Professional Documents

Culture Documents

Astm D2042-15

Astm D2042-15

Uploaded by

anjanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm D2042-15

Astm D2042-15

Uploaded by

anjanaCopyright:

Available Formats

Designation: D2042 − 15

Standard Test Method for

Solubility of Asphalt Materials in Trichloroethylene1

This standard is issued under the fixed designation D2042; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope cies Testing and Inspecting Road and Paving Materials

1.1 This test method covers the determination of the degree 2.2 AASHTO Standard:3

of solubility in trichloroethylene of asphalt materials having T44 Solubility of Bituminous Materials in Organic Solvents

little or no mineral matter.

3. Summary of Method

NOTE 1—This method is not applicable to tars and their distillation

residues or highly cracked petroleum products. For methods covering tars, 3.1 The sample is dissolved in trichloroethylene and filtered

pitches, and other highly cracked petroleum products, and the use of other through a glass fiber pad. The insoluble material is washed,

solvents, see Test Methods D4, D2318, and D2764.

dried, and weighed.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this 4. Significance and Use

standard.

4.1 This test method is a measure of the solubility of asphalt

1.3 The text of this standard references notes and footnotes in trichloroethylene. The portion that is soluble in trichloroeth-

which provide explanatory material. These notes and footnotes ylene represents the active cementing constituents.

(excluding those in tables and figures) shall not be considered

NOTE 2—The quality of the results produced by this standard are

as requirements of the standard. dependent on the competence of the personnel performing the procedure

1.4 This standard does not purport to address all of the and the capability, calibration, and maintenance of the equipment used.

safety concerns, if any, associated with its use. It is the Agencies that meet the criteria of Specification D3666 are generally

considered capable of competent and objective testing/sampling/

responsibility of the user of this standard to establish appro-

inspection/etc. Users of this standard are cautioned that compliance with

priate safety and health practices and determine the applica- Specification D3666 alone does not completely assure reliable results.

bility of regulatory limitations prior to use. Specific precaution Reliable results depend on many factors; following the suggestions of

statements are given in Section 7. Specification D3666 or some similar acceptable guideline provides a

means of evaluating and controlling some of these factors.

2. Referenced Documents

5. Apparatus and Materials

2.1 ASTM Standards:2

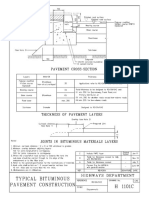

C670 Practice for Preparing Precision and Bias Statements 5.1 The assembly of a typical filtering apparatus is illus-

for Test Methods for Construction Materials trated in Fig. 1. Details of the component parts are as follows:

D4 Test Method for Bitumen Content 5.1.1 Bitumen Crucible or Gooch Crucible, glazed inside

D2318 Test Method for Quinoline-Insoluble (QI) Content of and outside with the exception of outside bottom surface. The

Tar and Pitch approximate dimensions shall be a diameter of 44 mm at the

D2764 Test Method for Dimethylformamide-Insoluble top, tapering to 36 mm at the bottom, and a depth of 20-30 mm.

(DMF-I) Content of Tar and Pitch 5.1.2 Glass Microfiber Filter Pad, 32–34 mm diameter, fine

D3666 Specification for Minimum Requirements for Agen- porosity, fast flow rate, 1.5 µm particle retention.

5.1.3 Filter Flask, heavy-wall, with side tube, 250-, 500-, or

1000-mL capacity.

1

This test method is under the jurisdiction of ASTM Committee D04 on Road 5.1.4 Filter Tube, 40- to 42-mm inside diameter.

--``,,`,,,,,,```,,,`,`,,```,``,,-`-`,,`,,`,`,,`---

and Paving Materials and is the direct responsibility of Subcommittee D04.47 on

Miscellaneous Asphalt Tests.

