Professional Documents

Culture Documents

BBR H Bar System Flyer Rev3 1219

BBR H Bar System Flyer Rev3 1219

Uploaded by

Юлия ДамOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BBR H Bar System Flyer Rev3 1219

BBR H Bar System Flyer Rev3 1219

Uploaded by

Юлия ДамCopyright:

Available Formats

BBR H Bar System

Hot Rolled Threaded Bars for Construction and

Underground Applications

The BBR H Bar is a steel threaded bar with superior fatigue performance and the widest

range of bar diameters on the international market place. It is available with steel

grades ranging from 500/550MPa to 930/1080MPa (yield/ultimate) and in

diameters from 20mm to 75mm.

ut

kn

Loc

The BBR H Bar has a specially designed continuous thread over

its entire length allowing it to be easily cut or lengthened with upl

er

Co

couplers at any location. With its reliability, robustness kn

ut

Loc

and ease of installation and the full range of

accessories - BBR H Bar is the ideal system

for the most complex and technically bar

e a ded

r

challenging applications. Th

late

i n gp

ar e

Be h con

wit

ut

edn

Dom

Yusufeli Dam (Turkey)

BBR H Bar System

Hot Rolled Threaded Bars for Construction and

Underground Applications

Testing & quality assurance to international standards

At BBR, we take pride in every piece of construction technology

that we supply and this is why we conduct thorough independently

verified laboratory testing. We expect that each product should

conform to the highest standards and that it should reach our

customers in prime condition, ready for immediate use.

Independently verified testing The maximum force and force at yield

As a part of our testing program for must meet the specified values as 5%

technical approval, we have performed fractiles. The ratio of maximum force to

key tests to verify the major mechanical force at yield, as well as the elongation at

properties of the BBR H Bar System. maximum force (Agt) must meet values as

We have carried out static, fatigue and 10% fractiles. Agt is expected to be at least

material testing on the system, comprising 3.5%.

the accessories. All the tests were executed

in independent accredited European Static test on bar system

laboratories. Static testing of the whole system

complies with European technical approval

The testing results proved that the guidelines. A complete bar system kit

BBR H Bar System not only complies with consists of bar, anchor plate, nut and Fatigue test on tensile bar element

the latest European norms, standards coupler. The assembled system is stressed Fatigue testing of the bars is executed

and guidelines, but also fulfills additional in stages using standard stressing under the provisions of European norms

requirements specified by local authorities equipment to 80% of characteristic and international standards. A bar

in other regions. ultimate tensile stress. The load is then specimen is stressed by a resonance

maintained for one hour for the bonded testing rig to a specified force range

Static test on tensile bar element system, or two hours for the unbonded with stress variation cycles. All the bars

Static testing of tensile elements is carried system. The deformation during loading withstood two million load cycles, with

out according to European norms and is measured. Additionally, any slip at an upper limit at 70% of characteristic

international standards. the anchorage and coupler, as well as ultimate tensile stress and a specified

A bar specimen is stressed by standard any residual deformation of anchorage stress range without failure.

stressing equipment to the maximum components after stressing is monitored.

force (corresponding to ultimate tensile All type of nuts and couplers are tested.

strength) at a specified loading rate. In each test, 100% of the specified

Elongation of the bars is measured during maximum force is attained, with

the tests. deformation stabilizing at 80% of ultimate

tensile stress within 30 minutes.

BBR VT International Ltd | Ringstrasse 2 | 8603 Schwerzenbach | Switzerland

Tel +41 44 806 80 60 | Fax +41 44 806 80 50 | www.bbrnetwork.com

BBR H Bar System

Hot Rolled Threaded Bars for Construction and

Underground Applications

Fatigue test on bar system Packing & shipping

Fatigue testing of the system follows Our products are shipped globally to

European technical approval guidelines. A various projects, therefore proper packing

complete bar system kit – consisting of bar, is a critical step in ensuring products are

anchor plate, nut and coupler – is stressed delivered undamaged. This is especially

by a resonance testing rig to a specified important when it concerns products which

force range with stress variation cycles. All feature additional corrosion protection –

types of nuts and couplers are also tested, such as galvanizing or epoxy coating.

and any slip at the anchorage and coupler

is measured. The acceptance criterion is to The highest standards are applied to the

pass two million load cycles, with an upper BBR packing regime, ensuring goods are

force at 65% of characteristic ultimate wrapped with protective paper or fabric,

tensile stress and a stress range of not less properly bound with steel strapping and

than 80MPa. placed inside wooden crates.

