Professional Documents

Culture Documents

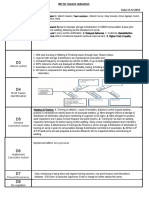

WPS Format

WPS Format

Uploaded by

Harshit AdwaniCopyright:

Available Formats

You might also like

- 04 ws2 Baleq2-KeyDocument2 pages04 ws2 Baleq2-KeyFerni Nishizaki70% (10)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- Koomey S S Manual PDFDocument95 pagesKoomey S S Manual PDFThomas Irwin Dsouza100% (6)

- WPS MCC 001 PDFDocument1 pageWPS MCC 001 PDFNuwan RanaweeraNo ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Solar Setup AnalysisDocument9 pagesSolar Setup AnalysisHarshit AdwaniNo ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Fcaw Wps-001a PDFDocument3 pagesFcaw Wps-001a PDFirfan bari100% (1)

- Welding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempDocument1 pageWelding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempPanneer SelvamNo ratings yet

- Welding ProceduresDocument29 pagesWelding ProceduresLaith Salman100% (1)

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDocument26 pagesNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNo ratings yet

- Record of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014Document2 pagesRecord of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014cisar0007No ratings yet

- WELDING SPECIFICATION Rev BDocument45 pagesWELDING SPECIFICATION Rev Bmurugesan0% (1)

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- (Signed) Quality Manual Revision K 7th EditionDocument32 pages(Signed) Quality Manual Revision K 7th EditionCricri Cri100% (1)

- Health Safety & Environment Procter & Gamble, Ibadan PlantDocument6 pagesHealth Safety & Environment Procter & Gamble, Ibadan PlantsacbaloNo ratings yet

- T Tuv Ind Dia Priva Ate Lim Ited: Inspe Ection Re Elease N Note / Ce Ertificat TEDocument2 pagesT Tuv Ind Dia Priva Ate Lim Ited: Inspe Ection Re Elease N Note / Ce Ertificat TEalpesh patelNo ratings yet

- BQ-ZUL-0XX10 Welding Consumable ControlDocument10 pagesBQ-ZUL-0XX10 Welding Consumable ControlRAMAKRISHNANo ratings yet

- Team Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitDocument1 pageTeam Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitRakesh KumarNo ratings yet

- Quality Control Manual: Rev. DateDocument1 pageQuality Control Manual: Rev. DatealokbdasNo ratings yet

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoNo ratings yet

- Project Quality Plan 8 7 2012 PDFDocument26 pagesProject Quality Plan 8 7 2012 PDFtalhaNo ratings yet

- S355 To Hardox 450Document1 pageS355 To Hardox 450Bien NguyenDuyNo ratings yet

- Standard QAPDocument9 pagesStandard QAPsivaNo ratings yet

- Welding Qualification: by L D PoyyaraDocument45 pagesWelding Qualification: by L D PoyyaraAshish GhadiyaNo ratings yet

- Welding Workshop ManualDocument16 pagesWelding Workshop ManualMuhammad FarooqNo ratings yet

- PQR Al 6xxxDocument7 pagesPQR Al 6xxxAmin ThabetNo ratings yet

- Bs Tech: Electrodes Issue and Return RegisterDocument1 pageBs Tech: Electrodes Issue and Return RegisterRhannie GarciaNo ratings yet

- FactoryDocument72 pagesFactorywhitebrosNo ratings yet

- Inspection and Test Plan Cargo Barge: Page 1 of 2Document2 pagesInspection and Test Plan Cargo Barge: Page 1 of 2ferdyNo ratings yet

- Weld ElectrodesDocument42 pagesWeld ElectrodesNarendraNo ratings yet

- ASME F and P Number Definitions..Document9 pagesASME F and P Number Definitions..Sankar KrishnanNo ratings yet

- Format-Welder Qualification Record (WQR)Document1 pageFormat-Welder Qualification Record (WQR)groshan20No ratings yet

- 1 WPS & PQRDocument2 pages1 WPS & PQRManoranjan sharmaNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- ADAPTER Class E Rev 1 - 5.2.2018Document16 pagesADAPTER Class E Rev 1 - 5.2.2018Rajbir SinghNo ratings yet

