Professional Documents

Culture Documents

Daily Co-Ordination Meeting: HPL, CPP Site

Daily Co-Ordination Meeting: HPL, CPP Site

Uploaded by

abhaymehta67Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daily Co-Ordination Meeting: HPL, CPP Site

Daily Co-Ordination Meeting: HPL, CPP Site

Uploaded by

abhaymehta67Copyright:

Available Formats

Daily Co-ordination Meeting

Daily Coordination Meeting No 915 Date: 27-10-2020

Attendees: - P K Das, A Mehata, O Pal, A K Chaitanya, H Roy, T Pramanik, S Rout

A. Plant Status at 09:30AM:

Sl. No EQUIPMENT LOAD (MW)/STEAM GENERATION (TPH) REASONS / REMARKS (If any)

1 GT 1/ GT 2/ CSTG/ BPSTG 30 MW/28 MW/12.5 MW/10.5 MW GT-2 is on 100% RFG.

2 AB 1 – RFG/NPH/CBFS 58 TPH, 1/0/2 -

3 AB 2 – RFG / NPH/CBFS 61 TPH, 0/0/3 -

4 HRSG-1 (SHP/MP) - RFG / NPH/ MIX 47 TPH / 16 TPH, 2/0/0 -

5 HRSG-2 (SHP/MP) - RFG / NPH/ MIX 44 TPH / 15 TPH, 2/0/0 -

Operating Hourssince last inspection ofGT 1/

6 19403.2/13636/19539.79/19356.7 -

GT 2/ CSTG/ BPSTG

B. Net Steam Export/ Net Power Export:

Steam Amount(TPH) Power Amount(MW)

SHP 14 IOP-1 27

HP 08 IOP-2 27

MP 90 IOP-3 23

LP 51 Total 77

TOTAL 163 Import/Export Floating

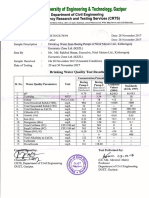

C. Water Chemistry:

Boiler Water Parameters Cooling Water Parameters

pH Conductivity(µS/cm)

Dated 21.10.2020

Parameters

Range Actual Range Actual

Parameters Range Actual

DM Water(at B/L) (6.5 – 7.0) * 8.1 <0.20 1.21 pH 7.2 –8.5 7.30

Main Steam sample (8.5 - 9.5) 8.65 <5.0 2.65 Conductivity

< 6000 1690

AB-1 (9.0 - 10.0) 9.70 <50 62 Chloride <1600 247

Drum Sample

AB-2 (9.0 - 10.0) 9.7 <50 61 FRC 0.20 - 0.5 0.60

HRSG1 (SHP) (9.0 - 10.0) 9.2 <50 35 COC based on MgH. 3.0-6.0 5.73

HRSG2 (SHP) (9.0 - 10.0) 9.7 <50 76 Remarks if any:

Drum Sample

HRSG1 (MP) (9.8 - 10.6) 10.4 <3000 275

HRSG2 (MP) (9.8 - 10.6) 10.2 <3000 144

Condensate CSTG (8.5-9.5) 8.8 <5.0 2.53

*DM water pH at DM plant O/L is 6.5 to 7.0. However morpholine is dosed to elevate pH & pH parameter at CPP B/L is 6.5 to 9.0&

Conductivity at CPP B/L is 0 to 2.0.

A. Work Request Status as on 19.10.2020:

Total

Priority Priority Priority Priority Priority Priority Defects pending for Top /Total% (not

Dept. (Not more than 20)

1 2 3 5 6 4 Spare availability >5%)

(Priority 1+2+3)

Mech 0 40 2 7 10 40 96 7 0

Elect 0 22 4 1 0 26 16 8 0

Inst 0 16 1 9 1 17 44 29 0

B. Major issues from Operations: NIL

C. Safety Observations:

1. GT-2 turbine compartment & LGB compartment temperature is very high: Continuous monitoring is to be done to see the further

deterioration of temperature profile, new exhaust plenum will be delivered in August’20, then it will be replaced in next opportunity.

