Professional Documents

Culture Documents

ASCE 2003 Berman Bruneau PDF

ASCE 2003 Berman Bruneau PDF

Uploaded by

shahin85Copyright:

Available Formats

You might also like

- GR 9 Eng BaselineDocument12 pagesGR 9 Eng BaselineMalie SibisiNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Visual Image Interpretation-TextDocument18 pagesVisual Image Interpretation-TextSaurabh Suman100% (5)

- Simplified and Detailed Finite Element Models of Steel Plate Shear WallsDocument13 pagesSimplified and Detailed Finite Element Models of Steel Plate Shear WallsponjoveNo ratings yet

- 1 s2.0 S1877705813003883 MainDocument10 pages1 s2.0 S1877705813003883 Mainfakher alaviNo ratings yet

- Sand 4Document17 pagesSand 4Pavan MNo ratings yet

- Earls, 1999Document24 pagesEarls, 1999carlosNo ratings yet

- The Effect of Infill Steel Plate Thickness On The Cycle Behavior of Steel Plate Shear WallsDocument7 pagesThe Effect of Infill Steel Plate Thickness On The Cycle Behavior of Steel Plate Shear WallsGogyNo ratings yet

- Effect of Shear Connectors On Local Buckling and Composite Action in Steel Concrete Composite Walls (Zhang Et Al, 2014)Document9 pagesEffect of Shear Connectors On Local Buckling and Composite Action in Steel Concrete Composite Walls (Zhang Et Al, 2014)Hamid GoodarziNo ratings yet

- Push Over Analysis of Unstiffened Steel Plate Shear Wall: Abhishek Verma, P. R. MaitiDocument9 pagesPush Over Analysis of Unstiffened Steel Plate Shear Wall: Abhishek Verma, P. R. MaitiIJERDNo ratings yet

- ACI STRUCTURAL JOURNAL-Shear Strength of Steel Fiber ReinforcedDocument9 pagesACI STRUCTURAL JOURNAL-Shear Strength of Steel Fiber ReinforcedMuchtar SufaatNo ratings yet

- Seismic Behavior of Steel Beam and Reinforced Concrete Column ConnectionsDocument20 pagesSeismic Behavior of Steel Beam and Reinforced Concrete Column Connectionsjuan carlosNo ratings yet

- Confined Concrete Columns With StubsDocument19 pagesConfined Concrete Columns With StubsKaren Perez LievanaNo ratings yet

- Use of Steel Fiber Reinforced Concrete For Enhanced Performance of Deep Beams With Large OpeningsDocument10 pagesUse of Steel Fiber Reinforced Concrete For Enhanced Performance of Deep Beams With Large OpeningssuhagNo ratings yet

- Behavior of Field Splice Details in Precast Concrete-Filled Steel Grid Bridge DeckDocument10 pagesBehavior of Field Splice Details in Precast Concrete-Filled Steel Grid Bridge DeckIoannis BazosNo ratings yet

- Bond Characteristics High-Strength Steel ReinforcementDocument6 pagesBond Characteristics High-Strength Steel ReinforcementUmair BaigNo ratings yet

- Esperimental StudyDocument9 pagesEsperimental Studyrafaelrp22009No ratings yet

- Creep Modeling For Concrete-Filled Steel Tubes: Wassim Naguib, Amir MirmiranDocument18 pagesCreep Modeling For Concrete-Filled Steel Tubes: Wassim Naguib, Amir Mirmiransaber javidNo ratings yet

- Composite Beams: P. AnsourianDocument27 pagesComposite Beams: P. AnsourianLeonardoMadeira11No ratings yet

- Plate Girders With Corrugated Steel Webs PDFDocument13 pagesPlate Girders With Corrugated Steel Webs PDFMarcelo Albe100% (1)

- Bond STRGDocument8 pagesBond STRGyuva_86No ratings yet

- Short ColumnsDocument15 pagesShort ColumnssrividyaNo ratings yet

- Static Behavior of Large Stud Shear Connectors: Chang-Su Shim, Pil-Goo Lee, Tae-Yang YoonDocument8 pagesStatic Behavior of Large Stud Shear Connectors: Chang-Su Shim, Pil-Goo Lee, Tae-Yang YoonHafiz Waheed IqbalNo ratings yet

- Elastic Buckling Behavior of Steel FrameDocument16 pagesElastic Buckling Behavior of Steel FrameSang NguyenNo ratings yet

- The Diagonal Tension Behavior of Fiber Reinforced Concrete BeamsDocument7 pagesThe Diagonal Tension Behavior of Fiber Reinforced Concrete BeamsChris LumyNo ratings yet

- Is I Journal PaperDocument20 pagesIs I Journal PaperYonny Pacompìa YucraNo ratings yet

- Creep Modeling For Concrete-Filled Steel TubesDocument18 pagesCreep Modeling For Concrete-Filled Steel TubesGunaNo ratings yet

- Shear Strength of Steel Fiber-Reinforced ConcreteDocument10 pagesShear Strength of Steel Fiber-Reinforced ConcreteSiva GuruNo ratings yet

- 1 s2.0 S0263823115301555 MainDocument15 pages1 s2.0 S0263823115301555 MainManonmani DNo ratings yet

- Cyclic Tests of Four Two-Story Narrow Steel Plate Shear Walls - Part 1: Analytical Studies and Specimen DesignDocument25 pagesCyclic Tests of Four Two-Story Narrow Steel Plate Shear Walls - Part 1: Analytical Studies and Specimen DesignMarimuthu KaliyamoorthyNo ratings yet

- Elastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004Document16 pagesElastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004EliyaHeninNo ratings yet

- Compatibility Torsion in Spandrel Beams Using Modified Compression Field TheoryDocument11 pagesCompatibility Torsion in Spandrel Beams Using Modified Compression Field TheoryMishraq ul quraishNo ratings yet

- Effect of Spacing of Fasteners Used To Attach The Corrugated Shear Plate To The Envelope Frame On Its Elastic Buckling BehaviorDocument21 pagesEffect of Spacing of Fasteners Used To Attach The Corrugated Shear Plate To The Envelope Frame On Its Elastic Buckling BehaviorEliyaHeninNo ratings yet

- CFSEI Shear Wall Design GuideDocument23 pagesCFSEI Shear Wall Design GuideJaypee Chang100% (1)

- Local Elastic Buckling Coefficients of Steel Plates in Composite Steel Plate Shear WallsDocument7 pagesLocal Elastic Buckling Coefficients of Steel Plates in Composite Steel Plate Shear WallsPrapa KaranNo ratings yet

- Habusadeh, Journal Manager, 182-187Document6 pagesHabusadeh, Journal Manager, 182-187Bhagirathi DengiNo ratings yet

- Journal of Constructional Steel Research: Mohamad-Ghasem Vetr, N. Mohamad Shirali, Ali GhamariDocument24 pagesJournal of Constructional Steel Research: Mohamad-Ghasem Vetr, N. Mohamad Shirali, Ali GhamariMekides KassayeNo ratings yet

- 1963 - Bresler Scordelis - Shear Strength of RC Beams PDFDocument24 pages1963 - Bresler Scordelis - Shear Strength of RC Beams PDFKaio César Arnaud DeonNo ratings yet

- Design Procedure For BRBsDocument17 pagesDesign Procedure For BRBsPremalatha JeyaramNo ratings yet

- Cantilever SlabDocument7 pagesCantilever Slabyuva_86No ratings yet

- Behaviour and Strength of Composite Slabs With Ribbed DeckingDocument19 pagesBehaviour and Strength of Composite Slabs With Ribbed DeckingRoberval PimentaNo ratings yet

- Tests of Cold-Formed Channel ColumnsDocument27 pagesTests of Cold-Formed Channel ColumnsHadeer MohamedNo ratings yet

- Journal of Constructional Steel Research: Ahmed R. Badr, Hazem H. Elanwar, Sherif A. MouradDocument15 pagesJournal of Constructional Steel Research: Ahmed R. Badr, Hazem H. Elanwar, Sherif A. MouradAB YADAVNo ratings yet

- Journal of Constructional Steel Research: Z. Li, T. Li, Y. XiaoDocument14 pagesJournal of Constructional Steel Research: Z. Li, T. Li, Y. XiaoSaeed MohebbiNo ratings yet

- Strength of Concrete Filled Tubular ColumnDocument10 pagesStrength of Concrete Filled Tubular ColumnJitendraNo ratings yet

- 15ECEE Hadzhiyaneva Belev 897 PDFDocument10 pages15ECEE Hadzhiyaneva Belev 897 PDFborisbelevNo ratings yet

- The Factors That Significantly Influence The ThreeDocument2 pagesThe Factors That Significantly Influence The ThreePankajNo ratings yet

- Shear-Bond Capacity of Composite Slabs Made With Profiled SheetingDocument7 pagesShear-Bond Capacity of Composite Slabs Made With Profiled SheetingPrapa KaranNo ratings yet