- Icr-Pr-18 NDT ProcedureDocument4 pagesIcr-Pr-18 NDT ProcedureBauyrzhanNo ratings yet

- Re Manufacturing Trends and IssuesDocument14 pagesRe Manufacturing Trends and Issuescallisto69No ratings yet

- Whitepaper Remanufacturing Liebherr enDocument11 pagesWhitepaper Remanufacturing Liebherr enAyaz İş MakinalarıNo ratings yet

- Atv Projects India LTD Mathura (U.P) : Rotary Kiln (Ø 4.2M)Document2 pagesAtv Projects India LTD Mathura (U.P) : Rotary Kiln (Ø 4.2M)alokbdas100% (1)

- Standard PracticeDocument14 pagesStandard PracticeRomi Abdul RahmanNo ratings yet

- Schedule of Test Welder Qualification:: 041/VIII/STWQ/2014Document2 pagesSchedule of Test Welder Qualification:: 041/VIII/STWQ/2014Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Procedure For Packing & Dispatch: Spectraa Technology Solutions LTDDocument4 pagesProcedure For Packing & Dispatch: Spectraa Technology Solutions LTDAshokkumar ThangarajNo ratings yet

- 17 Identification and Traceability: ISO 3834-2 and ISO 3834-3 Required Documents Typical Records/reportsDocument3 pages17 Identification and Traceability: ISO 3834-2 and ISO 3834-3 Required Documents Typical Records/reportselmiraNo ratings yet

- Welder Testing Procedure 2014 2Document3 pagesWelder Testing Procedure 2014 2Sandip JawalkarNo ratings yet

- Shell Gumusut Kakap OverviewDocument2 pagesShell Gumusut Kakap Overviewhanantas11No ratings yet

- Fabrication of Heavy Wall Reactors in Crmo V PlatesDocument24 pagesFabrication of Heavy Wall Reactors in Crmo V PlatesDinesh Vaghela100% (1)

- Quality Standars of ShipbuildingDocument60 pagesQuality Standars of ShipbuildingMohamed HassanNo ratings yet

- Quality Control in Welding Repair of Pelton RunnerDocument8 pagesQuality Control in Welding Repair of Pelton RunnerDheeraj ThakurNo ratings yet

- EM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFDocument37 pagesEM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFdang2172014No ratings yet

- Counter WeightDocument1 pageCounter WeightAvish100% (1)

- TDC-722-Rev-0-IS-2062-2011-E250 BO - DomesticDocument6 pagesTDC-722-Rev-0-IS-2062-2011-E250 BO - DomesticPrakash RajNo ratings yet

- Weld ShrinkageDocument16 pagesWeld ShrinkageWeff JingNo ratings yet

- Lloyds Approved Welding Consumables SuppliersDocument16 pagesLloyds Approved Welding Consumables SuppliersadammzjinNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- General Format For Girder Fabrication Check ListDocument4 pagesGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- WFP 2 01 Procedure R1Document8 pagesWFP 2 01 Procedure R1leodavid87No ratings yet

- Voestalpine Heavy Plate TTD ALDUR E 14012013Document13 pagesVoestalpine Heavy Plate TTD ALDUR E 14012013Dragan JerčićNo ratings yet

- Application CV - Muliana Famela Putra PDFDocument6 pagesApplication CV - Muliana Famela Putra PDFdewintaNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- 5Document1 page5Harshit AdwaniNo ratings yet

- MPBPL2570344000Document1 pageMPBPL2570344000Harshit AdwaniNo ratings yet

- ECR Statement FTM Jul 2023Document2 pagesECR Statement FTM Jul 2023Harshit AdwaniNo ratings yet

- Steel DivisionDocument3 pagesSteel DivisionHarshit AdwaniNo ratings yet

- Dc-1 Dimension of StaircaseDocument1 pageDc-1 Dimension of StaircaseHarshit AdwaniNo ratings yet

- Rate Workings-Profile Sheets KLBC (Byharshit)Document14 pagesRate Workings-Profile Sheets KLBC (Byharshit)Harshit AdwaniNo ratings yet

- Sno. Description Qty Unit Rate Per: UnitDocument1 pageSno. Description Qty Unit Rate Per: UnitHarshit AdwaniNo ratings yet