2. Turbine compartment overall exhaust temp near BT fan suction is 123degC, Highest is 323degC & LGB compartment exhaust tunnel

area max temp is 250degC.

D. Current Issues:

Sl. Issue Initiation Estimated date of completion or plans Resp.

HPL, CPP site

No date

Poor illumination in CT Fan area, to be

1. 12.10.2020 To be taken up. E

improved.

Bulk acid storage tank drain line flange joint

2. 13.10.2020 To be taken up M

leakage observed.

3. SHP CBD line leakage observed in HRSG-1 13.10.2020 To be taken up. M

E. Yesterday’s works:

*(Managers should come prepared to answer the status of previous day job status. Status to be filled up in the work request register on the

same day of completion by both Maintenance & operation)

PM/

Description Dept. Status Trial OK, defect closed. If not status

D No

72/73 HRSG#01, SHP CBD line elbow joint leakage arrested. M Completed -

132 Spare BPST & CST rotor rotation to 180 degree. M Completed -

- EDP# B servicing job M U/P -

- Erection of scaffolding at HRSG-2 chimney is being done. M U/P Work progress is slow

One rack has been prepared out of 6.

Rest will be done after material

- Fabrication of Store rack is being done. M Hold

availability.

Material (0.6T) is available.

F. Pending Issues (to shift from current issues which are more than a month old, to be discussed on first Monday of every month):

Initiation

No Issue Plans EDC Resp.

date

Mass flow meter:

- Installation technical limit needs to be Naphtha B/L mass flow meter is available,

verified from manual. scaffolding done; it will be replaced on 22.11.2020.

1. - Raise New PR for procurement of 12-11-19 - Inst

mass flow meter (Naphtha, CBFS, and PR raised for Mass flow meter for fuel flow

RFG). measurement (PR No-1067561).

- Raise a service PR for calibration.

Communication started with Woodward for onsite

GT-2 SRV & GCV both are having Inst/

2. 08-5-2019 services & to identify the spares of repair kit. -

passing. Mech

E-mail to be sent by 20.10.2020.

PO placed for servo motors on 17.09.2019 (No-

3. CSTG CV hunting 09-5-2019 3046478), follow up is being done for material Oct’2020 Inst

dispatch.

New Feed Control valve for AB/HRSGs PR to be raised after receiving technical budgetary Inst/

4. 22.11.2019 -

to be procured. offer. Mech

Spare shaft is to be made ready for

5. 29.06.2020 PR for critical motor is to be raised. - M/E

critical motor during overhauling.

PO NO: 3046926, Delivery date is over. Follow up is

6. AB-2 soot blower MOV is not working. 20.07.2020 - I

being done. Delivery Date: 19.03.2020

SHP BFP-C is tripping before reaching

BFP-C CAG34 (differential relay) & VAJH-13 (Master

the starting current without any alarm

7. 20.07.2020 trip relay) was replaced. - E

during 1st manual start, needs to be

Problem still persists.

studied.

G. Major Equipment scheduled outage Plans:

Sl. No Asset Objective Due date Remarks

MI along with AGB & LGB inspection of GT-1

1. GT-1/HRSG-1 06-06-19 GT-1 MI will be starting from 16.11.2020.

& other jobs.

GT-2 exhaust plenum rectification for high

2. GT-2 - GT-2 S/D will be on 02.11.2020 for 3-4 days

temp in turbine & LGB compartment.

H. Safety records for this month:

Near Miss Unsafe Act Unsafe Condition BBS generated

0 0 0 3

I. Reminder:

PR Status, Pending Material Inspection, Critical system study related to GT, Pending TBA Status, and Status of rejected material,

Emergency procurement issues.

J. Critical Issues which are waiting for S/D:

Sl. Date

Area Subject Dept. Comment EDC

No Initiated

1. HRSG-1/2 Flue gas leakage in HRSG-1 M/I Flame scanner installed in both the burners but the 30-5-2019 HRSG-1:

temperature was found high.

