Professional Documents

Culture Documents

Description of Finishing Machines Problems

Description of Finishing Machines Problems

Uploaded by

Dyeing Dyeing0 ratings0% found this document useful (0 votes)

88 views2 pagesThe document describes problems with various finishing machines and their effects. 1) A dewatering machine from Corino had problems with machine speed not being controlled, a damaged frame for diameter setting, and a malfunctioning detwisting roller. 2) A dryer machine from LK & LH Co. had a torn net, a steam line that did not work properly, and uneven temperatures across the machine. 3) Problems with tube tex, slitting, stenter, and open compactor machines produced a variety of quality issues like twisting, creasing, bowing, skewing, shade variation, GSM variation, compaction marks, and shining marks.

Original Description:

Original Title

Description of Finishing machines problems

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document describes problems with various finishing machines and their effects. 1) A dewatering machine from Corino had problems with machine speed not being controlled, a damaged frame for diameter setting, and a malfunctioning detwisting roller. 2) A dryer machine from LK & LH Co. had a torn net, a steam line that did not work properly, and uneven temperatures across the machine. 3) Problems with tube tex, slitting, stenter, and open compactor machines produced a variety of quality issues like twisting, creasing, bowing, skewing, shade variation, GSM variation, compaction marks, and shining marks.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

88 views2 pagesDescription of Finishing Machines Problems

Description of Finishing Machines Problems

Uploaded by

Dyeing DyeingThe document describes problems with various finishing machines and their effects. 1) A dewatering machine from Corino had problems with machine speed not being controlled, a damaged frame for diameter setting, and a malfunctioning detwisting roller. 2) A dryer machine from LK & LH Co. had a torn net, a steam line that did not work properly, and uneven temperatures across the machine. 3) Problems with tube tex, slitting, stenter, and open compactor machines produced a variety of quality issues like twisting, creasing, bowing, skewing, shade variation, GSM variation, compaction marks, and shining marks.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Description of Finishing machines problems & their effects:

Machine specifications Problems Effects in

finishing

Dewatering m/c (Corino, Italy). 1.Machine speed problem 1. Production

(not in control). is

hampered.

2. Frame for dia setting is 2. Fabric

damaged. quality

3.Detwisting roller does issue like

not work properly. twisting,

crease

Dryer m/c (LK & LH Co. Ltd, Taiwan). 1.Net has been teared. mark, dia

2.Steam line does not work mark , is

properly. produced.

3. At the middle point, 3. Bowing &

skewing is

temperature is less than

created.

left & right side. 4. M2M

Tube tex (USA). 1.60% Button does not Shade

work properly. variation is

2. Sensor of spreader created.

motor is damaged. 5. GSM

variation is

created.

Slitting m/c (Bianco, Evo tech, Italy). 1.Sensor roller does not 6. Compaction

work efficiently. mark &

2.Strainer for dust Shinning

removing is damaged. mark is

produced.

3.No fan in panel board.

4.There are padder up-

down problem.

Stenter m/c (Unitech, Italy). 1.Mahlo function does not

work .

2.Spring is damaged of 1st

& 2nd padder due to PLC

problem.

3.Expander roller is angled

of 1st padder.

4.Monitor of TV does not

work properly.

5.Communication media

(Phone ) does not work.

Open compactor m/c (Ferraro, Italy). 1.Blanket is damaged.

2.conveyor net is

malfunctioned.

3.Centering roller does not

work properly.

4. Key of Teflon is damage

5. hydraulic pressure nut

of centering shutter is

damaged.

6. Load cell is damaged.

7.Chain setting adjustment

is malfunctioned.