- Torsion of High-Strength Reinforced Concrete Beams and Minimum Reinforcement RequirementDocument8 pagesTorsion of High-Strength Reinforced Concrete Beams and Minimum Reinforcement RequirementSuhas Natu100% (1)

- Seismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsDocument10 pagesSeismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsleotramontinNo ratings yet

- ADVSteelConstKOROGLU PDFDocument16 pagesADVSteelConstKOROGLU PDFAbdulkadir ÇevikNo ratings yet

- 10.1016 - j.tws.2016.02.008 Analysis and Design Recommendations For Diagonally Stiffened Steel Plate Shear WallsDocument9 pages10.1016 - j.tws.2016.02.008 Analysis and Design Recommendations For Diagonally Stiffened Steel Plate Shear WallsmahdiNo ratings yet

- Performance of Jumbo Beam-to-Column Connections With High Strength SteelDocument9 pagesPerformance of Jumbo Beam-to-Column Connections With High Strength SteelMuhammad irfan javaidNo ratings yet

- Seismic Retrofit of Hollow Bridge PiersDocument10 pagesSeismic Retrofit of Hollow Bridge PiersFouad KehilaNo ratings yet

- Stiffened Coped I BeamDocument10 pagesStiffened Coped I BeamKLNo ratings yet

- Fatigue Strength Evaluation of Welded Structural Details in Corrugated Steel Web GirdersDocument15 pagesFatigue Strength Evaluation of Welded Structural Details in Corrugated Steel Web Girdersaminashash95No ratings yet

- Experiments On Cold-Formed Steel Columns With Holes: Cristopher D. Moen, B.W. SchaferDocument3 pagesExperiments On Cold-Formed Steel Columns With Holes: Cristopher D. Moen, B.W. SchaferAgung PratamaNo ratings yet

- Cold Form Steel DesignDocument6 pagesCold Form Steel Designakhilesh120No ratings yet

- Thesis On Steel Fibre Reinforced ConcreteDocument8 pagesThesis On Steel Fibre Reinforced Concretedenisemillerdesmoines100% (2)

- 1 s2.0 S0143974X22002760 MainDocument17 pages1 s2.0 S0143974X22002760 MainwflowerNo ratings yet

- Innovative Technique For Seismic Upgrade of RC Square ColumnsDocument15 pagesInnovative Technique For Seismic Upgrade of RC Square Columns오상진No ratings yet

- Behaviour and Strength of High Strength Concrete L-Beams Under Combined Shear, Bending and Torsional LoadingDocument17 pagesBehaviour and Strength of High Strength Concrete L-Beams Under Combined Shear, Bending and Torsional LoadingThulasi Raman KowsiganNo ratings yet

- A Topology Optimization Formulation Applied To Highly Flexible StructuresDocument4 pagesA Topology Optimization Formulation Applied To Highly Flexible Structuresshahin85No ratings yet

- Human Behaviour in Tunnel Fire Incidents PDFDocument12 pagesHuman Behaviour in Tunnel Fire Incidents PDFshahin85No ratings yet

- Pig Launcher Specifications PDFDocument1 pagePig Launcher Specifications PDFshahin85No ratings yet

- 8 543 PDFDocument12 pages8 543 PDFshahin85No ratings yet

- Feasibility Study For The Reuse of A Steel Offshore Platform As The Base of A Wind TowerDocument6 pagesFeasibility Study For The Reuse of A Steel Offshore Platform As The Base of A Wind Towershahin85No ratings yet

- Ramesh Text Lec1Document30 pagesRamesh Text Lec1shahin85No ratings yet

- 18 Solid State Formula Sheets Getmarks AppDocument7 pages18 Solid State Formula Sheets Getmarks AppHari KrishnaNo ratings yet

- Ultrasonic Examination Procedure For Asme CodeDocument23 pagesUltrasonic Examination Procedure For Asme CodeEdAlmNo ratings yet

- Firekab Lihch TP Fe180 Ph120Document2 pagesFirekab Lihch TP Fe180 Ph120Binh VoNo ratings yet

- TGD Part EDocument88 pagesTGD Part EOlivia SaferNo ratings yet

- Vib FileDocument3 pagesVib FileJohn Louie PimentelNo ratings yet

- System Sensor Product BrochureDocument24 pagesSystem Sensor Product BrochureJAY ROD AWITNo ratings yet

- Advance Power ElectronicsDocument20 pagesAdvance Power ElectronicsSudip MondalNo ratings yet

- Pretest, RC Part 1Document3 pagesPretest, RC Part 1leanne DespaNo ratings yet

- Electronic ComponentsDocument23 pagesElectronic ComponentsRussel Erese Garcia100% (1)

- Marble Run 1Document16 pagesMarble Run 1api-638167530No ratings yet

- E70 PDFDocument900 pagesE70 PDFАлексей100% (1)

- SLICE 141 Offical Manual S 716133Document50 pagesSLICE 141 Offical Manual S 716133joseguadalupe19canoNo ratings yet

- PX4 姿態控制算法 論文 Nonlinear Quadrocopter Attitude ControlDocument21 pagesPX4 姿態控制算法 論文 Nonlinear Quadrocopter Attitude Control鍾舒筠No ratings yet

- Assignment 3 - Mechanical VibrationDocument4 pagesAssignment 3 - Mechanical VibrationMusadiq ChaudhryNo ratings yet

- Chemical+Bonding+Lecture 1Document64 pagesChemical+Bonding+Lecture 1Sushma GuptaNo ratings yet

- HKDSE Maths Practice Paper 2Document15 pagesHKDSE Maths Practice Paper 2bradNo ratings yet

- Barad - Agential Cut - 3 - Rouse - Agential Cuts - The Conceptual and Ethical Normativity of Intra-Active PhenomenaDocument12 pagesBarad - Agential Cut - 3 - Rouse - Agential Cuts - The Conceptual and Ethical Normativity of Intra-Active PhenomenaRogerio Duarte Do Pateo Guarani KaiowáNo ratings yet

- Experiment No. 7 Induction Furnace Melting Practice: Aim - TheoryDocument6 pagesExperiment No. 7 Induction Furnace Melting Practice: Aim - TheoryDhananjay ShimpiNo ratings yet

- Nicolet Nic Plan Experiment Test IntructionsDocument5 pagesNicolet Nic Plan Experiment Test Intructionslacruz1960No ratings yet

- Certificate of Calibration: in Conformance With ISO 21501-4 Requirements For Calibration IntervalsDocument8 pagesCertificate of Calibration: in Conformance With ISO 21501-4 Requirements For Calibration IntervalsAzeddine LANo ratings yet

- Forced and Free Conv - PDFDocument11 pagesForced and Free Conv - PDFEkrema DasanNo ratings yet

- Heidenhain Touch ProbeDocument72 pagesHeidenhain Touch ProbeHoho Hahov100% (1)

- Matter Separation Tech Notes Myp4Document21 pagesMatter Separation Tech Notes Myp4anitNo ratings yet

- HW 3Document3 pagesHW 3JeeveshNo ratings yet

- Design of Reinforced Concrete Structures To BS 8110Document44 pagesDesign of Reinforced Concrete Structures To BS 8110Eng Clive KabelengaNo ratings yet

- Net Force WorksheetDocument2 pagesNet Force WorksheetJayson SisorNo ratings yet

- 10b Dodge SleevoilDocument32 pages10b Dodge SleevoilSofiane HalimiNo ratings yet

- Medilux 300 MaDocument6 pagesMedilux 300 MaVivek SrivastavaNo ratings yet

ASCE 2003 Berman Bruneau PDF

ASCE 2003 Berman Bruneau PDF

Uploaded by

shahin85Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASCE 2003 Berman Bruneau PDF

ASCE 2003 Berman Bruneau PDF

Uploaded by

shahin85Copyright:

Available Formats

Plastic Analysis and Design of Steel Plate Shear Walls

Jeffrey Berman, M.ASCE,1 and Michel Bruneau, M.ASCE2

Abstract: A revised procedure for the design of steel plate shear walls is proposed. In this procedure the thickness of the infill plate is

found using equations that are derived from the plastic analysis of the strip model, which is an accepted model for the representation of

steel plate shear walls. Comparisons of experimentally obtained ultimate strengths of steel plate shear walls and those predicted by plastic

analysis are given and reasonable agreement is observed. Fundamental plastic collapse mechanisms for several, more complex, wall

configurations are also given. Additionally, an existing codified procedure for the design of steel plate walls is reviewed and a section of

this procedure which could lead to designs with less-than-expected ultimate strength is identified. It is shown that the proposed procedure

eliminates this possibility without changing the other valid sections of the current procedure.

DOI: 10.1061/共ASCE兲0733-9445共2003兲129:11共1448兲

CE Database subject headings: Plastic analysis; Design; Shear walls; Plates; Steel.

