Professional Documents

Culture Documents

Eec426 Assignment 1: Mohan Mohinish Ram 2019003115 5/11/2020

Eec426 Assignment 1: Mohan Mohinish Ram 2019003115 5/11/2020

Uploaded by

mohan ramCopyright:

Available Formats

You might also like

- PLC ApplicationDocument56 pagesPLC ApplicationMohamed Gawad ARaya88% (8)

- ARL-300 Error Codes - enDocument4 pagesARL-300 Error Codes - enDaceDrop79% (29)

- 8.1 Parameters Set List: KP310V1.0 Controller Operation ManualDocument5 pages8.1 Parameters Set List: KP310V1.0 Controller Operation ManualConstru Roca RentalNo ratings yet

- Lc200a en V5.0Document8 pagesLc200a en V5.0Anu MaliNo ratings yet

- ACCESSORIES AND EQUIPMENT Body Control Module (BCM) - Electrical Diagnostics - DTCS B182C To U1433Document238 pagesACCESSORIES AND EQUIPMENT Body Control Module (BCM) - Electrical Diagnostics - DTCS B182C To U1433billNo ratings yet

- SPC Idc 2ls Iom Operation GuideDocument8 pagesSPC Idc 2ls Iom Operation GuideisurukalharaNo ratings yet

- Blender Service Manual 6700 0494 000 PDFDocument32 pagesBlender Service Manual 6700 0494 000 PDFEdmund S Maputi100% (1)

- Real Time Monitor WA150-320Document2 pagesReal Time Monitor WA150-320João MariaNo ratings yet

- Ma Loop Calibrator Fluke 707 EXDocument11 pagesMa Loop Calibrator Fluke 707 EXkhaleed.basherrNo ratings yet

- List of Instruments & EquipmentsDocument1 pageList of Instruments & EquipmentsRAHUL SINGHNo ratings yet

- Q145 WML 405Document16 pagesQ145 WML 405Sebastian Guzman camachoNo ratings yet

- PLC Applications AND Timers and ContersDocument26 pagesPLC Applications AND Timers and ConterschethanNo ratings yet

- Meca Sheet: Machine Trouble Shooting Power Train SystemDocument7 pagesMeca Sheet: Machine Trouble Shooting Power Train SystemJoko WahonoNo ratings yet

- Stirpak 5000710Document16 pagesStirpak 5000710celiaamerikarenvalenciacruzNo ratings yet

- Lambda Sensor LSU 4.2 Datasheet 51 en 2779111435Document3 pagesLambda Sensor LSU 4.2 Datasheet 51 en 2779111435Roberto OliveiraNo ratings yet

- Lc100a 2.5 LCD Digital High Precision Inductance Capacitance LC MeterDocument9 pagesLc100a 2.5 LCD Digital High Precision Inductance Capacitance LC MeterMourad hosniNo ratings yet

- COUNTERS IN PLC - Portal PDFDocument88 pagesCOUNTERS IN PLC - Portal PDFAhwangg xGAMINGNo ratings yet

- 4system OverviewDocument7 pages4system OverviewWajaht AliNo ratings yet

- Ford Escort Rs Turbo Technical and Fuel Injection Diagnosis InformationDocument11 pagesFord Escort Rs Turbo Technical and Fuel Injection Diagnosis Informationtuke_t100% (1)

- Windows 1256''Plc ApplicationDocument56 pagesWindows 1256''Plc ApplicationAlaa Faiq0% (1)

- Ladder Diagram: Rung 1 Rung 2 Rung 3Document26 pagesLadder Diagram: Rung 1 Rung 2 Rung 3abdullah 3mar abou reashaNo ratings yet

- Desain Modul PLC Eskalator Teh Press Revisi3Document1 pageDesain Modul PLC Eskalator Teh Press Revisi3mohammad nurNo ratings yet

- Automated Production Line With Bottle Filling Feedback Control SystemDocument16 pagesAutomated Production Line With Bottle Filling Feedback Control Systemاحمد بھائ انجینرز راجووالNo ratings yet

- Lc100a 2.5 LCD Digital High Precision Inductance Capacitance LC MeterDocument9 pagesLc100a 2.5 LCD Digital High Precision Inductance Capacitance LC MeterChandrashekhar KulkarniNo ratings yet

- C2000 Drive IM With TQC Sensorless PDFDocument4 pagesC2000 Drive IM With TQC Sensorless PDFDmitry VALEGURANo ratings yet