HRSG-2 burner-5 insulation work done again,

burner no-6 & HRSG-2 burner temperature will be measured after HRSG-2 in

no-5 to be attended& flame service.

Next

scanner installation to be HRSG-1 will be attended later in opportunity.

Opportunity

done. For temporary measurement, insulation shielding is

to be done in flame scanner.

Scope to be finalized and contractor to be informed,

also material to be arranged as per scope.

GT-1 GT-1 both BB4 & BB-5 Will be replaced in next opportunity

2. I 9.10.2019 Next S/D

vibration sensor not working. GT-1 vibration trend to be monitored.

AB-1/2

Hydra step needs to be

3. I/M Will be taken up during shutdown. 07.07.2020 Next S/D

HRSG-1/2 serviced.

In GT-2, Continuous monitoring is being done to see

the further deterioration of temperature profile, new

exhaust plenum will be delivered in August’20, and

then it will be replaced in next opportunity.

GT-1/2 both turbine

Turbine compartment overall exhaust temp near BT

4. GT-1/2 compartment temperature is M 09.05.2019 Next S/D

fan suction is 123degC, Highest is 323degC & LGB

high.

compartment exhaust tunnel area max temp is

250degC.

For GT-2, preparation to be done, PO on SIPL to be

finalized on priority.

HRSG-1/2 SHP CBD MOV PO for actuator servicing has been placed.

5. HRSG-1/2 actuator is not working M/I Work order issued to OEM for servicing. Job will be 21-5-2019 Next S/D

properly. taken up after receipt of gear box spares.

AB-1& 2 O2 analyzer is not O2 analyzers are available; those will be installed in

6. AB-1/2 I 29-5-2019 Next S/D

working. next opportunities.

Temporary sleeve provided on stem to restrict the

CSTG HP sealing steam Next S/D

7. CSTG I/M closing of valve, it will be replaced with new in 02.03.2020

pressure is hunting. opportunity

opportunity.

AB-1 drum LHS side level LHS isolation valve of gauge glass is passing; It will be Next S/D

8. AB-1 M 07.07.2020

gauge are to be replaced. replaced during shutdown opportunity. opportunity

In AB-2 & HRSG-2, Changing of

Replacement of root valves & Drain valves of DP type

AB-2 & root valves & flushing of Next S/D

9. I/M flow transmitters will be taken up during S/D 12.11.2019

HRSG-2 pipelines from flow element opportunity

opportunity.

to transmitter to be done.

10. GT-2 BB-4 vibration sensor is faulty. I Will be taken up during next S/D opportunity. 07.09.2020 Next S/D

Vibration sensor is faulty

11. BPSTG I Will be taken up during next S/D opportunity. 07.09.2020 Next S/D

(01MAA10CY010D)

RFG compressor suction

RFG control valve (5XV71211) is

12. compress hunting in the range of 45- M Will be taken up during next S/D opportunity. 18.09.2020 Next S/D

or 65% & inlet pressure is going

below 2.8 bar.

GT-2 additive dosing pump-A

improper dosing is to be

13. GT-2 rectified & dosing pump – B E/I Will be taken up during S/D. 18.09.2020 Next S/D

starting problem is to be

rectified.

In GT-1, 3 way valve motor

overload & flow divider motor

14. GT-1 E To be checked in S/D opportunity. 22.09.2020 Next S/D

overload alarm came & got

reset on 22.09.2020.

In GT-1, Compressor discharge

15. GT-1 temp 1 element got opened I To be taken up in next S/D opportunity. 22.09.2020 Next S/D

out of 2, to be checked.