Introduction investigated in some of the aforementioned papers as well as by

Elgaaly et al. 共1993兲 and Driver et al. 共1997兲.

Steel plate shear walls 共SPSW兲 have sometimes been used as the Recent research on the postbuckling strength of plate girder

lateral load resisting system in buildings. Until the 1980s, the webs using finite element analysis 共Marsh et al. 1988; Lee and

design limit state for SPSW in North America was out-of-plane Yoo 1998; Roberts and Shahabian 2001兲 also provided insight

buckling of the infill plates. This led engineers to design heavily into the postbuckling behavior and bending-shear interaction of

stiffened plates that offered little economic advantage over rein- steel plate shear walls having web width-to-thickness ratios com-

forced concrete shear walls. However, as Basler 共1961兲 demon- parable to typical plate girders 共i.e., 350 or less兲. However, for the

strated for plate girder webs, the post-buckling tension field ac- type of SPSWs considered in this paper 共for example, with a bay

width of 4 m, infill thickness of 5 mm, and resulting width-to-

tion of steel plate shear walls can provide substantial strength,

thickness ratio of 800兲, important differences with plate girder

stiffness, and ductility. The idea of utilizing the postbuckling

behavior are known to exist 共Thorburn et al. 1983兲. This is not

strength of steel plate shear walls was first formulated by Thor-

only due to the large width-to-thickness ratios, but also because

burn et al. 共1983兲 and verified experimentally by Timler and

the ‘‘flanges’’ of steel plate shear walls are columns, typically

Kulak 共1983兲. Studies performed to evaluate the strength, ductil-

wide flange shapes, with significantly more bending stiffness than

ity, and hysteretic behavior of such SPSW designed with unstiff- the typical flanges of a plate girder.

ened infill plates demonstrated their significant energy dissipation At the time of this writing, there are no U.S. specifications or

capabilities 共Timler and Kulak 1983兲 and substantial economic codes addressing the design of steel plate shear walls. The 2001

advantages 共Timler 1998兲. Canadian standard, CAN/CSA S16-01 共CSA 2001兲, now incorpo-

Additional research on unstiffened steel plate shear walls has rates mandatory clauses on the design of steel plate shear walls;

investigated the effect of simple versus rigid beam-to-column these are reviewed briefly in the next section. One of the models

connections on the overall behavior 共Caccese et al. 1993兲, the recommended to represent steel plate shear walls, which was de-

dynamic response of steel plate shear walls 共Sabouri-Ghomi and veloped by Thorburn et al. 共1983兲 and named the strip model, is

Roberts 1992; Rezia 1999兲, the behavior of light-gauge steel plate recognized for providing reliable assessments of their ultimate

shear walls 共Berman and Bruneau 2003兲, the effects of holes in strength. In this paper, using this strip model as a basis, the use of

the infill plates 共Roberts and Sabouri-Ghomi 1992兲, and the ef- plastic analysis as an alternative for the design of steel plate shear

fects of bolted versus welded infill connections, as well as other walls is investigated. Fundamental plastic collapse mechanisms

practical considerations, by Elgaaly 共1998兲. Furthermore, finite are described for single story and multistory SPSW with either

element modeling of unstiffened steel plate shear walls has been simple or rigid beam-to-column connections. Ultimate strengths

predicted from these collapse mechanisms are compared with ex-

1

Research Asst., Dept. of CSEE, Univ. at Buffalo, Amherst, perimental results by others, and used to assess the CAN/CSA

NY 14260. E-mail: jwberman@eng.buffalo.edu S16-01 design procedure.

2

Deputy Director, MCEER, Professor, Dept. of CSEE, Univ. at

Buffalo, Amherst, NY 14260. E-mail: bruneau@mceermail.buffalo.edu

Note. Associate Editor: Sherif El-Tawil. Discussion open until April Analysis and Design of Steel Plate

1, 2004. Separate discussions must be submitted for individual papers. To Shear Walls—CANÕCSA S16-01

extend the closing date by one month, a written request must be filed with

the ASCE Managing Editor. The manuscript for this paper was submitted

for review and possible publication on March 18, 2002; approved on The CAN/CSA S16-01 seismic design process for steel plate

February 5, 2003. This paper is part of the Journal of Structural Engi- shear walls follows the selection of a lateral load resisting system

neering, Vol. 129, No. 11, November 1, 2003. ©ASCE, ISSN 0733-9445/ 共i.e., shear walls with rigid or flexible beam-to-column connec-

2003/11-1448 –1456/$18.00. tions兲, calculation of the appropriate design base shear, and dis-

1448 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / NOVEMBER 2003

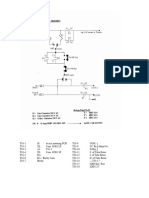

Fig. 1. Equivalent story brace model Fig. 2. Detailed strip model

excessive deformation leading to premature buckling under the

tribution of that base shear along the building height by the usual pulling action of the plates 共derived from Kuhn et al. 1952兲

methods described in building codes. Preliminary sizing of mem- 0.00307th 4s

bers is done using a model that treats the plate at each story as a I c⭓ (3)

L

single pin-ended brace 共known as the equivalent story brace

model兲 that runs along the diagonal of the bay 共Fig. 1兲. From the Once the above requirements have been satisfied, a more re-

area of the story brace, A, determined from that analysis, an fined model, known as the strip or multistrip model, that repre-

equivalent plate thickness can be calculated using the following sents the plates as a series of inclined tension members or strips

equation based on an elastic strain energy formulation 共Thorburn 共Fig. 2兲 is required for the analysis of steel plate shear walls 关with

et al. 1983兲: ␣ as calculated by Eq. 共2兲兴. Through comparison with experimen-

tal results, the adequacy of the strip model to predict the ultimate

2A sin sin 2 capacity of SPSW has been verified in several studies. Fig. 3,

t⫽ (1)

L sin2 2␣ adapted from Driver et al. 共1997兲, is one example of this verifi-

where ⫽angle between the vertical axis and the equivalent di- cation.

agonal brace; L⫽bay width; and ␣⫽angle of inclination of the A minimum of ten strips is required at each story to adequately

principal tensile stresses in the infill plate measured from vertical, model the wall. Each strip is assigned an area equal to the plate

which is given by thickness times the tributary width of the strip. Drifts obtained

from the elastic analysis of the multistrip model are then ampli-

tL fied by factors prescribed by the applicable building code to ac-

1⫹

2A c count for inelastic action and then checked against allowable drift

冉 冊

tan4 ␣⫽ (2) limits. For SPSW having rigid beam-to-column connections,

1 h 3s

1⫹th s ⫹ CAN/CSA S16-01 also requires that a capacity design be con-

A b 360I c L

ducted to prevent damage to the bounding columns of the wall.

where t⫽thickness of the plate; A c and I c ⫽respectively, the Due to practical considerations, infill thicknesses may be larger

cross-sectional area and moment of inertia of the bounding col- than necessary to resist the seismic loads, therefore, capacity de-

umn; h s ⫽story height; and A b ⫽beam cross-sectional area 共Tim- sign is required to insure a ductile failure mode 共i.e., infill yield-

ler and Kulak 1983兲. CAN/CSA S16-01 also provides the follow- ing prior to column buckling兲. To achieve this, the moments and

ing equation to ensure that a satisfactory minimum moment of axial forces 共obtained from an elastic analysis兲 in these columns

inertia is used for columns in steel plate shear walls to prevent are magnified by a factor B, defined as the ratio of the probable

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / NOVEMBER 2003 / 1449

Fig. 3. Comparison between experimental results and strip model 共Adapted from Driver et al. 1997兲

shear resistance at the base of the wall for the supplied plate equilibrium method of plastic analysis. Consider Fig. 4, which

thickness, to the factored lateral force at the base of the wall shows a single story SPSW in a frame with pin-ended beams. The

obtained from the calculated seismic load. The probable resis- model is divided into three zones. Zones 1 and 3 contain strips

tance of the wall (V re) is given by which run from a column to a beam while Zone 2 contains any

strips that connect from the top beam to the bottom beam. Note

V re⫽0.5R y F y tL sin 2␣ (4)

that the strip spacing in the direction perpendicular to the strip is

where R y ⫽ratio of the expected 共mean兲 steel yield stress to the s, with the first and last 共upper left and lower right兲 strips located

design yield stress 共specified as 1.1 for A572 Gr. 50 steel兲; F y at s/2 from the closest beam-to-column connections. The distance

⫽design yield stress of the plate; and all other parameters have d i from the beam-to-column connection to each strip is measured

been defined previously. Note that B need not be greater than the 共again, perpendicularly to the strip兲 from the upper-left beam-to-

ratio of the ultimate elastic base shear to the yield base shear, column connection in Zones 1 and 2, and in Zone 3 from the

which is the ductility factor R specified as 5.0 by CAN/CSA lower right connection.