- MS End Cap DrawingDocument1 pageMS End Cap DrawingHarshit AdwaniNo ratings yet

- Javed Bhai PQRDocument1 pageJaved Bhai PQRHarshit AdwaniNo ratings yet

- Isolation Valve Chamber: S.No. Location Chainage L W C D Rising Main Inner DiaDocument63 pagesIsolation Valve Chamber: S.No. Location Chainage L W C D Rising Main Inner DiaHarshit AdwaniNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- Priority-I by ABDocument1 pagePriority-I by ABHarshit AdwaniNo ratings yet

- L&T Constructions: Alirajpur Lift Irrigation Scheme Joinery Schedules/QuantitiesDocument1 pageL&T Constructions: Alirajpur Lift Irrigation Scheme Joinery Schedules/QuantitiesHarshit AdwaniNo ratings yet

- Catalogo Polea Dentada Polea Sincronica PDFDocument35 pagesCatalogo Polea Dentada Polea Sincronica PDFJuan Alberto JuannNo ratings yet

- Ionic Equilibrium PDFDocument54 pagesIonic Equilibrium PDFBhushan50% (2)

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsDocument2 pagesConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsRaghavendra GaNo ratings yet

- BiogeochemicalcycleswebqueststudentformDocument4 pagesBiogeochemicalcycleswebqueststudentformapi-2608174140% (1)

- Chapter 13alkaloidsDocument3 pagesChapter 13alkaloidsLeo GondayaoNo ratings yet

- Non Compartmental AnalysisDocument13 pagesNon Compartmental AnalysisMuhammad FaheemNo ratings yet

- 2008 North America Abstract - BookDocument371 pages2008 North America Abstract - BookTu NguyenNo ratings yet

- Specialty Acrylics Various TDS FormulationsDocument2 pagesSpecialty Acrylics Various TDS Formulationsfranchise.adajanNo ratings yet

- The Positive Impact of Plastic Recycling in The Built Environment, Architecture and The Waters of The WorldDocument9 pagesThe Positive Impact of Plastic Recycling in The Built Environment, Architecture and The Waters of The WorldEditor IJTSRDNo ratings yet

- PDS Hempafire Optima 500Document3 pagesPDS Hempafire Optima 500Tanmay GorNo ratings yet

- Pradeep Chemistry 12 2015-2016 Volume 2Document1,006 pagesPradeep Chemistry 12 2015-2016 Volume 2Mugdha100% (2)

- SDS Cellosize QP 100MHDocument9 pagesSDS Cellosize QP 100MHRND PT SIPNo ratings yet

- Superconductivity PresentationDocument26 pagesSuperconductivity PresentationSabrina Palazzese Di BasilioNo ratings yet

- Unit - 1 Building Materials Notes PDFDocument18 pagesUnit - 1 Building Materials Notes PDFTARANATH S DNo ratings yet

- Chemical Resistance BrochureDocument20 pagesChemical Resistance BrochurelanikhilNo ratings yet

- Scientific BooksDocument5 pagesScientific Booksapi-237984851No ratings yet

- Multiphase Separation Processes: AdsorptionDocument45 pagesMultiphase Separation Processes: AdsorptionRahul SahuNo ratings yet

- 1978 - Radhakrishnan-Cumulative Damage in Low-Cycle FatigueDocument5 pages1978 - Radhakrishnan-Cumulative Damage in Low-Cycle FatigueSRIKANTH K 15PHD1093No ratings yet

- Tds Kemira Cop 183 Emea enDocument1 pageTds Kemira Cop 183 Emea enSteven CoultonNo ratings yet

- Periodic Table of ElementsDocument1 pagePeriodic Table of ElementsRintuNo ratings yet

- Apple and Tomato Peels An AlternativeDocument18 pagesApple and Tomato Peels An AlternativeJahara MontesNo ratings yet

- Hybrid Ceramics.Document99 pagesHybrid Ceramics.mahaNo ratings yet

- Roller DesignDocument34 pagesRoller DesignAnonymous z4Fe39j100% (1)

- Raid S2+plusDocument4 pagesRaid S2+plussunilyadav687No ratings yet

- Kennedy Valve/UL/FM Butterfly Valves 11-1Document51 pagesKennedy Valve/UL/FM Butterfly Valves 11-1Allen Gutierrez FabricanteNo ratings yet

