of potential negative moment plastic hinges in the deck, and F - H

that of potential plastic hinges in the tower. Points I - L represent failure of

the brittle cables, and M - R localize where positive moment plastic hinging

is possible in the deck.

Some engineering assumptions are necessary as, even for this simple

structure, calculation of probabilities of failure in all possible branches of

the event tree represent an unreasonable computational effort. A consid-

erable amount of judgement is used to limit the cases studied to a smaller

representative subset; this may be more difficult on a more complex struc-

ture, and computer programs providing assistance for this decision making

would be most useful. For the case at hand, results from the series analysis

provided some guidance to identify dominant failure modes.

For each identified structural element, a component reliability analysis is

performed to calculate a probability of failure for this single element. Each

cable failure or local plastic hinge modifies the previous load-resistance path,

effectively triggering a new load redistribution among the remaining struc-

tural elements; in each case, the bridge is reanalyzed using a properly mod-

ified model. At each step, the process is repeated for the updated resulting

structural behavior, i.e., new performance functions are derived, and new

probabilities of failure are calculated for some selected components. For

expediency, progression along a given path on the event tree is stopped

when probabilities of failure for the subsequent events are expected to be

considerably high, even if the complete failure mechanism has not yet been

FIG. 3. Points of Possible Component Failures for Mixed System Analysis

1116

J. Struct. Eng. 1992.118:1106-1120.

attained. Still, the number of manual operations remains large, especially

since there is no existing interface currently available to bridge the static

analysis and reliability based programs. The prioritary workstation-based

structural reliability program PROBAN (1989) has apparently been suc-

cessfully linked to a structural analysis program to automatically handle

these operations in the perspective of a fault-tree analysis for brittle struc-

tural systems (Mehta, Private Communication, Veritas Sesam Systems

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

A. S., Det Norske Veritas, H0vik, Norway). However, this feature is not

available in the commercial version of PROBAN at the time of this writing,

but its inclusion in future releases is apparently being considered.

Analysis of Results

The partial event tree resulting from this analysis is presented in Fig. 4.

It is believed that all of the paths significantly contributing to the probability

of failure have been identified. The summation of the probability of failures

corresponding to each path give the forecasted total system probability of

failure. This calculated value ispf = 1.53 x 10~6. The effect of correlation

between modes of failure is not considered. Not surprisingly, due to the

brittleness of the cables, the failure probability of the system is raised beyond

that obtained with ductile cables, to a resulting safety index of (3 = 4.54.

The determination of system reliability for mixed systems is found to

require considerably more engineering effort than for comparable series

Hinee (a) A p, = 7.53 x 10'7

p, = 0.546 x lO"'

Hinge (5) E

p, = 0.138 x W Cable Failure p, = 1.40 x 10"'

p, = 0.102 x 10 J

Hinge (S G p, = 6.51 x 1 0 "

p, = 0.472 x 10-'

Hinee (3 C p, = 9.18 x 1 0 '

pr = 0.5951

Failure (5) J

pf = 0.154 x 10-' Failure (3> I p, = 2.56 x 10 41

p, = 0.166 x 10"

Hinge @ G p, = 5.00 x 1 0 "

p, = 0.323 x lO*

Hinge (ffl B pr = 6.26 x lO'10

p, = 0.764

Failure (5) I

p, = 0.820 x lO* Failure (a) J p, = 4.80 x 10' 2

p, = 0.586 x 10 J

Hinge (a) F p, = 5.32 x 1 0 "

pf = 0.649 x 10°

Hinge & G

p, = 0.362 x lO"* p,-1.0 p, = 3.62 x 1 0 '

(XpJ x 2 (symmeliy) = 1.53 x 10*

FIG. 4. Partial Event Tree Resulting from Mixed System Analysis of Sample Bridge

1117

J. Struct. Eng. 1992.118:1106-1120.

systems. As mentioned previously, without a computer-aided environment

tailored to address this problem, the incremental complexity inherent to

more realistic multicable bridges will hinder the transfer of this technology

to the state of practice. An efficient algorithm to address this problem in a

systematic manner is not available in the public domain at this time; although

the aforementioned strategy could undoubtedly be imitated, it may not be

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

an approach suited to the implementation of a sophisticated integrated

production tool. It is speculated that the algorithm used in the aforemen-

tioned PROBAN software package will likely not be distributed given its

prioritary nature. More research on this topic is required.