S16-01. Column axial loads are found from the overturning mo- From Figs. 5共a and b兲 the applied story shear for Zone 1 strips

ment BM f , where M f is the factored overturning moment at the can be found in terms of the strip force F st , the distance d i , and

bottom of the wall. Local column moments from tension field the story height h s , in two steps. First, summation of moments

action of the plates, as determined from the elastic analysis, are about Point C 关bottom of the left column in Fig. 5共a兲兴 gives,

also amplified by B. If a nonlinear pushover analysis is carried V 1 h s ⫽R byL 共where L is the bay width and R by is the vertical

out, these corrections need not be done and more accurate values

for the column axial forces and moments can be obtained. Since

pushover capabilities are becoming more common in structural

analysis software, this is also a viable option.

Plastic Analysis of Steel Plate

Shear Walls—Single Story Frames

In this section, plastic analysis of the strip model is used to de-

velop equations for the ultimate capacity of different types of

steel plate shear walls. In cases where general equations depend

on actual member sizes and strengths, procedures are presented to

determine the necessary equations. In the following section the

results of these analyses are used to develop a simple, consistent

method for determining the preliminary plate sizes for steel plate

shear walls.

Equilibrium Method—Simple Beam-to-Column

Connections

Fig. 4. Single story strip model with simple beam-to-column

First the ultimate strength of a single story steel plate shear wall

connections

having simple beam-to-column connections is found using the

1450 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / NOVEMBER 2003

Fig. 7. Zone 3 free body diagram

V 2⫽ 兺 F st sin ␣

j⫽1

(6)

Fig. 5. Zone 1 free body diagram

where m⫽number of strips in Zone 2.

Finally, taking moments about Point A in Fig. 7 one finds that

the contribution to the story shear from Zone 3 strips can be

support reaction at B兲. Then looking at the free body diagram of written as

the beam alone 关Fig. 5共b兲兴 and taking moments about Point D, n

d k F st

one obtains R byL⫽F std i . Therefore, the story shear due to the V 3⫽ 兺

k⫽1 hs

(7)

forces in Zone 1 strips can be written as

l where n⫽number of strips in Zone 3.

F std i

V 1⫽ 兺

i⫽1 hs

(5) Now if it is assumed that there are n strips in each of Zones 1

and 3 共due to equal strip spacing兲 the contributions from each

where l⫽number of strips in Zone 1. zone can be combined to give

For Zone 2, by taking moments about Point C again 关Fig. l

d i F st

m n

d i F st

6共a兲兴, one obtains V 2 h s ⫽R byL⫹F st(sin ␣)hs⫺Fstd j . From the V⫽ 兺 hs

⫹ 兺 F st sin ␣⫹ 兺

i⫽1 h s

(8)

free body diagram of the beam 关Fig. 6共b兲兴 and taking moments i⫽1 j⫽1

about Point D, one finds R byL⫽F std j . The story shear due to the From the geometry in Fig. 4 it can be shown that

forces in Zone 2 strips is therefore

h sin ␣ L cos ␣⫺h sin ␣

l⫽n⫽ and m⫽ (9)

s s

Keeping in mind that the upper left and lower right strips are s/2

from the closest beam-to-column connections, the summation

over d i can be written as

n

n 2s

兺

i⫽1

d i⫽

2

(10)

Substituting Eqs. 共9兲 and 共10兲 into Eq. 共8兲, recognizing the fact

that the strip force (F st) is equal to the strip area 共st兲 times the

plate yield stress in tension (F y ) and using the trigonometric

identity 关 (1/2)sin 2␣⫽cos ␣ sin ␣兴 the story shear strength can be

expressed as

1

V⫽ F tL sin 2␣ (11)

2 y

Note that this equation is identical to the one used to calculate the

probable shear resistance of a SPSW in the CAN/CSA S16-01

procedure 关Eq. 共4兲兴, without the material factor R y .

Kinematic Method—Simple Beam-to-Column

Connections

The same result can be obtained more directly using the kine-

Fig. 6. Zone 2 free body diagram

matic method of plastic analysis. Consider the same frame with

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / NOVEMBER 2003 / 1451

to insure that a ductile failure mode will be achieved 共i.e., plate

yielding prior to columns or beams developing plastic hinges兲.

Plastic Analysis of Steel Plate

Shear Walls—Multistory Frames

For multistory SPSWs with pin-ended beams, plastic analysis can

also be used to predict the ultimate capacity. The purpose here is

Fig. 8. Single story kinematic collapse mechanism not to present closed-form solutions for all possible failure

mechanisms, but to identify some key plastic mechanisms that

should be considered in estimating the ultimate capacity of a steel

inclined strips shown in Fig. 4. When the shear force V displaces plate shear wall. These could be used to define a desirable failure

the top beam by a value ⌬ sufficient to yield all the strips, the mode in a capacity design perspective, or to prevent an undesir-

external work done is equal to V⌬ 共see Fig. 8兲. If the beams and able failure mode, as well as complement traditional design ap-

columns are assumed to remain elastic, their contribution to the proaches.

internal work may be neglected when compared to the internal In soft-story plastic mechanisms 关Fig. 9共a兲兴, the plastic hinges

work done by the strips, hence, the internal work is that would form in the columns at the mechanism level could be

(n b A st F y sin ␣)⌬, where n b is the number of strips anchored to included in the plastic analysis. Calculating and equating the in-

the top beam. This result can be obtained by the product of the ternal and external work, the following general expression could

yield force times the yield displacement of the strips, but for be used for soft-story i in which all flexural hinges develop in

simplicity it can also be found using the horizontal and vertical columns:

components of these values. Note that the horizontal components ns

1 4M pci

of the yield forces of the strips on the columns cancel 共the forces

on the left column do negative internal work and the forces on the

兺

j⫽i

V j ⫽ F y t i L sin 2␣⫹

2 h si

(15)

right column do positive internal work兲 and the vertical compo- where V j ⫽applied lateral forces above the soft-story i; t i ⫽plate

nents of all the yield forces do no internal work because there is thickness at the soft-story; M pci⫽plastic moment capacity of the

no vertical deflection. Therefore, the only internal work done is columns at the soft-story; h si⫽height of the soft-story; and n s

by the horizontal components of the strip yield forces anchored to ⫽total number of stories. Note that only the applied lateral forces

the top beam. Equating the external and internal work gives above the soft-story do external work and they all move the same

V⫽n b F st sin ␣ (12) distance 共⌬兲. The internal work is done only by the strips on the

soft-story itself and by column hinges forming at the top and

Using the geometry shown in Fig. 4, n b ⫽(L cos ␣)/s and the bottom of the soft-story. Using the above equation, the possibility

strip force F st is again F y ts. Substituting these into Eq. 共12兲 and of a soft-story mechanism should be checked at every story in

knowing (1/2)sin 2␣⫽cos ␣ sin ␣, the resulting base shear rela- which there is a significant change in plate thickness or column

tionship is again size. Additionally, the soft-story mechanism is independent of the

1 beam connection type 共simple or rigid兲 because hinges must form

V⫽ F tL sin 2␣ (13) in the columns, not the beams.

2 y

A second 共and more desirable兲 possible collapse mechanism

involves uniform yielding of the plates over every story 关Fig.

Kinematic Method—Rigid Beam-to-Column 9共b兲兴. For this mechanism, each applied lateral force V i moves a

Connections distance ⌬ i ⫽h i , and does external work equal to V i h i , where

In single story steel plate shear walls having rigid beam-to- h i is the elevation of the ith story. The internal work is done by

column connections 共as opposed to simple connections兲, plastic the strips of each story yielding. It is important to note that the

hinges also need to form in the boundary frame to produce a strip forces acting on the bottom of a story beam do positive

collapse mechanism. The corresponding additional internal work internal work and the strip forces acting on top of the same beam

is 4M p , where ⫽⌬/h s , is the story displacement over the do negative internal work. Therefore, the internal work at any

story height, and M p is the smaller of the plastic moment capacity story i is equal to the work done by strip yield forces along the

of the beams M pb , or columns M pc 共for most single-story frames bottom of the story beam minus the work done by strip yield

that are wider than tall, if the beams have sufficient strength and forces on the top of the same beam. This indicates that in order

stiffness to anchor the tension field, plastic hinges will typically for every plate at every story to contribute to the internal work,

form at the top and bottom of the columns and not in the beams兲. the plate thicknesses would have to vary at each story in direct

The ultimate strength of a single-story steel plate shear wall in a proportion to the demands from the applied lateral forces. Even

moment frame with plastic hinges in the columns becomes with this in mind, this mechanism provides insight into the capac-

ity and failure mechanism of the wall. The general equation for

1 4M pc the ultimate strength of a multistory SPSW with simple beam-to-

V⫽ F tL sin 2␣⫹ (14)

2 y hs column connections and this plastic mechanism 共equating the in-

ternal and external work兲 is

In a design process, failure to account for the additional

ns ns

strength provided by the beams or columns results in a larger 1

plate thicknesses than necessary, this would translate into lower 兺

i⫽1

V ih i⫽ 兺 F y 共 t i ⫺t i⫹1 兲 Lh sin 2␣

i⫽1 2

(16)

ductility demands in the walls and frame members, and could

therefore be considered to be a conservative approach. However, where h i ⫽ith story elevation; n s ⫽total number of stories; and

capacity design of the beams and columns must still be performed t i ⫽thickness of the plate on the ith story.

