Professional Documents

Culture Documents

Cutera GIS-HP Cooling FFA Data Capture - Rev A

Cutera GIS-HP Cooling FFA Data Capture - Rev A

Uploaded by

Mickey A CouvertierCopyright:

Available Formats

You might also like

- SM Mag2000 EN A OriginalDocument27 pagesSM Mag2000 EN A OriginalZeljkoRogic67% (3)

- Troubleshooting and Error Codes PDFDocument2 pagesTroubleshooting and Error Codes PDFMickey A CouvertierNo ratings yet

- Stat Fax 2100 Service ManualDocument50 pagesStat Fax 2100 Service ManualMohammed Kahla'a100% (6)

- Bayer Clinitek - Service ManualDocument172 pagesBayer Clinitek - Service ManualAngeles Lagunes100% (2)

- Technical and Service Information Oiltronix Troubleshooting Guide 2954 3790 00Document28 pagesTechnical and Service Information Oiltronix Troubleshooting Guide 2954 3790 00Haitham yousif100% (1)

- Regtronic Eh EngDocument44 pagesRegtronic Eh Enggogame2014100% (1)

- Solera Opus v1.2.0 Error ListDocument3 pagesSolera Opus v1.2.0 Error ListMickey A CouvertierNo ratings yet

- Neraca Digital Denver Instrumen M-220Document29 pagesNeraca Digital Denver Instrumen M-220AbelNugrahaNo ratings yet

- MC785 FAC v25 ENDocument18 pagesMC785 FAC v25 ENWayne100% (1)

- Greenstar CDi Classic Engineer Service BookletDocument40 pagesGreenstar CDi Classic Engineer Service BookletsagmonaNo ratings yet

- Amazon VRF Site Monitor Software Instruction 130131 PDFDocument8 pagesAmazon VRF Site Monitor Software Instruction 130131 PDFReginaldo LealNo ratings yet

- RB Schem Cutera XEO SystemDocument1 pageRB Schem Cutera XEO SystemMickey A Couvertier50% (2)

- PCB Design WorkshopDocument18 pagesPCB Design WorkshopPrasun SinhaNo ratings yet

- PCB Kit For Mmjoy2 Project / Shield BoardDocument7 pagesPCB Kit For Mmjoy2 Project / Shield Boardsjosjo-1No ratings yet

- Raymarine E-Series Service ManualDocument56 pagesRaymarine E-Series Service ManualXesnova DevelopmentNo ratings yet

- Esab Caddy Mig C200i Service ManualDocument50 pagesEsab Caddy Mig C200i Service ManualJohn Metaxas100% (2)

- Operating Manual TR250Document17 pagesOperating Manual TR250Gerardo PulidoNo ratings yet

- ED 27X User ManualDocument11 pagesED 27X User ManualAsian InternationalNo ratings yet

- In-Cab TG-V ControllerDocument46 pagesIn-Cab TG-V Controllersamyb.am425893No ratings yet

- Ccba Lago 0321 GBDocument40 pagesCcba Lago 0321 GBGeorge KoukoutianosNo ratings yet

- Install Manual, Wired SensorsDocument20 pagesInstall Manual, Wired Sensorsian_gushepiNo ratings yet

- NT538Document15 pagesNT538Hubert Maraza JaliriNo ratings yet

- Evita 2 Dura Service Plus: Supplement To The Instructions For Use of The Evita 2 DuraDocument20 pagesEvita 2 Dura Service Plus: Supplement To The Instructions For Use of The Evita 2 DuraAsad AhmedNo ratings yet

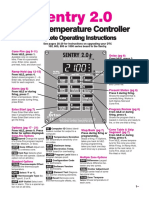

- Manual Horno Sentry 2.0 PDFDocument32 pagesManual Horno Sentry 2.0 PDFJose BacaNo ratings yet

- Haier Hrf-329aa 349aa 369aaDocument32 pagesHaier Hrf-329aa 349aa 369aaDmitriy BalabashNo ratings yet

- Tektronix DMM914 OmDocument200 pagesTektronix DMM914 Omlarryschleifer7945No ratings yet

- MTD3 - 1999Document24 pagesMTD3 - 1999kperenNo ratings yet

- 9000 8 3 Acc2 214395Document33 pages9000 8 3 Acc2 214395András TóthNo ratings yet