5.1.5 Rubber Tubing or Adapter, for holding the crucible on

Current edition approved June 1, 2015. Published July 2015. Originally approved the filter tube.

in 1966. Last previous edition approved in 2009 as D2042 – 09. DOI: 10.1520/

D2042-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Association of State Highway and Transportation

Standards volume information, refer to the standard’s Document Summary page on Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

the ASTM website. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright ASTM International

Provided by IHS Markit under license with ASTM

1Licensee=Vocational Training Council/5924389100, User=Hong, Haojue

No reproduction or networking permitted without license from IHS Not for Resale, 09/18/2018 20:39:37 MDT

D2042 − 15

solution shall be placed in a water bath maintained at 38.0 6

0.3°C for 1 h before filtering.

10. Procedure

10.1 Note safety precautions in Section 7. Transfer approxi-

mately 2 g of the sample into a tared 125-mL Erlenmeyer flask

or other suitable container. Smaller sample sizes may be

necessary if more than 0.5 % insoluble material is expected.

Allow the sample to cool to ambient temperature and then

determine the mass to the nearest 1 mg. Designate this mass as

B. Add 100 mL of the trichloroethylene to the container in

small portions with continuous agitation until all lumps disap-

pear and no undissolved sample adheres to the container.

Stopper the flask or otherwise cover the container and set aside

for at least 15 min (see Section 9.1).

10.2 Place the previously prepared and weighed crucible in

the filtering tube. Wet the filter pad with a small portion of

trichloroethylene and decant the solution through the filter pad

of the crucible with or without light suction as may be

necessary. When the insoluble matter is appreciable, retain as

much of it as possible in the container until the solution has

drained through the mat. Wash the container with a small

amount of solvent and, using a stream of solvent from a wash

bottle, transfer all insoluble matter to the crucible. Use a

“policeman” if necessary to remove any insoluble matter

adhering to the container. Rinse the policeman and container

thoroughly. Wash the insoluble matter in the crucible with

solvent until the filtrate is substantially colorless, then apply

strong suction to remove the remaining solvent. Remove the

FIG. 1 Filtering Apparatus Assembly crucible from the tube, wash the bottom free of any dissolved

matter, and place the crucible on top of an oven or on a steam

bath until all odor of the trichloroethylene is removed (see

NOTE 3—Other suitable assemblies permitting vacuum filtration with a safety precautions in Section 7). Place the crucible in an oven

crucible may be used.

at 110 6 5°C for at least 20 min. Cool the crucible in a

5.1.6 Erlenmeyer Flask, 125 mL. desiccator for 30 6 5 min and determine its mass to the nearest

5.1.7 Oven, capable of maintaining a temperature of 110 6 0.1 mg. Repeat the drying and weighing until constant mass (6

5°C. 0.3 mg) is obtained. Designate this mass as C.

6. Reagent NOTE 4—To obtain precise results, the cooling time in the desiccator

must be approximately the same (within 65 min) after all heatings. For

6.1 Trichloroethylene, technical grade. example, if the mass of the empty crucible is determined after a 30-min

cooling period in the desiccator, the mass of the crucible containing the

7. Safety Precautions insoluble matter should be determined after a 30 6 5-min cooling period

in the desiccator. Either empty crucibles or crucibles containing insoluble

--``,,`,,,,,,```,,,`,`,,```,``,,-`-`,,`,,`,`,,`---

7.1 Trichloroethylene is toxic, and good ventilation should matter that have remained in a desiccator overnight should be reheated in

be provided. an oven for at least 30 min, then allowed to cool for the prescribed period

before the mass is determined.

8. Preparation of Crucible

11. Calculation and Report

8.1 Place the crucible plus one thickness of the filter pad in

11.1 Calculate either the total percentage of insoluble matter

an oven at 110 6 5°C for 15 min, allow to cool in a desiccator

or the percentage of the sample soluble in the solvent used as

for 30 6 5 min, and then determine the mass to the nearest 0.1

follows:

mg. Designate this mass as A. Store in the desiccator until

ready for use. % Insoluble 5 S C2A

B

3 100 D (1)

9. Sample Preparation

9.1 If the sample is not fluid, heat to any convenient

% Soluble 5 S B 2 ~C 2 A!