1452 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / NOVEMBER 2003

Fig. 9. Examples of collapse mechanisms for multistory steel plate shear walls

The ultimate strength of SPSW having rigid beam-to-column a soft story is likely to develop 共by comparing the ultimate capac-

connections capable of developing the beam’s plastic moment, ity found from the soft story mechanism with that of the uniform

can also be calculated following the same kinematic approach. yielding mechanism兲.

The resulting general equation for the uniform yielding mecha-

nism can be written as Comparison with Experimental Results

ns n s ⫺1

To validate ultimate strengths predicted by Eqs. 共13兲 and/or 共14兲

兺 V i h i ⫽2M pc1 ⫹2M pcn ⫹ i⫽1

i⫽1

兺 M pbi for the plastic analysis of single story frames with either simple or

rigid beam-to-column connections, a comparison is made with

ns

1 results obtained experimentally by others 共Table 1兲. The experi-

⫹ 兺 F y Lh i共 t i ⫺t i⫹1 兲 sin 2␣

i⫽1 2

(17) mental results given for multistory specimens are either those for

the first story shear 共in the case of Driver et al. 1997兲 or they are

where M pc1 ⫽first story column plastic moment; M pcn ⫽top story the total base shear in cases where loading was applied to the top

column plastic moment; M pbi ⫽plastic moment of the ith story story only 共Caccese et al. 1993; Elgaaly 1998兲. Furthermore, no

beam, and the rest of the terms were previously defined. Note that results are given for tests on SPSWs that had openings. As shown

it is assumed that column hinges will form instead of beam hinges in Table 1, on average Eq. 共13兲 predicts an ultimate load capacity

at the roof and base levels. Sizable beams are usually required at for steel plate shear walls with true pin or semirigid beam-to-

these two locations to anchor the tension field forces from the column connections that is 5.9% below the experimentally ob-

wall plate and hence plastic hinges typically develop in columns tained values. Eq. 共14兲 gives predictions for ultimate capacity of

there. However, this may not be the case for certain wall aspect steel plate shear walls with rigid beam-to-column connections

ratios, and the engineer is cautioned to use judgement, as M pc1 that are on average 17% above the experimentally obtained val-

and M pcn may have to be replaced by M pb1 and M pbn in some ues, however, that equation assumes a fully developed frame

instances, where M pb1 and M pbn are the plastic moment capacities mechanism which was not reported in any of the cited tests. Note

of the base and roof beams, respectively. Furthermore, note that that Cases 6 and 10, included in Table 1 for completeness, were

hinges were assumed to develop in beams at all other levels, not included in the averages because their ultimate failure was

which is usually the case as small beams are required there in due to column instability or problems with the test setup. Hence,

well proportioned SPSW. the equations derived from plastic analysis of the strip model are

After examining the results of several different pushover generally conservative for calculating the expected ultimate

analyses for such multistory SPSW 共using a single three-story strength of steel plate shear walls.

frame geometry, with arbitrarily selected beams, columns, and

plate thicknesses兲, it has been observed that the actual failure Impact of Design Procedure on Ultimate Strength

mechanism is typically somewhere between a soft-story mecha- of Steel Plate Shear Walls

nism and uniform yielding of the plates on all stories. Finding the

actual failure mechanism is difficult by hand, therefore, a com-

CAN ÕCSA S16-01 Approach

puterized pushover analysis should be used. However, the mecha-

nisms described above will provide a rough estimate of the ulti- The procedure given for preliminary sizing of plates in CAN/CSA

mate capacity. They will also provide some insight as to whether S16-01 is simple but results in designs that may not be consistent

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / NOVEMBER 2003 / 1453

Table 1. Comparison of Experimental and Calculated Ultimate Strengths

Specimen Number h L t Fy ␣ V uexp V upred 共kN兲 V upred 共kN兲 % Error for

Case Researcher identification of stories 共mm兲 共mm兲 共mm兲 共Mpa兲 共°兲 共kN兲 Eq. 共13兲 Eq. 共14兲 Eq. 共13兲

共i兲 Simple 共physical pin兲 beam-to-column connections

1 Timler and Kulak 共1983兲 —c 1 2,500 3,750 5 270.8 42.7 2698 2,530.9 —c ⫺6.2

2 Roberts and Sabouri-Ghomi SW2 1 370 370 0.83 219 45.0 35.1 33.6 —c ⫺4.2

3 共1992兲 SW3 1 370 370 1.23 152 45.0 38.2 34.6 —c ⫺9.5

4 SW14 1 370 450 0.83 219 45.0 44.5 40.9 —c ⫺8.1

5 SW15 1 370 450 1.23 152 45.0 45.3 42.1 —c ⫺7.1

共ii兲 Semirigid beam-to-column connections 共web-angle or other兲

6 Elgaaly 共1998兲 SWT11b 2 1,118 1,380 2.28 239 41.5 370 373.1 —c 0.85

7 SWT15 2 1,118 1,380 2.28 239 41.3 426 372.9 —c ⫺12

8 Caccese et al. 共1993兲 S22 3 838 1,244 0.76 256 42.2 142 120.4 —c ⫺15

9 S14 3 838 1,244 1.9 332 40.2 356 386.8 —c 8.64

共iii兲 Rigid beam-to-column connections

10 Lubell et al. 共2000兲 SPSW1a 1 900 900 1.5 320 36.9 210 207.3 261.4 —c

11 SPSW2 1 900 900 1.5 320 36.9 260 207.3 261.4 —c

12 Driver et al. 共1997兲 —c 4 1,927 3,050 4.8 355.4 41.1 3080 2,577.7 3886.4 —c

a

Testing stopped due to failure of lateral bracing.

b

Testing stopped due column buckling.

c

Not applicable.

with the demands implicit in the seismic force modification factor ratios. From these, the plate thicknesses were found as described

R. The transition from the equivalent story brace model 共used for above and the detailed strip models were developed using Eq. 共2兲

preliminary proportioning and to select the amount of steel in the to find the angle of inclination for the strips.

infill plates兲 to the multistrip model 共used for final analysis兲 may Pushover analyses of all resulting SPSW were then conducted

change the ultimate capacity and shape of the pushover curve for and the resulting ultimate strengths of the various walls, designed

the structure being designed, while the R-factor is not revised. to resist the same applied lateral loads, were compared. Fig. 10

In the equivalent story brace model, the ultimate capacity of shows a plot of the base shear 共normalized by dividing out the

the wall is only a function of the brace area, yield stress, and the design base shear used to find the area of the equivalent story

bay geometry 共aspect ratio兲. The story shear can be used to size brace兲 versus percent story drift for several SPSW of different

the equivalent brace for each story by using simple statics 共recall aspect ratios, obtained from pushover analyses of the strip models

Fig. 1兲. Then Eq. 共1兲 can be employed to relate the brace area to and equivalent story brace models. The resulting ultimate capac-

the plate thickness which, along with the strip spacing, yields the ity of the strip model is below the capacity of the equivalent story

strip area for the detailed strip model. However, these two models brace model for all aspect ratios, except 1:1 for which it is the

will not produce the same ultimate capacity unless the aspect ratio same. The difference between the capacity of the strip model and

of the bay is 1:1. To demonstrate this consider a single story equivalent story brace model increases as the aspect ratio further

SPSW 共with simple beam-to-column connections兲 as shown in deviates from 1.0. Fig. 11 shows how the difference between the

Fig. 4. Let the aspect ratio of the bay be equal to the bay width strip model capacity and the equivalent story brace model capac-

over the story height. Using the same design base shear, beam, ity changes with the aspect ratio of the bay. At an aspect ratio of

and column sizes 共selected to remain elastic for all cases兲, the 2:1 共or 1:2 since the results are symmetric in that sense兲 the strip

area of the equivalent story braces were found for several aspect model is only able to carry 80% of the base shear for which it

should have been designed.