Given the laborious effort required for the system-reliability assessment

of an already designed structure, it appears unrealistic to expect these an-

alytical methods to routinely assist in the design of new structures at this

time. These state-of-the-art analytical methods may nonetheless prove jus-

tified for the evaluation of existing structures for which reliability is ques-

tioned and which are found to be deficient using traditional deterministic

analysis procedures. It could be a rational alternative to the use of reduced

load factors proposed elsewhere (Foster et al. 1981).

CONCLUSIONS

The application of the system-reliability theory to a simple cable-stayed

bridge provides useful insight into the potential failure modes of such struc-

tures and reveals how additional strength can be best apportioned to further

enhance overall reliability. The sample structure selected has proven to be

very reliable.

Nonetheless, the assessment of this system reliability for the simple se-

lected bridge is a rather involved exercise. While an improved understanding

of the ultimate global behavior logically leads to more economical, rational,

and reliable structures, the absence of an integrated computer program

combining both the standard static and reliability analyses significantly de-

ters from conducting such assessment of structural reliability, even more so

in a design perspective. Additional research is needed to determine how

this integration of complex engineering software is best achieved. The re-

sulting reduction in engineering efforts (and costs) required would hopefully

provide the needed incentive to bring these most valuable reliability analysis

techniques to the state of practice for the design of such complex structures

having numerous potential failure modes.

Further research is also required for integrating the deterioration effect

of corrosion, fatigue, and other practical problems, in the formulation of

the performance functions, particularly if aiming at the evaluation of existing

bridges. Future system-reliability studies incorporating wind and seismic

loading, P-A effects and geometric nonlinearities of such bridges are also

desirable.

Finally, this study confirms that system reliability has the potential to

become a useful engineering analytical tool. It not only provides a quan-

tification of global structural safety, but may also be used to avoid needlessly

reinforcing structural components who do not contribute to the most likely

failure mode, or similarly, to limit the upper-bound strength of local struc-

tural components (relatively to that of other key structural elements), to

ensure that easily repairable local structural failure modes are more probable

than the first more dramatic global failure mode, in a perspective similar

to that of capacity design in earthquake engineering.

1118

J. Struct. Eng. 1992.118:1106-1120.

ACKNOWLEDGMENTS

The writer thanks A. DerKiureghian of the University of California,

Berkeley, for providing the framework that made this study possible, in-

cluding early prereleases versions of the necessary reliability-analysis pro-

grams, and for his valuable comments. The findings and conclusions of this

paper are, however, those of the writer alone.

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

APPENDIX. REFERENCES

Agarwal, A. C , and Wolkowicz, M. (1976). "Ontario commercial vehicle survey."

Interim Report, Engrg. Res. and Dev. Branch, Ontario Ministry of Transp. and

Communications, Downsview, Ontario, Canada.

Ang, A. H-S., and Tang, W. H. (1984). Probability concepts in engineering planning

and design, Volume II: Decision, risk, and reliability, John Wiley & Sons, New

York, N.Y.

Buckland, P. G., and Sexsmith, R. G. (1981). "A comparison of design load for

highway bridges." Canadian J. Civ. Engrg., 8(1), 16-21.

"Design of highway bridges." (1978). CAN3-S6-M78, Nat. Standard of Canada,

Canadian Standard Assoc, Rexdale, Ontario, Canada.

"Design of highway bridges." (1988). CAN3-S6-M88, Nat. Standard of Canada,

Canadian Standard Assoc, Rexdale, Ontario, Canada.

Ellingwood, B. (1983). "Probabilistic codified design." Structural reliability: Theory

and applications, Univ. of California, Berkeley, Calif.