B

3 100 D (2)

temperature, but in any case not more than 100°C above the

where:

softening point. Normally the temperature at which this test is

run is not critical, and it may be performed at the laboratory air A = mass of crucible and filter,

temperature. For referee tests, however, the flask and sample in B = mass of sample, and

Copyright ASTM International

Provided by IHS Markit under license with ASTM

2Licensee=Vocational Training Council/5924389100, User=Hong, Haojue

No reproduction or networking permitted without license from IHS Not for Resale, 09/18/2018 20:39:37 MDT

D2042 − 15

C = mass of crucible, filter and insoluble material. between 99.5 % and 100.0 %. For samples within this range,

the analysis suggests the following precision values are appro-

11.2 For percentages of insoluble less than 1.0, report to the

priate:

nearest 0.01 %. For percentages of insoluble 1.0 or more,

Multilab Standard Deviation (1S) = 0.01 + (0.75× % Insoluble)

report to the nearest 0.1 %. Single-Operator Standard Deviation (1S) = 0.01 + (0.25 × % Insoluble)

12. Precision 12.2 Since there is no accepted reference material suitable

12.1 AASHTO Materials Reference Laboratory (AMRL) for determining the bias in this test method, no statement on

data for Test Method D2042 (and its AASHTO equivalent bias is made.

standard, T44) were analyzed in 2001 as prescribed in Practice

C670. These data represent approximately 13 200 repetitions 13. Keywords

of the test, conducted on 132 samples having solubility values 13.1 asphalt; Gooch crucible; solubility; trichloroethylene

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the Copyright Clearance Center, 222

Rosewood Drive, Danvers, MA 01923, Tel: (978) 646-2600; http://www.copyright.com/

--``,,`,,,,,,```,,,`,`,,```,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS Markit under license with ASTM

3Licensee=Vocational Training Council/5924389100, User=Hong, Haojue

No reproduction or networking permitted without license from IHS Not for Resale, 09/18/2018 20:39:37 MDT

You might also like

- Specific Gravity of Soil Solids by The Water Displacement MethodDocument9 pagesSpecific Gravity of Soil Solids by The Water Displacement MethodHandyNo ratings yet

- 9500 ManualDocument37 pages9500 Manualanjana0% (1)

- Automated Extraction of Asphalt Binder From Asphalt MixturesDocument6 pagesAutomated Extraction of Asphalt Binder From Asphalt MixturesJose Luis Contreras RamaycunaNo ratings yet

- Astm D6934-08 (Me6) PDFDocument2 pagesAstm D6934-08 (Me6) PDFJosé Manuel MejíaNo ratings yet

- Astm D6930-19Document3 pagesAstm D6930-19dannychacon27100% (3)

- D559 D559M-15 Standard Test Methods For Wetting and DryingDocument6 pagesD559 D559M-15 Standard Test Methods For Wetting and DryingFaten Abou ShakraNo ratings yet

- Aashto t305Document3 pagesAashto t305SyahrulRamadhanNo ratings yet

- Astm D70 Rev ADocument5 pagesAstm D70 Rev Asawitri diah ayu komalaNo ratings yet

- Aashto T 269-111 - Astm D 3203-05Document4 pagesAashto T 269-111 - Astm D 3203-05iipmnpti iipmNo ratings yet

- D5444 PDFDocument3 pagesD5444 PDFZamir Danilo Morera Forero0% (1)

- D244-09 Standard Test Methods and Practices For Emulsified Asphalts - AASHTO No. T59Document9 pagesD244-09 Standard Test Methods and Practices For Emulsified Asphalts - AASHTO No. T59Vag Katsikopoulos100% (1)

- Sampling Bituminous Paving Mixtures: Standard Practice ForDocument4 pagesSampling Bituminous Paving Mixtures: Standard Practice ForAnonymous x7VY8VF7No ratings yet