11KV bus under voltage alarm

16. GT-2 E This issue to be solved during GT-2 next S/D. 23.09.2020 Next S/D

to be resolved

17. GT-2 GT-2 trip from ECS E During next opportunity of GT-2 S/D, to be analyzed. 23.09.2020 Next S/D

You might also like

- Jindal Food Compliance Certificate - BOPP (Updated)Document6 pagesJindal Food Compliance Certificate - BOPP (Updated)MATTHEW MUNGAINo ratings yet

- Navigation Lights UnitDocument36 pagesNavigation Lights UnitAyman64No ratings yet

- Jobber XLDocument4 pagesJobber XLDeva RajNo ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument4 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument4 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument3 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument3 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- Daily Coordination Meeting 29-10-20.dcoxDocument4 pagesDaily Coordination Meeting 29-10-20.dcoxabhaymehta67No ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument3 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument3 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- Nbml-Nf-0127-2024-Pond AshDocument1 pageNbml-Nf-0127-2024-Pond AshRavindra singh TanwarNo ratings yet

- PG Grade Selection - Adjusting T For TrafficDocument3 pagesPG Grade Selection - Adjusting T For TrafficFrimini BeatusNo ratings yet

- Welltest Summary: Pt. Putra Sejati IndomakmurDocument18 pagesWelltest Summary: Pt. Putra Sejati IndomakmurAditya FathurachmanNo ratings yet

- 10 MM AS0480104Document1 page10 MM AS0480104mamdouhNo ratings yet

- Environmental Statement of NUMALIGARH REFINERY LIMITED For The Financial Year - 2016-17 Part - ADocument16 pagesEnvironmental Statement of NUMALIGARH REFINERY LIMITED For The Financial Year - 2016-17 Part - ASarang BondeNo ratings yet

- Unit-L: & Gujarat Electricity Corporation Ltd. Stack Sample AnalysisDocument1 pageUnit-L: & Gujarat Electricity Corporation Ltd. Stack Sample AnalysisAbhijeet OundhakarNo ratings yet

- THG1365YLSDocument4 pagesTHG1365YLSRolando LopezNo ratings yet

- Dimensioning 21 Gerald WWTP 484Document23 pagesDimensioning 21 Gerald WWTP 484Osoba Ismail AbiodunNo ratings yet

- Laporan Mngr. Shift P-2B, 25 Agustus 2023 (Night Shift)Document1 pageLaporan Mngr. Shift P-2B, 25 Agustus 2023 (Night Shift)kurniapusriNo ratings yet

- PO SR - No.8, HEL REPORT 120004Document4 pagesPO SR - No.8, HEL REPORT 120004Agni DuttaNo ratings yet

- DDR N°40 Omf-50 TP202 Du 05092021Document3 pagesDDR N°40 Omf-50 TP202 Du 05092021Mohamed SouidiNo ratings yet

- Septic Tank Data Sheet PDFDocument2 pagesSeptic Tank Data Sheet PDFAditya JainNo ratings yet

- Radiometer Abl9 Po2 Blood Gas AnalyzerDocument2 pagesRadiometer Abl9 Po2 Blood Gas AnalyzerREJI Raju100% (1)

- T1/Cept/ISDN-PRI TransformersDocument10 pagesT1/Cept/ISDN-PRI Transformers497286858No ratings yet

- Raw Water Analysis ReportDocument1 pageRaw Water Analysis ReportSajib Chandra RoyNo ratings yet

- Pond AshDocument1 pagePond AshRavindra singh TanwarNo ratings yet

- Ariel Performance: Company: Customer: Quote: Inquiry: Case 1: ProjectDocument1 pageAriel Performance: Company: Customer: Quote: Inquiry: Case 1: ProjectJose FavaNo ratings yet

- Equipment DatasheetDocument9 pagesEquipment DatasheetBimal DeyNo ratings yet

- DDR NZ25 - N045 - 26032011Document2 pagesDDR NZ25 - N045 - 26032011Mustapha BouregaaNo ratings yet

- Presentation - Jeddah Airport 2 ISTP (KOM)Document44 pagesPresentation - Jeddah Airport 2 ISTP (KOM)Karam Fta Al-andalusNo ratings yet

