Professional Documents

Culture Documents

Leuterio ECE43 EXP1 ECET421La PDF

Leuterio ECE43 EXP1 ECET421La PDF

Uploaded by

Thea LeuterioCopyright:

Available Formats

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- DC Motor Speed Control Using C++Document23 pagesDC Motor Speed Control Using C++eraditya200150% (2)

- Enron Case StudyDocument3 pagesEnron Case StudycharleejaiNo ratings yet

- Agile Project Charter Template ExampleDocument5 pagesAgile Project Charter Template ExampleOmair Gull100% (1)

- Table of Content S.No Page No.: I 1.1 Conventional Methods of Speed Control 4Document17 pagesTable of Content S.No Page No.: I 1.1 Conventional Methods of Speed Control 4Janani JanuNo ratings yet

- Analogue Communications ReportDocument12 pagesAnalogue Communications ReportNitesh ChaurasiyaNo ratings yet

- Speed Control of DC Motor Using Pid Controller BasedDocument16 pagesSpeed Control of DC Motor Using Pid Controller Basedayesha amjadNo ratings yet

- Speed Control of DC Motor by Various MethodsDocument5 pagesSpeed Control of DC Motor by Various MethodsVIVA-TECH IJRINo ratings yet

- Four - Quadrant Control SystemsDocument4 pagesFour - Quadrant Control SystemsRICHARDNo ratings yet

- Four Quadrant Speed Control of DC Motor With The Help of AT89S52 MicrocontrollerDocument12 pagesFour Quadrant Speed Control of DC Motor With The Help of AT89S52 MicrocontrollerpriyaNo ratings yet

- Selection of Motor: 1. SPEED: in PIC IC The Execution of An Instruction Is Very Fast (In Micro Seconds) and Can BeDocument12 pagesSelection of Motor: 1. SPEED: in PIC IC The Execution of An Instruction Is Very Fast (In Micro Seconds) and Can Bebsirisha415No ratings yet

- DC Motor Interfacing With PIC Microcontroller Using L293 Motor Driver ICDocument4 pagesDC Motor Interfacing With PIC Microcontroller Using L293 Motor Driver ICifyNo ratings yet

- Touch Screen Controlled Wheel ChairDocument5 pagesTouch Screen Controlled Wheel Chairnirajthakkar100% (2)

- Closed Loop Speed and Position Control of DC MotorsDocument7 pagesClosed Loop Speed and Position Control of DC Motorslizhi0007No ratings yet

- Projects Based On Audino DC Motor ControlDocument15 pagesProjects Based On Audino DC Motor Controlnagasaikiran ponnapalli0% (1)

- Synopsis PPT 4Document7 pagesSynopsis PPT 4Appu SpecialNo ratings yet

- Microcontroller Based DC Motor Control: Jayshree Sahu, S.K.Sahu, Jayendra KumarDocument4 pagesMicrocontroller Based DC Motor Control: Jayshree Sahu, S.K.Sahu, Jayendra KumarJagdish PatankarNo ratings yet

- A Review: Speed Control of DC Motor Using Android ApplicationDocument3 pagesA Review: Speed Control of DC Motor Using Android ApplicationMaulik BariaNo ratings yet

- Exp1 DC Motor Control With Computer Interfacing To MicrocontrollerDocument4 pagesExp1 DC Motor Control With Computer Interfacing To MicrocontrollerKyle Janssen VillanuevaNo ratings yet

- Camera Movement Control Using PID Controller in LabVIEWDocument5 pagesCamera Movement Control Using PID Controller in LabVIEWEditor IJTSRDNo ratings yet

- Career Episode 1 PC Based Speed Control of DC Motor Using MicrocontrollerDocument7 pagesCareer Episode 1 PC Based Speed Control of DC Motor Using MicrocontrollerMadhu SahukhalNo ratings yet

- AnotherDocument51 pagesAnotherRoopam AmborNo ratings yet

- PM Stepper Motor Control System by Pic - NG Wai Liang - QA76.5.N48 2006Document28 pagesPM Stepper Motor Control System by Pic - NG Wai Liang - QA76.5.N48 2006Nirmal KumarNo ratings yet

- "Speed Control of DC Motor by Using PWM": IjarcceDocument3 pages"Speed Control of DC Motor by Using PWM": IjarcceRishi GaddaNo ratings yet

- Advanced Control System Lab PDFDocument15 pagesAdvanced Control System Lab PDFarpitg2208No ratings yet

- Electronics Projects Farhan ShakeelDocument236 pagesElectronics Projects Farhan Shakeelfarhanshakeel100% (2)