- Emerson Panel ControlDocument12 pagesEmerson Panel ControlTekos7No ratings yet

- Denver Inst Analytical Balances M-Series Operation ManualDocument29 pagesDenver Inst Analytical Balances M-Series Operation ManualRichard BedellNo ratings yet

- Ad 7746Document28 pagesAd 7746pskorovsNo ratings yet

- Elcometer 116CDocument8 pagesElcometer 116ChetpinNo ratings yet

- UC8 Troubleshooting Guide v2 0715Document24 pagesUC8 Troubleshooting Guide v2 0715Thom ReynoldsNo ratings yet

- Midmark M11 Classic Series - Operation - Install Manual PDFDocument44 pagesMidmark M11 Classic Series - Operation - Install Manual PDFNancy Esperanza Barreto BernalNo ratings yet

- UC8 Troubleshooting Guide v2 0715 2Document18 pagesUC8 Troubleshooting Guide v2 0715 2j.knightNo ratings yet

- Cruzpro: Digital Pyrometer With Memory, Alarms and Nmea 0183Document4 pagesCruzpro: Digital Pyrometer With Memory, Alarms and Nmea 0183MarioNo ratings yet

- TroubleshootingDocument34 pagesTroubleshootingFernando MadeiraNo ratings yet

- User Manual Iec Micro Cl17 Cl17r Cl21 Cl21rDocument83 pagesUser Manual Iec Micro Cl17 Cl17r Cl21 Cl21rFredy Fernando Huarhua Garcia0% (1)

- Gram User Manual UK 08 - 11 - 16Document40 pagesGram User Manual UK 08 - 11 - 16Raj KumarNo ratings yet

- HL EH HB Desiccant Dryer Troubleshooting Guide Rev 2Document21 pagesHL EH HB Desiccant Dryer Troubleshooting Guide Rev 2Ramsi Edianta Sembiring100% (1)

- Honeywell VisionPRO TH8000 Series PDFDocument96 pagesHoneywell VisionPRO TH8000 Series PDFEstebanNo ratings yet

- TS 606... - I/1006-I: Operating ManualDocument24 pagesTS 606... - I/1006-I: Operating ManualEyoel AwokeNo ratings yet

- Hh-520 Instruction ManualDocument20 pagesHh-520 Instruction ManualAdrian AvendañoNo ratings yet

- Controls Start-Up, Operation, Service, and TroubleshootingDocument104 pagesControls Start-Up, Operation, Service, and TroubleshootingJerine BabuNo ratings yet

- UTI TypeDocument9 pagesUTI TypeSuresh VinzudaNo ratings yet

- SMC Service 2006-10 EngDocument339 pagesSMC Service 2006-10 EngMitica Popescu100% (4)

- 45kW Chiller Guide Product Manual394 PDFDocument50 pages45kW Chiller Guide Product Manual394 PDFtrutleptNo ratings yet

- Troubleshooting: 4-1 Setting Option Setup MethodDocument26 pagesTroubleshooting: 4-1 Setting Option Setup Methodsonic8659No ratings yet

- Legend Micro 21 Marshall ScientificDocument83 pagesLegend Micro 21 Marshall ScientificDon HusseyNo ratings yet

- Ref Centrifuge CL 21R PDFDocument83 pagesRef Centrifuge CL 21R PDFAshari EndraNo ratings yet

- 479585FanMonitoringSystem IomDocument24 pages479585FanMonitoringSystem IommoathNo ratings yet

- Washer Tech Data Sheet: Contents PageDocument16 pagesWasher Tech Data Sheet: Contents PageGarbanzo Diaz PerezNo ratings yet

- Atf7000fe Affinity 35 Cu FT Front Load Washer PDFDocument16 pagesAtf7000fe Affinity 35 Cu FT Front Load Washer PDFGarbanzo Diaz PerezNo ratings yet

- Codigos Lavadora FrigidaireDocument16 pagesCodigos Lavadora FrigidaireLeonardoNo ratings yet

- Diagnose of Particlefilter ControllerDocument16 pagesDiagnose of Particlefilter ControllerMarko StuparNo ratings yet

- Float Switch: Replaces: - English Type ABZMS-41Document40 pagesFloat Switch: Replaces: - English Type ABZMS-41Renato PaivaNo ratings yet

- Manual Precedent MultitempDocument163 pagesManual Precedent MultitempCiwank ToNo ratings yet

- TECHNICAL INFORMATION FTL8x PDFDocument32 pagesTECHNICAL INFORMATION FTL8x PDFhamr01No ratings yet