Fig. 10. Pushover curves for different aspect ratios Fig. 11. Variation of ultimate capacity with aspect ratio

1454 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / NOVEMBER 2003

Using the concepts presented in FEMA 369 共FEMA 2001兲, the

R factor can be expressed as

R⫽R ⍀ o ⫽R ⍀ D ⍀ M ⍀ S (19)

where ⍀ D ⫽design overstrength factor; ⍀ M ⫽material factor; and

⍀ S ⫽system overstrength factor. Although the quantification of

⍀ D , ⍀ M , and ⍀ S , are to be determined by panels of experts in

code committees, the following observations are submitted for

consideration. According to FEMA 369 共FEMA 2001兲 these over-

strength factors may be thought of as follows:

• ⍀ D is to account for overstrength resulting from the design

procedure. This would occur in drift controlled designs and

designs in which architectural considerations may result in

overstrength. For most low to medium rise SPSW, this is un-

likely to be an issue and ⍀ D could be considered as low as 1.0.

Fig. 12. Generic pushover curve

• ⍀ M accounts for overstrength due to strength reduction factors

used in load and resistance factor design, strain hardening, and

Plastic Analysis the ratio of mean to specified yield stress. In this particular

Using the results of the plastic analyses described previously, the case R y already accounts for the ratio of mean to specified

infill plates of steel plate shear walls can be sized to consistently yield stress in the capacity design approach and there is no

achieve the desired ultimate strength. The procedure is simple, strength reduction factor involved in the sizing of the infill

even for a multistory SPSW, and neglecting the contribution of plates. Furthermore, simple calculations would show that

plastic hinges in beams and columns will always give a conser- strain hardening would begin to develop at drifts of approxi-

vative design in the case of rigid beam-to-column connections. mately 0.02h, the typical drift limit, assuming a strain of 0.01

The proposed procedure requires the designer to before strain hardening. Therefore, ⍀ M may be taken as low as

1. Calculate the design base shear, and distribute it along the 1.0 as well.

height of the building as described by the applicable building • ⍀ S accounts for the difference between the ultimate lateral

code; load and the load at first significant yielding. Based on push-

2. Use the following equation to calculate the minimum plate over results, the system overstrength ⍀ S appears to vary be-

thicknesses required for each story: tween 1.1 and 1.5 depending on aspect ratio.

2Vs⍀s Using these definitions, it appears that only the system over-

t⫽ (18) strength factor needs to be used to amplify the design base shear

FyL sin 2␣

共or reduce the plastic capacity兲 in order to use Eq. 共13兲 for the

where ⍀ s ⫽system overstrength described below and V s

design of infill plates for steel plate shear walls. Therefore, Eq.

⫽design story shear found using the equivalent lateral force

共18兲 is recommended, with values for the system overstrength

method;

factor taken between 1.1 and 1.5, the actual system overstrength

3. Develop the strip model for computer 共elastic兲 analysis using

factor can be obtained from a pushover analysis, or conserva-

Eq. 共2兲 to calculate the angle of inclination of the strips;

tively used as 1.5.

4. Design beams and columns according to capacity design

principles 共to insure the utmost ductility兲 or other rational Incidentally, on the basis of the work presented above, the

methods using plate thicknesses specified 共in case those ex- CAN/CSA S16-01 procedure should be modified to eliminate the

ceed the minimum required for practical reasons兲; and possibility of designs having less-than-expected ultimate strength.

5. Check story drifts against allowable values from the appli- For this purpose, Eq. 共1兲 could be rewritten as

cable building code. 2A sin sin 2

Note that Eq. 共18兲 is identical to Eq. 共13兲 but modified to account t⫽

L sin2 2␣

(20)

for the proper relationship between the equivalent lateral force

procedure and R, the seismic force modification factor. Fig. 12 is where ⫽correction factor obtained by calibrating the equivalent

the generic pushover curve used to define R, where R is the story brace model to the plastic analysis results presented in this

ductility factor, V y is 共for practical purposes兲 the fully yielded paper. Setting Eq. 共20兲 equal to Eq. 共18兲 and solving for  gives

base shear, ⍀ o is the overstrength factor, V s is the design base ⍀ s sin 2␣

shear, ⌬ s is the displacement at the design base shear, ⌬ y is the ⫽ (21)

sin 2

displacement at the yield base shear, V eu is the ultimate elastic

base shear, ⌬ max is the displacement at the ultimate elastic base

shear, s is the displacement ductility factor, and C d is the elastic

displacement amplification factor. Note the distinction between Conclusions

V y 共the yield base shear兲 and V s 共the design base shear兲. Because The CAN/CSA S16-01 recommended procedure for the analysis

Eq. 共13兲 was obtained from plastic analysis of the strip model, it and design of steel plate shear walls has been reviewed and in-

gives the maximum strength achieved at the peak of the pushover stances where this procedure can lead to unconservative designs

curve, which is V y . Therefore, to account for this and to use the with lower than expected ultimate capacity have been identified.

calculated design base shear V s from the equivalent lateral force Plastic collapse mechanisms for single and multistory SPSW with

procedure with Eq. 共13兲 to size the infill plates of a steel plate simple and rigid beam-to-column connections have been investi-

shear wall, V s must be amplified by the overstrength factor. In this gated and simple equations that capture the ultimate strength of

particular case the majority of the overstrength factor comes from SPSW have been developed and compared with experimental re-

the system overstrength factor. sults reported by others with reasonable agreement. Using the

JOURNAL OF STRUCTURAL ENGINEERING © ASCE / NOVEMBER 2003 / 1455

results of these plastic analyses a new procedure for the sizing of steel-plate shear walls under cyclic loads.’’ J. Struct. Eng., 119共2兲,

the infill plates has been proposed. The proposed procedure al- 588 – 605.

lows the engineer to control the ultimate failure mechanism of the Federal Emergency Management Agency 共FEMA兲. 共2001兲. FEMA 369

SPSW, and directly accounts for structural overstrength. NEHRP recommended provisions for seismic regulations for new

buildings and other structures, Part 2—commentary, Building Seis-

mic Safety Council for the Federal Emergency Management Agency,

Washington, D.C.

Acknowledgments Kuhn, P., Peterson, J. P., and Levin, L. R. 共1952兲. ‘‘A summary of diag-

onal tension, Part 1—Methods of analysis.’’ Tech. Note 2661, National

This work was supported in part by the Earthquake Engineering Advisory Committee for Aeronautics, Langley Aeronautical Labora-

tory, Langley Field, Va.

Research Centers Program of the National Science Foundation

Lee, S. C., and Yoo, C. H. 共1998兲. ‘‘Strength of plate girder web panels

under Award No. ECC-9701471 to the Multidisciplinary Center under pure shear.’’ J. Struct. Eng., 124共2兲, 184 –194.

for Earthquake Engineering Research. However, any opinions, Lubell, A. S., Prion, H. G. L., Ventura, C. E., and Rezai, M. 共2000兲.

findings, conclusions, and recommendations presented in this ‘‘Unstiffened steel plate shear wall performance under cyclic load-

paper are those of the writers and do not necessarily reflect the ing.’’ J. Struct. Eng., 126共4兲, 453– 460.

views of the sponsors. Marsh, C., Ajam, W., and Ha, H. 共1988兲. ‘‘Finite element analysis of

postbuckled shear webs.’’ J. Struct. Eng., 114共7兲, 1571–1587.

Rezia, M. 共1999兲. ‘‘Seismic behavior of steel plate shear walls by shake

table testing.’’ PhD dissertation, Univ. of British Columbia, Vancou-

References ver, British Columbia, Canada.

Roberts, T. M., and Sabouri-Ghomi, S. 共1992兲. ‘‘Hysteretic characteristics

Basler, K. 共1961兲. ‘‘Strength of plate girders in shear.’’ J. Struct. Div., of unstiffened perforated steel plate shear walls.’’ Thin-Walled Struct.,

ASCE, 87共7兲, 150–180. 14, 139–151.

Berman, J., and Bruneau, M. 共2003兲. ‘‘Experimental investigation of Roberts, T. M., and Shahabian, F. 共2001兲. ‘‘Ultimate resistance of slender

light-gauge steel plate shear walls for the seismic retrofit of build- web panels to combined bending, shear and patch loading.’’ J. Constr.

ings.’’ Tech. Rep. MCEER-03-0001, Multidisciplinary Center for Steel Res., 57, 779–790.

Earthquake Engineering Research, State University of New York at Sabouri-Ghomi, S., and Roberts, T. M. 共1992兲. ‘‘Nonlinear dynamic

Buffalo, Buffalo, N.Y. analysis of steel plate shear walls including shear and bending defor-

Caccese, V., Elgaaly, M., and Chen, R. 共1993兲. ‘‘Experimental study of mations.’’ Eng. Struct., 14共3兲, 309–317.

thin steel-plate shear walls under cyclic load.’’ J. Struct. Eng., 119共2兲, Thorburn, L. J., Kulak, G. L., and Montgomery, C. J. 共1983兲. ‘‘Analysis

573–587. of steel plate shear walls.’’ Structural Engineering Rep. No. 107,

Canadian Standards Association 共CSA兲. 共2001兲. ‘‘Limit states design of Dept. of Civil Engineering, Univ. of Alberta, Edmonton, Alberta,

steel structures.’’ CAN/CSA S16-01, Canadian Standards Association, Canada.

