Professional Documents

Culture Documents

191-198 Rosenberg PDF

191-198 Rosenberg PDF

Uploaded by

AntHony K-ianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

191-198 Rosenberg PDF

191-198 Rosenberg PDF

Uploaded by

AntHony K-ianCopyright:

Available Formats

ROSENBERG, H.

Topsoe wet gas sulphuric acid (WSA) technology—an attractive alternative for reduction of sulphur emissions from furnaces and

converters. International Platinum Conference ‘Platinum Surges Ahead’, The Southern African Institute of Mining and Metallurgy, 2006.

Topsoe wet gas sulphuric acid (WSA) technology—an

attractive alternative for reduction of sulphur emissions from

furnaces and converters

H. ROSENBERG

Haldor Topsoe A/S, Lyngby, Denmark

Haldor Topsoe A/S has developed its WSA technology to meet the demand in the market for a

simple and reliable process that converts sulphurous emissions from off-gasses into high-grade

sulphuric acid. With more than 50 references in 25 countries, the WSA technology has proven its

ability to generate acid at 98% concentration, efficiently and economically.

The wet gas sulphuric acid (WSA) technology treats the furnace off-gas directly from upstream

gas cleaning plants. No further drying is required, since the humidity present in the off-gas is used

to hydrate the SO3 generated in the converter and produce sulphuric acid.

The heat generated during the oxidation, hydration and condensation processes is principally

reused in the process to preheat the off-gas to the required temperature level, and also to generate

high pressure superheated steam for process use. This advantage of steam production, coupled

with lower water and power consumption requirements, is particularly important in the African

production environment.

Having fewer process components than conventional acid plants, the WSA technology is a

simple and compact operation, which makes it easier to retrofit into an existing smelter plant.

Further, the WSA technology simultaneously offers the possibility to treat multiple gas streams

arising within the production facility due to superior flexibility in terms of SO2 concentration and

turndown ratio.

Introduction • In the coke and coke chemical industry for treatment of

The Topsoe WSA technology was developed and acid gas streams from coke gas purification units and

commercialized during the early 1980s. The original sulphurous gaseous and liquid streams from e.g. BTX

intention was to make a cost-effective technology available rectification

to the industry for removal of sulphur compounds from • In the viscose fibre industry for treatment of hydrogen

sulphide and carbon disulphide containing off-gases.

modest gas flows having only a low content of sulphur.

Such lean gases are produced in a variety of industries and

were to a large extent vented to the atmosphere. Due to new Fundamental principles of the WSA process

and expected future environmental legislations and The fundamental principles of the WSA process are shown

regulations, there was in that period an emerging demand in block diagram, Figure 1, and described below.

for technologies capable of treating this type of gas without The block diagram applies both to the case when the

prohibitively high investment and operating costs. sulphurous feed is received as a combustible compound, as

History has proven, however, that the range of e.g. elemental molten sulphur or hydrogen sulphide gas, or

applications for the WSA technology is much wider than as an SO2 gas, e.g. from a metallurgical smelter. The name

originally anticipated. Today, more than 55 units have been wet gas sulphuric acid was given to the Topsoe acid

contracted for gas flows ranging from 2600 Nm 3 /h to technology in order to emphasize that the concentrated acid

1000000 Nm3/h, and with daily sulphuric acid production is produced by condensation from a wet process gas. In

ranging from 11 MTPD to 1200 MTPD. The WSA consequence of this, the need for drying of the process feed

technology has found application in a variety of industries, gas prior to further processing (or for drying of combustion

viz: air when producing sulphuric acid from elemental sulphur)

• In the oil refining industry for treatment of amine is eliminated.

regenerator and sour water stripper off-gases and for The process layout of the front end and the heat

regeneration of spent alkylation acid management system depends on whether the sulphurous

• In the non-ferrous metallurgical industry for treatment feed is received in a form that needs incineration in order to

of SO2 containing off-gases from a variety of process oxidize the sulphur compound to sulphur dioxide, or the

units sulphur content already is on sulphur dioxide form.

• In the petrochemical industry for treatment of acid

gases from synthesis gas preparation units after heavy Sulphurous feed on sulphur dioxide form

oil and coal gasifiers Sulphur dioxide containing gases generated in the

TOPSOE WET GAS SULPHURIC ACID (WSA) TECHNOLOGY 191

Clean process

Hot air for preheating or combustion gas to stack

Cooling

water

Sulphurous feed Product acid

Acid Acid

condensation cooling

Gas

Front-end Heat SO2 cooling

(preheating management conversion

or incineration)

Atmospheric Cooling

air water

return

Figure 1. Principles of the WSA process

metallurgical industry vary greatly, both in gas flow and of the condenser, which is maximum 290ºC. As will be

sulphur dioxide concentration, all depending on the described below, the process gas cooling can be performed

processes upstream of the SO2 fixation plant. If the SO2 in several ways, and contributes substantially to the

fixation unit is based on a catalytic SO2 oxidation process, excellent heat efficiency of the WSA technology. It is,

the gas must in any event be pretreated in order to remove however, equally essential that the process gas temperature

particulate matters and catalyst poison, such as arsenic, is kept well above the sulphuric acid dew point, thus

down to levels acceptable to the SO2 oxidation catalyst. ensuring that no condensation of acid takes place outside