- Obat PatenDocument144 pagesObat PatenSucci Ariessa ReviantiNo ratings yet

- Molecules: HPLC-ESI-MS/MS of Imidazole Alkaloids in PilocarpusDocument12 pagesMolecules: HPLC-ESI-MS/MS of Imidazole Alkaloids in PilocarpusclaraNo ratings yet

- Demulsif SaltDocument12 pagesDemulsif SaltLidiya KirilovaNo ratings yet

WPS Format

WPS Format

Uploaded by

Harshit AdwaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS Format

WPS Format

Uploaded by

Harshit AdwaniCopyright:

Available Formats

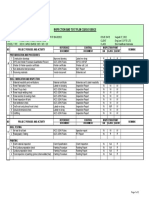

WPS NO.

:-KIP-RB/WPS/

FORMAT NO.

:-L&T/KIP-RB/QMF-

REV. NO. 00 DATE:- 01/04/2019

CODE:- ASME SEC IX SUPPORTING PQR NO. :- L&T/

WELDING PROCESS:- SMAW TYPE :- MANUAL

JOINTS(QW 402) BASE METAL :- QW(403)

GROOVE DESIGN:- SINGLE V P.NO. 1 GR 1 P.NO. 1 GR 1 POSITION (QW 405)

BASE METAL THICKNESS:- UPTO 12

ROOT SPACING:- 2.0 -4.5 MM MM GROOVE :- ALL

BACKING:- N/A for root pass(groove)weld FILLET : ALL GROOVE:-UPTO 12 FILLET :- ALL

metal for subsequent MM

BACKING MATERIAL TYPE: BASE/WELD Max. Pass THICKNESS <= 13

METAL mm(Yes/No): Yes WELD PROGRESSION:

UPHILL

GAS(QW 408) PREHEAT (QW-406) PWHT(QW-407)

INTER PASS TEMPER. TYPE OF PWHT: N/A

PURPOSE GAS % (MAX) :- 250 ̊ C

PRE HEAT

TEMP. HEATING RATE:- N/A

(min):N/A

PRE HEAT

Shielding Gas N/A N/A MAINTAINANCE :- N/A

Backing Gas N/A N/A METHOD OF PREHEATING :- N/A COOLING RATE:- N/A

POST HEATING TEPMERATURE :- SOAKING

Trailing Gas N/A N/A N/A TEMPERATURE:- N/A

POST HEATING TIME :- N/A SOAKING TIME :- N/A

FILLER METALS ELECTRICAL CHARCTERSTICS & TECHNIQUES (QW 404,409 & 410)

Process SMAW

AWS Class E6010 E6013

F/A NO. 3/1 2/1

SFA NO. 5.1

Diameter (mm) 2.5 3.15

Polarity DCEP DCEP

Current Range(A) 50-80 60-90

Voltage Range(V) 18-22 18-24

Deposited Weld Metal

thick. 14 mm(MAX)

Travel Speed(mm/ 85 mm/min.

thick.) (minimum)

Heat input(KJ/ mm) N/A

Flux type N/A

Gas Cup Size(mm) N/A

Tungsten Type N/A

Tungsten Size(mm) N/A

Mode of Metal Transfer N/A

String & Weave String/ weave As

Applicable

Oscillation N/A

Contact Tube Distance N/A

Method of back

goughing GRINDING

Initial and inter pass By Brush,

cleaning Chipping as

applicable

Multi/Single Pass MULTIPLE

Multi/Single Electrode SINGLE

Peening N/A

PREPARED BY

KRISHNA STEEL APPROVED BY PM L&T - WET

INDUSTRIES - A.R. IC

Sinha

Signature with Date

NAME

You might also like

- 04 ws2 Baleq2-KeyDocument2 pages04 ws2 Baleq2-KeyFerni Nishizaki70% (10)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- Koomey S S Manual PDFDocument95 pagesKoomey S S Manual PDFThomas Irwin Dsouza100% (6)