- Astm D 5892Document3 pagesAstm D 5892Ricardo75% (4)

- ASTM D 560-96 Standard Test Methods For Freezing and Thawing Compacted Soil-Cement MixturesDocument6 pagesASTM D 560-96 Standard Test Methods For Freezing and Thawing Compacted Soil-Cement MixturesPablo Antonio Valcárcel Vargas100% (1)

- Astm D4402-15Document4 pagesAstm D4402-15SusanaTorresGonzálezNo ratings yet

- AASHTO M 231-95 (2002) Weighing Devices Used in The Testing of MaterialsDocument5 pagesAASHTO M 231-95 (2002) Weighing Devices Used in The Testing of MaterialsanjanaNo ratings yet

- AASHTO M 323-04 Superpave Volumetric Mix DesignDocument12 pagesAASHTO M 323-04 Superpave Volumetric Mix Designanjana100% (3)

- AASHTO M 270M 270-05 Structural Steel For BridgesDocument14 pagesAASHTO M 270M 270-05 Structural Steel For BridgesanjanaNo ratings yet

- Evolution of Patent System in IndiaDocument11 pagesEvolution of Patent System in IndiaMuskan KhatriNo ratings yet

- Bulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt MixturesDocument4 pagesBulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt MixturesKev SantiagoNo ratings yet

- Minimum Requirements For Agencies Testing and Inspecting Road and Paving MaterialsDocument7 pagesMinimum Requirements For Agencies Testing and Inspecting Road and Paving Materialsاحمد علي احمدNo ratings yet

- D7496 17334 PDFDocument3 pagesD7496 17334 PDFUsama TariqNo ratings yet

- ASTM D4402 - D4402M-15 (Reapproved 2022)Document4 pagesASTM D4402 - D4402M-15 (Reapproved 2022)anant1123550% (2)

- Astm D2172Document5 pagesAstm D2172Joaquin Dix's100% (1)

- Astm D6084 D6084M-21Document5 pagesAstm D6084 D6084M-21bestoon RamadhanNo ratings yet

- Estimating Application Rate and Residual Application Rate of Bituminous DistributorsDocument4 pagesEstimating Application Rate and Residual Application Rate of Bituminous DistributorsShaker Qaidi100% (2)

- Astm-D 5361Document3 pagesAstm-D 5361Ricardo Davila100% (1)

- D 692 - 00 Rdy5mi0wmaDocument2 pagesD 692 - 00 Rdy5mi0wmaRufo Casco0% (1)

- D 4867 - D 4867M - 04Document5 pagesD 4867 - D 4867M - 04Luisinho Alvarez ChávezNo ratings yet

- ASTM D-4753-9502-AmtysywDocument7 pagesASTM D-4753-9502-AmtysywAndres David HerradaNo ratings yet

- ASTM D 2042 - 09 - Standard Test Method For Solubility of Asphalt Materials in TrichloroethyleneDocument3 pagesASTM D 2042 - 09 - Standard Test Method For Solubility of Asphalt Materials in Trichloroethylenehenry rojas100% (2)

- D4753 19711 PDFDocument6 pagesD4753 19711 PDFeduardo bonillaNo ratings yet

- Astm D5444-15Document3 pagesAstm D5444-15UNUSED MUSIC MIRANDANo ratings yet

- ASTM D1461 (1994) - Moisture or Volatile Distillates in Bituminous Paving MixturesDocument5 pagesASTM D1461 (1994) - Moisture or Volatile Distillates in Bituminous Paving Mixturesnoto SugiartoNo ratings yet

- Astm D242 D242M 19Document1 pageAstm D242 D242M 19Mohamed SaadNo ratings yet

- ASTM D6927 - 15 Standard Test Method For Marshall Stability and Flow of Asphalt MixturesDocument2 pagesASTM D6927 - 15 Standard Test Method For Marshall Stability and Flow of Asphalt MixturesAzlan Abd50% (8)