Verification of load transfer in the Additional testing on request

anchorage zone BBR has a long experience of working with

The load transfer in the anchorage international standards and laboratory test

zone, including relevant reinforcement regimes, thus our engineers are able to

and concrete with the recommended perform any project-specific tests that may

dimensions for a particular concrete be required. For example, static and fatigue

strength, should be verified according to testing conforming with EN ISO 15630-1

the European and international codes and and also with ETAG 013 are available.

technical approval guidelines. During a load Please contact us for further details.

transfer test, the anchorage components

are subjected to 10 load cycles between

12% and 80% of characteristic ultimate

tensile stress, before the complete

assembly is loaded to failure. An efficiency

of at least 110% of characteristic ultimate

tensile stress must be achieved.

BBR H Bar System

Hot Rolled Threaded Bars for Construction and

Underground Applications

BBR H930 Bar System BBR H830 Bar System

Threaded Bar Specifications Threaded Bar Specifications

Component dimensions Component dimensions

Property Size

ø25 ø32 ø36 ø40 ø50 ø25 ø32 ø36 ø40

Nominal diameter mm 25 32 36 40 50 25 32 36 40

Yield stress MPa 930 930 930 930 930 830 830 830 830

Ultimate stress MPa 1080 1080 1080 1080 1080 1030 1030 1030 1030

Yield load kN 457 748 947 1169 1827 407 667 844 1043

Ultimate load kN 530 869 1099 1357 2121 505 828 1048 1294

Nom. cross section mm2 491 804 1018 1257 1964 491 804 1018 1257

Weight kg/m 4.10 6.65 8.41 10.34 16.28 4.10 6.65 8.41 10.34

Right-hand thread Elongation at max. load Agt = 3.5% Elongation at max. load Agt = 3.5%