- LS6000AT ControllerDocument24 pagesLS6000AT ControllerTrung Hiếu CamNo ratings yet

- Manual Book HEAT STRESS METER (Iklim kerja-ISBB)Document25 pagesManual Book HEAT STRESS METER (Iklim kerja-ISBB)rofik azisNo ratings yet

- BeaconII HeatcraftDocument36 pagesBeaconII HeatcraftManNo ratings yet

- User GuideDocument42 pagesUser Guidemiguel carrasco100% (1)

- Service Manual: Outdoor Unit Series Trane TVR™ II DC Inverter VRF SystemDocument343 pagesService Manual: Outdoor Unit Series Trane TVR™ II DC Inverter VRF SystemUNNI VENUGOPAL67% (3)

- Allsensor DLVR DatasheetDocument19 pagesAllsensor DLVR DatasheetmvanoudenaardeNo ratings yet

- Eja Hart Im 08Document31 pagesEja Hart Im 08vishnunair27No ratings yet

- Tec 3000 Quick Reference GuideDocument57 pagesTec 3000 Quick Reference GuidemhdNo ratings yet

- Am036fxmdch PDFDocument65 pagesAm036fxmdch PDFAnonymous wCXFHQOl4No ratings yet

- Compresores Carrier 30gtne045 - 620ka Serie 4101F16033 PDFDocument96 pagesCompresores Carrier 30gtne045 - 620ka Serie 4101F16033 PDFLeonel IntriagoNo ratings yet

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- Cutera E211 Field TestingDocument2 pagesCutera E211 Field TestingMickey A CouvertierNo ratings yet

- Siemens Kion Multigas 2000 - Service ManualDocument32 pagesSiemens Kion Multigas 2000 - Service ManualisbelNo ratings yet

- + Instruction PicturesDocument840 pages+ Instruction PicturesRodrigoNo ratings yet

- Crescent Legacy DocumentationDocument6 pagesCrescent Legacy DocumentationЕвгений ЯвищенкоNo ratings yet

- Eagle TutorialDocument6 pagesEagle Tutorialgenuinelycool100% (1)

- Coral SBDX: Office VersionDocument88 pagesCoral SBDX: Office VersionRohit ShakyaNo ratings yet

- SLIDES Isola 26feb14Document67 pagesSLIDES Isola 26feb14JavpNo ratings yet

- Technical Manual Storage Electric Water Heaters - VLSDocument18 pagesTechnical Manual Storage Electric Water Heaters - VLSdim-elNo ratings yet

- Report Phase 3Document42 pagesReport Phase 3somesh shatalwarNo ratings yet

- HEADER MOLEX - KK 7395 - 5-Pin - 0022057058 - PCB - HEADERS PDFDocument2 pagesHEADER MOLEX - KK 7395 - 5-Pin - 0022057058 - PCB - HEADERS PDFLodewyk KleynhansNo ratings yet

- Sustainability 13 10357 v3Document33 pagesSustainability 13 10357 v3SALAH NETNo ratings yet

- Product Manual 85580V4 (Revision J) : Micronet TMR 5009 Digital Control SystemDocument46 pagesProduct Manual 85580V4 (Revision J) : Micronet TMR 5009 Digital Control SystemAshraf AbdelrahmanNo ratings yet

- High Reliability PCB Design Tips For Aerosapce and Other Harsh EnvironmentsDocument10 pagesHigh Reliability PCB Design Tips For Aerosapce and Other Harsh Environmentsf22kmaNo ratings yet

- BMS 3S 25A Circuit Diagram and Modified - Electronics Projects CDocument5 pagesBMS 3S 25A Circuit Diagram and Modified - Electronics Projects CSitarda WantonoNo ratings yet

- Flatronl 194 WTDocument29 pagesFlatronl 194 WTRadames Chibas EstradaNo ratings yet

- ADMP401Document12 pagesADMP401Ayman Thafer Abdul-nafaNo ratings yet

- MiCOM P40 5th Gen PC Platform 28022023 - LAMDocument28 pagesMiCOM P40 5th Gen PC Platform 28022023 - LAMWILSONNo ratings yet

- Z Series DC/DC Converter: SpecificationsDocument3 pagesZ Series DC/DC Converter: SpecificationsRaj PatelNo ratings yet