- Ijsrp p8321Document7 pagesIjsrp p8321Vipul SharmaNo ratings yet

- 4drives Lehtla PDFDocument21 pages4drives Lehtla PDFdennypolariszNo ratings yet

- Speed Control of BLDC Motor Using DSP: 1 4 1 JNTUH Hyderabad, India 2 JNTUH Hyderabad, IndiaDocument5 pagesSpeed Control of BLDC Motor Using DSP: 1 4 1 JNTUH Hyderabad, India 2 JNTUH Hyderabad, IndiapravnkumarNo ratings yet

- Solar Powered Speed Control of Brushless DC MotorDocument7 pagesSolar Powered Speed Control of Brushless DC MotorIJRASETPublicationsNo ratings yet

- Control BLDC Motor Speed Using PID ControllerDocument5 pagesControl BLDC Motor Speed Using PID ControllerAbhay JangirNo ratings yet

- Microcontroller Based DC Motor Speed Control Using PWM TechniqueDocument5 pagesMicrocontroller Based DC Motor Speed Control Using PWM Techniquelovely personNo ratings yet

- MSD Exp2Document5 pagesMSD Exp2ngolos247No ratings yet

- Pulse Width Modulation (PWM) Speed Control of A DC MotorDocument5 pagesPulse Width Modulation (PWM) Speed Control of A DC MotorShahab JavedNo ratings yet

- Arduino DC Motor Control Using L298N Motor DriverDocument3 pagesArduino DC Motor Control Using L298N Motor DriverSONA100% (1)

- Closed Loop DC Motor Speed ControlDocument3 pagesClosed Loop DC Motor Speed ControlKhayaz KunhabduNo ratings yet

- 3.automated Transformer Coil Winding MachineDocument31 pages3.automated Transformer Coil Winding Machinecelphone533No ratings yet

- Speed Control of A DC Motor Using Hand GestureDocument4 pagesSpeed Control of A DC Motor Using Hand GestureArka Prava LahiriNo ratings yet

- Speed Control of DC Motor Using Dual Converter: Saniya Naseem Zunjani, Amit Shrivastava, Amol BarveDocument4 pagesSpeed Control of DC Motor Using Dual Converter: Saniya Naseem Zunjani, Amit Shrivastava, Amol BarveEdul BrianNo ratings yet

- Microcontroller Based Closed-Loop Automatic Speed Control of DC Motor Using PWMDocument4 pagesMicrocontroller Based Closed-Loop Automatic Speed Control of DC Motor Using PWMSphasonke Daniel ZhouNo ratings yet

- Microcontroller Based DC Motor Speed Control Using PWM TechniqueDocument5 pagesMicrocontroller Based DC Motor Speed Control Using PWM TechniqueswetaNo ratings yet

- Evaluation of Two Different Method For Speed Control of DC MotorDocument4 pagesEvaluation of Two Different Method For Speed Control of DC MotorUmer EhsanNo ratings yet

- Ijert Ijert: Microcontroller Controlled BLDC Drive For Electric Vehicle Raju Yanamshetti, Juhi Nishat AnsariDocument4 pagesIjert Ijert: Microcontroller Controlled BLDC Drive For Electric Vehicle Raju Yanamshetti, Juhi Nishat AnsariAvinash Babu KmNo ratings yet

- Driver Motor BrushlesDocument48 pagesDriver Motor BrushlesGONAJ2008No ratings yet

- DC Motor ControlDocument11 pagesDC Motor ControlPearl Joyce SubereNo ratings yet

- Project Report On Robotic ArmDocument28 pagesProject Report On Robotic Armpatel ketan84% (25)

- Accelerazation Operating of DC Motor Through IrDocument3 pagesAccelerazation Operating of DC Motor Through IrKethavath Sakrunaik KNo ratings yet

- CEP EM ReportDocument15 pagesCEP EM ReportManish RanaNo ratings yet

- An Overview of PLC Based Control Panel System For External Plunge Grinding Machine and CNC MachineDocument3 pagesAn Overview of PLC Based Control Panel System For External Plunge Grinding Machine and CNC MachineIJMERNo ratings yet

- Novel Method PMDC Motor Speed ControlDocument15 pagesNovel Method PMDC Motor Speed ControlTravis WoodNo ratings yet

- Speed Control of A Conveyor BeltDocument24 pagesSpeed Control of A Conveyor BeltSumu Talal50% (2)

- Microcontroller Based DC Motor Speed Control Using PWM TechniqueDocument5 pagesMicrocontroller Based DC Motor Speed Control Using PWM TechniqueJigar PatelNo ratings yet

- PMDC Motor Control Using PWM Techniques: Ms. Dipti K. Shah Prof. B. T. DeshmukhDocument3 pagesPMDC Motor Control Using PWM Techniques: Ms. Dipti K. Shah Prof. B. T. Deshmukhritu rajNo ratings yet