- Evaluating, Selecting, and Specifying Balances and Standard Masses For Use in Soil, Rock, and Construction Materials TestingDocument6 pagesEvaluating, Selecting, and Specifying Balances and Standard Masses For Use in Soil, Rock, and Construction Materials TestingAhmedJardakNo ratings yet

- Quantitative Extraction of Bitumen From Bituminous Paving MixturesDocument12 pagesQuantitative Extraction of Bitumen From Bituminous Paving MixturesROHITNo ratings yet

- Aashto T265-15Document4 pagesAashto T265-15Besha aliNo ratings yet

- Residue by Evaporation of Emulsified Asphalt: Standard Test Method ForDocument2 pagesResidue by Evaporation of Emulsified Asphalt: Standard Test Method ForManuel Enrique VásquezNo ratings yet

- Astm D1558Document3 pagesAstm D1558johan lopez100% (1)

- AASHTO T283-14 (2018) - Resistance of Compacted Asphalt Mixtures To Moisture-Induced DamageDocument9 pagesAASHTO T283-14 (2018) - Resistance of Compacted Asphalt Mixtures To Moisture-Induced Damageferry2005No ratings yet

- Aashto T 391Document9 pagesAashto T 391Ramy Hussein100% (1)

- ASTM 4867 (Reapproved 2014) Standard Test Method For Effect of Moisture On Asphalt Concrete Paving MixturesDocument5 pagesASTM 4867 (Reapproved 2014) Standard Test Method For Effect of Moisture On Asphalt Concrete Paving MixturesErnesto Oscar VidelaNo ratings yet

- Astm10 0403Document7 pagesAstm10 0403Venu GopalNo ratings yet

- Astm C617 - C617M-23Document6 pagesAstm C617 - C617M-23vmuribecNo ratings yet

- Astm D140-15Document6 pagesAstm D140-15SusanaTorresGonzálezNo ratings yet

- Astm D36Document5 pagesAstm D36Oscar Mauricio Santos M80% (5)

- Kinematic Viscosity of Asphalts (Bitumens) : Standard Test Method ForDocument10 pagesKinematic Viscosity of Asphalts (Bitumens) : Standard Test Method ForMohamed Maamoun T.No ratings yet

- Temperature of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForDocument3 pagesTemperature of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForCory BradleyNo ratings yet

- C97 - C97M-18 Standard Test Methods For Absorption and Bulk Specific Gravity of Dimension StoneDocument4 pagesC97 - C97M-18 Standard Test Methods For Absorption and Bulk Specific Gravity of Dimension Stoneangeles vegaNo ratings yet

- Aashto TP 70-2007Document7 pagesAashto TP 70-2007Leonardo JaimesNo ratings yet

- 5 Astm c123 c123m 2011 Lighweight Particles in AggregateDocument4 pages5 Astm c123 c123m 2011 Lighweight Particles in AggregateGeorges Abi JaoudeNo ratings yet

- Astm D 2170 - 07Document10 pagesAstm D 2170 - 07m_seyedNo ratings yet

- Astm D6373 - 23Document5 pagesAstm D6373 - 23rtiyer1970No ratings yet

- Astm D5444Document3 pagesAstm D5444karenmerino94No ratings yet

- D 2041 D 2041M 11Document4 pagesD 2041 D 2041M 11gadNo ratings yet

- Calibration of Laboratory Mechanical-Rammer Soil Compactors: Standard Practices ForDocument6 pagesCalibration of Laboratory Mechanical-Rammer Soil Compactors: Standard Practices ForAbid HussainNo ratings yet

- ASTM D 2042 09 Standard Test Method For Solubility of Asphalt Materials in TrichloroethyleneDocument3 pagesASTM D 2042 09 Standard Test Method For Solubility of Asphalt Materials in TrichloroethyleneibnuruslanmNo ratings yet

- Solubility of Asphalt Materials in Trichloroethylene: Standard Test Method ForDocument3 pagesSolubility of Asphalt Materials in Trichloroethylene: Standard Test Method Forraja qammarNo ratings yet