- Day 5Document57 pagesDay 5AKSHAY NANGIANo ratings yet

- Onkyo - 899Sv636 DC 1Document1 pageOnkyo - 899Sv636 DC 1kizonzNo ratings yet

- 10 True Repair Case Histories of LCD Monitors Volume IDocument58 pages10 True Repair Case Histories of LCD Monitors Volume IZerihun TadesseNo ratings yet

- APW 35 1B 2 6 3 DatasheetDocument2 pagesAPW 35 1B 2 6 3 DatasheetirinaNo ratings yet

- ProjectDocument35 pagesProjectMoHamedNo ratings yet

- Operations Manual PCM-UIO96B-GDocument37 pagesOperations Manual PCM-UIO96B-Gjigg1777No ratings yet

Cutera GIS-HP Cooling FFA Data Capture - Rev A

Cutera GIS-HP Cooling FFA Data Capture - Rev A

Uploaded by

Mickey A CouvertierOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cutera GIS-HP Cooling FFA Data Capture - Rev A

Cutera GIS-HP Cooling FFA Data Capture - Rev A

Uploaded by

Mickey A CouvertierCopyright:

Available Formats

Field Failure Analysis Data Capture

This Form’s purpose is to assist in the resolution of problems discovered in the field by capturing data

at the time of the failure in a pre-defined format.

GIS / HANDPIECE COOLING

THE SYSTEM REVERTS INTO STANDBY MODE WHEN THE HANDPIECE TEMP RISES ABOVE THE 15 THRESHOLD.

Tracking Data Date:

Failed Handpiece serial#: Laser serial#:

Location/Doctor: Technician name:

RMA#: Software Versions _________U5

_________U14

_________U25

SYMPTOM / SITUATION CHECKS (CHECK ALL THAT APPLY)

QUESTIONS FOR CUSTOMERS

Goes into standby during long treatment (when laser umbilical is warm- legs& backs)?………… Yes No

Goes into standby during short treatment (when laser umbilical is cool- armpits, faces)?..…….. Yes No

Has customer ever seen E323 during treatment? …………….…..………………………. Yes No

Has customer ever seen a E221 during treatment?…………………………....………….. Yes No

Sudden

Has the problem progressed or did it show up all at once?……………………………….. Progressive

Temp< 80F

What is the max temperature of the treatment room during a long case?……………….

Temp> 80F

Make sure customer knows that monthly heat exchanger vacuum maintenance is

required

Please fill in with the operating conditions that cause the handpiece cooling problem if they are

not covered above

Notes:

FIELD SERVICE ENGINEER OBSERVATIONS

Laser will not go into “Ready” mode at all?………………………………………………... Yes No

Clean

Heat exchanger condition?……..……………………………………………………………. Dirty

Plugged

System water level measured from top of reservoir (approx)…..………………… _______ inches

Is there any water leakage from the handpiece?…………………………………………… Yes No

Does room/system have adequate ventilation?…………………………………………….. Yes No

Black

What style are the handpiece thermistor wires? Gold

Ribbon

110v or 220v system?………………………………………………………………………… 110v 220v

VERIFICATION OF DEVIATIONS/FMI’S INCORPORATED INTO THE SYSTEM:

Fan Speed Deviation

o Using an DMMr measure from FAN_PC testpoint to U1-1 on the Interconnect bd MEASURE VALUE

Ω

Verify fan is model # 039202 (printed on top of fan hub)………………………….. Yes No

What is the version fan control PIC, U14 on the Interconnect bd?……………………………. VERSION ______________

NOTES:______________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

____________________________________________________________________________________________________________________

Altus P/N#90-200-0100 Rev A

HANDPIECE TESTS

Record factory Temp-Offset written on handpiece bezel ……………………… Offset

Novram

Record calibration offset from LaserBox(ServiceTools) NVRam calib screen…

HANDPIECE CONTINUITY

DETERMINES LEAKAGE BETWEEN THE THERMISTOR AND TEC COOLING UNIT AND THE METAL

SURFACES OF THE HANDPIECE. TURN INSTRUMENT OFF, DISCONNECT HANDPIECE FROM DISPLAY

BOARD, AND MEASURE WITH A QUALITY DMM. Min Value Max

Measure the resistance between each leg of the thermistor leads to the metal

10MΏ OPEN

surface of the handpiece. Record the minimum value read……...

Measure the resistance between each leg of the Tec supply leads to the metal

10MΏ OPEN

surface of the handpiece. Record the minimum value read……...