You might also like

- Solid % ReportDocument30 pagesSolid % ReportDyeing Dyeing100% (2)

- IES Master Editorial Board - CSE (Prelims) - Civil Engineering-IES Master Publication (2017)Document671 pagesIES Master Editorial Board - CSE (Prelims) - Civil Engineering-IES Master Publication (2017)Sourabh Raj Desai100% (1)

- Tu Clothing Fabric Manual v2 2017Document28 pagesTu Clothing Fabric Manual v2 2017Dyeing DyeingNo ratings yet

- Airjet Loom Toyotaa Jat710 Trouble ShootingDocument18 pagesAirjet Loom Toyotaa Jat710 Trouble Shootingselvapdm100% (25)

- Briot 6000 Scanform III Maintenance ManualDocument153 pagesBriot 6000 Scanform III Maintenance ManualLeonardoNo ratings yet

- 8D Report of Urea Tank For Pump Welding Leakage IssueDocument122 pages8D Report of Urea Tank For Pump Welding Leakage IssueAvinash NikamNo ratings yet

- AutoCAD Plant3D 2014 - PIP Specs (Updated V2)Document4 pagesAutoCAD Plant3D 2014 - PIP Specs (Updated V2)Zvonko Bešlić100% (1)

- MOT Spot Welder: Food Living Outside Play Technology WorkshopDocument11 pagesMOT Spot Welder: Food Living Outside Play Technology Workshopprivate 2No ratings yet

- Manual - Labeling MachineDocument10 pagesManual - Labeling MachineGilang WijayaNo ratings yet

- 09 JaouenDocument20 pages09 JaouenCésarNo ratings yet

- AM 201 Fully Automatic Terminal Crimping MachineDocument16 pagesAM 201 Fully Automatic Terminal Crimping MachineademirffNo ratings yet

- Service Bulletin: Failure To Install The Toner Container in The MachineDocument2 pagesService Bulletin: Failure To Install The Toner Container in The MachineAndrey KhodanitskiNo ratings yet

- BASF Injection Molding Defects PDFDocument38 pagesBASF Injection Molding Defects PDFSenthil Kumar100% (1)

- Alpha (ENG)Document9 pagesAlpha (ENG)bbing4021No ratings yet

- MX-5300CE Error Code - V01.00.05Document28 pagesMX-5300CE Error Code - V01.00.05jair olmosNo ratings yet

- TroubleshootingDocument58 pagesTroubleshootingCobi MiglioraNo ratings yet

- Form 1.1d - Air Conditioner ChecklistDocument2 pagesForm 1.1d - Air Conditioner ChecklistvalveworkshseNo ratings yet

- URIT-50 Service Manual Main BodyDocument11 pagesURIT-50 Service Manual Main BodyJerry MnguniNo ratings yet

- Redsail Cutting Plotter TroubleDocument6 pagesRedsail Cutting Plotter TroublezaharimanNo ratings yet

- URT180-Mantenance ManualDocument10 pagesURT180-Mantenance ManualthaungmtNo ratings yet

- ERROR CODE TROUBLE SHOOTING - SK Series SterilizerDocument2 pagesERROR CODE TROUBLE SHOOTING - SK Series SterilizerDaniel CornielNo ratings yet

- TSP800 Series: Thermal PrinterDocument39 pagesTSP800 Series: Thermal Printercsaba1111No ratings yet

- Epson WF-7720, WF-7710, WF-7210 Series Service Manual Page 21-40Document20 pagesEpson WF-7720, WF-7710, WF-7210 Series Service Manual Page 21-40OlegNo ratings yet

- Centrifuge DSC-203,303SD (Manual) - 2021Document3 pagesCentrifuge DSC-203,303SD (Manual) - 2021Leah DarinoNo ratings yet

- Lifting Fibre Nylon Slings ChecklistDocument2 pagesLifting Fibre Nylon Slings Checklistmohamed Abo-EwishaNo ratings yet

- Unit 4 of Et&cDocument9 pagesUnit 4 of Et&cRaj vardhan PrasadNo ratings yet

- CMR For 2gs Am CrackDocument7 pagesCMR For 2gs Am CrackKumaravelNo ratings yet

- TNC ConectorDocument2 pagesTNC ConectorLong ComtechNo ratings yet

- BM Nozzle MaintenanceDocument6 pagesBM Nozzle Maintenancemartin.weisshaarNo ratings yet

- E-DAY TIPS - MAY 09, 2022: A. To CureDocument3 pagesE-DAY TIPS - MAY 09, 2022: A. To Curemechelle turnoNo ratings yet

- Tool Life, Tool Wear Machinability PDFDocument9 pagesTool Life, Tool Wear Machinability PDFshivaNo ratings yet