Ellingwood, B., Galambos, T. V., MacGregor, J. C , and Cornell, C. A. (1980).

"Development of a probability-based load criterion for American standard A58."

National Bureau of Standards Special Publication No. SP 577, Nat. Bureau of

Standards, Washington, D.C.

Foster, R. L., Peterson, C. W., and Buckland, P. G. (1981). "Commentary on clause

12' existing bridge evaluation of CAN3-S6-M78, supplement No. 1-1980." Cana-

dian J. Civ. Engrg., 8(2), 196-205.

Frangopol, D. M., and Nakib, R. (1990). "Damage-redundancy-reliability interac-

tion in bridge analysis." Third Int. Conference on Short and Medium Span Bridges,

Toronto, Canada, 343-350.

Gimsing, N. J. (1983). Cable supported bridges. John Wiley & Sons, New York,

N.Y.

Harr, M. E. (1987). Reliability-based design in civil engineering. McGraw-Hill, New

York, N. Y.

Harman, D. J., and Davenport, A. G. (1979). "A statistical approach to traffic

loading on highway bridges. Canadian J. Civ. Engrg., 6(4).

Liu, P. L., Lin, H. Z., and DerKiureghian, A. (1989). CALREL—A computer

program for structural reliability analysis, Dept. of Civ. Engrg., Univ. of California,

Berkeley, Calif.

MacGregor, J. G. (1976). Safety and limit states design for reinforced concrete. Ca-

nadian Soc for Civ. Engrg., Univ. of Alberta and the Portland Cement Assoc,

Edmonton, Alberta, Canada.

Melchers, R. E. (1987). Structural reliability, analysis and prediction. John Wiley &

Sons, New York, N.Y.

Nowak, A. S., and Lind, C. (1979). "Practical code calibration procedures." Ca-

nadian J. Civ. Engrg., 6, 112-119.

Nowak, A. S., and Tharmabala, T. (1988). "Bridge reliability evaluation using load

tests." /. Struct. Engrg. J., 114(10), 2268-2279.

Ontario Highway Bridge Design Code. (1983). Ministry of Transp. of Ontario, High-

way Engrg. Div., Ontario, Canada.

PROBAN—Computer Program for Probabilistic Reliability and Sensitivity Analysis.

(1989). Det Norske Veritas, Veritas Sesam Systems A.S., H0vik, Norway.

Special publication—S408-1981—Guideline for the development of limit states design.

(1981). Canadian Standard Assoc, Rexdale, Ontario, Canada.

1119

J. Struct. Eng. 1992.118:1106-1120.

Tang, M. C. (1984). "Safety of cable-stayed bridges." Proc. of the 4th ASCE Specialty

Conference on Probabilistic Mech. and Struct. Reliability, ASCE, 432-435.

Thoft-Christensen, P., and Murotsu, Y. (1986). Application of structural system

reliability theory. Springer-Verlag, New York, N.Y.

Tharmabala, T., and Nowak, A. S. (1987). "Mathematical models for bridge reli-

ability." Canadian J. Civ. Engrg., 14(2), 155-162.

Wilson, E. L., and Habibullah, A. (1989). SAP-90: Structural analysis program.

Computers & Structures Inc., Berkeley, Calif.

Downloaded from ascelibrary.org by University of Cincinnati on 11/13/14. Copyright ASCE. For personal use only; all rights reserved.

1120

J. Struct. Eng. 1992.118:1106-1120.

You might also like

- Design of An Industrial TrussDocument15 pagesDesign of An Industrial Trussammarsteel68No ratings yet

- API 570 Study Guide - FullDocument18 pagesAPI 570 Study Guide - Fullochable100% (1)

- MEP ChecklistDocument8 pagesMEP ChecklistvirtechNo ratings yet

- 52c, P-3ae PtacDocument56 pages52c, P-3ae Ptackennethfbarnes0% (1)