- Xyz@pqrsDocument3 pagesXyz@pqrsrituNo ratings yet

- A PID Controller For Real-Time DC Motor Speed Control Using The C505C Micro ControllerDocument6 pagesA PID Controller For Real-Time DC Motor Speed Control Using The C505C Micro Controllerbhargav103No ratings yet

- Controlling DC Motor Using Microcontroller (PIC16F72) With PWMDocument4 pagesControlling DC Motor Using Microcontroller (PIC16F72) With PWMAkah PreciousNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Power Systems-On-Chip: Practical Aspects of DesignFrom EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardNo ratings yet

- Laws, RA, PD, EO or Memorandum Circular About Broadcasting Regulations in The PhilippinesDocument8 pagesLaws, RA, PD, EO or Memorandum Circular About Broadcasting Regulations in The PhilippinesThea LeuterioNo ratings yet

- De La Salle University - Dasmariñas Dasmariñas, Cavite: Daily Work ActivitiesDocument9 pagesDe La Salle University - Dasmariñas Dasmariñas, Cavite: Daily Work ActivitiesThea LeuterioNo ratings yet

- Leuterio Act1 PDFDocument8 pagesLeuterio Act1 PDFThea LeuterioNo ratings yet

- Topic-1 Intro To DatacomDocument39 pagesTopic-1 Intro To DatacomThea LeuterioNo ratings yet

- Leuterio Act1 PDFDocument8 pagesLeuterio Act1 PDFThea LeuterioNo ratings yet

- Performance of 1 and 2 Order Systems: ST NDDocument6 pagesPerformance of 1 and 2 Order Systems: ST NDThea LeuterioNo ratings yet

- ECET512L - Transmission Media and Antenna SystemsDocument4 pagesECET512L - Transmission Media and Antenna SystemsThea LeuterioNo ratings yet

- EEET423L Exp3 Script Functions and FlowCOntrolDocument2 pagesEEET423L Exp3 Script Functions and FlowCOntrolThea LeuterioNo ratings yet

- Integrated NLP Train The Trainer BootcampDocument8 pagesIntegrated NLP Train The Trainer BootcampHitesh ParmarNo ratings yet

- Mars EssayDocument3 pagesMars EssayAlejandro Cervantes100% (1)

- Angela's Infantwear and Accessories: InvoiceDocument1 pageAngela's Infantwear and Accessories: InvoiceAngelas InfantwearNo ratings yet

- FIN201 CF T3 2021 BBUS Unit Guide V2 07092021Document11 pagesFIN201 CF T3 2021 BBUS Unit Guide V2 07092021Nguyen Quynh AnhNo ratings yet

- Medicinal Benefits of HoneyDocument8 pagesMedicinal Benefits of HoneyTauseef AshrafNo ratings yet

- Bhutan Alternatives Competitive Advantage CCCDocument5 pagesBhutan Alternatives Competitive Advantage CCCSonam LodayNo ratings yet

- Royal Caribbean CEO LetterDocument5 pagesRoyal Caribbean CEO LetterOnPointRadioNo ratings yet

- Lenntech: 60 Frame Plunger PumpDocument4 pagesLenntech: 60 Frame Plunger PumpJHONY TEODORO ALBORNOZ DIONICIONo ratings yet

- Blue Printing Pharmacology AssessmentDocument6 pagesBlue Printing Pharmacology Assessmentprasan bhandariNo ratings yet

- Saracrease HG 10Document2 pagesSaracrease HG 10NAGARAJNo ratings yet

- Organization and Management: Quarter 1, Week 2 Functions, Roles and Skills of A ManagerDocument13 pagesOrganization and Management: Quarter 1, Week 2 Functions, Roles and Skills of A ManagerMaryNo ratings yet

- Victor Manuel Chevere v. Jerry Johnson Stephen Kaiser Rick E. Peters Jim Keith Bob Affolter, 38 F.3d 1220, 10th Cir. (1994)Document4 pagesVictor Manuel Chevere v. Jerry Johnson Stephen Kaiser Rick E. Peters Jim Keith Bob Affolter, 38 F.3d 1220, 10th Cir. (1994)Scribd Government DocsNo ratings yet

- Contoh Safety Inspection ChecklistDocument2 pagesContoh Safety Inspection Checklistbernardusbesta heryogaNo ratings yet

- Tifr SSRDocument972 pagesTifr SSRAbhishek UpadhyayNo ratings yet

- Lgu Night 2024 ScriptDocument13 pagesLgu Night 2024 Scriptmedy drizaNo ratings yet