Measure the resistance between the thermistor leads and the Tec supply

10MΏ OPEN

leads. Record the minimum value read……...

THERMISTOR CIRCUIT ACCURACY

Display the “Set-Actual” handpiece temperature in the shot counter by

toggling Dip-Switch 7 on the Control PCB to “ON”.

Turn the system on. Min Value Max

FSE

When the temp display reads “04” measure the actual handpiece temperature

using an external isolated thermocouple applied to the handpiece gold tip 3ºC Factpru 5ºC

Record the temp of the external thermocouple………

FSE

Unplug the Tec supply cable (J5 on display PCB) and allow the handpiece 14ºC 16ºC

Factory

temp display to rise to 15º.

Record the temp of the external thermocouple………

Recalibration necessary?……………………………………………………………. Yes No

Record new calibration offset if recalibrated………………………………….. ….. New Offset _________________________

COOLING PERFORMANCE VERIFICATION

THESE TESTS MUST BE PERFORMED WITH WATER AT ABOUT ROOM TEMPERATURE.

Arm load test

Turn system on Min Value Max

FSE

Allow handpiece to cool until display reads “04” “04”

Rub gold tip on arm for 15 seconds and watch temp display N/A Factory 08º

Record maximum temperature………………………………………………………

Countdown test

Place a shunt or jumper wire across “shunt1” and “shunt2” on display PCB

(near J5). This forces max cooling, overriding the 4 deg control loop.

Warm handpiece tip above 20C by rubbing on arm.

Turn system on FSE

Start timing when the display temp transitions from “21” to “20”

Stop timing when the display temp transitions from “01” to “00” na Factory

34sec

Record time at right Record the time in seconds……

SYSTEM TESTS

TEC SUPPLY CURRENT

DETERMINES MAXIMUM CURRENT CAPABILITY OF THE TEC SUPPLY.

Min Value Max

With shunts 1 and 2 still in place, turn system on. FSE

Measure the voltage across R64 on the Display board 330mV Factory

360mV

Turn off system and remove shunts Record the voltage across R64……….

Min Value Max

Altus P/N#90-200-0100 Rev A

SYSTEM VOLTAGES 22vdc 30vdc

Measure the Tec supply voltage at the Cathode of D40 on the Display bd.

Record the minimum value read…….. 4.9vdc 5.2vdc

Measure the +5v supply voltage at TP4(Daughter bd)/TP15(Display bd). Yes No

Record the minimum value read……..

Do the values fluctuate at all?………..

FAN SPEED CONTROL Time Water Temp Fan Voltage

DETERMINES FAN SPEED/VOLTAGE/SYSTEM HEATING CHARACTERISTICS 0sec 22º 55vac

Unplug the fan(J3 on the interconnect PCB) and connect DMM across J3 pins

on interconnect PCB to measure the fan voltage..

Apply thermocouple to side of water reservoir to measure system water temp.

Run at maximum Rep rate at 60J-30mS. Record each voltage step up with the

time running and reservoir water temperature.

Stop recording and shut system off after water temperature reaches 45C.

Fan supply should be at full voltage (between 115 and 125 VAC) if otherwise,

contact Tech Supt.

Record the voltage / temp / time of each fan voltage rise.……….

Note: the amount of fan voltage steps depends on the version

of fan control sw (U14) on the interconnect bd.

Plug fan back in

Run at maximum rep rate at 60J-30mS for 3 minutes

Reservoir Water temp__________

After 3 minutes, measure the temperature of the water reservoir

Measure the input airflow temperature by placing the thermocouple under the Air temperature_______________

system heat exchanger near the reservoir corner Difference ___________________

Subtract air temp from reservoir temp. Difference must be less than 18C. If

otherwise, contact Tech Supt.

Record maximum rep rate Max Rep Rate ________________

FACTORY TESTS ONLY

HIPOT TEST

HIPOT PARAMETERS: 150VDC/50UA

Tie thermistor leads together and Hipot between the connected thermistor

leads and the diffusor………………………………………………………………… Pass Fail

Tie Tec leads together and Hipot between the connected Tec leads and the

diffusor………………………………………………………………………………… Pass Fail

Altus P/N#90-200-0100 Rev A

You might also like

- SM Mag2000 EN A OriginalDocument27 pagesSM Mag2000 EN A OriginalZeljkoRogic67% (3)

- Troubleshooting and Error Codes PDFDocument2 pagesTroubleshooting and Error Codes PDFMickey A CouvertierNo ratings yet