- 001-2. Fast ConnectorDocument4 pages001-2. Fast ConnectorHebert SánchezNo ratings yet

- Breaker Maintenance and Common Failure Modes NWsu07 WhiteDocument8 pagesBreaker Maintenance and Common Failure Modes NWsu07 WhiteTruong HungNo ratings yet

- Lesson: Generator, and ExciterDocument5 pagesLesson: Generator, and ExciterazizNo ratings yet

- 036 UQ3 NewsletterDocument2 pages036 UQ3 NewsletterMubbashir KhalilNo ratings yet

- Balanced Microphone From An Old TelephoneDocument6 pagesBalanced Microphone From An Old TelephoneAjaxFree OficialNo ratings yet

- PolishingDocument60 pagesPolishingrgraciar010% (1)

- User Manual Gen5 1610 2513Document62 pagesUser Manual Gen5 1610 2513Ediget TefferiNo ratings yet

- Activities As Commented by MODESDocument1 pageActivities As Commented by MODESraza.slietNo ratings yet

- Instruction Manual For Digital Centrifuge DSC-202SD / DSC-302SDDocument3 pagesInstruction Manual For Digital Centrifuge DSC-202SD / DSC-302SDSAUL CHINCHILLANo ratings yet

- Section Troubleshooting: T.2 in WeavingDocument24 pagesSection Troubleshooting: T.2 in Weavingsuperficies cuadraticasNo ratings yet

- REFUone WiFi Stick LSW-3 Manual EN 20191218Document16 pagesREFUone WiFi Stick LSW-3 Manual EN 20191218gianluca.tricoliNo ratings yet

- User Manual of NA201Document13 pagesUser Manual of NA201Ariel BruniNo ratings yet

- 0 - 07 - A - 0112 - SMART NOVA Receiver Insert 22072013-BM-webDocument2 pages0 - 07 - A - 0112 - SMART NOVA Receiver Insert 22072013-BM-webDieter van RooyenNo ratings yet

- Cutter Datasheet 628-1Document12 pagesCutter Datasheet 628-1dcackovski.henryNo ratings yet

- CRT Process Flow ChartDocument9 pagesCRT Process Flow ChartyeekaiNo ratings yet

- Operation of Winding Machine 03Document2 pagesOperation of Winding Machine 03Aris PurnamaNo ratings yet

- Cable Applying Front Steering SystemDocument8 pagesCable Applying Front Steering SystemHachalinga SheltonNo ratings yet

- Problems Encountered in Sewing Machine MaintainanceDocument2 pagesProblems Encountered in Sewing Machine MaintainanceROJANE F. BERNAS, PhD.No ratings yet

- XT1754 (Moto C)Document29 pagesXT1754 (Moto C)Erick ContrerasNo ratings yet

- TL-3 - Horn Troubleshooting (SinglePgs) HRDocument4 pagesTL-3 - Horn Troubleshooting (SinglePgs) HRJ Eduardo Osegueda CNo ratings yet

- GSM TelephoneDocument53 pagesGSM Telephonemr_phenriqueNo ratings yet

- URIT-50 Service ManualDocument12 pagesURIT-50 Service ManualBaBuiDinhNo ratings yet

- Manual of Metal Roofing Sheet Roll Forming MachineDocument8 pagesManual of Metal Roofing Sheet Roll Forming Machinenovo orderNo ratings yet

- Melco EMT 10/12TDocument118 pagesMelco EMT 10/12TAlex PerexNo ratings yet

- Improvement Activity at FC SupplierDocument10 pagesImprovement Activity at FC Supplier25aprilNo ratings yet

- Goldcut Manual PDFDocument28 pagesGoldcut Manual PDFRoxanna SabandoNo ratings yet

- Sunflag Crack IssueDocument7 pagesSunflag Crack IssueKumaravelNo ratings yet

- 4 Troubleshooting ML-3750NDDocument42 pages4 Troubleshooting ML-3750NDLaboratorio BvtechNo ratings yet

- Installation Manual OLM3 - ENDocument41 pagesInstallation Manual OLM3 - ENamramir987No ratings yet