- Zikr-e-Masoom (A.s.)Document262 pagesZikr-e-Masoom (A.s.)Shian-e-Ali Network0% (1)

- CV Marius Lupoian 12.12.2012 - enDocument5 pagesCV Marius Lupoian 12.12.2012 - enLupoian Florin MariusNo ratings yet

- Malunggay Oleifera As Cleaning AgentDocument2 pagesMalunggay Oleifera As Cleaning AgentMackieNo ratings yet

- AfterMath RulesDocument185 pagesAfterMath RulesWilliam May II67% (3)

- Date Itinerary Total Per Head x2 Rate (Est) : C/o Miss Pearl (7,000 3,500 Per Head) Taiwander (1,000/head)Document1 pageDate Itinerary Total Per Head x2 Rate (Est) : C/o Miss Pearl (7,000 3,500 Per Head) Taiwander (1,000/head)PatOcampoNo ratings yet

- CHEMFISH Fluorinated CompoundsDocument11 pagesCHEMFISH Fluorinated Compoundssunny StevenNo ratings yet

- Car Sales Cover LetterDocument8 pagesCar Sales Cover Letterf5de9mre100% (2)

- Peds HemeImmune OUTLINEDocument10 pagesPeds HemeImmune OUTLINEAshleyNo ratings yet

- Pyton Ls DynaDocument9 pagesPyton Ls DynaNandaNo ratings yet

- Zabala Auto SupplyDocument7 pagesZabala Auto SupplyLeighsen VillacortaNo ratings yet

- NABH Series5 HIC - 0Document57 pagesNABH Series5 HIC - 0Shejil BalakrishnanNo ratings yet

- MC CSSM JR Correction LSCQ3023 Courier Delivery Executive 16.07.2018Document16 pagesMC CSSM JR Correction LSCQ3023 Courier Delivery Executive 16.07.2018Abhishek ThakurNo ratings yet

- Sample Diary Curriculum Map SUBJECT: Mathematics QUARTER: Second Grade Level: 10 TOPIC: CircleDocument3 pagesSample Diary Curriculum Map SUBJECT: Mathematics QUARTER: Second Grade Level: 10 TOPIC: CircleRichimon LicerioNo ratings yet

Leuterio ECE43 EXP1 ECET421La PDF

Leuterio ECE43 EXP1 ECET421La PDF

Uploaded by

Thea LeuterioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leuterio ECE43 EXP1 ECET421La PDF

Leuterio ECE43 EXP1 ECET421La PDF

Uploaded by

Thea LeuterioCopyright:

Available Formats

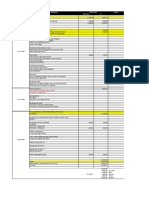

_________DC Motor Control with Computer and Microcontroller Interfacing_________

I. Introduction

Basically, Electrical DC Motors are actuators that convert electrical energy into mechanical energy.

Such can have its rotation speed and direction controlled through various ways, most popularly through PWM and

basic motor drivers. In this experiment, the rotation speed and direction of the DC Motor in a conveyor was

controlled through a microprocessor (Arduino Uno) and programmed GUI’s. The mechanisms and processes

found in DC Motor control were aimed to be investigated yielding an improved understanding of DC Motor

control and operations.

II. Objectives

• To control the direction of rotation of a DC motor using H-bridge circuit.

• To control the speed of rotation of a DC motor using Pulse width modulation.

• To create an Arduino programming to control the DC motor.

• To create a computer program user interface to send data control to Arduino

III. Discussion

A DC Motor was placed as the actuator of a conveyor. Upon connecting the DC Motor to the L293D

driver, the said configuration was connected to the microcontroller. For the first part, a program to control the

direction of the DC Motor was coded and uploaded to the microcontroller. The circuit is configured in such a way

that the IN1 and IN2 of the motor driver was connected to the pin 1 and pin 2 of the microcontroller consecutively.

Sending characters serially provide control for the motor’s rotary direction. An input of ‘A’ made the motor rotate

in a clockwise direction while an input of ‘B’ made the motor rotate in a counter clockwise direction. An input of

‘C’ on the other hand, caused the motor to stop. This happens as the L293D IC works on the basic principle of H-

bridge. The microprocessor was programmed to send logic 1 to pin 1 and logic 0 to pin 2 when it receives ‘A’, to

send logic 0 to pin 1 and logic 1 to pin 2 when it receives ‘B’ and to send logic 0 to both pin 1 and pin 2 when it

receives ‘C’. As the basic principle of H-bridge is applied on the said IC, it acts as if it has four switches namely S1,

S2, S3 and S4. When the S1 and S4 switches are closed, then a positive voltage will be applied across the motor. By

opening the switches S1 and S4 and closing the switches S2 and S3, this voltage is inverted, allowing invert operation

of the motor. The values in IN1 and IN2 controls such switching mechanism hence changes the direction of DC

motor rotation.