- b1. Compressor - Accessories - b2. Ariel Performance RunDocument1 pageb1. Compressor - Accessories - b2. Ariel Performance Runargasi.mrysiNo ratings yet

- DDR N°1 - Atk29 - TP180 - 08022017Document3 pagesDDR N°1 - Atk29 - TP180 - 08022017Nour MohammedNo ratings yet

- Flow Line and Well Hook-Up Authorisation (GD) : (Well SRS - V48A)Document1 pageFlow Line and Well Hook-Up Authorisation (GD) : (Well SRS - V48A)Qayyum KhanNo ratings yet

- Saisw-2 TP221 DDR N°45 22-03-2024Document3 pagesSaisw-2 TP221 DDR N°45 22-03-2024Abdellah AbdellahNo ratings yet

- R 32 Inverter RotaryDocument1 pageR 32 Inverter RotaryŠemsuddin SefićNo ratings yet

- SRP7028AA Series - Shielded Power Inductors: FeaturesDocument6 pagesSRP7028AA Series - Shielded Power Inductors: FeaturesKiran PatelNo ratings yet

- Gas Engine Technical Data: Rating Notes Load 100% 75% 50%Document4 pagesGas Engine Technical Data: Rating Notes Load 100% 75% 50%m. iqbal fadhillahNo ratings yet

- Water Sample 2Document2 pagesWater Sample 2WaquarAhmadAnsariNo ratings yet

- Scan Report of Analysis - PT. BORNEO INDOBARA GLOBALDocument1 pageScan Report of Analysis - PT. BORNEO INDOBARA GLOBALjh0ny.geosNo ratings yet

- Chem30 10 2022Document1,312 pagesChem30 10 2022RavinderGuptaNo ratings yet

- Bitzer 3x6ge-34yDocument9 pagesBitzer 3x6ge-34yMario UrsuNo ratings yet

- To Find:: 1. Voluewtric MethodDocument3 pagesTo Find:: 1. Voluewtric MethodAsad Ul HaqNo ratings yet

- Model: THG1365YLS: Technical Data SheetDocument3 pagesModel: THG1365YLS: Technical Data SheetAndres VargazNo ratings yet

- Presents MMB: One Unique Product For Plenty of InnovationsDocument31 pagesPresents MMB: One Unique Product For Plenty of InnovationsSvetlana ChiganovaNo ratings yet

- Sizing Sheet Dengan Cv. 133 PDFDocument3 pagesSizing Sheet Dengan Cv. 133 PDFJoko WisnugrohoNo ratings yet

- 2500-15-00-80-001 - R1 (Unit 15 Operating Manual)Document185 pages2500-15-00-80-001 - R1 (Unit 15 Operating Manual)Clash with HBNo ratings yet

- 15-501-EP-DS-001 (Metering Skid Data Sheet), Rev.1Document2 pages15-501-EP-DS-001 (Metering Skid Data Sheet), Rev.1Umair A. KhanNo ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (KG/H) (CP) (Psi (A) )Document5 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (KG/H) (CP) (Psi (A) )Elias EliasNo ratings yet

- Laporan Manager Shift P-2B, 02 September 2023 (Swing Shift)Document1 pageLaporan Manager Shift P-2B, 02 September 2023 (Swing Shift)kurniapusriNo ratings yet

- 4ZS01350 Data Sheet DM8605 G3606 A3Document5 pages4ZS01350 Data Sheet DM8605 G3606 A3MitulNo ratings yet

- Well Test Case StudyDocument17 pagesWell Test Case StudyAarzoo JobanputraNo ratings yet

- TUV SUD BSR Test Report PDFDocument2 pagesTUV SUD BSR Test Report PDFAzrof AhmedNo ratings yet

- A44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0Document2 pagesA44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0m.shehreyar.khanNo ratings yet

- Daily Chemistry Report 31.01.2021.Document2 pagesDaily Chemistry Report 31.01.2021.Shobhit SrivastavaNo ratings yet