- WPS MCC 001 PDFDocument1 pageWPS MCC 001 PDFNuwan RanaweeraNo ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Solar Setup AnalysisDocument9 pagesSolar Setup AnalysisHarshit AdwaniNo ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Fcaw Wps-001a PDFDocument3 pagesFcaw Wps-001a PDFirfan bari100% (1)

- Welding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempDocument1 pageWelding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempPanneer SelvamNo ratings yet

- Welding ProceduresDocument29 pagesWelding ProceduresLaith Salman100% (1)

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDocument26 pagesNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNo ratings yet

- Record of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014Document2 pagesRecord of Welder Qualification Test WQR NO: SD006 DATE: 24.07.2014cisar0007No ratings yet

- WELDING SPECIFICATION Rev BDocument45 pagesWELDING SPECIFICATION Rev Bmurugesan0% (1)

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- (Signed) Quality Manual Revision K 7th EditionDocument32 pages(Signed) Quality Manual Revision K 7th EditionCricri Cri100% (1)

- Health Safety & Environment Procter & Gamble, Ibadan PlantDocument6 pagesHealth Safety & Environment Procter & Gamble, Ibadan PlantsacbaloNo ratings yet

- T Tuv Ind Dia Priva Ate Lim Ited: Inspe Ection Re Elease N Note / Ce Ertificat TEDocument2 pagesT Tuv Ind Dia Priva Ate Lim Ited: Inspe Ection Re Elease N Note / Ce Ertificat TEalpesh patelNo ratings yet

- BQ-ZUL-0XX10 Welding Consumable ControlDocument10 pagesBQ-ZUL-0XX10 Welding Consumable ControlRAMAKRISHNANo ratings yet

- Team Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitDocument1 pageTeam Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitRakesh KumarNo ratings yet

- Quality Control Manual: Rev. DateDocument1 pageQuality Control Manual: Rev. DatealokbdasNo ratings yet

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoNo ratings yet

- Project Quality Plan 8 7 2012 PDFDocument26 pagesProject Quality Plan 8 7 2012 PDFtalhaNo ratings yet

- S355 To Hardox 450Document1 pageS355 To Hardox 450Bien NguyenDuyNo ratings yet

- Standard QAPDocument9 pagesStandard QAPsivaNo ratings yet

- Welding Qualification: by L D PoyyaraDocument45 pagesWelding Qualification: by L D PoyyaraAshish GhadiyaNo ratings yet

- Welding Workshop ManualDocument16 pagesWelding Workshop ManualMuhammad FarooqNo ratings yet

- PQR Al 6xxxDocument7 pagesPQR Al 6xxxAmin ThabetNo ratings yet

- Bs Tech: Electrodes Issue and Return RegisterDocument1 pageBs Tech: Electrodes Issue and Return RegisterRhannie GarciaNo ratings yet

- FactoryDocument72 pagesFactorywhitebrosNo ratings yet

- Inspection and Test Plan Cargo Barge: Page 1 of 2Document2 pagesInspection and Test Plan Cargo Barge: Page 1 of 2ferdyNo ratings yet

- Weld ElectrodesDocument42 pagesWeld ElectrodesNarendraNo ratings yet

- ASME F and P Number Definitions..Document9 pagesASME F and P Number Definitions..Sankar KrishnanNo ratings yet

- Format-Welder Qualification Record (WQR)Document1 pageFormat-Welder Qualification Record (WQR)groshan20No ratings yet

- 1 WPS & PQRDocument2 pages1 WPS & PQRManoranjan sharmaNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- ADAPTER Class E Rev 1 - 5.2.2018Document16 pagesADAPTER Class E Rev 1 - 5.2.2018Rajbir SinghNo ratings yet

- Icr-Pr-18 NDT ProcedureDocument4 pagesIcr-Pr-18 NDT ProcedureBauyrzhanNo ratings yet

- Re Manufacturing Trends and IssuesDocument14 pagesRe Manufacturing Trends and Issuescallisto69No ratings yet

- Whitepaper Remanufacturing Liebherr enDocument11 pagesWhitepaper Remanufacturing Liebherr enAyaz İş MakinalarıNo ratings yet

- Atv Projects India LTD Mathura (U.P) : Rotary Kiln (Ø 4.2M)Document2 pagesAtv Projects India LTD Mathura (U.P) : Rotary Kiln (Ø 4.2M)alokbdas100% (1)