- Solubility of Asphalt Materials in N-Propyl Bromide: Standard Test Method ForDocument3 pagesSolubility of Asphalt Materials in N-Propyl Bromide: Standard Test Method ForOscar LopezNo ratings yet

- Standard Test Method For Moisture or Volatile Distillates in Asphalt MixturesDocument6 pagesStandard Test Method For Moisture or Volatile Distillates in Asphalt MixturesP20TP004 HARSHAGOWDA G GANGANAGOWDAR SVNITNo ratings yet

- Quantitative Extraction of Bitumen From Bituminous Paving MixturesDocument5 pagesQuantitative Extraction of Bitumen From Bituminous Paving MixturesIsmail ALamerNo ratings yet

- Astm D2172-11Document13 pagesAstm D2172-11hugouzumaki12No ratings yet

- E1219-10 Standard Practice For Fluorescent Liquid Penetrant Testing Using The Solvent - Removable Process PDFDocument6 pagesE1219-10 Standard Practice For Fluorescent Liquid Penetrant Testing Using The Solvent - Removable Process PDFManuel Andres Mantilla DuranNo ratings yet

- Wearing Coat ThicknessDocument1 pageWearing Coat ThicknessanjanaNo ratings yet

- Preservation of Bituminous CarriagewayDocument32 pagesPreservation of Bituminous CarriagewayanjanaNo ratings yet

- kwah20mmWC Mix DesignDocument8 pageskwah20mmWC Mix DesignanjanaNo ratings yet

- Spindle and Speed of Brookfield ViscometerDocument3 pagesSpindle and Speed of Brookfield ViscometeranjanaNo ratings yet

- Vialit Cohesion and Cracking Performance: June 2016Document11 pagesVialit Cohesion and Cracking Performance: June 2016anjanaNo ratings yet

- Guidance Notes Application of Polymer Modified Stone Mastic AsphaltDocument7 pagesGuidance Notes Application of Polymer Modified Stone Mastic AsphaltanjanaNo ratings yet

- Evaluation of Bond Strength Between Pavement LayerDocument64 pagesEvaluation of Bond Strength Between Pavement LayeranjanaNo ratings yet

- 9900E Operators Manual - 3312016Document10 pages9900E Operators Manual - 3312016anjanaNo ratings yet

- AASHTO Part 2A Tests 2006Document27 pagesAASHTO Part 2A Tests 2006anjanaNo ratings yet

- Emulsified Asphalt Distillation ApparatusDocument1 pageEmulsified Asphalt Distillation ApparatusanjanaNo ratings yet

- Polymer Modified Binder, 2018Document11 pagesPolymer Modified Binder, 2018anjanaNo ratings yet

- Porous Asphalt-NZ UKDocument1 pagePorous Asphalt-NZ UKanjanaNo ratings yet

- Marshall Asphalt Base Course 132.6.16Document8 pagesMarshall Asphalt Base Course 132.6.16anjanaNo ratings yet

- DSR SHRP A 369Document15 pagesDSR SHRP A 369anjanaNo ratings yet

- Guidance Notes HW WorksDocument37 pagesGuidance Notes HW WorksanjanaNo ratings yet

- Pav SHRP A-367Document10 pagesPav SHRP A-367anjanaNo ratings yet

- Astm D1742 83Document6 pagesAstm D1742 83anjanaNo ratings yet

- Astm D4327 84Document8 pagesAstm D4327 84anjanaNo ratings yet

- Natural Stone Test Methods - Determination of Uniaxial Compressive StrengthDocument20 pagesNatural Stone Test Methods - Determination of Uniaxial Compressive Strengthanjana100% (1)

- World CementDocument4 pagesWorld CementMichael WarnerNo ratings yet

- Administrator Release Notes 211 EnuDocument28 pagesAdministrator Release Notes 211 EnuCretu RazvanNo ratings yet