- THG 1374 YfsDocument4 pagesTHG 1374 YfsJembrong DerrilNo ratings yet

- Bof Lab Daily Production Report: TotalDocument2 pagesBof Lab Daily Production Report: TotalBinod Kumar PadhiNo ratings yet

- Permit Sample Evaluation Natural Gas Fired Boiler 5-20 Mmbtu/HrDocument8 pagesPermit Sample Evaluation Natural Gas Fired Boiler 5-20 Mmbtu/HrAnonymous bHh1L1No ratings yet

- Rotor General Characteristics: Flowmeter 4.2. Rototron RRHDocument2 pagesRotor General Characteristics: Flowmeter 4.2. Rototron RRHmihirNo ratings yet

- CDU IV Highlights 21-Feb'2024Document2 pagesCDU IV Highlights 21-Feb'2024Manjunath GangaramNo ratings yet

- MPBA1con 40 Psi en SucciónDocument1 pageMPBA1con 40 Psi en SucciónleonnelNo ratings yet

- Daily Coordination Meeting 29-10-20.dcoxDocument4 pagesDaily Coordination Meeting 29-10-20.dcoxabhaymehta67No ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument4 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- STG HRSG - Procontrol ArchitectureDocument3 pagesSTG HRSG - Procontrol Architectureabhaymehta67No ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument4 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument3 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument3 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument3 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- Aeroderivative Technology PDFDocument10 pagesAeroderivative Technology PDFabhaymehta67No ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument3 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- GE LM6000 Gas Turbine Generator Drive Application Control PackageDocument3 pagesGE LM6000 Gas Turbine Generator Drive Application Control Packageabhaymehta67100% (1)

- 2.3 Principle of Turbine Governing CompressedDocument54 pages2.3 Principle of Turbine Governing Compressedabhaymehta67100% (2)

- Basic Electrical Parameters Measurement Laboratory: A K-12 Outreach ProjectDocument13 pagesBasic Electrical Parameters Measurement Laboratory: A K-12 Outreach Projectabhaymehta67No ratings yet

- Flue Gas Desulphurization Plant: Vidarbha Industries Power LimitedDocument56 pagesFlue Gas Desulphurization Plant: Vidarbha Industries Power Limitedabhaymehta67No ratings yet

- 200MW Volume 1Document350 pages200MW Volume 1api-19984595100% (10)

- NDT Method Magnetic Particle InspectionDocument23 pagesNDT Method Magnetic Particle Inspectionabhaymehta67No ratings yet

- Worksheet, Control System: Ge Packaged Power, L.PDocument2 pagesWorksheet, Control System: Ge Packaged Power, L.Pabhaymehta67No ratings yet

- Coal Mill CO Analyzer Codel ManualDocument38 pagesCoal Mill CO Analyzer Codel Manualabhaymehta67No ratings yet

- MYTHS N TRUTHS DIAGNOSIS OF ELECTRICAL INSULATION SYSTEM CompressedDocument92 pagesMYTHS N TRUTHS DIAGNOSIS OF ELECTRICAL INSULATION SYSTEM Compressedabhaymehta67No ratings yet

- LM6 PC MNet Plus ChasisDocument4 pagesLM6 PC MNet Plus Chasisabhaymehta67No ratings yet

- Electrical Measurements and Instrumentation KG ReddyDocument158 pagesElectrical Measurements and Instrumentation KG Reddyabhaymehta67No ratings yet

- Ge Packaged Power, L.P.: Worksheet, Control SystemDocument1 pageGe Packaged Power, L.P.: Worksheet, Control Systemabhaymehta67No ratings yet

- XM-121 Absolute Shaft Module RockwellDocument158 pagesXM-121 Absolute Shaft Module Rockwellabhaymehta67No ratings yet

- Endura AZ20 Oxygen MonitorDocument20 pagesEndura AZ20 Oxygen Monitorabhaymehta67No ratings yet

- P&id-Fiscal Metering SkidDocument1 pageP&id-Fiscal Metering SkidHsein WangNo ratings yet