- Ajrua6 0001122Document25 pagesAjrua6 0001122Vinay KumarNo ratings yet

- Dimensional Analysis in NDT Rigid Pavement EvaluationDocument14 pagesDimensional Analysis in NDT Rigid Pavement EvaluationAnabelPradoSNo ratings yet

- Yang Et Al. Seismic Performance Evaluation of Facilities - PACTDocument9 pagesYang Et Al. Seismic Performance Evaluation of Facilities - PACTJaime MercadoNo ratings yet

- System Reliability Analysis of Transmission Line Towers: Pergamon 00457949 (94) E0206-HDocument8 pagesSystem Reliability Analysis of Transmission Line Towers: Pergamon 00457949 (94) E0206-HJitendraNo ratings yet

- Structure and Infrastructure Engineering: Maintenance, Management, Life-Cycle Design and PerformanceDocument18 pagesStructure and Infrastructure Engineering: Maintenance, Management, Life-Cycle Design and PerformanceAnna's ParadiseNo ratings yet

- Design RigidDocument11 pagesDesign RigidRushikesh sapkalNo ratings yet

- Ezzeldin 2017Document11 pagesEzzeldin 2017Benjamin RuzNo ratings yet

- FatigueDocument12 pagesFatigueStructureClassNo ratings yet

- Rel Updating SubsetDocument17 pagesRel Updating SubsetJimmy PhoenixNo ratings yet

- FullPaper ReliabilityAssessmentofExistingReinforcedConcreteStructures HKDocument7 pagesFullPaper ReliabilityAssessmentofExistingReinforcedConcreteStructures HKwafiullah sayedNo ratings yet

- Ghodoosi 2015Document10 pagesGhodoosi 2015doni erlanggaNo ratings yet

- 7.0 Overview of Vibrational Structural Health Monitoring With Representative Case StudiesDocument9 pages7.0 Overview of Vibrational Structural Health Monitoring With Representative Case Studiesankurshah1986No ratings yet

- Infrastructure Rehabilitation Management Applying Life-Cycle Cost AnalysisDocument10 pagesInfrastructure Rehabilitation Management Applying Life-Cycle Cost AnalysisUmang UpadhyayNo ratings yet

- FullPaper ReliabilityAssessmentofExistingReinforcedConcreteStructures HKDocument7 pagesFullPaper ReliabilityAssessmentofExistingReinforcedConcreteStructures HKinigo38No ratings yet

- A Multi Stage Quantitative Resilience Analysis and Opti 2024 Reliability EngDocument16 pagesA Multi Stage Quantitative Resilience Analysis and Opti 2024 Reliability EngbihailantianmyNo ratings yet

- Fault Detection in Complex Mechatronic Systems by A Hi - 2024 - Reliability EngiDocument11 pagesFault Detection in Complex Mechatronic Systems by A Hi - 2024 - Reliability EngibihailantianmyNo ratings yet

- 711-Document Upload-2298-1-10-20190317Document3 pages711-Document Upload-2298-1-10-20190317Ashwin RaiNo ratings yet

- Literature ReviewDocument21 pagesLiterature ReviewKuntal GhoshNo ratings yet

- Integrity Assessment of Pipeline Systems by An Enhanced Indentation TechniqueDocument7 pagesIntegrity Assessment of Pipeline Systems by An Enhanced Indentation TechniqueangelNo ratings yet

- Expert Assessments of The Cost of Light WaterDocument6 pagesExpert Assessments of The Cost of Light WaterStephen CrooksNo ratings yet

- Methodology For Forensic Investigations of Seismic DamageDocument19 pagesMethodology For Forensic Investigations of Seismic DamageFarhan DanishNo ratings yet

- Engineering, Vol. 113, No. 3, March, 1987. ©ASCE, ISSN 0733-9445/87/0003-0429Document16 pagesEngineering, Vol. 113, No. 3, March, 1987. ©ASCE, ISSN 0733-9445/87/0003-0429Ronald SenzanoNo ratings yet