- Auxiliary FunctionDocument22 pagesAuxiliary Functions_barriosNo ratings yet

- Quotation M/S. Sensors India Quotation No.: Q00205 09/07/2020: Quotation DateDocument2 pagesQuotation M/S. Sensors India Quotation No.: Q00205 09/07/2020: Quotation DateStandards IndiaNo ratings yet

- Report Task 1 Lab 3Document3 pagesReport Task 1 Lab 3Mimi??No ratings yet

- Greer RCI510 Troubleshooting W450270ADocument19 pagesGreer RCI510 Troubleshooting W450270ARam SisodiaNo ratings yet

- Service Vibration Meter Operation ManualDocument6 pagesService Vibration Meter Operation Manualpranav_mistry0033938No ratings yet

- Allison MD-3060 TPS AdjustmentDocument5 pagesAllison MD-3060 TPS AdjustmentTimothy PautzNo ratings yet

- Backup 804005 Aguada ChivatoDocument4 pagesBackup 804005 Aguada ChivatosergioNo ratings yet

- 10-1 Pump Calibration 390MJ 950MJ PDFDocument6 pages10-1 Pump Calibration 390MJ 950MJ PDFGREGWEILERNo ratings yet

- Chapter 61Document83 pagesChapter 61mustapha sahraouiNo ratings yet

- Form Pressure Gauge Rev.1Document3 pagesForm Pressure Gauge Rev.1ismail BCMNo ratings yet

- Industrial Automation Group AssignmentDocument5 pagesIndustrial Automation Group Assignmenteyoule abdiNo ratings yet

- PLC ExamplesDocument78 pagesPLC ExamplesMuhammad Mahfud RosyidiNo ratings yet

- How To Test The Rear O2 HeaterDocument120 pagesHow To Test The Rear O2 Heaterاحمدميدو100% (3)

- Ac Voltage ControllerDocument2 pagesAc Voltage ControllerJoe RanteNo ratings yet

- Buchholz Relay PDFDocument12 pagesBuchholz Relay PDFSajjad PirzadaNo ratings yet

- Arl 300 Error Codesen PDFDocument4 pagesArl 300 Error Codesen PDFAbdul sattar100% (1)

- (B) Bills of Quantities For Internal Fire Fighting InstallationsDocument5 pages(B) Bills of Quantities For Internal Fire Fighting InstallationsNana BarimaNo ratings yet

- Chapter 5 - PLC Application in The IndustryDocument32 pagesChapter 5 - PLC Application in The IndustryMOHD SABREENo ratings yet

- Ems39 Eng PDFDocument4 pagesEms39 Eng PDFbambang0% (1)

- Bus NumberDocument27 pagesBus NumberCristian GomezNo ratings yet

- Hd785-3 Electric OptionalDocument13 pagesHd785-3 Electric OptionalBima Dwi UtomoNo ratings yet

- Electric Shift Transfer: Code ItemDocument4 pagesElectric Shift Transfer: Code ItemHerowan YumaNo ratings yet

- SMART Accumax USER MANUAL - SINGLE CHANNELDocument22 pagesSMART Accumax USER MANUAL - SINGLE CHANNELYessica PinedaNo ratings yet

- S-SB-0033-13 DifficultyStarting RoughIdle CamPosition MisfireDocument8 pagesS-SB-0033-13 DifficultyStarting RoughIdle CamPosition MisfireEl rincón de RaulNo ratings yet

- ENGINEDocument2,790 pagesENGINEAdan Flores CorreaNo ratings yet

- Controls: User'S ManualDocument9 pagesControls: User'S ManualAngel Salvador Polanco RosarioNo ratings yet

- 09 Control SytmDocument18 pages09 Control Sytmnugraha kurniawanNo ratings yet

- Form Service ScaniaDocument12 pagesForm Service Scaniazaid chidmahNo ratings yet

- Esm ManualDocument4 pagesEsm ManualAkhil BhadouriaNo ratings yet

- Codigos Fallas DTC Index - 2.0L (AEG, AVH & AZG Engines)Document27 pagesCodigos Fallas DTC Index - 2.0L (AEG, AVH & AZG Engines)Jose PichinteNo ratings yet

- Wheelock SA-S70 - Sa70sls24Document7 pagesWheelock SA-S70 - Sa70sls24ale22 ale33No ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Project: EEC307 - Workshop Practice IIDocument2 pagesProject: EEC307 - Workshop Practice IImohan ramNo ratings yet

- Assignment 1 PDFDocument1 pageAssignment 1 PDFmohan ramNo ratings yet

- Project: EEC421 - Electronic InstrumentationDocument2 pagesProject: EEC421 - Electronic Instrumentationmohan ramNo ratings yet