- Medupi Units 6 Shutdown Daily Update.: Unit: 6Document1 pageMedupi Units 6 Shutdown Daily Update.: Unit: 6Mbalekelwa MpembeNo ratings yet

- High Efficiency RF and Microwave Solid State Power AmplifiersFrom EverandHigh Efficiency RF and Microwave Solid State Power AmplifiersRating: 3 out of 5 stars3/5 (2)

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Skaywhit 4BK GHS - MSDSDocument8 pagesSkaywhit 4BK GHS - MSDSDyeing DyeingNo ratings yet

- RSL Usg Brands 2013Document29 pagesRSL Usg Brands 2013Dyeing DyeingNo ratings yet

- Primark Chemical Commitment Meeting - Dhaka - Sep - 2016Document31 pagesPrimark Chemical Commitment Meeting - Dhaka - Sep - 2016Dyeing DyeingNo ratings yet

- ZDHC Module 2 - Hazards & RisksDocument25 pagesZDHC Module 2 - Hazards & RisksDyeing DyeingNo ratings yet

- Tu Clothing Approved Laboratory Contact DetailsDocument19 pagesTu Clothing Approved Laboratory Contact DetailsDyeing DyeingNo ratings yet

- Waste AgreementDocument3 pagesWaste AgreementDyeing DyeingNo ratings yet

- TESCO - 391 - Requirement For Supplier Restricted Substances in Textiles...Document19 pagesTESCO - 391 - Requirement For Supplier Restricted Substances in Textiles...Dyeing DyeingNo ratings yet

- Sludge Record-2020Document12 pagesSludge Record-2020Dyeing DyeingNo ratings yet

- NEXT - ENG - Restricted Substance List - Voice Norge - May 2017 - Marked Changes...Document13 pagesNEXT - ENG - Restricted Substance List - Voice Norge - May 2017 - Marked Changes...Dyeing DyeingNo ratings yet

- Polymer MSDSDocument4 pagesPolymer MSDSDyeing DyeingNo ratings yet

- NEXT - MRSL (Next) DDocument8 pagesNEXT - MRSL (Next) DDyeing DyeingNo ratings yet

- Chem InventoryDocument121 pagesChem InventoryErivertonNo ratings yet

- ZDHC Module 1 - Introduction of Chemical Management PDFDocument36 pagesZDHC Module 1 - Introduction of Chemical Management PDFDyeing DyeingNo ratings yet

- International Classic Composite LTD.: GOTS Approved Dyes & Chemicals ListDocument2 pagesInternational Classic Composite LTD.: GOTS Approved Dyes & Chemicals ListDyeing DyeingNo ratings yet

- MRSL Chemical Formulation Declaration Form: Restricted Substance StandardsDocument2 pagesMRSL Chemical Formulation Declaration Form: Restricted Substance StandardsDyeing DyeingNo ratings yet

- CMS Imrovement PlanDocument7 pagesCMS Imrovement PlanDyeing DyeingNo ratings yet

- CMS ImrovementDocument7 pagesCMS ImrovementDyeing DyeingNo ratings yet

- Reduce Plan of Hazardous ChemicalsDocument7 pagesReduce Plan of Hazardous ChemicalsDyeing DyeingNo ratings yet

- Ferrous Sulphate - MSDSDocument6 pagesFerrous Sulphate - MSDSDyeing DyeingNo ratings yet

- Agent Supplier: Name of Chemical Remark'sDocument30 pagesAgent Supplier: Name of Chemical Remark'sDyeing Dyeing100% (1)

- MRSL Chemical Formulation Declaration Form: Restricted Substance StandardsDocument2 pagesMRSL Chemical Formulation Declaration Form: Restricted Substance StandardsDyeing DyeingNo ratings yet

- Chemical Purchasing PolicyDocument3 pagesChemical Purchasing PolicyDyeing Dyeing100% (1)

- Washoff Compatibility TestDocument3 pagesWashoff Compatibility TestDyeing DyeingNo ratings yet

- System Plans MRSL Monitoring & Update With ComplianceDocument1 pageSystem Plans MRSL Monitoring & Update With ComplianceDyeing Dyeing100% (1)

- Silicone Compatibility TestDocument2 pagesSilicone Compatibility TestDyeing DyeingNo ratings yet