- Integrated Structural - Nonstructural Performance-Based Seismic Design and Retrofit Optimization of BuildingsDocument13 pagesIntegrated Structural - Nonstructural Performance-Based Seismic Design and Retrofit Optimization of BuildingsrksjcitNo ratings yet

- Fuzzy Logic Based Condition Rating of Existing Reinforced Concrete BridgesDocument13 pagesFuzzy Logic Based Condition Rating of Existing Reinforced Concrete BridgesS LNo ratings yet

- Inspection Survey of Support Bearings in Road Bridges: Luís M. R. Freire Jorge de Brito and João R. CorreiaDocument11 pagesInspection Survey of Support Bearings in Road Bridges: Luís M. R. Freire Jorge de Brito and João R. CorreiaAlex JuniorNo ratings yet

- Paper ReznikovDocument7 pagesPaper ReznikovДмитрий РезниковNo ratings yet

- Ye2009 PDFDocument11 pagesYe2009 PDFAnandhuHaridasNo ratings yet

- Research Paper2Document10 pagesResearch Paper2phbck.up.kbNo ratings yet

- Marjan Ish Vili 2006Document10 pagesMarjan Ish Vili 2006Ion SococolNo ratings yet

- JCCE2014Document18 pagesJCCE2014Bruno RavioloNo ratings yet

- Structural Health Monitoringfor Sustainableand Resilient Infastructure ManagementDocument15 pagesStructural Health Monitoringfor Sustainableand Resilient Infastructure ManagementMariana GarsteaNo ratings yet

- Two-Stepped Evolutionary Algorithm and Its Application To Stability Analysis of SlopesDocument9 pagesTwo-Stepped Evolutionary Algorithm and Its Application To Stability Analysis of SlopesLaedson PedreiraNo ratings yet

- 1997 System Sustainability Trends Loucks1997Document19 pages1997 System Sustainability Trends Loucks1997Giampier Lopez RiveraNo ratings yet

- Detection of Common Defects in Concrete Bridge Decks Using Nondestructive Evaluation TechniquesDocument11 pagesDetection of Common Defects in Concrete Bridge Decks Using Nondestructive Evaluation TechniquesnagarajuNo ratings yet

- Degroot Baecher 1993 Estimating Autocovariance of in Situ Soil PropertiesDocument20 pagesDegroot Baecher 1993 Estimating Autocovariance of in Situ Soil PropertiesLucas LuzziNo ratings yet

- Teaching Distribution System Reliability Evaluation Using Monte Carlo SimulationDocument7 pagesTeaching Distribution System Reliability Evaluation Using Monte Carlo SimulationMansoor AsifNo ratings yet

- Bulk Electric System Well-Being Analysis Using Sequential Monte Carlo SimulationDocument6 pagesBulk Electric System Well-Being Analysis Using Sequential Monte Carlo SimulationJorgeMoisesNo ratings yet

- Capacitive Sensors 2Document7 pagesCapacitive Sensors 2Chidananda GNo ratings yet

- Ahmad Et Al - 2018 - Generalized Approach For The Formulation of Analytical Model of Hybrid CableDocument13 pagesAhmad Et Al - 2018 - Generalized Approach For The Formulation of Analytical Model of Hybrid CablezhangenqiNo ratings yet

- Improved Seismic Performance of Gusset Plate ConnectionsDocument12 pagesImproved Seismic Performance of Gusset Plate ConnectionsPrateek PandaNo ratings yet

- Data Sources For Reliability Design Analysis: Technical NoteDocument7 pagesData Sources For Reliability Design Analysis: Technical NoteAdelmo FilhoNo ratings yet

- Wu 2015Document12 pagesWu 2015roshanrajasNo ratings yet

- Reliability Safety and Security of InnovDocument6 pagesReliability Safety and Security of InnovRubenNo ratings yet

- Performance-Based Assessment Methodology For Retrofit of BuildingsDocument15 pagesPerformance-Based Assessment Methodology For Retrofit of BuildingsfaisaladeNo ratings yet

- Stability Analysis and Design of Composite StructuresDocument12 pagesStability Analysis and Design of Composite StructuresJanCarlosPampaVaraNo ratings yet