Accessory Specifications Accessory Specifications

Component dimensions Component dimensions

Anchor nut Size

ø25 ø32 ø36 ø40 ø50 ø25 ø32 ø36 ø40

SW mm 50 60 65 70 80 50 60 65 70

L mm 60 72 80 100 110 60 72 80 100

Weight kg 0.7 1.2 1.5 2.0 2.7 0.7 1.2 1.5 2.0

Domed nut

SW mm 50 60 65 70 85 50 60 65 70

L mm 75 90 100 115 145 75 90 100 115

D mm 72 80 90 100 120 72 80 90 100

Weight kg 1.1 1.8 2.3 3.1 5.4 1.1 1.8 2.3 3.1

Spherical nut

SW mm 50 60 65 70 80 50 60 65 70

L mm 60 72 80 100 110 60 72 80 100

Weight kg 0.6 1.2 1.4 2.0 2.7 0.6 1.2 1.4 2.0

Coupler

D mm 50 60 70 75 90 50 60 70 75

L mm 132 168 180 220 270 132 168 180 220

Weight kg 1.4 2.5 3.6 5.1 8.9 1.4 2.5 3.6 5.1

BBR VT International Ltd | Ringstrasse 2 | 8603 Schwerzenbach | Switzerland

Tel +41 44 806 80 60 | Fax +41 44 806 80 50 | www.bbrnetwork.com

BBR H Bar System

Hot Rolled Threaded Bars for Construction and

Underground Applications

BBR H930 Bar System BBR H830 Bar System

Accessory Specifications Accessory Specifications

Component dimensions Component dimensions

Property Size

ø25 ø32 ø36 ø40 ø50 ø25 ø32 ø36 ø40

Bearing plate for anchor nut

L mm 115 150 165 185 225 100 150 155 170

E mm 30 40 45 50 65 25 40 40 45

Weight kg 2.9 6.6 8.9 12.5 24.1 1.8 6.6 6.9 9.4

Bearing plate for domed nut

L mm 115 150 165 185 225 100 150 155 170

E mm 30 40 45 50 65 25 40 40 45

D mm 35 45 50 55 65 35 45 50 55

Weight kg 2.7 6.3 8.5 11.9 23.5 1.6 6.3 6.6 8.9

Bearing plate for spherical nut

L mm 115 150 165 185 225 100 150 155 170

E mm 30 40 45 50 65 25 40 40 45

D mm 35 45 50 55 65 35 45 50 55

Weight kg 2.8 6.4 8.8 12.3 23.9 1.7 6.4 6.8 9.2

Steel Accessoires

SW

SW

SW

L L

L

Domed anchor nut Spherical anchor nut Hex anchor nut

D

D

L

L

Dext

L t L t

L

Coupler Bearing plate with cone Bearing plate

BBR H Bar System

Hot Rolled Threaded Bars for Construction and

Underground Applications

BBR H670 Bar System

Threaded Bar Specifications

Component dimensions

Property Size

ø22 ø25 ø28 ø30 ø35 ø43 ø50 ø57.5 ø63.5 ø75

Nominal diameter mm 22 25 28 30 35 43 50 57.5 63.5 75

Yield stress MPa 670 670 670 670 670 670 670 670 670 670

Ultimate stress MPa 800 800 800 800 800 800 800 800 800 800

Yield load kN 255 329 413 474 645 973 1315 1740 2122 2960

Ultimate load kN 304 393 493 566 770 1162 1571 2078 2534 3535

Nom. cross section mm2 380 491 616 707 962 1466 1960 2597 3167 4418

Weight kg/m 2.98 3.85 4.83 5.54 7.55 11.40 15.41 20.38 24.86 34.68

Right-hand thread Elongation at max. load Agt = 5%

Accessory Specifications

Component dimensions

Property Size

ø22 ø25 ø28 ø30 ø35 ø43 ø50 ø57.5 ø63.5 ø75

Anchor nut

SW mm 41 46 50 55 65 80 80 90 100 100

L mm 50 55 60 65 70 90 100 120 110 130

Weight kg 0.39 0.53 0.67 0.90 1.37 2.62 2.80 4.42 4.41 4.90

Domed nut

SW mm 36 41 46 50 60 70 80 90 100 120

D mm 45 50 55 60 70 85 100 115 125 150

L mm 53 60 67 71 83 102 116 137 151 174

Weight kg 0.31 0.43 0.60 0.79 1.30 2.20 3.59 5.50 7.30 11.90

Lock nut

SW mm 36 41 46 50 55 70 80 90 100 100

L mm 22 22 30 30 40 50 50 60 70 80

Weight kg 0.12 0.15 0.26 0.31 0.47 1.00 1.39 1.93 3.03 2.33

Coupler

D mm 40 45 50 55 65 80 90 102 114 108

L mm 110 120 140 150 170 200 210 250 300 260

Weight kg 0.71 0.94 1.36 1.84 2.95 5.42 7.24 10.31 14.48 8.74

Bearing plate for anchor nut

L mm 80 90 100 110 125 150 175 200 220 260

E mm 20 20 20 25 25 30 30 45 50 65

Weight kg 2.26 2.20 2.90 3.74 5.80 11.40 17.03 25.46 31.05 53.10

Bearing plate for domed nut

L mm 110 125 135 145 170 210 240 275 300 325

E mm 30 30 35 35 40 50 55 60 65 70

Weight kg 2.62 3.39 4.59 5.32 8.36 15.96 22.77 32.77 42.00 52.44

BBR VT International Ltd | Ringstrasse 2 | 8603 Schwerzenbach | Switzerland

Tel +41 44 806 80 60 | Fax +41 44 806 80 50 | www.bbrnetwork.com

BBR H Bar System

Hot Rolled Threaded Bars for Construction and

Underground Applications

BBR H500 Bar System

Threaded Bar Specifications

Component dimensions

Property Size

ø20 ø25 ø28 ø32 ø40 ø43 ø50 ø57.5 ø63.5 ø75

Nominal diameter mm 20 25 28 32 40 43 50 57.7 63.5 75

Yield stress MPa 500 500 500 500 500 500 500 555 555 500

Ultimate stress MPa 550 550 550 550 550 550 550 700 700 550

Yield load kN 157 246 308 402 629 726 982 1441 1758 2209

Ultimate load kN 172 270 339 442 691 799 1078 1818 2217 2430

Nom. cross section mm2 314 491 616 804 1257 1466 1964 2597 3167 4418

Weight kg/m 2.47 3.85 4.83 6.31 9.87 11.40 15.41 20.38 24.86 34.68

Left-hand thread Elongation at max. load Agt = 6% ≤ ø32mm Elongation at max. load Agt = 5% ø40 to 75mm