Such gas pre-treatment systems typically consist of quench the WSA condenser.

cooler, scrubbing unit, cooling tower and wet electrostatic The patented WSA condenser, as schematically shown on

precipitator. The feed gas to the WSA plant will in this case Figure 2, is a vertical shell and tube falling film

therefore usually be saturated, i.e. typically at the condenser/concentrator with tubes made of acid and shock

temperature of 30–35ºC and with a water content of resistant boron-silicate glass. While the process gas flows

approximately 6–7%. upwards inside the tubes, which are cooled on the shell side

The air, which has been used for cooling in the WSA by ambient air, the sulphuric acid condenses on the tube

condenser, will be available at a temperature of typically walls. When flowing downwards and meeting the hot rising

210–220ºC and in sufficient quantities to preheating the process gas, the acid will concentrate to typically 98% wt.

process feed gas to approximately 150ºC. Further preheat of The WSA condenser generates hot air at a temperature of

the process gas to the operating temperature of the SO2 approximately 220ºC, which may be used either for process

conversion catalyst of approximately 410ºC takes place in gas preheating or as combustion air, as described above,

the heat management system, using the heat generated in thus recovering the heat of sulphuric acid condensation.

the SO2 conversion reactor. The clean process gas leaves the condenser at

Downstream of the heat management system, the process approximately 100ºC and can usually be sent directly to

consists of the following process units: stack without further treatment, it being a distinct feature of

• SO2 conversion the WSA technology that the clean gas contains only a very

• Acid condensation low amount of acid mist.

• Acid cooling.

Clean gas outlet

SO2 conversion

The catalytic SO2 conversion process in a WSA plant is

similar to the SO2 conversion in a conventional acid plant

based on absorption, except that the catalytic reaction takes

place in a wet gas. Wet SO2 oxidation catalysis has been

practised for decades, and most of the Topsoe SO 2 Cooling air inlet

oxidation catalysts of the VK-series have in fact higher

activity when operating in a wet gas.

The design of the SO2 converter depends on the SO2

concentration in the process gas and on the required degree

of SO2, conversion, i.e. degree of SO2 removal, and features

one, two or three catalyst beds. In case of a multi bed

concept, interbed cooling is required.

Hot air outlet

Process gas cooling and acid condensation Acid gas inlet

The process gas will leave the last catalyst bed with a

temperature typically between 400–450ºC and will typically Product acid outlet

contain SO 3 plus water vapour. Before the process gas

enters the WSA condenser, the temperature must be

reduced to a level acceptable to the construction materials Figure 2. Principle design of the WSA condenser

192 PLATINUM SURGES AHEAD

Sulphuric acid cooling The process layout of that early WSA plant is

The sulphuric acid leaves the condenser at the condensation schematically shown in Figure 4.

temperature, typically in the order of 250–260ºC. By It will be seen that hot air generated in the WSA

recirculation of cold acid, the hot acid is cooled condenser is used for the first preheat of the wet process gas

immediately to a temperature acceptable to the as described above. This principle is also used in today’s

fluorpolymer lined acid piping and to the plate type acid layout. The process gas temperature is further increased by

cooler with plates in Hastelloy. Figure 3 shows a cooling approximately 90ºC by recycling a considerable amount of

and recirculation system in a WSA plant producing 895 gas from downstream the second feed gas preheater. The

MTPD acid. second feed gas preheater is a gas/gas feed/effluent heat

exchanger across the SO2 conversion system.

With an SO2 content in the process gas of only 2% vol.,

Development of the WSA technology the system does not generate sufficient heat to operate

autothermally, and a further increase in temperature, by

Process layout of an early WSA plant means of support fuel, is therefore required before the

One of the very first WSA plants constructed for the process gas enters the SO2 conversion system.

metallurgical industry was contracted in 1989 with the The SO2 conversion system consists of two reactors in

Belgium company, N.V. Sadaci S.A., and was startedup in series. In between the two reactors, the temperature is

1990. The plant, which is still in operation, was designed to decreased by adding approximately 8500 Nm3/h of quench

treat 35000 Nm3/h off-gas from a molybdenum sulphide gas taken from upstream of the second feed gas preheater.

roaster with an average content of SO2 in the order of 2% After being cooled in the feed/effluent heat exchanger

vol. (second feed gas preheater), the gas from the second SO2

ACID TANK

ACID

COOLER

ACID CIRCULATION

PUMPS

ACID TRANSPORT PUMPS

Figure 3. Acid cooling and recirculation system for a WSA plant producing 895 MTPD, 98% wt. acid at OAO Kazzinc, Kazakhstan