The next activity was controlling the DC motor speed. The circuit is configured in such a way that

the EN1 of the motor driver was connected to the pin 9 of microcontroller. A program to control the speed of the

DC Motor rotation was coded and uploaded to the microcontroller. The input PWM was received as the serial

input was programmed to be written to pin 9. Such was done through pulse width modulation (PWM). RPM

variation is performed by increasing or decreasing the time interval when the control signal has the logic value 1

(tON). Thus, at a duty-cycle of 100%, the motor will have the maximum rpm, tON will be maximal and tOFF will be

zero. In inputing these to the microcontroller, 255 equates 100% duty-cyle and 0 equates 0%. It was observed that

the DC Motor rotation speed increased as the input value approached 255 and decreased as the input decreased.

The DC Motor stopped rotating when the serial input was zero.

For the last two activities, GUI’s were programmed to create an interface that will serially

communicate with the motor driver. The first GUI was created to control the direction of motor direction while

the second GUI was programmed to control DC motor rotation speed with the help of a slider.

The main obstacles found in this experiment was programming; errors were encountered before the

correct code was successfully uploaded to the microcontroller. Another was confusion with setting up the circuits

as there as an IC motor driver involved. Such can be improved though practice and improved understanding of

the circuits being used.

Sheet ____ of ____

IV. Conclusion

A DC Motor can be controlled with the help of a microcontroller and L293D Motor Driver. L293D

IC works on the basic principle of H-bridge. The H-bridge mechanism acts like four switches namely S1, S2, S3

and S4 are switched to give different operations such as clockwise, counter-clockwise, brake, free run and short. Pulse width

modulation (PWM) provides another way to control DC Motor. The motor rpm can be varied by increasing or

decreasing the time interval when the control signal has the logic value 1, or the width of TON’s pulse, thus increasing

or decreasing the rotation speed. The instruction for direction and PWM can be serially sent to the microprocessor

through serial monitor or, better, with the help of a Graphical User Interface. All in all, the DC Motor was

successfully controlled with the help of H-Bridge mechanism and PWM. It is as well concluded that the graphical

user interfaces and Arduino codes were successfully programmed.

V. References

• Agarwal, T. (2014). H-Bridge Motor Control Circuit Using L293d Motor Driver IC. Retrieved from

https://www.elprocus.com/h-bridge-motor-control-circuit-using-l293d-ic/

• Petru, L. and Mazen, G. (2014). PWM Control of a DC Motor Used to Drive a Conveyor Belt. Retrieved from

https://core.ac.uk/download/pdf/81962714.pdf

You might also like

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- DC Motor Speed Control Using C++Document23 pagesDC Motor Speed Control Using C++eraditya200150% (2)

- Enron Case StudyDocument3 pagesEnron Case StudycharleejaiNo ratings yet

- Agile Project Charter Template ExampleDocument5 pagesAgile Project Charter Template ExampleOmair Gull100% (1)

- Table of Content S.No Page No.: I 1.1 Conventional Methods of Speed Control 4Document17 pagesTable of Content S.No Page No.: I 1.1 Conventional Methods of Speed Control 4Janani JanuNo ratings yet

- Analogue Communications ReportDocument12 pagesAnalogue Communications ReportNitesh ChaurasiyaNo ratings yet

- Speed Control of DC Motor Using Pid Controller BasedDocument16 pagesSpeed Control of DC Motor Using Pid Controller Basedayesha amjadNo ratings yet

- Speed Control of DC Motor by Various MethodsDocument5 pagesSpeed Control of DC Motor by Various MethodsVIVA-TECH IJRINo ratings yet

- Four - Quadrant Control SystemsDocument4 pagesFour - Quadrant Control SystemsRICHARDNo ratings yet

- Four Quadrant Speed Control of DC Motor With The Help of AT89S52 MicrocontrollerDocument12 pagesFour Quadrant Speed Control of DC Motor With The Help of AT89S52 MicrocontrollerpriyaNo ratings yet

- Selection of Motor: 1. SPEED: in PIC IC The Execution of An Instruction Is Very Fast (In Micro Seconds) and Can BeDocument12 pagesSelection of Motor: 1. SPEED: in PIC IC The Execution of An Instruction Is Very Fast (In Micro Seconds) and Can Bebsirisha415No ratings yet

- DC Motor Interfacing With PIC Microcontroller Using L293 Motor Driver ICDocument4 pagesDC Motor Interfacing With PIC Microcontroller Using L293 Motor Driver ICifyNo ratings yet