- CSP Hmi 2 - I0r43tr10002p PDFDocument2,006 pagesCSP Hmi 2 - I0r43tr10002p PDFrobinyNo ratings yet

- Action Verbs Vocabulary Esl Missing Letters in Words Worksh0for Kids PDFDocument10 pagesAction Verbs Vocabulary Esl Missing Letters in Words Worksh0for Kids PDFHuayhualla Palomino EverNo ratings yet

- Rising in The World - Orison Swett MardenDocument575 pagesRising in The World - Orison Swett MardenWarrior SoulNo ratings yet

- Gretl Ref A4 PDFDocument226 pagesGretl Ref A4 PDFDianaNo ratings yet

- India MapDocument3 pagesIndia MapJyoti KumarNo ratings yet

- Lethal Lit: Murder of Crows ExcerptDocument17 pagesLethal Lit: Murder of Crows ExcerptI Read YANo ratings yet

- United States Patent: Annis (10) Patent No .: US 9, 742, 252 B2Document14 pagesUnited States Patent: Annis (10) Patent No .: US 9, 742, 252 B2Mladen MuskinjaNo ratings yet

- Crow Superband2 Jin San Kim KevinNitroDocument1 pageCrow Superband2 Jin San Kim KevinNitroПривет ЮтубNo ratings yet

- Broken Chessboard - Zbigniew BrzezinskiDocument5 pagesBroken Chessboard - Zbigniew BrzezinskibuhaptserenNo ratings yet

- Goraleczka Mateusz Mijal Dukat Keyboard IgniaeDocument3 pagesGoraleczka Mateusz Mijal Dukat Keyboard IgniaeMarcin NykielNo ratings yet

- Commonly Used Tcodes in SAP PP Module Part 1Document3 pagesCommonly Used Tcodes in SAP PP Module Part 1Sidharth KumarNo ratings yet

- Minter Et. Al. v. AdswizzDocument4 pagesMinter Et. Al. v. AdswizzPriorSmartNo ratings yet

- Asmolean MuseumDocument210 pagesAsmolean MuseumMustafaNo ratings yet

- Erotic Paranormal Romance Amazon Awakening ExcerptDocument8 pagesErotic Paranormal Romance Amazon Awakening ExcerptCaridad Pineiro0% (1)

- DB13 FixDocument5 pagesDB13 FixanupamNo ratings yet

- Formato para VPN Site2sitev3Document4 pagesFormato para VPN Site2sitev3Alex PalaciosNo ratings yet

- Course Um970: Wireless DMS MCS/VLR TranslationsDocument9 pagesCourse Um970: Wireless DMS MCS/VLR Translationshungpm2013No ratings yet

- Roland CutChoiceDocument24 pagesRoland CutChoiceDexter DanielNo ratings yet

- C H McIlwain - The High Court of Parliament and Its SupremacyDocument447 pagesC H McIlwain - The High Court of Parliament and Its SupremacyPedro AlcantaraNo ratings yet

- TN3 Assessment Final ExamDocument14 pagesTN3 Assessment Final ExamHajiime HinataNo ratings yet

- Dharma No SakshatkarDocument101 pagesDharma No SakshatkarNIRAV PANDYANo ratings yet

- Introduction To Trademark Law 1573639273Document5 pagesIntroduction To Trademark Law 1573639273soumyaNo ratings yet

- Adventures of Huckleberry Finn: Disc 6 Disc 1Document1 pageAdventures of Huckleberry Finn: Disc 6 Disc 1José Luis Marcos DiezNo ratings yet

- Guide To Estimating Wind SpeedsDocument1 pageGuide To Estimating Wind SpeedsfcaskiiNo ratings yet

- HFP v1.7.1Document144 pagesHFP v1.7.1sjbv.hardik582No ratings yet

- Sony v. CoxDocument32 pagesSony v. CoxBillboardNo ratings yet

- UGLE Apporved Pathway StepsDocument24 pagesUGLE Apporved Pathway StepsmicrodartNo ratings yet