Air to vent

Support fuel

2nd Feed gas

preheater Clean process gas

to stack

SO2 Gas

WSA

1st Feed gas Gas Proces Support condenser

preheater mixer gas blower heater

SO2

converter Cooling air

system Quench blower

box

Acid Acid

pump cooler

Product acid

Cooling water

Figure 4. Process layout of an early WSA plant treating 35000 Nm3/h, 2% vol. SO2 gas at N.V. Sadaci S.A., Belgium

TOPSOE WET GAS SULPHURIC ACID (WSA) TECHNOLOGY 193

reactor is sent to the WSA condenser, and the acid is With this system, it is extremely easy to control the

condensed and cooled by recirculation of cold acid as process gas temperatures, and optimum operating

described above. conditions in the SO2 converter can therefore be sustained

Although the Sadaci WSA plant has been in operation at all times.

successfully for 15 years, the principles of feed effluent The heat exchangers in the SO 2 converter, which is

heat exchange and quench gas cooling evidently have a shown as a two bed converter, but also could contain three

number of disadvantages for design of plants with catalyst beds if requirements of SO2 conversion so dictates,

considerably larger gas flow and a higher SO2 content in are fully integrated into the converter shell, thereby

the process gas. To cope with this demand, the process reducing the amount of ductwork to a minimum.

layout has been further developed as described below. If sufficient steam is available in the system, e.g. in case

sulphuric acid is produced by burning molten elemental

State-of-the-art process layout sulphur, the molten salt recirculation system can with

Figure 5 shows schematically the process layout of a WSA certain advantages be replaced by a steam cooling system,

plant of the most recent design for treatment of SO2 gases allowing production and export of high pressure steam with

in the metallurgical industry. a pressure of approximately 60 bar and superheated to a

Whereas the principle of using hot air generated in the temperature in the order of 450ºC, suitable for generation of

WSA condenser for the first preheat of the process feed gas electric power.

up to a temperature of approximately 150ºC is maintained,

the feed/effluent heat exchange and the quench cooling Conservation of resources

principles have been abandoned. Conservation of resources is inherent in the process design

Instead all heat management is performed by means of a of a WSA plant, both with respect to electric power,

system of circulating molten salt. The salt consists of a thermal energy and cooling water.

water-free mixture of potassium and sodium nitrate and

nitrite, which has a melting point of 150–160ºC. In brief, Electric power

the salt melt circulates between the heat exchangers in the With the need for drying of the process gas prior to further

plant. Thus, the melt cools the process gas leaving the first processing being eliminated and with heat exchangers

catalyst bed to the optimum temperature at the inlet to the incorporated in the SO2 converter shell, it is obvious that

second catalyst bed, and further cools the process gas the total number of itemized equipment is very low, and the

leaving the second catalyst bed to the temperature of amount of ductwork is therefore also reduced to a

280–290ºC, before the gas enters the WSA condenser. By minimum. This, together with the low pressure drop over

circulation of the melt, the recovered heat is displaced to the WSA condenser, as compared to the pressure drop over

the process feed gas by means of the second feed gas conventional absorbers, results in a total pressure drop on

preheater. Surplus heat will be removed in the salt the process gas side for a plant, as shown in Figure 5, as

cooler/boiler, and excess energy therefore exported as low as approximately 100 mbar, and on the cooling air side,

steam. as low as 40 mbar.

Stack gas

Feed gas

blower

Feed gas

Feed gas

preheater Start-up/

support burner

Feed

gas

Natural pre-

Gas heater

Air

Boiler blower

Interbed Salt

cooler circulation Air

system

Salt WSA condenser

tank

Salt pump

Acid pump

Acid cooler

Product acid

Figure 5. State-of-the-art process layout of WSA plants in the metallurgical industry

194 PLATINUM SURGES AHEAD

This translates into a power consumption of only 45–50 Environmental considerations

kWh/MT produced acid, when processing a gas received at When one is designing and operating a sulphuric acid plant,

battery limit at 0 barg with 6% SO2. environmental considerations essentially concentrate on

emissions to the atmosphere of SO2 and acid mist.

Thermal energy

The chemical reactions involved in production of sulphuric SO2 emission

acid from sulphur dioxide are highly exothermal. Most national environmental legislations related to SO2

The reactions in the WSA process are the following: emissions, including the American Code of Federal

SO2 oxidation: Regulations, Protection of Environment make distinction

SO2 + 1/2O2 → SO3 + 99 kJ/mole (242000 kcal/MT acid) between emissions from dedicated sulphuric acid

SO3 hydration: production units, e.g. based on elemental sulphur or

SO 3 + H 2 O → H 2 SO 4 (gas) + 101 kJ/mole (247000 roasting of pyrite and other sulphuric acid production units,

kcal/MT acid) constructed for the purpose of controlling SO2 emissions

H2SO4 condensation: from fatal SO2 sources. Most SO2 fixation plants in the

H 2 SO 4 gas → H 2 SO 4 liquid + 90 kJ/mole (219000 metallurgical industry will fall in the second category with

kcal/MT acid) less strict requirements for SO2 removal efficiency than

Whereas it is state of the art in all known sulphuric acid plants falling in the first category.