- Introduction CCTVDocument13 pagesIntroduction CCTVSabin NikNo ratings yet

- Solenoid Coils For Proportional Valves (Solenoid Operated) Types 40-1836 50-1836Document2 pagesSolenoid Coils For Proportional Valves (Solenoid Operated) Types 40-1836 50-1836Dew บุรุษสุดตีนNo ratings yet

- ECMDocument6 pagesECMRodney Richardson100% (7)

- Kaeser SK21T 26042Document4 pagesKaeser SK21T 26042AnthonyNo ratings yet

- Electrical Drawings As Built PDFDocument71 pagesElectrical Drawings As Built PDFsemajamesNo ratings yet

- Firefly Lighting FlyerDocument16 pagesFirefly Lighting Flyergianfutol1No ratings yet

- CNC Milling and Horizontal Milling MachineDocument7 pagesCNC Milling and Horizontal Milling MachineAsma PrinceNo ratings yet

- BE Electric Pressure Washer USER MANUALDocument19 pagesBE Electric Pressure Washer USER MANUALAl CrosbyNo ratings yet

- MVGC Operating ManualDocument46 pagesMVGC Operating ManualMartin ManuelNo ratings yet

- Fisher 585C BulletinDocument16 pagesFisher 585C BulletinMark HaneyNo ratings yet

- RXD-V333/V333S/V535/V535-GR/V535S/ V535S-H/V636/V737/V737S: Service ManualDocument43 pagesRXD-V333/V333S/V535/V535-GR/V535S/ V535S-H/V636/V737/V737S: Service ManualKasun Chamara PrathapasinghaNo ratings yet

- ST09222i Floor PolisherDocument2 pagesST09222i Floor PolisherSirbcdNo ratings yet

- Sopa de LetrasDocument1 pageSopa de LetrasJohana Andrea Sepulveda SabogalNo ratings yet

- DIY Automatic Alcohol Dispenser No Arduino NeededDocument16 pagesDIY Automatic Alcohol Dispenser No Arduino NeededLuigi Ceda100% (1)

- Dewal Tapper Pro ScrewDocument2 pagesDewal Tapper Pro Screwchong pak limNo ratings yet

- Dokumen - Tips Installation User Maintenance Installation User Maintenance ManualDocument54 pagesDokumen - Tips Installation User Maintenance Installation User Maintenance ManualEdmond HungNo ratings yet

- Ptac Series Manual: 7,000-15,000 BTU/HDocument23 pagesPtac Series Manual: 7,000-15,000 BTU/HJose Enrique Sanchez ThompsonNo ratings yet

- Iron BeamDocument2 pagesIron Beamrapha.sassonNo ratings yet

- FX Cable Suspended Platform LR FADocument6 pagesFX Cable Suspended Platform LR FABoruida MachineryNo ratings yet

- Service Mode, Troubleshooting - Toshiba - E-Studio 223 - Service Mode 05. Adjustment ModeDocument1 pageService Mode, Troubleshooting - Toshiba - E-Studio 223 - Service Mode 05. Adjustment Modems.international060No ratings yet

- MNPTP - 02 - 8-16A Ton Electronic Control SystemDocument19 pagesMNPTP - 02 - 8-16A Ton Electronic Control SystemGlobal Teknik Abadi100% (1)

- IP123Document15 pagesIP123IR MA Al AzharNo ratings yet

- ISO 4308-2-1988 Scan PDFDocument4 pagesISO 4308-2-1988 Scan PDFIngeniero mecanico F.N.I.No ratings yet

- 4.0 Lab Sheet K1Document10 pages4.0 Lab Sheet K1zharensNo ratings yet

- Optic Fiber Cable-UnArmouredDocument2 pagesOptic Fiber Cable-UnArmouredAnonymous yugocxnNo ratings yet

- Delonghi En166Document158 pagesDelonghi En166danielradu27No ratings yet

- Gas Insulated TransformersDocument12 pagesGas Insulated TransformersmohamedNo ratings yet