- Structural Response and Reliability Estimates - Slepian Model Approach - LindtDocument9 pagesStructural Response and Reliability Estimates - Slepian Model Approach - LindtCarlos Manuel CorregidorNo ratings yet

- Pile Design and Installation Specification Based On ConceptDocument4 pagesPile Design and Installation Specification Based On ConceptMoe Oo HtunNo ratings yet

- Earthquake Duration Effect On Structural ReliabilityDocument6 pagesEarthquake Duration Effect On Structural ReliabilitymaNo ratings yet

- ShinozukaDocument9 pagesShinozukaIon SococolNo ratings yet

- Health Monitoring of A Truss Bridge Using Adaptive IdentificationDocument6 pagesHealth Monitoring of A Truss Bridge Using Adaptive IdentificationBabita SharmaNo ratings yet

- Uang 1991 ESTABLISHING R (OR RW) AND CD FACTORS FOR BUILDING SEISMIC PROVISIONSDocument10 pagesUang 1991 ESTABLISHING R (OR RW) AND CD FACTORS FOR BUILDING SEISMIC PROVISIONSMaria AngelNo ratings yet

- Introduction To Safety and Reliability of StructuresDocument164 pagesIntroduction To Safety and Reliability of StructuresPaulo PerinazzoNo ratings yet

- Computation: The Use of Fragility Curves in The Life-Cycle Assessment of Deteriorating Bridge StructuresDocument17 pagesComputation: The Use of Fragility Curves in The Life-Cycle Assessment of Deteriorating Bridge StructuresBhairav ThakurNo ratings yet

- Evaluation and Rating of Masonry Arch BridgesDocument12 pagesEvaluation and Rating of Masonry Arch BridgesAreaya mahetemNo ratings yet

- Automatic Yield-Line Analysis of Practical Slab Configurations Via Discontinuity Layout OptimizationDocument17 pagesAutomatic Yield-Line Analysis of Practical Slab Configurations Via Discontinuity Layout OptimizationSolomon AhimbisibweNo ratings yet

- Girder Load Distribution For Seismic Design of Integral BridgesDocument11 pagesGirder Load Distribution For Seismic Design of Integral BridgesAkhmad Immamul AzizNo ratings yet

- STR Safety 2015Document12 pagesSTR Safety 2015Jimmy PhoenixNo ratings yet

- Fragility Analysis of Space Reinforced Concrete Frame Structures With Structural Irregularity in Plan - Do-Soo Moon, Young-Joo Lee, Sangmok LeeDocument12 pagesFragility Analysis of Space Reinforced Concrete Frame Structures With Structural Irregularity in Plan - Do-Soo Moon, Young-Joo Lee, Sangmok LeeStructural SpreadsheetsNo ratings yet

- 3-Fragility Analysis of Space Reinforced Concrete Frame Structures With Structural Irregularity in PlanDocument12 pages3-Fragility Analysis of Space Reinforced Concrete Frame Structures With Structural Irregularity in Planengomar nadyNo ratings yet

- Engineering Mechanics Final ExamDocument4 pagesEngineering Mechanics Final ExamEman SalehNo ratings yet

- Note 1 - 230724 - 201453Document6 pagesNote 1 - 230724 - 201453Eman SalehNo ratings yet

- Bayesian Monte Carlo Approach For Developing Stochastic Railway Track Degradation Model Using Expert-Based PriorsDocument23 pagesBayesian Monte Carlo Approach For Developing Stochastic Railway Track Degradation Model Using Expert-Based PriorsEman SalehNo ratings yet

- 20 001 FullCodeInside VFDocument136 pages20 001 FullCodeInside VFEman SalehNo ratings yet

- 2301489Document1 page2301489Eman SalehNo ratings yet

- Pile Cap Design For Shear Wall-1Document21 pagesPile Cap Design For Shear Wall-1Eman SalehNo ratings yet