- Stat Fax 2100 Service ManualDocument50 pagesStat Fax 2100 Service ManualMohammed Kahla'a100% (6)

- Bayer Clinitek - Service ManualDocument172 pagesBayer Clinitek - Service ManualAngeles Lagunes100% (2)

- Technical and Service Information Oiltronix Troubleshooting Guide 2954 3790 00Document28 pagesTechnical and Service Information Oiltronix Troubleshooting Guide 2954 3790 00Haitham yousif100% (1)

- Regtronic Eh EngDocument44 pagesRegtronic Eh Enggogame2014100% (1)

- Solera Opus v1.2.0 Error ListDocument3 pagesSolera Opus v1.2.0 Error ListMickey A CouvertierNo ratings yet

- Neraca Digital Denver Instrumen M-220Document29 pagesNeraca Digital Denver Instrumen M-220AbelNugrahaNo ratings yet

- MC785 FAC v25 ENDocument18 pagesMC785 FAC v25 ENWayne100% (1)

- Greenstar CDi Classic Engineer Service BookletDocument40 pagesGreenstar CDi Classic Engineer Service BookletsagmonaNo ratings yet

- Amazon VRF Site Monitor Software Instruction 130131 PDFDocument8 pagesAmazon VRF Site Monitor Software Instruction 130131 PDFReginaldo LealNo ratings yet

- RB Schem Cutera XEO SystemDocument1 pageRB Schem Cutera XEO SystemMickey A Couvertier50% (2)

- PCB Design WorkshopDocument18 pagesPCB Design WorkshopPrasun SinhaNo ratings yet

- PCB Kit For Mmjoy2 Project / Shield BoardDocument7 pagesPCB Kit For Mmjoy2 Project / Shield Boardsjosjo-1No ratings yet

- Raymarine E-Series Service ManualDocument56 pagesRaymarine E-Series Service ManualXesnova DevelopmentNo ratings yet

- Esab Caddy Mig C200i Service ManualDocument50 pagesEsab Caddy Mig C200i Service ManualJohn Metaxas100% (2)

- Operating Manual TR250Document17 pagesOperating Manual TR250Gerardo PulidoNo ratings yet

- ED 27X User ManualDocument11 pagesED 27X User ManualAsian InternationalNo ratings yet

- In-Cab TG-V ControllerDocument46 pagesIn-Cab TG-V Controllersamyb.am425893No ratings yet

- Ccba Lago 0321 GBDocument40 pagesCcba Lago 0321 GBGeorge KoukoutianosNo ratings yet

- Install Manual, Wired SensorsDocument20 pagesInstall Manual, Wired Sensorsian_gushepiNo ratings yet

- NT538Document15 pagesNT538Hubert Maraza JaliriNo ratings yet

- Evita 2 Dura Service Plus: Supplement To The Instructions For Use of The Evita 2 DuraDocument20 pagesEvita 2 Dura Service Plus: Supplement To The Instructions For Use of The Evita 2 DuraAsad AhmedNo ratings yet

- Manual Horno Sentry 2.0 PDFDocument32 pagesManual Horno Sentry 2.0 PDFJose BacaNo ratings yet

- Haier Hrf-329aa 349aa 369aaDocument32 pagesHaier Hrf-329aa 349aa 369aaDmitriy BalabashNo ratings yet

- Tektronix DMM914 OmDocument200 pagesTektronix DMM914 Omlarryschleifer7945No ratings yet

- MTD3 - 1999Document24 pagesMTD3 - 1999kperenNo ratings yet

- 9000 8 3 Acc2 214395Document33 pages9000 8 3 Acc2 214395András TóthNo ratings yet

- Emerson Panel ControlDocument12 pagesEmerson Panel ControlTekos7No ratings yet

- Denver Inst Analytical Balances M-Series Operation ManualDocument29 pagesDenver Inst Analytical Balances M-Series Operation ManualRichard BedellNo ratings yet

- Ad 7746Document28 pagesAd 7746pskorovsNo ratings yet

- Elcometer 116CDocument8 pagesElcometer 116ChetpinNo ratings yet

- UC8 Troubleshooting Guide v2 0715Document24 pagesUC8 Troubleshooting Guide v2 0715Thom ReynoldsNo ratings yet

- Midmark M11 Classic Series - Operation - Install Manual PDFDocument44 pagesMidmark M11 Classic Series - Operation - Install Manual PDFNancy Esperanza Barreto BernalNo ratings yet