- Name ID# Name ID#: Project TitleDocument33 pagesName ID# Name ID#: Project Titlemohan ramNo ratings yet

- Tutorial 2 Communication MediumsDocument3 pagesTutorial 2 Communication Mediumsmohan ramNo ratings yet

- EEC421 LAB 2: Mohan Mohinish Ram 2019003115 10/24/2020Document4 pagesEEC421 LAB 2: Mohan Mohinish Ram 2019003115 10/24/2020mohan ramNo ratings yet

- Tutorial 1 Computer Interface: Ease of Use, Reliability, Flexibility, and CompatibilityDocument1 pageTutorial 1 Computer Interface: Ease of Use, Reliability, Flexibility, and Compatibilitymohan ramNo ratings yet

- Eec462 Radio Receivers & TransmittersDocument1 pageEec462 Radio Receivers & Transmittersmohan ramNo ratings yet

- Eec463 AssignmentDocument3 pagesEec463 Assignmentmohan ramNo ratings yet

- Introduction To TroubleshootingsDocument14 pagesIntroduction To Troubleshootingsmohan ramNo ratings yet

- Eec421 Lab 3Document6 pagesEec421 Lab 3mohan ramNo ratings yet

- EEC461 LAB 2: Mohan Mohinish Ram 2019003115 11/2/2020Document4 pagesEEC461 LAB 2: Mohan Mohinish Ram 2019003115 11/2/2020mohan ramNo ratings yet

- Varactor: Voltage Current Characteristic Negative Resistance Region OscillatorsDocument2 pagesVaractor: Voltage Current Characteristic Negative Resistance Region Oscillatorsmohan ramNo ratings yet

- Surface Acoustic Wave (Saw) FiltersDocument2 pagesSurface Acoustic Wave (Saw) Filtersmohan ramNo ratings yet

- Tank Circuits & OscillatorsDocument5 pagesTank Circuits & Oscillatorsmohan ramNo ratings yet

- The Concept of ResonanceDocument6 pagesThe Concept of Resonancemohan ramNo ratings yet

- EEC462 Radio Receivers and TransmittersDocument6 pagesEEC462 Radio Receivers and Transmittersmohan ramNo ratings yet

- Eec461 Assignment 2: Mohan Mohinish Ram 2019003115 11/6/2020Document2 pagesEec461 Assignment 2: Mohan Mohinish Ram 2019003115 11/6/2020mohan ramNo ratings yet

- Project Progress Report Form 5Document5 pagesProject Progress Report Form 5mohan ramNo ratings yet

- EEC461 Television Systems Quarter 4 2020 Assignment 1: Name: Sufyaan Naushad Ali Id: 2020001829Document2 pagesEEC461 Television Systems Quarter 4 2020 Assignment 1: Name: Sufyaan Naushad Ali Id: 2020001829mohan ramNo ratings yet

- Electronics Project: Music Operated DJ Lights and Infrared Remote Control SwitchDocument4 pagesElectronics Project: Music Operated DJ Lights and Infrared Remote Control Switchmohan ramNo ratings yet

- Project Progress Report Form 2Document3 pagesProject Progress Report Form 2mohan ramNo ratings yet

- Project Progress Report Form 3Document4 pagesProject Progress Report Form 3mohan ramNo ratings yet

- Project Progress Report Form 4Document4 pagesProject Progress Report Form 4mohan ramNo ratings yet

- Control - Motion - Interface: High Performance Flying Shear ControlDocument42 pagesControl - Motion - Interface: High Performance Flying Shear Controlقلمي كنزىNo ratings yet

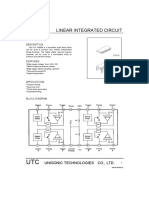

- UTC NE558 Linear Integrated Circuit: Quad TimerDocument2 pagesUTC NE558 Linear Integrated Circuit: Quad TimerCajun LeBeauNo ratings yet

- 7600 PM ProcedureDocument14 pages7600 PM ProceduremrscribdNo ratings yet

- Hawke Accessories NylonWasherDocument1 pageHawke Accessories NylonWasherKaustabha DasNo ratings yet

- Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy TubesDocument6 pagesElectromagnetic (Eddy Current) Examination of Copper and Copper-Alloy Tubesedapo79No ratings yet

- Using Non-Inverting Buck-Boost Converter For Voltage StabilizationDocument8 pagesUsing Non-Inverting Buck-Boost Converter For Voltage StabilizationTobi CliffordrxNo ratings yet