technologies to recover the heat of SO2 oxidation, only very All newer WSA plants in the metallurgical industry

few technologies are capable of recovering the heat of SO3 feature two catalyst beds in the SO2 converter, as shown in

hydration and the heat of sulphuric acid condensation. For Figure 5, and a charge of conventional SO 2 oxidation

instance, in sulphuric acid technologies based on catalyst of the Topsoe VK-series with an operation

absorption, the heat from these two sources, which is temperature of approximately 410ºC.

essentially equal to the heat of absorption of SO3 in the With this design, it is, depending on the SO 2

absorbers, is lost to the cooling water. concentration in the process gas, possible to achieve an SO2

In the WSA technology, both the heat of SO3 hydration, conversion of between 98-99%, which conversion has

and the heat of sulphuric acid condensation are recovered to proved sufficient in most cases.

a very high degree. However, when the Chilean company Molibdenos y

As described above, the process gas leaving the last Metales S.A., Santiago at the beginning of 2005 decided to

catalyst bed in the SO2 converter is cooled to a temperature construct a new WSA plant at their molybdenum sulphide

of approximately 290ºC in the final gas cooler, which is roasting facility in Santiago de Chile, the environmental

integrated in the converter. At this temperature, a large part authorities required that the SO2 conversion was increased

of the SO3 will be hydrated to H2SO4 on gas form. The as the roasting facility is situated in a densely populated

corresponding amount of the heat of hydration will area close to the city of Santiago de Chile. Therefore, the

therefore be recovered in the molten salt heat displacement new plant, which will be the fourth in operation at the

system and available for process feed gas preheating in the Molymet group and which is scheduled to start up in 2007,

second process feed gas preheater and/or for production of will be equipped with an SO2 converter featuring three

steam. catalyst beds with conventional catalyst in the two upper

The remaining hydration of SO 3 together with beds, and a low temperature, alkali promoted catalyst in the

condensation of the sulphuric acid will take place in the last bed. With this configuration, an SO2 conversion of

WSA condenser in which the process gas is cooled to 99.6% is achieved.

100ºC. The corresponding amounts of heat will be removed

by means of ambient air, resulting in generation of a hot air Acid mist

stream with a temperature of approximately 210–220ºC. The design and operating conditions of the WSA condenser

This hot air is, as described above, available for process gas ensure a very low content of acid mist in the clean process

preheating in the first process gas preheater, and the latent gas leaving the WSA condenser, and usually a mist content

heat is therefore utilized down to a temperature of of less than 10 vol. ppm is achieved. In spite of this, a few

125–135ºC. clients have decided to install a mist filter at the clean

In consequence, the WSA technology is extremely process gas outlet duct, often dictated by local

efficient for thermal energy conservation. This is illustrated environmental authorities’ requirements.

by the fact that a WSA plant is capable of operating Two main options based on different operating principles

autothermally, i.e. without use of support fuel for process (the so-called candle filters and wet electrostatic

gas preheating, when processing feed gas with an SO 2 precipitators respectively) are available for mist filtration.

content as low as 3%, whereas other sulphuric acid

technologies, not capable of recovering the heat of Case study

hydration and condensation, will need an SO2 concentration

of 6–7% in order to operate autothermally. OAO Kazzinc, Kazakhstan

OAO Kazzinc is a fully integrated zinc producer with

Cooling water considerable copper, lead and precious metal credits. It

Cooling water is used only for cooling of the produced employs some 22000 people in mining, ore dressing and

sulphuric acid from the temperature of condensation, metallurgy. OAO Kazzinc has chosen Topsoe’s WSA

typically 250–260ºC, down to the storage temperature of technology to treat the off-gasses coming from the lead

typically 30-35ºC. Therefore the cooling requirement is sinter plant and zinc roaster at their metallurgical complex

only 80000–90000 kcal/MT produced acid, corresponding in Ust-Kamengorsk. The complex consists of a 180000

to a cooling water flow of 8–9 m3/MT produced acid at a TPY zinc refinery, a 140000 TPY lead smelter and a

temperature increase of the cooling water of 10ºC. precious metals refinery.

TOPSOE WET GAS SULPHURIC ACID (WSA) TECHNOLOGY 195

In May 2002, OAO Kazzinc signed a contract with The sulphuric acid produced at the Ust-Kamengorsk

Topsoe for the supply of its WSA technology. OAO complex is sold to customers within the fertilizer, refinery

Kazzinc undertook the erection works by themselves and or petrochemical industry. To secure off-take of the acid

during summer 2004 the plant was put on stream, hence the also during low demand periods in the sulphuric acid

total lead-time from order date to on-stream production was market, OAO Kazzinc has also constructed an acid neu-

less than 24 months. tralization plant producing saleable gypsum for use by the

Figure 6 shows a computerized model of the WSA plant. cement and construction material industries.