- UC8 Troubleshooting Guide v2 0715 2Document18 pagesUC8 Troubleshooting Guide v2 0715 2j.knightNo ratings yet

- Cruzpro: Digital Pyrometer With Memory, Alarms and Nmea 0183Document4 pagesCruzpro: Digital Pyrometer With Memory, Alarms and Nmea 0183MarioNo ratings yet

- TroubleshootingDocument34 pagesTroubleshootingFernando MadeiraNo ratings yet

- User Manual Iec Micro Cl17 Cl17r Cl21 Cl21rDocument83 pagesUser Manual Iec Micro Cl17 Cl17r Cl21 Cl21rFredy Fernando Huarhua Garcia0% (1)

- Gram User Manual UK 08 - 11 - 16Document40 pagesGram User Manual UK 08 - 11 - 16Raj KumarNo ratings yet

- HL EH HB Desiccant Dryer Troubleshooting Guide Rev 2Document21 pagesHL EH HB Desiccant Dryer Troubleshooting Guide Rev 2Ramsi Edianta Sembiring100% (1)

- Honeywell VisionPRO TH8000 Series PDFDocument96 pagesHoneywell VisionPRO TH8000 Series PDFEstebanNo ratings yet

- TS 606... - I/1006-I: Operating ManualDocument24 pagesTS 606... - I/1006-I: Operating ManualEyoel AwokeNo ratings yet

- Hh-520 Instruction ManualDocument20 pagesHh-520 Instruction ManualAdrian AvendañoNo ratings yet

- Controls Start-Up, Operation, Service, and TroubleshootingDocument104 pagesControls Start-Up, Operation, Service, and TroubleshootingJerine BabuNo ratings yet

- UTI TypeDocument9 pagesUTI TypeSuresh VinzudaNo ratings yet

- SMC Service 2006-10 EngDocument339 pagesSMC Service 2006-10 EngMitica Popescu100% (4)

- 45kW Chiller Guide Product Manual394 PDFDocument50 pages45kW Chiller Guide Product Manual394 PDFtrutleptNo ratings yet

- Troubleshooting: 4-1 Setting Option Setup MethodDocument26 pagesTroubleshooting: 4-1 Setting Option Setup Methodsonic8659No ratings yet

- Legend Micro 21 Marshall ScientificDocument83 pagesLegend Micro 21 Marshall ScientificDon HusseyNo ratings yet

- Ref Centrifuge CL 21R PDFDocument83 pagesRef Centrifuge CL 21R PDFAshari EndraNo ratings yet

- 479585FanMonitoringSystem IomDocument24 pages479585FanMonitoringSystem IommoathNo ratings yet

- Washer Tech Data Sheet: Contents PageDocument16 pagesWasher Tech Data Sheet: Contents PageGarbanzo Diaz PerezNo ratings yet

- Atf7000fe Affinity 35 Cu FT Front Load Washer PDFDocument16 pagesAtf7000fe Affinity 35 Cu FT Front Load Washer PDFGarbanzo Diaz PerezNo ratings yet

- Codigos Lavadora FrigidaireDocument16 pagesCodigos Lavadora FrigidaireLeonardoNo ratings yet

- Diagnose of Particlefilter ControllerDocument16 pagesDiagnose of Particlefilter ControllerMarko StuparNo ratings yet

- Float Switch: Replaces: - English Type ABZMS-41Document40 pagesFloat Switch: Replaces: - English Type ABZMS-41Renato PaivaNo ratings yet

- Manual Precedent MultitempDocument163 pagesManual Precedent MultitempCiwank ToNo ratings yet

- TECHNICAL INFORMATION FTL8x PDFDocument32 pagesTECHNICAL INFORMATION FTL8x PDFhamr01No ratings yet

- LS6000AT ControllerDocument24 pagesLS6000AT ControllerTrung Hiếu CamNo ratings yet

- Manual Book HEAT STRESS METER (Iklim kerja-ISBB)Document25 pagesManual Book HEAT STRESS METER (Iklim kerja-ISBB)rofik azisNo ratings yet

- BeaconII HeatcraftDocument36 pagesBeaconII HeatcraftManNo ratings yet

- User GuideDocument42 pagesUser Guidemiguel carrasco100% (1)