Accessory Specifications

Component dimensions

Property Size

ø20 ø25 ø28 ø32 ø40 ø43 ø50 ø57.5 ø63.5 ø75

Anchor nut

SW mm 36 41 46 55 65 70 80 90 100 110

L mm 45 50 55 60 70 85 85 100 135 120

Weight kg 0.26 0.34 0.48 0.78 1.19 1.86 2.17 3.65 6.60 7.02

Domed nut

SW mm 36 41 41 46 60 70 80 90 100 120

L mm 41 45 54 57 70 80 85 100 115 120

D mm 49 55 62 70 88 100 107 120 144 165

Weight kg 0.26 0.35 0.45 0.65 1.25 2.26 2.60 4.15 6.00 9.69

Lock nut

SW mm 32 41 41 50 60 70 80 90 90 110

L mm 20 20 25 30 35 40 50 60 75 80

Weight kg 0.08 0.14 0.15 0.28 0.45 0.87 1.21 2.16 2.18 4.54

Coupler

D mm 36 40 45 52 65 80 80 102 102 140

L mm 105 115 125 140 160 170 200 230 260 290

Weight kg 0.52 0.61 0.85 1.26 2.34 4.75 4.23 10.31 9.55 24.96

Bearing plate for anchor nut

L mm 70 70 100 120 150 170 190 220 245 275

E mm 10 10 12 20 30 35 45 50 50 65

Weight kg 0.33 0.35 0.86 2.06 4.90 7.40 11.82 17.69 22.38 35.60

Bearing plate for domed nut

L mm 70 70 100 120 150 170 190 220 245 275

E mm 12 12 20 20 30 35 45 50 50 65

Weight kg 0.37 0.34 1.33 1.91 4.48 6.61 10.78 16.25 20.09 32.60

BBR H Bar System

Hot Rolled Threaded Bars for Construction and

Underground Applications

Features

• Widest range of bar diameters from 20mm up to 75mm

• Continuous robust thread appropriate for all environmental conditions

and suitable for cutting or lengthening with a coupler at any location

• High quality threaded bar system with superior fatigue performance

• Widest range of bar grades from 550MPa up to 1080MPa (ultimate)

• Full range of accessories facilitate easy and reliable installation

• Suitable for temporary or permanent applications

• Available in standard lengths of 11.8m (custom lengths on request)

• Tested to the latest international standards

Applications

• Post-tensioning

• Geotechnical anchoring

• Ground stabilisation

• Temporary or permanent works

• Construction & civil engineering projects

• Concrete reinforcement

BBR reserves the right to change the system specifications without prior notice.

Fairbairn Dam (Australia)

Rev 3 - 12/19

BBR VT International Ltd | Ringstrasse 2 | 8603 Schwerzenbach | Switzerland

Tel +41 44 806 80 60 | Fax +41 44 806 80 50 | www.bbrnetwork.com

You might also like

- NORSOK U CR 006r1 - Subsea Production Control UmbilicalDocument14 pagesNORSOK U CR 006r1 - Subsea Production Control UmbilicalNils Antoine FreundNo ratings yet

- Komatsu PW200-7 Wheeled - ExcavatorDocument16 pagesKomatsu PW200-7 Wheeled - ExcavatorЮлия Дам100% (3)

- BBR H Bar System Flyer EN Rev1 0418 PDFDocument8 pagesBBR H Bar System Flyer EN Rev1 0418 PDFarnakorn20015933No ratings yet

- Cooper MEDC CU1SEM024506RDI1MR Conjunto Sinalizador e Sirene Inmetro Ficha Tecnica Catalogo DatasheetDocument2 pagesCooper MEDC CU1SEM024506RDI1MR Conjunto Sinalizador e Sirene Inmetro Ficha Tecnica Catalogo DatasheetPeter PenhaNo ratings yet