The plant treats 125000 Nm 3/h of off-gas with an SO 2 From the exothermal processes of the WSA technology,

content of 6.5% vol. and produces approximately 900 heat is generated and converted into valuable steam

MTPD, 98% sulphuric acid. The footprint of that plant is providing OAO Kazzinc with more than 7 tons/h steam at

only 61.5 x 25.0 metres = 1537 m2. 15 barg. If OAO Kazzinc, in theory, had installed a small

Now, in what way has the WSA plant contributed to the multi-stage condensing steam turbine, they would have

business of OAO Kazzinc? Clearly, it has brought the plant

been able to generate approx. 1.1 MWe. All steam,

at Ust-Kamengorsk in compliance with its stated objective,

however, is sent into their common steam system and used

which is to reduce the emissions of SO 2 from its

for heating and tracing purposes, hence saving them from

metallurgical operations to an insignificant level. This in

itself constitutes a priceless value in terms of securing its additional investment and operating expenses associated

ecological responsibility and provision of a clean with such steam production.

environment to the densely populated surrounding areas. The WSA technology differs from other conventional

Experiences have shown that public focus on a severely plants by its limited consumption requirements, resulting in

irresponsible environmental policy of a particular smelter reduced operating expenses, and for OAO Kazzinc, this

plant could, in fact, have a significant impact on its share means that less than 400 m3/h of cooling water is needed to

prices, causing losses to the owner, which may be even remove excess heat from the sulphuric acid. Finally, the

bigger than the corresponding investment required for an total power requirement for their ID/FD fans is low due to

off-gas treatment plant. the limited pressure drop, caused by the few and simple

In addition to such economical considerations, the WSA components of the WSA plant. Reference is made to

plant itself generates valuable products from the reduction Table I for a summary of consumption details and OPEX

of SO 2 and this even with very low overall operating for a plant operated in South Africa, having a size and

expenses. capacity similar to the OAO Kazzinc project.

PROCESS GAS INLET

WSA CONDERSER

24m

11m

2nd FEED GAS PREHETER 61.5m 25m

SALT COOLER/BOILER

SALT TANK ACID TANK

COOLING AIR BLOWER

Figure 6. Model of the WSA plant at OAO Kazzinc, Kazakhstan

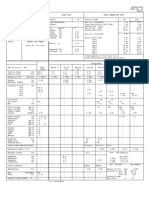

Table I

Summary of OPEX as applied for a project in RSA with a capacity similar to OAO Kazzinc

Consumption: Specification Annual operating cost/earning Assumptions

Cooling water 398 m3/h (25 -> 35ºC) - R1.6m R0.5 /m3

Power 2130 kW - R6.0m R0.35/kWh

Fuel N.A N.A.

Production:

Sulphuric acid 854 MTPD (98%) + R114.0m R400/ton

Steam 7036 kg/h (15 barg) + R5.1m R90/ton

Total operating income + R111.5 m

196 PLATINUM SURGES AHEAD

Table II

Tapsoe clients using WSA technology

Client Type of up-stream plant Initial Content of SO2 Process gas Nm3/h H2SO4 prod.MTPD Start-up year

N.V. Sadaci S.A., MoS2 0.6–2.8% 35.000 106 1990

Belgium Roaster

Molibdenos y Metales MoS2 2.0–2.4% 40.000 104 1993

S.A., Chile Roaster

Metaleurop S.A., PbS 3.4% 110.000 380 1993

France Roaster

Molymex S.A. de MoS2 2.0–4.5% 20.000 65 2001

C.V., Mexico Roaster

Zhuzhou Smelter, PbS 2.2–4.6% 110.000 525 2001

China Roaster

ZAO Karabashmed, CuS 6.5% 170.000 1140 2003

Russia Smelter

OAO Kazzinc, PbS Sinter 6.5% 125.000 895 2004

Kazakhstan ZnS Roaster

Molibdenos y Metales MoS2 1.4–3.8% 60.000 170 2007

S.A., Chile Roaster

Table I is based on 8000 operating hours per year. Spare industries treating sulphurous feed stocks, ranging from

parts and staff expenses are not included. concentrated hydrogen sulphide gas, over spent alkylation

In total, OAO Kazzinc has been furnished with a state-of- acid, to lean SO2 gas in the metallurgical industry.

the-art sulphuric acid plant, which has not only released The technology features a very high degree of energy

them from certain environmental burdens, but also has efficiency, meaning that gases containing as little as 3%

managed to do so within commercially attractive vol. SO 2 allow autothermal operation. Moreover, the

conditions. consumption of utilities, such as electric power and in

Table II lists metallurgical plants that have profited from particular cooling water, is extremely low.