- Standard PracticeDocument14 pagesStandard PracticeRomi Abdul RahmanNo ratings yet

- Schedule of Test Welder Qualification:: 041/VIII/STWQ/2014Document2 pagesSchedule of Test Welder Qualification:: 041/VIII/STWQ/2014Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Procedure For Packing & Dispatch: Spectraa Technology Solutions LTDDocument4 pagesProcedure For Packing & Dispatch: Spectraa Technology Solutions LTDAshokkumar ThangarajNo ratings yet

- 17 Identification and Traceability: ISO 3834-2 and ISO 3834-3 Required Documents Typical Records/reportsDocument3 pages17 Identification and Traceability: ISO 3834-2 and ISO 3834-3 Required Documents Typical Records/reportselmiraNo ratings yet

- Welder Testing Procedure 2014 2Document3 pagesWelder Testing Procedure 2014 2Sandip JawalkarNo ratings yet

- Shell Gumusut Kakap OverviewDocument2 pagesShell Gumusut Kakap Overviewhanantas11No ratings yet

- Fabrication of Heavy Wall Reactors in Crmo V PlatesDocument24 pagesFabrication of Heavy Wall Reactors in Crmo V PlatesDinesh Vaghela100% (1)

- Quality Standars of ShipbuildingDocument60 pagesQuality Standars of ShipbuildingMohamed HassanNo ratings yet

- Quality Control in Welding Repair of Pelton RunnerDocument8 pagesQuality Control in Welding Repair of Pelton RunnerDheeraj ThakurNo ratings yet

- EM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFDocument37 pagesEM-SRC-0005-Marking Packaging Preservation and Shipping Requirements PDFdang2172014No ratings yet

- Counter WeightDocument1 pageCounter WeightAvish100% (1)

- TDC-722-Rev-0-IS-2062-2011-E250 BO - DomesticDocument6 pagesTDC-722-Rev-0-IS-2062-2011-E250 BO - DomesticPrakash RajNo ratings yet

- Weld ShrinkageDocument16 pagesWeld ShrinkageWeff JingNo ratings yet

- Lloyds Approved Welding Consumables SuppliersDocument16 pagesLloyds Approved Welding Consumables SuppliersadammzjinNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- General Format For Girder Fabrication Check ListDocument4 pagesGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- WFP 2 01 Procedure R1Document8 pagesWFP 2 01 Procedure R1leodavid87No ratings yet

- Voestalpine Heavy Plate TTD ALDUR E 14012013Document13 pagesVoestalpine Heavy Plate TTD ALDUR E 14012013Dragan JerčićNo ratings yet

- Application CV - Muliana Famela Putra PDFDocument6 pagesApplication CV - Muliana Famela Putra PDFdewintaNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- 5Document1 page5Harshit AdwaniNo ratings yet

- MPBPL2570344000Document1 pageMPBPL2570344000Harshit AdwaniNo ratings yet

- ECR Statement FTM Jul 2023Document2 pagesECR Statement FTM Jul 2023Harshit AdwaniNo ratings yet

- Steel DivisionDocument3 pagesSteel DivisionHarshit AdwaniNo ratings yet

- Dc-1 Dimension of StaircaseDocument1 pageDc-1 Dimension of StaircaseHarshit AdwaniNo ratings yet

- Rate Workings-Profile Sheets KLBC (Byharshit)Document14 pagesRate Workings-Profile Sheets KLBC (Byharshit)Harshit AdwaniNo ratings yet

- Sno. Description Qty Unit Rate Per: UnitDocument1 pageSno. Description Qty Unit Rate Per: UnitHarshit AdwaniNo ratings yet

- MS End Cap DrawingDocument1 pageMS End Cap DrawingHarshit AdwaniNo ratings yet

- Javed Bhai PQRDocument1 pageJaved Bhai PQRHarshit AdwaniNo ratings yet

- Isolation Valve Chamber: S.No. Location Chainage L W C D Rising Main Inner DiaDocument63 pagesIsolation Valve Chamber: S.No. Location Chainage L W C D Rising Main Inner DiaHarshit AdwaniNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- Priority-I by ABDocument1 pagePriority-I by ABHarshit AdwaniNo ratings yet