- Viva QuestionsDocument11 pagesViva QuestionsRaj Kumar0% (1)

- Wilo Rexa Fit V05da 222 Ead1 2 t0025 540 oDocument27 pagesWilo Rexa Fit V05da 222 Ead1 2 t0025 540 oIntendencia UsinaNo ratings yet

- Minty BoostDocument101 pagesMinty BoostJohnny Lariu LabininayNo ratings yet

- Float Cum Boost Battery ChargerDocument3 pagesFloat Cum Boost Battery ChargerBadal PatnaikNo ratings yet

- 04 - Hpu Skydrol 5431Document255 pages04 - Hpu Skydrol 5431cleberNo ratings yet

- JBL Control SB-5 Service ManualDocument2 pagesJBL Control SB-5 Service ManualBillyKidda100% (3)

- JC3000 - Brochure Dec10 (En)Document12 pagesJC3000 - Brochure Dec10 (En)Thiago GarciaNo ratings yet

- rdr-919q 60w High Input Voltage Psu Automotive Innoswitch3-Aq-1700v SicDocument60 pagesrdr-919q 60w High Input Voltage Psu Automotive Innoswitch3-Aq-1700v SicTeyfik koyuncuNo ratings yet

- Quasi-Z-Source Inverter For Photovoltaic Power Generation Systems PDFDocument7 pagesQuasi-Z-Source Inverter For Photovoltaic Power Generation Systems PDFSudip MondalNo ratings yet

- Lab Report Workshop 10Document3 pagesLab Report Workshop 10Abdullah AnsariNo ratings yet

- Flying MachinesDocument2 pagesFlying MachinesGuillermo CadmastersNo ratings yet

- From PG 03: Lotus Powergear PVT - Ltd.,BangaloreDocument1 pageFrom PG 03: Lotus Powergear PVT - Ltd.,BangalorethavaselvanNo ratings yet

- Research On SVPWM OkDocument6 pagesResearch On SVPWM OkAnonymous 1D3dCWNcNo ratings yet

- Boost Battery Performance Through Advanced Charging - Electronic DesignDocument30 pagesBoost Battery Performance Through Advanced Charging - Electronic DesignAlan WeissNo ratings yet

- Technical Characteristics: A-1900 Test CardDocument2 pagesTechnical Characteristics: A-1900 Test CardThanosEleftheroudisNo ratings yet

- Components of Power GenerationDocument3 pagesComponents of Power GenerationWyndellRioNo ratings yet

- Digital Speed Controller: Description FeaturesDocument2 pagesDigital Speed Controller: Description FeaturesZHIRAYR TitizyanNo ratings yet

- LED Engine On TinkercadDocument4 pagesLED Engine On Tinkercadiyan leadNo ratings yet

- 3GAA182062 BDA 3gaa182062 BdaDocument2 pages3GAA182062 BDA 3gaa182062 BdaefverfNo ratings yet

- Makalah BHS Inggris InsanulDocument12 pagesMakalah BHS Inggris InsanulInsanul AdliNo ratings yet

- The Planning, Design and Analysis of The Bloukrans BridgeDocument14 pagesThe Planning, Design and Analysis of The Bloukrans BridgetevredeNo ratings yet

- SBB5089Z Data SheetDocument11 pagesSBB5089Z Data SheetRaziel EsauNo ratings yet

- Features: Low Input Voltage and High Efficiency Synchronous Boost Converter With 1.3A SwitchDocument15 pagesFeatures: Low Input Voltage and High Efficiency Synchronous Boost Converter With 1.3A SwitchGenaro AyalaNo ratings yet

Eec426 Assignment 1: Mohan Mohinish Ram 2019003115 5/11/2020

Eec426 Assignment 1: Mohan Mohinish Ram 2019003115 5/11/2020

Uploaded by

mohan ramOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eec426 Assignment 1: Mohan Mohinish Ram 2019003115 5/11/2020

Eec426 Assignment 1: Mohan Mohinish Ram 2019003115 5/11/2020

Uploaded by

mohan ramCopyright:

Available Formats

2020

EEC426 ASSIGNMENT 1

MOHAN MOHINISH RAM

2019003115

5/11/2020

EEC 426 PLC & SCADA ASSIGNMENT

- Chute Height Control Consider the above chute height and feeder control for a boiler. The chute

height is controlled by the High and Low sensor switches.

- If the feed is below the Low Level Sensor O solenoid is energized to open the Feed Plough. It

continues to take feed until the High level sensor I is reached.

- It then waits for the feed to fall below low level and repeats the cycle. If the sensor X is reached

the conveyor should stop. Remember nothing should be operational if the conveyor is stopped.