- Softner Compatibility TestDocument8 pagesSoftner Compatibility TestDyeing DyeingNo ratings yet

- Leatex-Shunsol RHDocument1 pageLeatex-Shunsol RHDyeing DyeingNo ratings yet

- Silicone Compatibility TestDocument2 pagesSilicone Compatibility TestDyeing DyeingNo ratings yet

- Heating, Ventilation and Air ConditioningDocument130 pagesHeating, Ventilation and Air ConditioningClaudio Godoy GallegosNo ratings yet

- Novel Technologies in Food Science Book PDFDocument432 pagesNovel Technologies in Food Science Book PDFAfnanNo ratings yet

- Study On Design of Casing of Steam TurbineDocument3 pagesStudy On Design of Casing of Steam Turbinesevero97No ratings yet

- Troubleshooting GuideDocument23 pagesTroubleshooting GuideIwan P. Hermawan100% (1)

- Kavitan Plus SPC R2 EN PDFDocument2 pagesKavitan Plus SPC R2 EN PDFMaria Cristina ConduracheNo ratings yet

- Gladiator Microwave ManualDocument49 pagesGladiator Microwave ManualCardonettiNo ratings yet

- Geopier Soil ImprovementDocument8 pagesGeopier Soil ImprovementJose MartinezNo ratings yet

- Iso 11114 2 2021Document11 pagesIso 11114 2 2021Xiaohang HENo ratings yet

- CH 1Document113 pagesCH 1long nguyenNo ratings yet

- IAMI Science A and B SyllabusDocument3 pagesIAMI Science A and B SyllabusKarthikManikandan100% (1)

- Plexus PC 120Document2 pagesPlexus PC 120Eduardo Javier Granados SanchezNo ratings yet

- Jesco PDFDocument16 pagesJesco PDFOktiara Dwita PertiwiNo ratings yet

- SLC CatalogDocument19 pagesSLC CatalogLuke GomezNo ratings yet

- Power-Based Comminution Calculations Using AusgrindDocument13 pagesPower-Based Comminution Calculations Using AusgrindMarcos Bueno100% (1)

- Types of Chemical ReactionsDocument27 pagesTypes of Chemical ReactionsSheena LidasanNo ratings yet

- High Voltage Engineering - Lecture Notes, Study Material and Important Questions, AnswersDocument7 pagesHigh Voltage Engineering - Lecture Notes, Study Material and Important Questions, AnswersM.V. TV0% (1)

- Voltage Drop GuideDocument2 pagesVoltage Drop Guidemherold2No ratings yet

- Pre-Qualification Docs ListDocument11 pagesPre-Qualification Docs ListNikhil RajuNo ratings yet

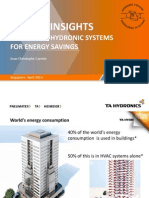

- Energy Insights Singapore 2013-04Document66 pagesEnergy Insights Singapore 2013-04Yh LeongNo ratings yet

- Vikas Rana Resume 12.09.2016Document4 pagesVikas Rana Resume 12.09.2016vikas ranaNo ratings yet

- Lubricante en StockDocument1 pageLubricante en StockJhordan SmithNo ratings yet

- Spring Coil AssignmentDocument1 pageSpring Coil AssignmentAll TutorialNo ratings yet

- Swifts Laddercat UkDocument84 pagesSwifts Laddercat Ukcharleselitb92No ratings yet

- MAN CatalogDocument172 pagesMAN CatalogAlexandruSeverin0% (1)

- Sop at Combined MechDocument36 pagesSop at Combined MechVinod Kumar VermaNo ratings yet

- Universal Patch Fittings Pt10!20!22 0719 PDFDocument10 pagesUniversal Patch Fittings Pt10!20!22 0719 PDFLouisse EsparasNo ratings yet

- Appendix - X Mechanical Design Criteria, Equipment/Material and Technical SpecificationsDocument35 pagesAppendix - X Mechanical Design Criteria, Equipment/Material and Technical SpecificationsAijaz MalikNo ratings yet

- Maintenance RecommendationsDocument15 pagesMaintenance Recommendationsmsalem730% (1)