- Deep Learning-Based Instance Segmentation of Cracks From Shield Tunnel Lining ImagesDocument15 pagesDeep Learning-Based Instance Segmentation of Cracks From Shield Tunnel Lining ImagesEman SalehNo ratings yet

- American Accounting AssociationDocument36 pagesAmerican Accounting AssociationEman SalehNo ratings yet

- Journal Pre-Proof: Corrosion ScienceDocument27 pagesJournal Pre-Proof: Corrosion ScienceEman SalehNo ratings yet

- Moment Frame Analysis - 1Document27 pagesMoment Frame Analysis - 1Eman SalehNo ratings yet

- Modeling and Simulation of Shear Resistance of R/C Beams Using Artificial Neural NetworkDocument16 pagesModeling and Simulation of Shear Resistance of R/C Beams Using Artificial Neural NetworkEman SalehNo ratings yet

- E Cient Implementation of Leave-One-Out Cross-Validation and WAIC For Evaluating Fitted Bayesian ModelsDocument23 pagesE Cient Implementation of Leave-One-Out Cross-Validation and WAIC For Evaluating Fitted Bayesian ModelsEman SalehNo ratings yet

- Probabilistic Engineering Mechanics: Swarup Ghosh, Subrata ChakrabortyDocument12 pagesProbabilistic Engineering Mechanics: Swarup Ghosh, Subrata ChakrabortyEman SalehNo ratings yet

- Towards Data Based Corrosion Analysis of Concrete With Supervised Machine LearningDocument8 pagesTowards Data Based Corrosion Analysis of Concrete With Supervised Machine LearningEman SalehNo ratings yet

- RaviMullapudi-Ayoub2018 Article FiberBeamAnalysisOfReinforcedCDocument16 pagesRaviMullapudi-Ayoub2018 Article FiberBeamAnalysisOfReinforcedCEman SalehNo ratings yet

- Machine Learning - Based Backbone Curve Model of Reinforced Concrete Columns Subjected To Cyclic Loading ReversalsDocument14 pagesMachine Learning - Based Backbone Curve Model of Reinforced Concrete Columns Subjected To Cyclic Loading ReversalsEman SalehNo ratings yet

- 110-s83 (1) - UnlockedDocument14 pages110-s83 (1) - UnlockedEman SalehNo ratings yet

- Effectiveness of Swimmer Bars As Shear Reinforcement in Rectangular Concrete BeamsDocument8 pagesEffectiveness of Swimmer Bars As Shear Reinforcement in Rectangular Concrete BeamsEman SalehNo ratings yet

- J Engstruct 2010 12 025Document9 pagesJ Engstruct 2010 12 025Eman SalehNo ratings yet

- An Introduction To Sensitivity Assessment of Simulation ModelsDocument20 pagesAn Introduction To Sensitivity Assessment of Simulation ModelsEman SalehNo ratings yet

- Audit Risk Formula With Mixed EvidenceDocument6 pagesAudit Risk Formula With Mixed EvidenceEman SalehNo ratings yet

- Screw 109-s49Document10 pagesScrew 109-s49Eman SalehNo ratings yet

- Comparison of Load Combination Models For Probabilistic CalibrationsDocument9 pagesComparison of Load Combination Models For Probabilistic CalibrationsEman SalehNo ratings yet

- Engineering Structures: Zdeněk KalaDocument5 pagesEngineering Structures: Zdeněk KalaEman SalehNo ratings yet

- Research Article: A Methodology For Multihazards Load Combinations of Earthquake and Heavy Trucks For BridgesDocument9 pagesResearch Article: A Methodology For Multihazards Load Combinations of Earthquake and Heavy Trucks For BridgesEman SalehNo ratings yet

- 18 331 PDFDocument10 pages18 331 PDFEman SalehNo ratings yet

- E W S U C S M: Stimating Inter Treamflow Sing Onceptual Treamflow OdelDocument18 pagesE W S U C S M: Stimating Inter Treamflow Sing Onceptual Treamflow OdelEman SalehNo ratings yet