Operation should only continue once the conveyor starts again.

- Senor MH and ML control the feeder motor.

- If the feed goes below ML sensor, the motor must stop and only come ON when the high level

has been reached.

- Include an overload for the feeder motor that will also trip the conveyor.

- Also include a delay (3 secs) on each sensor input to avoid momentary activation of the inputs to

the PLC.

Sensors and switches addresses outputs addresses

STOP PB 0.01 INDICATOR 100.00

STARTPB 0.02 FEED PLOUGH 100.02

INDICATOR LATCH 100.00 FEED CONVEYER 100.03

OVERLOAD 0.03 ASH CONVEYER 100.04

LOW LEVEL SENSOR 0.04 FEEDER MOTOR 100.05

HIGH LEVEL SENSOR 0.05 FEEDER MOTOR OFF 100.06

INDICATOR

SENSOR X 0.06 TIMER 1 TIM 0000 #30

ML SENSOR 0.08 TIMER 2 TIM 0001 #30

MH SENSOR 0.07 TIMER 3 TIM 0002 #30

FEED CONVEYER 100.03 TIMER 4 TIM 0003 #30

------------------------------- ------------------------------- TIMER 5 TIM 0004 #30

------------------------------- ------------------------------- TIMER 6 TIM 0005 #30

You might also like

- PLC ApplicationDocument56 pagesPLC ApplicationMohamed Gawad ARaya88% (8)

- ARL-300 Error Codes - enDocument4 pagesARL-300 Error Codes - enDaceDrop79% (29)

- 8.1 Parameters Set List: KP310V1.0 Controller Operation ManualDocument5 pages8.1 Parameters Set List: KP310V1.0 Controller Operation ManualConstru Roca RentalNo ratings yet

- Lc200a en V5.0Document8 pagesLc200a en V5.0Anu MaliNo ratings yet

- ACCESSORIES AND EQUIPMENT Body Control Module (BCM) - Electrical Diagnostics - DTCS B182C To U1433Document238 pagesACCESSORIES AND EQUIPMENT Body Control Module (BCM) - Electrical Diagnostics - DTCS B182C To U1433billNo ratings yet

- SPC Idc 2ls Iom Operation GuideDocument8 pagesSPC Idc 2ls Iom Operation GuideisurukalharaNo ratings yet

- Blender Service Manual 6700 0494 000 PDFDocument32 pagesBlender Service Manual 6700 0494 000 PDFEdmund S Maputi100% (1)

- Real Time Monitor WA150-320Document2 pagesReal Time Monitor WA150-320João MariaNo ratings yet

- Ma Loop Calibrator Fluke 707 EXDocument11 pagesMa Loop Calibrator Fluke 707 EXkhaleed.basherrNo ratings yet

- List of Instruments & EquipmentsDocument1 pageList of Instruments & EquipmentsRAHUL SINGHNo ratings yet

- Q145 WML 405Document16 pagesQ145 WML 405Sebastian Guzman camachoNo ratings yet

- PLC Applications AND Timers and ContersDocument26 pagesPLC Applications AND Timers and ConterschethanNo ratings yet

- Meca Sheet: Machine Trouble Shooting Power Train SystemDocument7 pagesMeca Sheet: Machine Trouble Shooting Power Train SystemJoko WahonoNo ratings yet

- Stirpak 5000710Document16 pagesStirpak 5000710celiaamerikarenvalenciacruzNo ratings yet

- Lambda Sensor LSU 4.2 Datasheet 51 en 2779111435Document3 pagesLambda Sensor LSU 4.2 Datasheet 51 en 2779111435Roberto OliveiraNo ratings yet

- Lc100a 2.5 LCD Digital High Precision Inductance Capacitance LC MeterDocument9 pagesLc100a 2.5 LCD Digital High Precision Inductance Capacitance LC MeterMourad hosniNo ratings yet

- COUNTERS IN PLC - Portal PDFDocument88 pagesCOUNTERS IN PLC - Portal PDFAhwangg xGAMINGNo ratings yet

- 4system OverviewDocument7 pages4system OverviewWajaht AliNo ratings yet

- Ford Escort Rs Turbo Technical and Fuel Injection Diagnosis InformationDocument11 pagesFord Escort Rs Turbo Technical and Fuel Injection Diagnosis Informationtuke_t100% (1)

- Windows 1256''Plc ApplicationDocument56 pagesWindows 1256''Plc ApplicationAlaa Faiq0% (1)