Topsoe’s WSA technology. The only product streams from a WSA plant are

commercial quality, concentrated sulphuric acid, clean

process gas and steam, and no solid or liquid effluents

Conclusion needing subsequent treatments are produced.

The WSA technology has been constantly developed and The WSA technology is also an attractive alternative for

improved during the past two decades, and the list of small-to medium-sized plants, producing sulphuric acid

references now counts more than 55 plants in a variety of from elemental molten sulphur.

TOPSOE WET GAS SULPHURIC ACID (WSA) TECHNOLOGY 197

198 PLATINUM SURGES AHEAD

You might also like

- E1409 13Document7 pagesE1409 13senthilNo ratings yet

- Proespektif of PlantDocument8 pagesProespektif of Plantrudy_423522658No ratings yet

- Indirect Dryers For Biomass Drying-Comparison of Experimental Characteristics For Drum and Rotary ConfigurationsDocument11 pagesIndirect Dryers For Biomass Drying-Comparison of Experimental Characteristics For Drum and Rotary ConfigurationsRenalyn TorioNo ratings yet

- Topsoe Wsa Process Principles 0Document4 pagesTopsoe Wsa Process Principles 0Carlos de la TorreNo ratings yet

- HTAS - HTCR - Medium-Sized Hydrogen Plants Based PDFDocument5 pagesHTAS - HTCR - Medium-Sized Hydrogen Plants Based PDFlaquetengoNo ratings yet

- Costs and Results of Hydrogen Drying and PurificationDocument3 pagesCosts and Results of Hydrogen Drying and PurificationMarco BuraniNo ratings yet

- Nanoporous Materials Synthesis and ApplicationsDocument371 pagesNanoporous Materials Synthesis and ApplicationsTabatta Britto100% (1)

- Topsoe Wsa Meet Industry DemandsDocument6 pagesTopsoe Wsa Meet Industry DemandsBobie C. Kurniawan100% (1)

- Gastech2015 - WSA Case StudyDocument1 pageGastech2015 - WSA Case StudyIlham HakimNo ratings yet

- Proses Wsa 2Document2 pagesProses Wsa 2Lily Diana100% (1)

- Strategies For Reducing Start-Up Emissions From Sulfuric Acid PlantsDocument19 pagesStrategies For Reducing Start-Up Emissions From Sulfuric Acid PlantsAbu Izzan Al BunyNo ratings yet

- Proses Wsa 1Document19 pagesProses Wsa 1Lily DianaNo ratings yet

- COBRAS 2015 HaldorTopsoe WSARioSecoDocument25 pagesCOBRAS 2015 HaldorTopsoe WSARioSecoBambang HermawanNo ratings yet

- 21 Haldor Topsoe - Topsoe Wsa Technology Aplication in A Small Sulfuric Acid Production UnitDocument31 pages21 Haldor Topsoe - Topsoe Wsa Technology Aplication in A Small Sulfuric Acid Production UnitAntHony K-ianNo ratings yet

- IAWPS GUIDELINES ON Instrumentation-2015Document25 pagesIAWPS GUIDELINES ON Instrumentation-2015prakashNo ratings yet

- Mitsubishi Power Systems PDFDocument8 pagesMitsubishi Power Systems PDFasimsek1309100% (1)

- Tkis AmmoniaDocument28 pagesTkis AmmoniaAhmed Nagy100% (1)

- COEN 13116 Duct Burner Solutions LR WebDocument2 pagesCOEN 13116 Duct Burner Solutions LR WebscribdkhatnNo ratings yet

- Sulfur Burning Processes and Acid Plant DDocument4 pagesSulfur Burning Processes and Acid Plant DacckypenrynNo ratings yet

- D20b - European Workshop Sept 2009Document229 pagesD20b - European Workshop Sept 2009arsalanrabbanianNo ratings yet

- Oxygen Enrichment FundamentalsDocument15 pagesOxygen Enrichment FundamentalsahmadNo ratings yet

- Oxygen Sensor Zirconia Vs TDLSDocument20 pagesOxygen Sensor Zirconia Vs TDLSRaymundus Rizki DomoNo ratings yet

- AlkyDocument37 pagesAlkyMỹ PhanNo ratings yet

- Ud He TechnologyDocument16 pagesUd He TechnologyBejavada Suresh100% (1)

- KLM Olefin Furnace Rev 3Document6 pagesKLM Olefin Furnace Rev 3Saqib AliNo ratings yet

- Shell Gasification Business in Action v2Document19 pagesShell Gasification Business in Action v2Vangelis Nanos100% (1)

- 2002 Tech AzconaDocument19 pages2002 Tech AzconaOgunranti Rasaq100% (1)

- Operation of The First HIsmelt Plant in ChinaDocument8 pagesOperation of The First HIsmelt Plant in ChinaJJNo ratings yet

- AkzoNobel - Hydrogen Peroxide Product Information Manual - December 2015 - tcm56-94028 - 2Document32 pagesAkzoNobel - Hydrogen Peroxide Product Information Manual - December 2015 - tcm56-94028 - 2PungkyRamadhaniPamungkasAminotoNo ratings yet