- Partial Safety Factors For Homogeneous Reliability of Nonlinear Reinforced Concrete ColumnsDocument20 pagesPartial Safety Factors For Homogeneous Reliability of Nonlinear Reinforced Concrete ColumnsEman SalehNo ratings yet

- Types of ConcreteDocument5 pagesTypes of ConcretePaul Ivan Asencio CasumpangNo ratings yet

- BR PDF AD G 2015 With 2016 AmendmentsDocument55 pagesBR PDF AD G 2015 With 2016 AmendmentsGeorgeNo ratings yet

- Structural Analysis - I Unit-IDocument22 pagesStructural Analysis - I Unit-ITamizhan_KNo ratings yet

- Aci 201 Guide To Durable Concrete PDFDocument17 pagesAci 201 Guide To Durable Concrete PDFHamidAffandyNo ratings yet

- Outline SpecsDocument5 pagesOutline SpecsKendrick RickNo ratings yet

- Choked Flow of FluidsDocument4 pagesChoked Flow of FluidsGnana Subramanian ArumugamNo ratings yet

- Site Works Infra Package 24-12-2020Document37 pagesSite Works Infra Package 24-12-2020Mohamed Abou El hassanNo ratings yet

- Boiler Design Step 2Document2 pagesBoiler Design Step 2Amad TaupiqNo ratings yet

- 42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe SpratDocument2 pages42NH Ductable in Room Fan Coil With Multi Speed Motor: Performance Summary For Sobe Spratvelikimag87No ratings yet

- Curved BeamsDocument19 pagesCurved BeamsRobel MetikuNo ratings yet

- 50 Contoh Soal Bahasa InggrisDocument12 pages50 Contoh Soal Bahasa InggrisArief RahmanNo ratings yet

- DEVELOPMENT CONTROL FORMULAS - PROf. PRAC. 1Document4 pagesDEVELOPMENT CONTROL FORMULAS - PROf. PRAC. 1JOHN FRANCIS BARRIOSNo ratings yet

- BẢN VẼ MT70-2022Document31 pagesBẢN VẼ MT70-2022MảimêchinhchiếnVàYêuđương50% (2)

- Sheet Metal Ductwork: Specification ForDocument98 pagesSheet Metal Ductwork: Specification Forkoray100% (1)

- ENC Bearings Catalog enDocument20 pagesENC Bearings Catalog enDaniel AndreevskiNo ratings yet

- Crane Runway Beam Design - AISC LRFD 2010 and ASD 2010s PDFDocument6 pagesCrane Runway Beam Design - AISC LRFD 2010 and ASD 2010s PDFAnonymous 7Aw2NbCNo ratings yet

- 2ND Floor Beam DesignDocument14 pages2ND Floor Beam DesignJustinNo ratings yet

- #Inspection List After Heater InstallmentDocument30 pages#Inspection List After Heater InstallmentHariajahNo ratings yet

- Typenreihe NE enDocument6 pagesTypenreihe NE encspivetta6095No ratings yet

- Inspection Test Plan ITP Painting WorksDocument4 pagesInspection Test Plan ITP Painting WorksMichael AntipuestoNo ratings yet

- Aci 562-13Document4 pagesAci 562-13Ynmer GallegosNo ratings yet

- Construction of Stone Masonry Footing PDFDocument6 pagesConstruction of Stone Masonry Footing PDFvenkateswara rao PothinaNo ratings yet

- Mendocmedia: Wishing Well Hose Reel Assembly InstructionsDocument4 pagesMendocmedia: Wishing Well Hose Reel Assembly InstructionsDaniel LourençoNo ratings yet

- TDS Foodsafe Plus 1 & 2 GreasesDocument2 pagesTDS Foodsafe Plus 1 & 2 Greasesjohanes kharismaNo ratings yet

- Flexural Design of Prestress Concrete PDFDocument30 pagesFlexural Design of Prestress Concrete PDFEdson MilanoNo ratings yet

- Installation Guide Jul 08Document50 pagesInstallation Guide Jul 08FlokkasNo ratings yet