- Ladder Diagram: Rung 1 Rung 2 Rung 3Document26 pagesLadder Diagram: Rung 1 Rung 2 Rung 3abdullah 3mar abou reashaNo ratings yet

- Desain Modul PLC Eskalator Teh Press Revisi3Document1 pageDesain Modul PLC Eskalator Teh Press Revisi3mohammad nurNo ratings yet

- Automated Production Line With Bottle Filling Feedback Control SystemDocument16 pagesAutomated Production Line With Bottle Filling Feedback Control Systemاحمد بھائ انجینرز راجووالNo ratings yet

- Lc100a 2.5 LCD Digital High Precision Inductance Capacitance LC MeterDocument9 pagesLc100a 2.5 LCD Digital High Precision Inductance Capacitance LC MeterChandrashekhar KulkarniNo ratings yet

- C2000 Drive IM With TQC Sensorless PDFDocument4 pagesC2000 Drive IM With TQC Sensorless PDFDmitry VALEGURANo ratings yet

- Auxiliary FunctionDocument22 pagesAuxiliary Functions_barriosNo ratings yet

- Quotation M/S. Sensors India Quotation No.: Q00205 09/07/2020: Quotation DateDocument2 pagesQuotation M/S. Sensors India Quotation No.: Q00205 09/07/2020: Quotation DateStandards IndiaNo ratings yet

- Report Task 1 Lab 3Document3 pagesReport Task 1 Lab 3Mimi??No ratings yet

- Greer RCI510 Troubleshooting W450270ADocument19 pagesGreer RCI510 Troubleshooting W450270ARam SisodiaNo ratings yet

- Service Vibration Meter Operation ManualDocument6 pagesService Vibration Meter Operation Manualpranav_mistry0033938No ratings yet

- Allison MD-3060 TPS AdjustmentDocument5 pagesAllison MD-3060 TPS AdjustmentTimothy PautzNo ratings yet

- Backup 804005 Aguada ChivatoDocument4 pagesBackup 804005 Aguada ChivatosergioNo ratings yet

- 10-1 Pump Calibration 390MJ 950MJ PDFDocument6 pages10-1 Pump Calibration 390MJ 950MJ PDFGREGWEILERNo ratings yet

- Chapter 61Document83 pagesChapter 61mustapha sahraouiNo ratings yet

- Form Pressure Gauge Rev.1Document3 pagesForm Pressure Gauge Rev.1ismail BCMNo ratings yet

- Industrial Automation Group AssignmentDocument5 pagesIndustrial Automation Group Assignmenteyoule abdiNo ratings yet

- PLC ExamplesDocument78 pagesPLC ExamplesMuhammad Mahfud RosyidiNo ratings yet

- How To Test The Rear O2 HeaterDocument120 pagesHow To Test The Rear O2 Heaterاحمدميدو100% (3)

- Ac Voltage ControllerDocument2 pagesAc Voltage ControllerJoe RanteNo ratings yet

- Buchholz Relay PDFDocument12 pagesBuchholz Relay PDFSajjad PirzadaNo ratings yet

- Arl 300 Error Codesen PDFDocument4 pagesArl 300 Error Codesen PDFAbdul sattar100% (1)

- (B) Bills of Quantities For Internal Fire Fighting InstallationsDocument5 pages(B) Bills of Quantities For Internal Fire Fighting InstallationsNana BarimaNo ratings yet

- Chapter 5 - PLC Application in The IndustryDocument32 pagesChapter 5 - PLC Application in The IndustryMOHD SABREENo ratings yet

- Ems39 Eng PDFDocument4 pagesEms39 Eng PDFbambang0% (1)

- Bus NumberDocument27 pagesBus NumberCristian GomezNo ratings yet

- Hd785-3 Electric OptionalDocument13 pagesHd785-3 Electric OptionalBima Dwi UtomoNo ratings yet

- Electric Shift Transfer: Code ItemDocument4 pagesElectric Shift Transfer: Code ItemHerowan YumaNo ratings yet

- SMART Accumax USER MANUAL - SINGLE CHANNELDocument22 pagesSMART Accumax USER MANUAL - SINGLE CHANNELYessica PinedaNo ratings yet

- S-SB-0033-13 DifficultyStarting RoughIdle CamPosition MisfireDocument8 pagesS-SB-0033-13 DifficultyStarting RoughIdle CamPosition MisfireEl rincón de RaulNo ratings yet

- ENGINEDocument2,790 pagesENGINEAdan Flores CorreaNo ratings yet

- Controls: User'S ManualDocument9 pagesControls: User'S ManualAngel Salvador Polanco RosarioNo ratings yet