- SBS-30 SBS30Document8 pagesSBS-30 SBS30damarNo ratings yet

- ST2 Vibrating Wire Arc Weldable Strain GaugeDocument4 pagesST2 Vibrating Wire Arc Weldable Strain GaugeGianni MenaNo ratings yet

- RC Cable Lugs May2020Document140 pagesRC Cable Lugs May2020Whisnu BhuntoroNo ratings yet

- MEDC CU1SEM120T06RNR2BR Sirene de Segurança Ficha Tecnica Catalogo DatasheetDocument2 pagesMEDC CU1SEM120T06RNR2BR Sirene de Segurança Ficha Tecnica Catalogo DatasheetPeter PenhaNo ratings yet

- Ttelectric en PDFDocument24 pagesTtelectric en PDFjuandajdjNo ratings yet

- Shock & Vibration Solutions Product InformationDocument146 pagesShock & Vibration Solutions Product InformationKaharul Afandi100% (1)

- Captura de Tela 2023-11-29 À(s) 20.19.42Document44 pagesCaptura de Tela 2023-11-29 À(s) 20.19.42Julio SantosNo ratings yet

- PowersafeDocument8 pagesPowersafeRamón CalixNo ratings yet

- Calibri Type LP44 Load Cell AssemblyDocument4 pagesCalibri Type LP44 Load Cell Assemblyabdullahaygn1No ratings yet

- Proceq Metal Hardness Catalog - 81053502EDocument8 pagesProceq Metal Hardness Catalog - 81053502EramalingamNo ratings yet

- Cables and Connections: Servo SeriesDocument20 pagesCables and Connections: Servo SeriesFakhreddine HammoudiNo ratings yet

- Concrete Inspection & Metal DetectionDocument18 pagesConcrete Inspection & Metal Detectiondhan singhNo ratings yet

- Prysmian Esp Cable DW 205 R PDFDocument2 pagesPrysmian Esp Cable DW 205 R PDFJava Cable Center50% (2)

- Xtera Repeater Datasheet 03 May 2018 1Document5 pagesXtera Repeater Datasheet 03 May 2018 1tuan80bk43No ratings yet

- Certified, Strong & DurableDocument16 pagesCertified, Strong & DurableЮлия ДамNo ratings yet

- Type 123 Class II 1.2m Ku Band Offset Antenna - REV 3 PDFDocument2 pagesType 123 Class II 1.2m Ku Band Offset Antenna - REV 3 PDFWesley JordãoNo ratings yet

- GT210-10 NGR W TransformerDocument2 pagesGT210-10 NGR W TransformerDeepen SharmaNo ratings yet

- Specification of RCC: Submitted To:-Prof R.J.Shah Submitted By: - Madhav Purohit 000RDMTCE1920007Document39 pagesSpecification of RCC: Submitted To:-Prof R.J.Shah Submitted By: - Madhav Purohit 000RDMTCE1920007Madhav PurohitNo ratings yet

- Roots Comodities, Rev. Technical DescriptionDocument56 pagesRoots Comodities, Rev. Technical Descriptionnu.arabiaNo ratings yet

- Grid Xtreme VR Green-Series Data Sheet enDocument3 pagesGrid Xtreme VR Green-Series Data Sheet enlong bạchNo ratings yet

- Compresión InconfinadaDocument1 pageCompresión InconfinadaJorge SanchezNo ratings yet

- Panelboards SpecificationsDocument7 pagesPanelboards SpecificationsBladimir MichelNo ratings yet

- All Offerings 2017Document8 pagesAll Offerings 2017Andres SanchezNo ratings yet

- TS of HardwareDocument9 pagesTS of HardwareabhishekNo ratings yet

- MK0024 Test and Iso Prod Line Guide - ENGDocument8 pagesMK0024 Test and Iso Prod Line Guide - ENGSagar SamantNo ratings yet

- 2.4m Type 243 C CP RT Class III SpecDocument2 pages2.4m Type 243 C CP RT Class III SpecTran Duy TrongNo ratings yet

- TE Raychem HVBT Tape - Product DescriptionDocument2 pagesTE Raychem HVBT Tape - Product Descriptionnathan.schmittouNo ratings yet

- W4 Heavy Duty PiezometerDocument4 pagesW4 Heavy Duty PiezometerJorge Armando Ysuiza RomeroNo ratings yet