- Session: NH Fuel Use: Facilitator: Bill DavidDocument24 pagesSession: NH Fuel Use: Facilitator: Bill Davidkwayneolson6081No ratings yet

- MTGDocument17 pagesMTGVidyasenNo ratings yet

- Aspen-Hysys Simulation of Sulfuric Acid PlantDocument3 pagesAspen-Hysys Simulation of Sulfuric Acid PlantacckypenrynNo ratings yet

- 07 Ammonia Synthesis Revamps - March 2015Document37 pages07 Ammonia Synthesis Revamps - March 2015Kvspavan KumarNo ratings yet

- STAMICARBON Reference List September 2012 2Document36 pagesSTAMICARBON Reference List September 2012 2fjafarvand100% (1)

- Nps 38 CFDocument16 pagesNps 38 CFGauden Marie C. BangngayNo ratings yet

- Control of Fuel Combustion in BoilersDocument132 pagesControl of Fuel Combustion in BoilersPedro Henrique Rebelatto100% (1)

- LNG Industry, August 2016Document68 pagesLNG Industry, August 2016ihllhmNo ratings yet

- Plant Nutrient Dashboard (25.1.2019) - MosaicDocument2 pagesPlant Nutrient Dashboard (25.1.2019) - MosaicAhmed SalehNo ratings yet

- Acid DewpointDocument4 pagesAcid DewpointCowdrey IlanNo ratings yet

- 8 SMST-Tubes Urea Plants Brochure 2009Document12 pages8 SMST-Tubes Urea Plants Brochure 2009Lee Hui YiNo ratings yet

- CRYOTEC-CO2 Technologies and Application-2017 Mit Comtec PDFDocument45 pagesCRYOTEC-CO2 Technologies and Application-2017 Mit Comtec PDFTaufik ArrahmanNo ratings yet

- ECONOMIZER DESIGN FOR 2013 - Sayı 3 - 4 - Selçuk Selimli PDFDocument6 pagesECONOMIZER DESIGN FOR 2013 - Sayı 3 - 4 - Selçuk Selimli PDFNITINNo ratings yet

- BrownDocument3 pagesBrown3azeezNo ratings yet

- Flue Gas Desulfurization by Jojo Basa FINALDocument40 pagesFlue Gas Desulfurization by Jojo Basa FINALJohnCarloTolibas100% (2)

- Industrial ReportDocument89 pagesIndustrial ReportArnab DasNo ratings yet

- De Sulfur IzationDocument2 pagesDe Sulfur IzationngotrongthucNo ratings yet

- 10.2.2 PCS Phosphate's New 4500 STPD Sulfuric Acid Plant in AuroraDocument20 pages10.2.2 PCS Phosphate's New 4500 STPD Sulfuric Acid Plant in AuroraCarlosNo ratings yet

- Re Liquefaction System EcoRel - Cryostar Magazine 10Document12 pagesRe Liquefaction System EcoRel - Cryostar Magazine 10Narayan Marndi100% (1)

- Viscosity IndexDocument3 pagesViscosity Indexdassi99No ratings yet

- Rectisol Master ThesisDocument236 pagesRectisol Master ThesismvooNo ratings yet

- Pulse Firing BasicsDocument3 pagesPulse Firing BasicsdrbaneNo ratings yet

- Topsoe Prereforming CatalystDocument13 pagesTopsoe Prereforming CatalystReza RhiNo ratings yet

- Fisher Tropsch RefiningDocument12 pagesFisher Tropsch Refiningblackbeast8No ratings yet

- 2000 Ifa Neworleans GobbitDocument14 pages2000 Ifa Neworleans GobbitFajar ZonaNo ratings yet

- 06 Ammonia Synthesis Catalyst in Action - March 2015Document49 pages06 Ammonia Synthesis Catalyst in Action - March 2015Kvspavan KumarNo ratings yet

- Bayer Process Chemistry: Dr. M. ColeyDocument22 pagesBayer Process Chemistry: Dr. M. ColeyToanique HeadmanNo ratings yet

- Walid Zaki Ahmed: Key ExperienceDocument8 pagesWalid Zaki Ahmed: Key ExperienceArpit ParikhNo ratings yet

- Petroleum Refining Chemistry SlidsDocument61 pagesPetroleum Refining Chemistry SlidsJoyful GreenNo ratings yet

- Gasification Based Topsoe WSA Process PrinciplesDocument4 pagesGasification Based Topsoe WSA Process PrinciplesGopiNo ratings yet

- Sulfuric Acid Manufacturing PlantDocument6 pagesSulfuric Acid Manufacturing PlantmichsantosNo ratings yet

- Simulation of A Wet Sulfuric Acid Process (WSA)Document12 pagesSimulation of A Wet Sulfuric Acid Process (WSA)Ahmed AliNo ratings yet