- 09 Control SytmDocument18 pages09 Control Sytmnugraha kurniawanNo ratings yet

- Form Service ScaniaDocument12 pagesForm Service Scaniazaid chidmahNo ratings yet

- Esm ManualDocument4 pagesEsm ManualAkhil BhadouriaNo ratings yet

- Codigos Fallas DTC Index - 2.0L (AEG, AVH & AZG Engines)Document27 pagesCodigos Fallas DTC Index - 2.0L (AEG, AVH & AZG Engines)Jose PichinteNo ratings yet

- Wheelock SA-S70 - Sa70sls24Document7 pagesWheelock SA-S70 - Sa70sls24ale22 ale33No ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Project: EEC307 - Workshop Practice IIDocument2 pagesProject: EEC307 - Workshop Practice IImohan ramNo ratings yet

- Assignment 1 PDFDocument1 pageAssignment 1 PDFmohan ramNo ratings yet

- Project: EEC421 - Electronic InstrumentationDocument2 pagesProject: EEC421 - Electronic Instrumentationmohan ramNo ratings yet

- Name ID# Name ID#: Project TitleDocument33 pagesName ID# Name ID#: Project Titlemohan ramNo ratings yet

- Tutorial 2 Communication MediumsDocument3 pagesTutorial 2 Communication Mediumsmohan ramNo ratings yet

- EEC421 LAB 2: Mohan Mohinish Ram 2019003115 10/24/2020Document4 pagesEEC421 LAB 2: Mohan Mohinish Ram 2019003115 10/24/2020mohan ramNo ratings yet

- Tutorial 1 Computer Interface: Ease of Use, Reliability, Flexibility, and CompatibilityDocument1 pageTutorial 1 Computer Interface: Ease of Use, Reliability, Flexibility, and Compatibilitymohan ramNo ratings yet

- Eec462 Radio Receivers & TransmittersDocument1 pageEec462 Radio Receivers & Transmittersmohan ramNo ratings yet

- Eec463 AssignmentDocument3 pagesEec463 Assignmentmohan ramNo ratings yet

- Introduction To TroubleshootingsDocument14 pagesIntroduction To Troubleshootingsmohan ramNo ratings yet

- Eec421 Lab 3Document6 pagesEec421 Lab 3mohan ramNo ratings yet

- EEC461 LAB 2: Mohan Mohinish Ram 2019003115 11/2/2020Document4 pagesEEC461 LAB 2: Mohan Mohinish Ram 2019003115 11/2/2020mohan ramNo ratings yet

- Varactor: Voltage Current Characteristic Negative Resistance Region OscillatorsDocument2 pagesVaractor: Voltage Current Characteristic Negative Resistance Region Oscillatorsmohan ramNo ratings yet

- Surface Acoustic Wave (Saw) FiltersDocument2 pagesSurface Acoustic Wave (Saw) Filtersmohan ramNo ratings yet

- Tank Circuits & OscillatorsDocument5 pagesTank Circuits & Oscillatorsmohan ramNo ratings yet

- The Concept of ResonanceDocument6 pagesThe Concept of Resonancemohan ramNo ratings yet

- EEC462 Radio Receivers and TransmittersDocument6 pagesEEC462 Radio Receivers and Transmittersmohan ramNo ratings yet

- Eec461 Assignment 2: Mohan Mohinish Ram 2019003115 11/6/2020Document2 pagesEec461 Assignment 2: Mohan Mohinish Ram 2019003115 11/6/2020mohan ramNo ratings yet

- Project Progress Report Form 5Document5 pagesProject Progress Report Form 5mohan ramNo ratings yet

- EEC461 Television Systems Quarter 4 2020 Assignment 1: Name: Sufyaan Naushad Ali Id: 2020001829Document2 pagesEEC461 Television Systems Quarter 4 2020 Assignment 1: Name: Sufyaan Naushad Ali Id: 2020001829mohan ramNo ratings yet

- Electronics Project: Music Operated DJ Lights and Infrared Remote Control SwitchDocument4 pagesElectronics Project: Music Operated DJ Lights and Infrared Remote Control Switchmohan ramNo ratings yet

- Project Progress Report Form 2Document3 pagesProject Progress Report Form 2mohan ramNo ratings yet

- Project Progress Report Form 3Document4 pagesProject Progress Report Form 3mohan ramNo ratings yet

- Project Progress Report Form 4Document4 pagesProject Progress Report Form 4mohan ramNo ratings yet