- L&T Constructions: Alirajpur Lift Irrigation Scheme Joinery Schedules/QuantitiesDocument1 pageL&T Constructions: Alirajpur Lift Irrigation Scheme Joinery Schedules/QuantitiesHarshit AdwaniNo ratings yet

- Catalogo Polea Dentada Polea Sincronica PDFDocument35 pagesCatalogo Polea Dentada Polea Sincronica PDFJuan Alberto JuannNo ratings yet

- Ionic Equilibrium PDFDocument54 pagesIonic Equilibrium PDFBhushan50% (2)

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsDocument2 pagesConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsRaghavendra GaNo ratings yet

- BiogeochemicalcycleswebqueststudentformDocument4 pagesBiogeochemicalcycleswebqueststudentformapi-2608174140% (1)

- Chapter 13alkaloidsDocument3 pagesChapter 13alkaloidsLeo GondayaoNo ratings yet

- Non Compartmental AnalysisDocument13 pagesNon Compartmental AnalysisMuhammad FaheemNo ratings yet

- 2008 North America Abstract - BookDocument371 pages2008 North America Abstract - BookTu NguyenNo ratings yet

- Specialty Acrylics Various TDS FormulationsDocument2 pagesSpecialty Acrylics Various TDS Formulationsfranchise.adajanNo ratings yet

- The Positive Impact of Plastic Recycling in The Built Environment, Architecture and The Waters of The WorldDocument9 pagesThe Positive Impact of Plastic Recycling in The Built Environment, Architecture and The Waters of The WorldEditor IJTSRDNo ratings yet

- PDS Hempafire Optima 500Document3 pagesPDS Hempafire Optima 500Tanmay GorNo ratings yet

- Pradeep Chemistry 12 2015-2016 Volume 2Document1,006 pagesPradeep Chemistry 12 2015-2016 Volume 2Mugdha100% (2)

- SDS Cellosize QP 100MHDocument9 pagesSDS Cellosize QP 100MHRND PT SIPNo ratings yet

- Superconductivity PresentationDocument26 pagesSuperconductivity PresentationSabrina Palazzese Di BasilioNo ratings yet

- Unit - 1 Building Materials Notes PDFDocument18 pagesUnit - 1 Building Materials Notes PDFTARANATH S DNo ratings yet

- Chemical Resistance BrochureDocument20 pagesChemical Resistance BrochurelanikhilNo ratings yet

- Scientific BooksDocument5 pagesScientific Booksapi-237984851No ratings yet

- Multiphase Separation Processes: AdsorptionDocument45 pagesMultiphase Separation Processes: AdsorptionRahul SahuNo ratings yet

- 1978 - Radhakrishnan-Cumulative Damage in Low-Cycle FatigueDocument5 pages1978 - Radhakrishnan-Cumulative Damage in Low-Cycle FatigueSRIKANTH K 15PHD1093No ratings yet

- Tds Kemira Cop 183 Emea enDocument1 pageTds Kemira Cop 183 Emea enSteven CoultonNo ratings yet

- Periodic Table of ElementsDocument1 pagePeriodic Table of ElementsRintuNo ratings yet

- Apple and Tomato Peels An AlternativeDocument18 pagesApple and Tomato Peels An AlternativeJahara MontesNo ratings yet

- Hybrid Ceramics.Document99 pagesHybrid Ceramics.mahaNo ratings yet

- Roller DesignDocument34 pagesRoller DesignAnonymous z4Fe39j100% (1)

- Raid S2+plusDocument4 pagesRaid S2+plussunilyadav687No ratings yet

- Kennedy Valve/UL/FM Butterfly Valves 11-1Document51 pagesKennedy Valve/UL/FM Butterfly Valves 11-1Allen Gutierrez FabricanteNo ratings yet

- Obat PatenDocument144 pagesObat PatenSucci Ariessa ReviantiNo ratings yet

- Molecules: HPLC-ESI-MS/MS of Imidazole Alkaloids in PilocarpusDocument12 pagesMolecules: HPLC-ESI-MS/MS of Imidazole Alkaloids in PilocarpusclaraNo ratings yet

- Demulsif SaltDocument12 pagesDemulsif SaltLidiya KirilovaNo ratings yet