- Touch Screen Controlled Wheel ChairDocument5 pagesTouch Screen Controlled Wheel Chairnirajthakkar100% (2)

- Closed Loop Speed and Position Control of DC MotorsDocument7 pagesClosed Loop Speed and Position Control of DC Motorslizhi0007No ratings yet

- Projects Based On Audino DC Motor ControlDocument15 pagesProjects Based On Audino DC Motor Controlnagasaikiran ponnapalli0% (1)

- Synopsis PPT 4Document7 pagesSynopsis PPT 4Appu SpecialNo ratings yet

- Microcontroller Based DC Motor Control: Jayshree Sahu, S.K.Sahu, Jayendra KumarDocument4 pagesMicrocontroller Based DC Motor Control: Jayshree Sahu, S.K.Sahu, Jayendra KumarJagdish PatankarNo ratings yet

- A Review: Speed Control of DC Motor Using Android ApplicationDocument3 pagesA Review: Speed Control of DC Motor Using Android ApplicationMaulik BariaNo ratings yet

- Exp1 DC Motor Control With Computer Interfacing To MicrocontrollerDocument4 pagesExp1 DC Motor Control With Computer Interfacing To MicrocontrollerKyle Janssen VillanuevaNo ratings yet

- Camera Movement Control Using PID Controller in LabVIEWDocument5 pagesCamera Movement Control Using PID Controller in LabVIEWEditor IJTSRDNo ratings yet

- Career Episode 1 PC Based Speed Control of DC Motor Using MicrocontrollerDocument7 pagesCareer Episode 1 PC Based Speed Control of DC Motor Using MicrocontrollerMadhu SahukhalNo ratings yet

- AnotherDocument51 pagesAnotherRoopam AmborNo ratings yet

- PM Stepper Motor Control System by Pic - NG Wai Liang - QA76.5.N48 2006Document28 pagesPM Stepper Motor Control System by Pic - NG Wai Liang - QA76.5.N48 2006Nirmal KumarNo ratings yet

- "Speed Control of DC Motor by Using PWM": IjarcceDocument3 pages"Speed Control of DC Motor by Using PWM": IjarcceRishi GaddaNo ratings yet

- Advanced Control System Lab PDFDocument15 pagesAdvanced Control System Lab PDFarpitg2208No ratings yet

- Electronics Projects Farhan ShakeelDocument236 pagesElectronics Projects Farhan Shakeelfarhanshakeel100% (2)

- Ijsrp p8321Document7 pagesIjsrp p8321Vipul SharmaNo ratings yet

- 4drives Lehtla PDFDocument21 pages4drives Lehtla PDFdennypolariszNo ratings yet

- Speed Control of BLDC Motor Using DSP: 1 4 1 JNTUH Hyderabad, India 2 JNTUH Hyderabad, IndiaDocument5 pagesSpeed Control of BLDC Motor Using DSP: 1 4 1 JNTUH Hyderabad, India 2 JNTUH Hyderabad, IndiapravnkumarNo ratings yet

- Solar Powered Speed Control of Brushless DC MotorDocument7 pagesSolar Powered Speed Control of Brushless DC MotorIJRASETPublicationsNo ratings yet

- Control BLDC Motor Speed Using PID ControllerDocument5 pagesControl BLDC Motor Speed Using PID ControllerAbhay JangirNo ratings yet

- Microcontroller Based DC Motor Speed Control Using PWM TechniqueDocument5 pagesMicrocontroller Based DC Motor Speed Control Using PWM Techniquelovely personNo ratings yet

- MSD Exp2Document5 pagesMSD Exp2ngolos247No ratings yet

- Pulse Width Modulation (PWM) Speed Control of A DC MotorDocument5 pagesPulse Width Modulation (PWM) Speed Control of A DC MotorShahab JavedNo ratings yet

- Arduino DC Motor Control Using L298N Motor DriverDocument3 pagesArduino DC Motor Control Using L298N Motor DriverSONA100% (1)

- Closed Loop DC Motor Speed ControlDocument3 pagesClosed Loop DC Motor Speed ControlKhayaz KunhabduNo ratings yet

- 3.automated Transformer Coil Winding MachineDocument31 pages3.automated Transformer Coil Winding Machinecelphone533No ratings yet

- Speed Control of A DC Motor Using Hand GestureDocument4 pagesSpeed Control of A DC Motor Using Hand GestureArka Prava LahiriNo ratings yet

- Speed Control of DC Motor Using Dual Converter: Saniya Naseem Zunjani, Amit Shrivastava, Amol BarveDocument4 pagesSpeed Control of DC Motor Using Dual Converter: Saniya Naseem Zunjani, Amit Shrivastava, Amol BarveEdul BrianNo ratings yet