- Control - Motion - Interface: High Performance Flying Shear ControlDocument42 pagesControl - Motion - Interface: High Performance Flying Shear Controlقلمي كنزىNo ratings yet

- UTC NE558 Linear Integrated Circuit: Quad TimerDocument2 pagesUTC NE558 Linear Integrated Circuit: Quad TimerCajun LeBeauNo ratings yet

- 7600 PM ProcedureDocument14 pages7600 PM ProceduremrscribdNo ratings yet

- Hawke Accessories NylonWasherDocument1 pageHawke Accessories NylonWasherKaustabha DasNo ratings yet

- Electromagnetic (Eddy Current) Examination of Copper and Copper-Alloy TubesDocument6 pagesElectromagnetic (Eddy Current) Examination of Copper and Copper-Alloy Tubesedapo79No ratings yet

- Using Non-Inverting Buck-Boost Converter For Voltage StabilizationDocument8 pagesUsing Non-Inverting Buck-Boost Converter For Voltage StabilizationTobi CliffordrxNo ratings yet

- Viva QuestionsDocument11 pagesViva QuestionsRaj Kumar0% (1)

- Wilo Rexa Fit V05da 222 Ead1 2 t0025 540 oDocument27 pagesWilo Rexa Fit V05da 222 Ead1 2 t0025 540 oIntendencia UsinaNo ratings yet

- Minty BoostDocument101 pagesMinty BoostJohnny Lariu LabininayNo ratings yet

- Float Cum Boost Battery ChargerDocument3 pagesFloat Cum Boost Battery ChargerBadal PatnaikNo ratings yet

- 04 - Hpu Skydrol 5431Document255 pages04 - Hpu Skydrol 5431cleberNo ratings yet

- JBL Control SB-5 Service ManualDocument2 pagesJBL Control SB-5 Service ManualBillyKidda100% (3)

- JC3000 - Brochure Dec10 (En)Document12 pagesJC3000 - Brochure Dec10 (En)Thiago GarciaNo ratings yet

- rdr-919q 60w High Input Voltage Psu Automotive Innoswitch3-Aq-1700v SicDocument60 pagesrdr-919q 60w High Input Voltage Psu Automotive Innoswitch3-Aq-1700v SicTeyfik koyuncuNo ratings yet

- Quasi-Z-Source Inverter For Photovoltaic Power Generation Systems PDFDocument7 pagesQuasi-Z-Source Inverter For Photovoltaic Power Generation Systems PDFSudip MondalNo ratings yet

- Lab Report Workshop 10Document3 pagesLab Report Workshop 10Abdullah AnsariNo ratings yet

- Flying MachinesDocument2 pagesFlying MachinesGuillermo CadmastersNo ratings yet

- From PG 03: Lotus Powergear PVT - Ltd.,BangaloreDocument1 pageFrom PG 03: Lotus Powergear PVT - Ltd.,BangalorethavaselvanNo ratings yet

- Research On SVPWM OkDocument6 pagesResearch On SVPWM OkAnonymous 1D3dCWNcNo ratings yet

- Boost Battery Performance Through Advanced Charging - Electronic DesignDocument30 pagesBoost Battery Performance Through Advanced Charging - Electronic DesignAlan WeissNo ratings yet

- Technical Characteristics: A-1900 Test CardDocument2 pagesTechnical Characteristics: A-1900 Test CardThanosEleftheroudisNo ratings yet

- Components of Power GenerationDocument3 pagesComponents of Power GenerationWyndellRioNo ratings yet

- Digital Speed Controller: Description FeaturesDocument2 pagesDigital Speed Controller: Description FeaturesZHIRAYR TitizyanNo ratings yet

- LED Engine On TinkercadDocument4 pagesLED Engine On Tinkercadiyan leadNo ratings yet

- 3GAA182062 BDA 3gaa182062 BdaDocument2 pages3GAA182062 BDA 3gaa182062 BdaefverfNo ratings yet

- Makalah BHS Inggris InsanulDocument12 pagesMakalah BHS Inggris InsanulInsanul AdliNo ratings yet

- The Planning, Design and Analysis of The Bloukrans BridgeDocument14 pagesThe Planning, Design and Analysis of The Bloukrans BridgetevredeNo ratings yet

- SBB5089Z Data SheetDocument11 pagesSBB5089Z Data SheetRaziel EsauNo ratings yet

- Features: Low Input Voltage and High Efficiency Synchronous Boost Converter With 1.3A SwitchDocument15 pagesFeatures: Low Input Voltage and High Efficiency Synchronous Boost Converter With 1.3A SwitchGenaro AyalaNo ratings yet