- SA01900005E 150dpiDocument2 pagesSA01900005E 150dpivaishgoa56No ratings yet

- Carbon Potentiometers CADocument12 pagesCarbon Potentiometers CAkamranNo ratings yet

- Presentation UTMDocument10 pagesPresentation UTMjanith.rndNo ratings yet

- PR 6201 (500kg 50t) Precision Compression Load CellDocument4 pagesPR 6201 (500kg 50t) Precision Compression Load CellGM HerbalsNo ratings yet

- Barrier Cable Systems SpecificationsDocument8 pagesBarrier Cable Systems SpecificationsJason GrossNo ratings yet

- CMS - Cable and Control Line ProtectorDocument4 pagesCMS - Cable and Control Line ProtectorAshutoshSharmaNo ratings yet

- Line Bushings: One Common SleeveDocument8 pagesLine Bushings: One Common SleeveAPNo ratings yet

- Phobos Ma PDFDocument9 pagesPhobos Ma PDFIoan PascuNo ratings yet

- RASNE-3 - Comments RepliedDocument2 pagesRASNE-3 - Comments RepliedPrashant KumarNo ratings yet

- Drill String Design - 6611074 - 01Document182 pagesDrill String Design - 6611074 - 01Youcef Lias100% (2)

- GCTS Rock Catalog 2022Document40 pagesGCTS Rock Catalog 2022ofentse lefadolaNo ratings yet

- Bend RestrictorsDocument2 pagesBend RestrictorsjiokoijikoNo ratings yet

- Wire Rope Usha MartinDocument36 pagesWire Rope Usha MartinashiyNo ratings yet

- Install PlusV9Document16 pagesInstall PlusV9Ben ZithaNo ratings yet

- TSB BOOM Barrier Spec - 30.03.2023Document2 pagesTSB BOOM Barrier Spec - 30.03.2023sbt.abhishekNo ratings yet

- GT110-08 NGR Trans PDFDocument2 pagesGT110-08 NGR Trans PDFrexNo ratings yet

- Barcol Hardness Tester 934-1Document2 pagesBarcol Hardness Tester 934-1mushtaquebhaldarNo ratings yet

- DYWIDAG Prestressing Systems Using BarsDocument18 pagesDYWIDAG Prestressing Systems Using Barsbignose93gmail.comNo ratings yet

- JVC Hr-J4020ua SM PDFDocument53 pagesJVC Hr-J4020ua SM PDFAnthony GonzalesNo ratings yet

- ST4 Vibrating Wire Embedment Strain GaugeDocument4 pagesST4 Vibrating Wire Embedment Strain GaugeNurul BaizuraNo ratings yet

- S12 LVBushingCantilever Presentation PDFDocument14 pagesS12 LVBushingCantilever Presentation PDFManikandan P Engineering EEENo ratings yet

- Abb ManualDocument20 pagesAbb ManualHamilton Velandia GalloNo ratings yet

- Littelfuse Varistor ULTRAMOV Datasheet PDFDocument11 pagesLittelfuse Varistor ULTRAMOV Datasheet PDFRafonixscribdNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- BBR SDX Bar System en Rev2 0818Document16 pagesBBR SDX Bar System en Rev2 0818Юлия ДамNo ratings yet

- Certified, Strong & DurableDocument16 pagesCertified, Strong & DurableЮлия ДамNo ratings yet

- Statistical Analysis of Sport Stadiums With Retractable Roof SystemsDocument8 pagesStatistical Analysis of Sport Stadiums With Retractable Roof SystemsЮлия ДамNo ratings yet

- Typology of Retractable Roof Structures in Stadiums and Sports HallsDocument12 pagesTypology of Retractable Roof Structures in Stadiums and Sports HallsЮлия ДамNo ratings yet

- DAF Superstructures BodyBuilders - GuideDocument34 pagesDAF Superstructures BodyBuilders - GuideЮлия Дам100% (1)

- Caterpillar M320D Wheel - ExcavatorDocument24 pagesCaterpillar M320D Wheel - ExcavatorЮлия Дам100% (5)

- Design of Tension MembersDocument43 pagesDesign of Tension MembersFritz LuzonNo ratings yet