- Sulphuric Acid PlantsDocument16 pagesSulphuric Acid PlantsSekar.SNo ratings yet

- 100 A HW1 SolnDocument13 pages100 A HW1 SolnJoy OchoaNo ratings yet

- PID Tuning Appendices WEB PDFDocument28 pagesPID Tuning Appendices WEB PDFVikas PatelNo ratings yet

- PP Chemical ResistanceDocument9 pagesPP Chemical ResistancetsalehNo ratings yet

- Bunding GuidelinesDocument5 pagesBunding GuidelinesmohanumaNo ratings yet

- 3rd Sem Syllabus EnergyDocument4 pages3rd Sem Syllabus EnergyManoj PepiNo ratings yet

- c68700 Aluminum BrassDocument1 pagec68700 Aluminum Brassm_f_deathNo ratings yet

- PVD HardCoating PDFDocument20 pagesPVD HardCoating PDFsatanjrNo ratings yet

- A Review On The Catalytic Pyrolysis of Biomass For The Bio-Oil Production WithDocument15 pagesA Review On The Catalytic Pyrolysis of Biomass For The Bio-Oil Production WithDaniiela Melo RomeroNo ratings yet

- Microsoft PowerPoint - Module 3-1 Sinner Circle Perf EffectsDocument40 pagesMicrosoft PowerPoint - Module 3-1 Sinner Circle Perf EffectsLê LợiNo ratings yet

- Kerke Customer List 2020 VersionDocument4 pagesKerke Customer List 2020 VersionLam NgoNo ratings yet

- DIN WS 1.4003UNS S41003 Ferritic Stainless SteelDocument2 pagesDIN WS 1.4003UNS S41003 Ferritic Stainless SteelIvanildo SilvaNo ratings yet

- Iris Conjugation PEGYLATIONDocument8 pagesIris Conjugation PEGYLATIONidownloadbooks3133No ratings yet

- Department of Education: Pply The Principles of Conservation of Mass To Chemical ReactionsDocument12 pagesDepartment of Education: Pply The Principles of Conservation of Mass To Chemical ReactionsCristina NobleNo ratings yet

- The New Anglo Platinum Converting Project: P Viviers and K HinesDocument8 pagesThe New Anglo Platinum Converting Project: P Viviers and K HinesHabram Miranda AlcantaraNo ratings yet

- Afrox Subarc 347: Back To Section 12Document2 pagesAfrox Subarc 347: Back To Section 12Branko FerenčakNo ratings yet

- Internship ReportDocument37 pagesInternship ReportSalif NarmawalaNo ratings yet

- Ternary CompoundsDocument27 pagesTernary CompoundsIam PaulNo ratings yet

- Ascorbic Acid EstimationDocument1 pageAscorbic Acid EstimationMahamud Hasan PrinceNo ratings yet

- Material Downloaded From - 1 / 5Document5 pagesMaterial Downloaded From - 1 / 5chaudhary TahiraliNo ratings yet

- List of Chemical Compound FormulaDocument12 pagesList of Chemical Compound FormulaJuanmiguel Ocampo Dion SchpNo ratings yet

- Qenos Alkatane GF7740F2Document1 pageQenos Alkatane GF7740F2Manoj SahuNo ratings yet

- Ecolab Permaclean PC 33 LDocument3 pagesEcolab Permaclean PC 33 LKumbang KambingNo ratings yet

- On The Formation of Expanded Austenite During Plasma Nitriding of An AISI 316L Austenitic Stainless SteelDocument4 pagesOn The Formation of Expanded Austenite During Plasma Nitriding of An AISI 316L Austenitic Stainless Steelo_l_0No ratings yet

- Carbon and Its CompoundDocument41 pagesCarbon and Its CompoundSamKris Guerrero MalasagaNo ratings yet

- Science NotesDocument244 pagesScience NotesA. PradeepaNo ratings yet

- BuffersDocument7 pagesBuffersLaila HassanNo ratings yet

- My L1 Antianginal DrugsDocument22 pagesMy L1 Antianginal DrugsDrGajanan VaishnavNo ratings yet

- Disaster Readiness and Risk Reduction Quarter 4 Week 4: Not For SaleDocument12 pagesDisaster Readiness and Risk Reduction Quarter 4 Week 4: Not For Saleraffy arranguezNo ratings yet

- 09 M.S. 073 SOALANDocument1 page09 M.S. 073 SOALANSAHDANAH MUDALIYAR A/P TUN SAMBANTHAN MoeNo ratings yet

- Chlor Alkali ProductionDocument24 pagesChlor Alkali ProductionSherina TaniaNo ratings yet

- Extraction of Oil From Some SeedsDocument18 pagesExtraction of Oil From Some SeedsSomu AdityaNo ratings yet

- Edited File Class XII Chemistry Solution Last PageDocument396 pagesEdited File Class XII Chemistry Solution Last PagePuskar ChaudharyNo ratings yet