- Microcontroller Based Closed-Loop Automatic Speed Control of DC Motor Using PWMDocument4 pagesMicrocontroller Based Closed-Loop Automatic Speed Control of DC Motor Using PWMSphasonke Daniel ZhouNo ratings yet

- Microcontroller Based DC Motor Speed Control Using PWM TechniqueDocument5 pagesMicrocontroller Based DC Motor Speed Control Using PWM TechniqueswetaNo ratings yet

- Evaluation of Two Different Method For Speed Control of DC MotorDocument4 pagesEvaluation of Two Different Method For Speed Control of DC MotorUmer EhsanNo ratings yet

- Ijert Ijert: Microcontroller Controlled BLDC Drive For Electric Vehicle Raju Yanamshetti, Juhi Nishat AnsariDocument4 pagesIjert Ijert: Microcontroller Controlled BLDC Drive For Electric Vehicle Raju Yanamshetti, Juhi Nishat AnsariAvinash Babu KmNo ratings yet

- Driver Motor BrushlesDocument48 pagesDriver Motor BrushlesGONAJ2008No ratings yet

- DC Motor ControlDocument11 pagesDC Motor ControlPearl Joyce SubereNo ratings yet

- Project Report On Robotic ArmDocument28 pagesProject Report On Robotic Armpatel ketan84% (25)

- Accelerazation Operating of DC Motor Through IrDocument3 pagesAccelerazation Operating of DC Motor Through IrKethavath Sakrunaik KNo ratings yet

- CEP EM ReportDocument15 pagesCEP EM ReportManish RanaNo ratings yet

- An Overview of PLC Based Control Panel System For External Plunge Grinding Machine and CNC MachineDocument3 pagesAn Overview of PLC Based Control Panel System For External Plunge Grinding Machine and CNC MachineIJMERNo ratings yet

- Novel Method PMDC Motor Speed ControlDocument15 pagesNovel Method PMDC Motor Speed ControlTravis WoodNo ratings yet

- Speed Control of A Conveyor BeltDocument24 pagesSpeed Control of A Conveyor BeltSumu Talal50% (2)

- Microcontroller Based DC Motor Speed Control Using PWM TechniqueDocument5 pagesMicrocontroller Based DC Motor Speed Control Using PWM TechniqueJigar PatelNo ratings yet

- PMDC Motor Control Using PWM Techniques: Ms. Dipti K. Shah Prof. B. T. DeshmukhDocument3 pagesPMDC Motor Control Using PWM Techniques: Ms. Dipti K. Shah Prof. B. T. Deshmukhritu rajNo ratings yet

- Xyz@pqrsDocument3 pagesXyz@pqrsrituNo ratings yet

- A PID Controller For Real-Time DC Motor Speed Control Using The C505C Micro ControllerDocument6 pagesA PID Controller For Real-Time DC Motor Speed Control Using The C505C Micro Controllerbhargav103No ratings yet

- Controlling DC Motor Using Microcontroller (PIC16F72) With PWMDocument4 pagesControlling DC Motor Using Microcontroller (PIC16F72) With PWMAkah PreciousNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Power Systems-On-Chip: Practical Aspects of DesignFrom EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardNo ratings yet

- Laws, RA, PD, EO or Memorandum Circular About Broadcasting Regulations in The PhilippinesDocument8 pagesLaws, RA, PD, EO or Memorandum Circular About Broadcasting Regulations in The PhilippinesThea LeuterioNo ratings yet

- De La Salle University - Dasmariñas Dasmariñas, Cavite: Daily Work ActivitiesDocument9 pagesDe La Salle University - Dasmariñas Dasmariñas, Cavite: Daily Work ActivitiesThea LeuterioNo ratings yet

- Leuterio Act1 PDFDocument8 pagesLeuterio Act1 PDFThea LeuterioNo ratings yet

- Topic-1 Intro To DatacomDocument39 pagesTopic-1 Intro To DatacomThea LeuterioNo ratings yet

- Leuterio Act1 PDFDocument8 pagesLeuterio Act1 PDFThea LeuterioNo ratings yet

- Performance of 1 and 2 Order Systems: ST NDDocument6 pagesPerformance of 1 and 2 Order Systems: ST NDThea LeuterioNo ratings yet

- ECET512L - Transmission Media and Antenna SystemsDocument4 pagesECET512L - Transmission Media and Antenna SystemsThea LeuterioNo ratings yet

- EEET423L Exp3 Script Functions and FlowCOntrolDocument2 pagesEEET423L Exp3 Script Functions and FlowCOntrolThea LeuterioNo ratings yet