Willowdale, Ont., Canada. Timler, P. A. 共1998兲. ‘‘Design procedures development, analytical verifi-

Driver, R. G., Kulak, G. L., Kennedy, D. J. L., and Elwi, A. E. 共1997兲. cation, and cost evaluation of steel plate shear wall structures.’’ Earth-

‘‘Seismic behavior of steel plate shear walls.’’ Structural Engineering quake Engineering Research Facility Technical Rep. No. 98-01, Dept.

Rep. No. 215, Dept. of Civil Engineering, Univ. of Alberta, Edmon- of Civil Engineering, Univ. of British Columbia, Vancouver, British

ton, Alberta, Canada. Columbia, Canada.

Elgaaly, M. 共1998兲. ‘‘Thin steel plate shear walls behavior and analysis.’’ Timler, P. A., and Kulak, G. L. 共1983兲. ‘‘Experimental study of steel plate

Thin-Walled Struct., 32, 151–180. shear walls.’’ Structural Engineering Rep. No. 114, Dept. of Civil

Elgaaly, M., Caccese, V., and Du, C. 共1993兲. ‘‘Postbuckling behavior of Engineering, Univ. of Alberta, Edmonton, Alberta, Canada.

1456 / JOURNAL OF STRUCTURAL ENGINEERING © ASCE / NOVEMBER 2003

You might also like

- GR 9 Eng BaselineDocument12 pagesGR 9 Eng BaselineMalie SibisiNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Visual Image Interpretation-TextDocument18 pagesVisual Image Interpretation-TextSaurabh Suman100% (5)

- Simplified and Detailed Finite Element Models of Steel Plate Shear WallsDocument13 pagesSimplified and Detailed Finite Element Models of Steel Plate Shear WallsponjoveNo ratings yet

- 1 s2.0 S1877705813003883 MainDocument10 pages1 s2.0 S1877705813003883 Mainfakher alaviNo ratings yet

- Sand 4Document17 pagesSand 4Pavan MNo ratings yet

- Earls, 1999Document24 pagesEarls, 1999carlosNo ratings yet

- The Effect of Infill Steel Plate Thickness On The Cycle Behavior of Steel Plate Shear WallsDocument7 pagesThe Effect of Infill Steel Plate Thickness On The Cycle Behavior of Steel Plate Shear WallsGogyNo ratings yet

- Effect of Shear Connectors On Local Buckling and Composite Action in Steel Concrete Composite Walls (Zhang Et Al, 2014)Document9 pagesEffect of Shear Connectors On Local Buckling and Composite Action in Steel Concrete Composite Walls (Zhang Et Al, 2014)Hamid GoodarziNo ratings yet

- Push Over Analysis of Unstiffened Steel Plate Shear Wall: Abhishek Verma, P. R. MaitiDocument9 pagesPush Over Analysis of Unstiffened Steel Plate Shear Wall: Abhishek Verma, P. R. MaitiIJERDNo ratings yet

- ACI STRUCTURAL JOURNAL-Shear Strength of Steel Fiber ReinforcedDocument9 pagesACI STRUCTURAL JOURNAL-Shear Strength of Steel Fiber ReinforcedMuchtar SufaatNo ratings yet

- Seismic Behavior of Steel Beam and Reinforced Concrete Column ConnectionsDocument20 pagesSeismic Behavior of Steel Beam and Reinforced Concrete Column Connectionsjuan carlosNo ratings yet

- Confined Concrete Columns With StubsDocument19 pagesConfined Concrete Columns With StubsKaren Perez LievanaNo ratings yet

- Use of Steel Fiber Reinforced Concrete For Enhanced Performance of Deep Beams With Large OpeningsDocument10 pagesUse of Steel Fiber Reinforced Concrete For Enhanced Performance of Deep Beams With Large OpeningssuhagNo ratings yet

- Behavior of Field Splice Details in Precast Concrete-Filled Steel Grid Bridge DeckDocument10 pagesBehavior of Field Splice Details in Precast Concrete-Filled Steel Grid Bridge DeckIoannis BazosNo ratings yet

- Bond Characteristics High-Strength Steel ReinforcementDocument6 pagesBond Characteristics High-Strength Steel ReinforcementUmair BaigNo ratings yet

- Esperimental StudyDocument9 pagesEsperimental Studyrafaelrp22009No ratings yet

- Creep Modeling For Concrete-Filled Steel Tubes: Wassim Naguib, Amir MirmiranDocument18 pagesCreep Modeling For Concrete-Filled Steel Tubes: Wassim Naguib, Amir Mirmiransaber javidNo ratings yet

- Composite Beams: P. AnsourianDocument27 pagesComposite Beams: P. AnsourianLeonardoMadeira11No ratings yet

- Plate Girders With Corrugated Steel Webs PDFDocument13 pagesPlate Girders With Corrugated Steel Webs PDFMarcelo Albe100% (1)

- Bond STRGDocument8 pagesBond STRGyuva_86No ratings yet

- Short ColumnsDocument15 pagesShort ColumnssrividyaNo ratings yet

- Static Behavior of Large Stud Shear Connectors: Chang-Su Shim, Pil-Goo Lee, Tae-Yang YoonDocument8 pagesStatic Behavior of Large Stud Shear Connectors: Chang-Su Shim, Pil-Goo Lee, Tae-Yang YoonHafiz Waheed IqbalNo ratings yet

- Elastic Buckling Behavior of Steel FrameDocument16 pagesElastic Buckling Behavior of Steel FrameSang NguyenNo ratings yet

- The Diagonal Tension Behavior of Fiber Reinforced Concrete BeamsDocument7 pagesThe Diagonal Tension Behavior of Fiber Reinforced Concrete BeamsChris LumyNo ratings yet

- Is I Journal PaperDocument20 pagesIs I Journal PaperYonny Pacompìa YucraNo ratings yet

- Creep Modeling For Concrete-Filled Steel TubesDocument18 pagesCreep Modeling For Concrete-Filled Steel TubesGunaNo ratings yet

- Shear Strength of Steel Fiber-Reinforced ConcreteDocument10 pagesShear Strength of Steel Fiber-Reinforced ConcreteSiva GuruNo ratings yet

- 1 s2.0 S0263823115301555 MainDocument15 pages1 s2.0 S0263823115301555 MainManonmani DNo ratings yet

- Cyclic Tests of Four Two-Story Narrow Steel Plate Shear Walls - Part 1: Analytical Studies and Specimen DesignDocument25 pagesCyclic Tests of Four Two-Story Narrow Steel Plate Shear Walls - Part 1: Analytical Studies and Specimen DesignMarimuthu KaliyamoorthyNo ratings yet

- Elastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004Document16 pagesElastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004EliyaHeninNo ratings yet

- Compatibility Torsion in Spandrel Beams Using Modified Compression Field TheoryDocument11 pagesCompatibility Torsion in Spandrel Beams Using Modified Compression Field TheoryMishraq ul quraishNo ratings yet

- Effect of Spacing of Fasteners Used To Attach The Corrugated Shear Plate To The Envelope Frame On Its Elastic Buckling BehaviorDocument21 pagesEffect of Spacing of Fasteners Used To Attach The Corrugated Shear Plate To The Envelope Frame On Its Elastic Buckling BehaviorEliyaHeninNo ratings yet

- CFSEI Shear Wall Design GuideDocument23 pagesCFSEI Shear Wall Design GuideJaypee Chang100% (1)

- Local Elastic Buckling Coefficients of Steel Plates in Composite Steel Plate Shear WallsDocument7 pagesLocal Elastic Buckling Coefficients of Steel Plates in Composite Steel Plate Shear WallsPrapa KaranNo ratings yet

- Habusadeh, Journal Manager, 182-187Document6 pagesHabusadeh, Journal Manager, 182-187Bhagirathi DengiNo ratings yet

- Journal of Constructional Steel Research: Mohamad-Ghasem Vetr, N. Mohamad Shirali, Ali GhamariDocument24 pagesJournal of Constructional Steel Research: Mohamad-Ghasem Vetr, N. Mohamad Shirali, Ali GhamariMekides KassayeNo ratings yet

- 1963 - Bresler Scordelis - Shear Strength of RC Beams PDFDocument24 pages1963 - Bresler Scordelis - Shear Strength of RC Beams PDFKaio César Arnaud DeonNo ratings yet

- Design Procedure For BRBsDocument17 pagesDesign Procedure For BRBsPremalatha JeyaramNo ratings yet

- Cantilever SlabDocument7 pagesCantilever Slabyuva_86No ratings yet

- Behaviour and Strength of Composite Slabs With Ribbed DeckingDocument19 pagesBehaviour and Strength of Composite Slabs With Ribbed DeckingRoberval PimentaNo ratings yet