- Service Manual: Outdoor Unit Series Trane TVR™ II DC Inverter VRF SystemDocument343 pagesService Manual: Outdoor Unit Series Trane TVR™ II DC Inverter VRF SystemUNNI VENUGOPAL67% (3)

- Allsensor DLVR DatasheetDocument19 pagesAllsensor DLVR DatasheetmvanoudenaardeNo ratings yet

- Eja Hart Im 08Document31 pagesEja Hart Im 08vishnunair27No ratings yet

- Tec 3000 Quick Reference GuideDocument57 pagesTec 3000 Quick Reference GuidemhdNo ratings yet

- Am036fxmdch PDFDocument65 pagesAm036fxmdch PDFAnonymous wCXFHQOl4No ratings yet

- Compresores Carrier 30gtne045 - 620ka Serie 4101F16033 PDFDocument96 pagesCompresores Carrier 30gtne045 - 620ka Serie 4101F16033 PDFLeonel IntriagoNo ratings yet

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- Cutera E211 Field TestingDocument2 pagesCutera E211 Field TestingMickey A CouvertierNo ratings yet

- Siemens Kion Multigas 2000 - Service ManualDocument32 pagesSiemens Kion Multigas 2000 - Service ManualisbelNo ratings yet

- + Instruction PicturesDocument840 pages+ Instruction PicturesRodrigoNo ratings yet

- Crescent Legacy DocumentationDocument6 pagesCrescent Legacy DocumentationЕвгений ЯвищенкоNo ratings yet

- Eagle TutorialDocument6 pagesEagle Tutorialgenuinelycool100% (1)

- Coral SBDX: Office VersionDocument88 pagesCoral SBDX: Office VersionRohit ShakyaNo ratings yet

- SLIDES Isola 26feb14Document67 pagesSLIDES Isola 26feb14JavpNo ratings yet

- Technical Manual Storage Electric Water Heaters - VLSDocument18 pagesTechnical Manual Storage Electric Water Heaters - VLSdim-elNo ratings yet

- Report Phase 3Document42 pagesReport Phase 3somesh shatalwarNo ratings yet

- HEADER MOLEX - KK 7395 - 5-Pin - 0022057058 - PCB - HEADERS PDFDocument2 pagesHEADER MOLEX - KK 7395 - 5-Pin - 0022057058 - PCB - HEADERS PDFLodewyk KleynhansNo ratings yet

- Sustainability 13 10357 v3Document33 pagesSustainability 13 10357 v3SALAH NETNo ratings yet

- Product Manual 85580V4 (Revision J) : Micronet TMR 5009 Digital Control SystemDocument46 pagesProduct Manual 85580V4 (Revision J) : Micronet TMR 5009 Digital Control SystemAshraf AbdelrahmanNo ratings yet

- High Reliability PCB Design Tips For Aerosapce and Other Harsh EnvironmentsDocument10 pagesHigh Reliability PCB Design Tips For Aerosapce and Other Harsh Environmentsf22kmaNo ratings yet

- BMS 3S 25A Circuit Diagram and Modified - Electronics Projects CDocument5 pagesBMS 3S 25A Circuit Diagram and Modified - Electronics Projects CSitarda WantonoNo ratings yet

- Flatronl 194 WTDocument29 pagesFlatronl 194 WTRadames Chibas EstradaNo ratings yet

- ADMP401Document12 pagesADMP401Ayman Thafer Abdul-nafaNo ratings yet

- MiCOM P40 5th Gen PC Platform 28022023 - LAMDocument28 pagesMiCOM P40 5th Gen PC Platform 28022023 - LAMWILSONNo ratings yet

- Z Series DC/DC Converter: SpecificationsDocument3 pagesZ Series DC/DC Converter: SpecificationsRaj PatelNo ratings yet

- Day 5Document57 pagesDay 5AKSHAY NANGIANo ratings yet

- Onkyo - 899Sv636 DC 1Document1 pageOnkyo - 899Sv636 DC 1kizonzNo ratings yet

- 10 True Repair Case Histories of LCD Monitors Volume IDocument58 pages10 True Repair Case Histories of LCD Monitors Volume IZerihun TadesseNo ratings yet

- APW 35 1B 2 6 3 DatasheetDocument2 pagesAPW 35 1B 2 6 3 DatasheetirinaNo ratings yet

- ProjectDocument35 pagesProjectMoHamedNo ratings yet

- Operations Manual PCM-UIO96B-GDocument37 pagesOperations Manual PCM-UIO96B-Gjigg1777No ratings yet