- 2016-Cmc-Supplement (California Mechanical Code)Document44 pages2016-Cmc-Supplement (California Mechanical Code)Sergio GarciaNo ratings yet

- Cesmm 3Document19 pagesCesmm 3Supun Viduranga67% (3)

- Final Report (Dam 2)Document27 pagesFinal Report (Dam 2)Ahmed AmediNo ratings yet

- B.4.4 - STD Spec For Steel StacksDocument6 pagesB.4.4 - STD Spec For Steel StacksEkta Sangule0% (1)

- Experiment 3: Strut BucklingDocument8 pagesExperiment 3: Strut BucklingEdmund TiewNo ratings yet

- Astm F2787 09Document10 pagesAstm F2787 09dhruvikavinodNo ratings yet

- Colums: Buckling Load Critical Load Crippling LoadDocument16 pagesColums: Buckling Load Critical Load Crippling LoadNavindra SNo ratings yet

- Ks SairamDocument428 pagesKs SairamIshan DograNo ratings yet

- Assignment 4Document6 pagesAssignment 4gowricivilNo ratings yet

- 10 1016@j Matpr 2020 01 384Document8 pages10 1016@j Matpr 2020 01 384Geeta JiraliNo ratings yet

- Calculation Sheet For Tower ProjectDocument23 pagesCalculation Sheet For Tower ProjectOsama NasserNo ratings yet

- Annexure D - For Cable Cellar MVWS SystemDocument1 pageAnnexure D - For Cable Cellar MVWS SystemVaibhav SawantNo ratings yet

- Fence Details: Site LayoutDocument1 pageFence Details: Site LayoutAthiyo MartinNo ratings yet

- BA 001 R0A (Without Mezzanine)Document1 pageBA 001 R0A (Without Mezzanine)Muhammad Hassan TariqNo ratings yet

- FloorDocument91 pagesFloorShaik FaridhNo ratings yet

- Wrinkling StressDocument8 pagesWrinkling StressCandace FrankNo ratings yet

- Beam Design CalculationDocument14 pagesBeam Design CalculationArnold VercelesNo ratings yet

- Tata Projects Limited: Purchase Order-Wise Material Receipt DetailsDocument2 pagesTata Projects Limited: Purchase Order-Wise Material Receipt DetailsHemantSharmaNo ratings yet

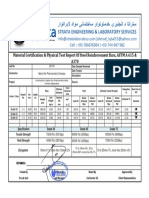

- Material Certification & Physical Test Report of Steel Reinforcement Bars, ASTM A 615 & A370Document1 pageMaterial Certification & Physical Test Report of Steel Reinforcement Bars, ASTM A 615 & A370Nasrullah Fazal AdeebNo ratings yet

- Xtreme WR30Document2 pagesXtreme WR30central labNo ratings yet

- Unit 1Document56 pagesUnit 1santoshdevi9758No ratings yet

- High Performance: Pretensioned Spun High Strength Concrete PilesDocument7 pagesHigh Performance: Pretensioned Spun High Strength Concrete PilesMd. Abu TaherNo ratings yet

- Hyd - Ref - Sol - 16 - 28 October 2023Document7 pagesHyd - Ref - Sol - 16 - 28 October 2023Jake AsueroNo ratings yet

- Transpo Printable Lecture2Document31 pagesTranspo Printable Lecture2Jabin Sta. TeresaNo ratings yet

- Structural Irregularities 2Document12 pagesStructural Irregularities 2Ankit DalviNo ratings yet

- Basics of Well CompletionDocument40 pagesBasics of Well CompletionBevin Babu100% (4)

- B Angkur M16x150 Precast Dinding Parapet Parkir Posisi Braket Di Atas BalokDocument31 pagesB Angkur M16x150 Precast Dinding Parapet Parkir Posisi Braket Di Atas BalokHerrys Eka Maulana MaulanaNo ratings yet

- Project On Residential Building: Sunken Slab DetailDocument1 pageProject On Residential Building: Sunken Slab DetailPraveen G MNo ratings yet

- Shear Strength (Soil) - Wikipedia, The Free EncyclopediaDocument6 pagesShear Strength (Soil) - Wikipedia, The Free Encyclopediaicemage1991No ratings yet