- Tests of Cold-Formed Channel ColumnsDocument27 pagesTests of Cold-Formed Channel ColumnsHadeer MohamedNo ratings yet

- Journal of Constructional Steel Research: Ahmed R. Badr, Hazem H. Elanwar, Sherif A. MouradDocument15 pagesJournal of Constructional Steel Research: Ahmed R. Badr, Hazem H. Elanwar, Sherif A. MouradAB YADAVNo ratings yet

- Journal of Constructional Steel Research: Z. Li, T. Li, Y. XiaoDocument14 pagesJournal of Constructional Steel Research: Z. Li, T. Li, Y. XiaoSaeed MohebbiNo ratings yet

- Strength of Concrete Filled Tubular ColumnDocument10 pagesStrength of Concrete Filled Tubular ColumnJitendraNo ratings yet

- 15ECEE Hadzhiyaneva Belev 897 PDFDocument10 pages15ECEE Hadzhiyaneva Belev 897 PDFborisbelevNo ratings yet

- The Factors That Significantly Influence The ThreeDocument2 pagesThe Factors That Significantly Influence The ThreePankajNo ratings yet

- Shear-Bond Capacity of Composite Slabs Made With Profiled SheetingDocument7 pagesShear-Bond Capacity of Composite Slabs Made With Profiled SheetingPrapa KaranNo ratings yet

- Torsion of High-Strength Reinforced Concrete Beams and Minimum Reinforcement RequirementDocument8 pagesTorsion of High-Strength Reinforced Concrete Beams and Minimum Reinforcement RequirementSuhas Natu100% (1)

- Seismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsDocument10 pagesSeismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsleotramontinNo ratings yet

- ADVSteelConstKOROGLU PDFDocument16 pagesADVSteelConstKOROGLU PDFAbdulkadir ÇevikNo ratings yet

- 10.1016 - j.tws.2016.02.008 Analysis and Design Recommendations For Diagonally Stiffened Steel Plate Shear WallsDocument9 pages10.1016 - j.tws.2016.02.008 Analysis and Design Recommendations For Diagonally Stiffened Steel Plate Shear WallsmahdiNo ratings yet

- Performance of Jumbo Beam-to-Column Connections With High Strength SteelDocument9 pagesPerformance of Jumbo Beam-to-Column Connections With High Strength SteelMuhammad irfan javaidNo ratings yet

- Seismic Retrofit of Hollow Bridge PiersDocument10 pagesSeismic Retrofit of Hollow Bridge PiersFouad KehilaNo ratings yet

- Stiffened Coped I BeamDocument10 pagesStiffened Coped I BeamKLNo ratings yet

- Fatigue Strength Evaluation of Welded Structural Details in Corrugated Steel Web GirdersDocument15 pagesFatigue Strength Evaluation of Welded Structural Details in Corrugated Steel Web Girdersaminashash95No ratings yet

- Experiments On Cold-Formed Steel Columns With Holes: Cristopher D. Moen, B.W. SchaferDocument3 pagesExperiments On Cold-Formed Steel Columns With Holes: Cristopher D. Moen, B.W. SchaferAgung PratamaNo ratings yet

- Cold Form Steel DesignDocument6 pagesCold Form Steel Designakhilesh120No ratings yet

- Thesis On Steel Fibre Reinforced ConcreteDocument8 pagesThesis On Steel Fibre Reinforced Concretedenisemillerdesmoines100% (2)

- 1 s2.0 S0143974X22002760 MainDocument17 pages1 s2.0 S0143974X22002760 MainwflowerNo ratings yet

- Innovative Technique For Seismic Upgrade of RC Square ColumnsDocument15 pagesInnovative Technique For Seismic Upgrade of RC Square Columns오상진No ratings yet

- Behaviour and Strength of High Strength Concrete L-Beams Under Combined Shear, Bending and Torsional LoadingDocument17 pagesBehaviour and Strength of High Strength Concrete L-Beams Under Combined Shear, Bending and Torsional LoadingThulasi Raman KowsiganNo ratings yet

- A Topology Optimization Formulation Applied To Highly Flexible StructuresDocument4 pagesA Topology Optimization Formulation Applied To Highly Flexible Structuresshahin85No ratings yet

- Human Behaviour in Tunnel Fire Incidents PDFDocument12 pagesHuman Behaviour in Tunnel Fire Incidents PDFshahin85No ratings yet

- Pig Launcher Specifications PDFDocument1 pagePig Launcher Specifications PDFshahin85No ratings yet

- 8 543 PDFDocument12 pages8 543 PDFshahin85No ratings yet

- Feasibility Study For The Reuse of A Steel Offshore Platform As The Base of A Wind TowerDocument6 pagesFeasibility Study For The Reuse of A Steel Offshore Platform As The Base of A Wind Towershahin85No ratings yet

- Ramesh Text Lec1Document30 pagesRamesh Text Lec1shahin85No ratings yet

- 18 Solid State Formula Sheets Getmarks AppDocument7 pages18 Solid State Formula Sheets Getmarks AppHari KrishnaNo ratings yet

- Ultrasonic Examination Procedure For Asme CodeDocument23 pagesUltrasonic Examination Procedure For Asme CodeEdAlmNo ratings yet

- Firekab Lihch TP Fe180 Ph120Document2 pagesFirekab Lihch TP Fe180 Ph120Binh VoNo ratings yet

- TGD Part EDocument88 pagesTGD Part EOlivia SaferNo ratings yet

- Vib FileDocument3 pagesVib FileJohn Louie PimentelNo ratings yet

- System Sensor Product BrochureDocument24 pagesSystem Sensor Product BrochureJAY ROD AWITNo ratings yet

- Advance Power ElectronicsDocument20 pagesAdvance Power ElectronicsSudip MondalNo ratings yet

- Pretest, RC Part 1Document3 pagesPretest, RC Part 1leanne DespaNo ratings yet

- Electronic ComponentsDocument23 pagesElectronic ComponentsRussel Erese Garcia100% (1)

- Marble Run 1Document16 pagesMarble Run 1api-638167530No ratings yet

- E70 PDFDocument900 pagesE70 PDFАлексей100% (1)

- SLICE 141 Offical Manual S 716133Document50 pagesSLICE 141 Offical Manual S 716133joseguadalupe19canoNo ratings yet

- PX4 姿態控制算法 論文 Nonlinear Quadrocopter Attitude ControlDocument21 pagesPX4 姿態控制算法 論文 Nonlinear Quadrocopter Attitude Control鍾舒筠No ratings yet

- Assignment 3 - Mechanical VibrationDocument4 pagesAssignment 3 - Mechanical VibrationMusadiq ChaudhryNo ratings yet

- Chemical+Bonding+Lecture 1Document64 pagesChemical+Bonding+Lecture 1Sushma GuptaNo ratings yet

- HKDSE Maths Practice Paper 2Document15 pagesHKDSE Maths Practice Paper 2bradNo ratings yet

- Barad - Agential Cut - 3 - Rouse - Agential Cuts - The Conceptual and Ethical Normativity of Intra-Active PhenomenaDocument12 pagesBarad - Agential Cut - 3 - Rouse - Agential Cuts - The Conceptual and Ethical Normativity of Intra-Active PhenomenaRogerio Duarte Do Pateo Guarani KaiowáNo ratings yet

- Experiment No. 7 Induction Furnace Melting Practice: Aim - TheoryDocument6 pagesExperiment No. 7 Induction Furnace Melting Practice: Aim - TheoryDhananjay ShimpiNo ratings yet

- Nicolet Nic Plan Experiment Test IntructionsDocument5 pagesNicolet Nic Plan Experiment Test Intructionslacruz1960No ratings yet

- Certificate of Calibration: in Conformance With ISO 21501-4 Requirements For Calibration IntervalsDocument8 pagesCertificate of Calibration: in Conformance With ISO 21501-4 Requirements For Calibration IntervalsAzeddine LANo ratings yet

- Forced and Free Conv - PDFDocument11 pagesForced and Free Conv - PDFEkrema DasanNo ratings yet

- Heidenhain Touch ProbeDocument72 pagesHeidenhain Touch ProbeHoho Hahov100% (1)

- Matter Separation Tech Notes Myp4Document21 pagesMatter Separation Tech Notes Myp4anitNo ratings yet

- HW 3Document3 pagesHW 3JeeveshNo ratings yet

- Design of Reinforced Concrete Structures To BS 8110Document44 pagesDesign of Reinforced Concrete Structures To BS 8110Eng Clive KabelengaNo ratings yet

- Net Force WorksheetDocument2 pagesNet Force WorksheetJayson SisorNo ratings yet

- 10b Dodge SleevoilDocument32 pages10b Dodge SleevoilSofiane HalimiNo ratings yet

- Medilux 300 MaDocument6 pagesMedilux 300 MaVivek SrivastavaNo ratings yet