- Integrated NLP Train The Trainer BootcampDocument8 pagesIntegrated NLP Train The Trainer BootcampHitesh ParmarNo ratings yet

- Mars EssayDocument3 pagesMars EssayAlejandro Cervantes100% (1)

- Angela's Infantwear and Accessories: InvoiceDocument1 pageAngela's Infantwear and Accessories: InvoiceAngelas InfantwearNo ratings yet

- FIN201 CF T3 2021 BBUS Unit Guide V2 07092021Document11 pagesFIN201 CF T3 2021 BBUS Unit Guide V2 07092021Nguyen Quynh AnhNo ratings yet

- Medicinal Benefits of HoneyDocument8 pagesMedicinal Benefits of HoneyTauseef AshrafNo ratings yet

- Bhutan Alternatives Competitive Advantage CCCDocument5 pagesBhutan Alternatives Competitive Advantage CCCSonam LodayNo ratings yet

- Royal Caribbean CEO LetterDocument5 pagesRoyal Caribbean CEO LetterOnPointRadioNo ratings yet

- Lenntech: 60 Frame Plunger PumpDocument4 pagesLenntech: 60 Frame Plunger PumpJHONY TEODORO ALBORNOZ DIONICIONo ratings yet

- Blue Printing Pharmacology AssessmentDocument6 pagesBlue Printing Pharmacology Assessmentprasan bhandariNo ratings yet

- Saracrease HG 10Document2 pagesSaracrease HG 10NAGARAJNo ratings yet

- Organization and Management: Quarter 1, Week 2 Functions, Roles and Skills of A ManagerDocument13 pagesOrganization and Management: Quarter 1, Week 2 Functions, Roles and Skills of A ManagerMaryNo ratings yet

- Victor Manuel Chevere v. Jerry Johnson Stephen Kaiser Rick E. Peters Jim Keith Bob Affolter, 38 F.3d 1220, 10th Cir. (1994)Document4 pagesVictor Manuel Chevere v. Jerry Johnson Stephen Kaiser Rick E. Peters Jim Keith Bob Affolter, 38 F.3d 1220, 10th Cir. (1994)Scribd Government DocsNo ratings yet

- Contoh Safety Inspection ChecklistDocument2 pagesContoh Safety Inspection Checklistbernardusbesta heryogaNo ratings yet

- Tifr SSRDocument972 pagesTifr SSRAbhishek UpadhyayNo ratings yet

- Lgu Night 2024 ScriptDocument13 pagesLgu Night 2024 Scriptmedy drizaNo ratings yet

- Zikr-e-Masoom (A.s.)Document262 pagesZikr-e-Masoom (A.s.)Shian-e-Ali Network0% (1)

- CV Marius Lupoian 12.12.2012 - enDocument5 pagesCV Marius Lupoian 12.12.2012 - enLupoian Florin MariusNo ratings yet

- Malunggay Oleifera As Cleaning AgentDocument2 pagesMalunggay Oleifera As Cleaning AgentMackieNo ratings yet

- AfterMath RulesDocument185 pagesAfterMath RulesWilliam May II67% (3)

- Date Itinerary Total Per Head x2 Rate (Est) : C/o Miss Pearl (7,000 3,500 Per Head) Taiwander (1,000/head)Document1 pageDate Itinerary Total Per Head x2 Rate (Est) : C/o Miss Pearl (7,000 3,500 Per Head) Taiwander (1,000/head)PatOcampoNo ratings yet

- CHEMFISH Fluorinated CompoundsDocument11 pagesCHEMFISH Fluorinated Compoundssunny StevenNo ratings yet

- Car Sales Cover LetterDocument8 pagesCar Sales Cover Letterf5de9mre100% (2)

- Peds HemeImmune OUTLINEDocument10 pagesPeds HemeImmune OUTLINEAshleyNo ratings yet

- Pyton Ls DynaDocument9 pagesPyton Ls DynaNandaNo ratings yet

- Zabala Auto SupplyDocument7 pagesZabala Auto SupplyLeighsen VillacortaNo ratings yet

- NABH Series5 HIC - 0Document57 pagesNABH Series5 HIC - 0Shejil BalakrishnanNo ratings yet

- MC CSSM JR Correction LSCQ3023 Courier Delivery Executive 16.07.2018Document16 pagesMC CSSM JR Correction LSCQ3023 Courier Delivery Executive 16.07.2018Abhishek ThakurNo ratings yet

- Sample Diary Curriculum Map SUBJECT: Mathematics QUARTER: Second Grade Level: 10 TOPIC: CircleDocument3 pagesSample Diary Curriculum Map SUBJECT: Mathematics QUARTER: Second Grade Level: 10 TOPIC: CircleRichimon LicerioNo ratings yet