Professional Documents

Culture Documents

Standard Features: RHF - High Temperature Chamber Furnaces 35

Standard Features: RHF - High Temperature Chamber Furnaces 35

Uploaded by

Hamed HamidpourOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Features: RHF - High Temperature Chamber Furnaces 35

Standard Features: RHF - High Temperature Chamber Furnaces 35

Uploaded by

Hamed HamidpourCopyright:

Available Formats

Chamber Furnaces

up to 1600 °C RHF – High Temperature

35

0 1000 2000 3000 [[°C]]

Chamber Furnaces

The RHF range of silicon carbide heated high

temperature chamber furnaces comprises four chamber

sizes, each available with three maximum operating

temperatures of 1400 °C, 1500 °C and 1600 °C.

Robust construction and high quality elements provide

rapid heating rates (typically reaching 1400 °C in under

40 minutes) and a long reliable working life.

Standard features

• 1400 °C, 1500 °C or 1600 °C maximum operating

temperature

• Carbolite Gero 301 PID controller with single ramp

to setpoint & process timer

• 3, 8, 15 or 35 litre chamber volumes

• NEW Soft closing parallel action door (3 & 8 litre

models only)

• Silicon carbide heating elements provide long life and are

able to withstand the stresses of intermittent operation

• RHF 3 & 8 litre have a cast alumina hearth

RHF 16/35 with 3216P1

RHF 15 & 35 have silicon carbide hearth

programmer and over-

• Low thermal mass insulation for energy efficiency & RHF 15/3

/3 with

i h33508P1

08 temperature options

rapid heating & cooling programmer option

Options (specif y these at time of order) Power supplies for RHF furnaces

• A range of sophisticated digital controllers, multi-segment A characteristic of the control systems used with silicon

programmers and data loggers is available. These can carbide elements results in a power supply which will be

be fitted with RS232, RS485 or Ethernet communications larger than expected e. g. RHF 14/3 at 4500 W =

(see pages 100 – 103) • Single phase / 200 – 240 V / 30 A or

• Over-temperature protection (recommended to protect • 2 phase / 380 – 415 V / 15 A per phase.

valuable contents & for unattended operation)

See pages 112 – 117 for power supply information.

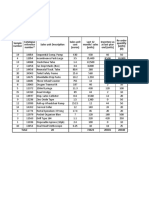

Technical data

Max. Dimensions: Dimensions:

CG H

temp. Heat-up time Internal H x W x D External H x W x D Volume Holding power Max. power Thermocouple Weight

Model [°C] [mins] [mm] [mm] H (door open) [litres] [W] [W] type [kg]

RHF 14/3 1400 33 120 x 120 x 205 655 x 435 x 610 (905) (Bench-top) 3 1900 4500 R 42

RHF 14/8 1400 22 170 x 170 x 270 705 x 505 x 675 (990) (Bench-top) 8 3200 8000 R 64

RHF 14/15 1400 35 220 x 220 x 310 810 x 690 x 780 (1105) (Bench-top) 15 2900 10000 R 125

RHF 14/35 1400 38 250 x 300 x 465 885 x 780 x 945 (1245) (Bench-top) 35 6000 16000 R 179

RHF 15/3 1500 45 120 x 120 x 205 655 x 435 x 610 (905) (Bench-top) 3 2000 4500 R 46

RHF 15/8 1500 40 170 x 170 x 270 705 x 505 x 675 (990) (Bench-top) 8 3500 8000 R 61

RHF 15/15 1500 46 220 x 220 x 310 810 x 690 x 780 (1105) (Bench-top) 15 3000 10000 R 125

RHF 15/35 1500 46 250 x 300 x 465 885 x 780 x 945 (1245) (Bench-top) 35 6200 16000 R 178

RHF 16/3 1600 42 120 x 120 x 205 655 x 435 x 610 (905) (Bench-top) 3 2300 4500 R 42

RHF 16/8 1600 35 170 x 170 x 270 705 x 505 x 675 (990) (Bench-top) 8 4000 8000 R 61

RHF 16/15 1600 58 220 x 220 x 310 810 x 690 x 780 (1105) (Bench-top) 15 3500 10000 R 140

RHF 16/35 1600 113 250 x 300 x 465 1530 x 900 x 1020 (1885) (Floor-standing) 35 7000 16000 R 270

Please note:

- Maximum continuous operating temperature is 100 °C below maximum temperature - Holding power is measured at continuous operating temperature

- Heat up time is measured to 100 °C below max, using an empty chamber

www.carbolite-gero.com | Leading Heat Technology

You might also like

- Hitachi Air-Cooled Chiller PDFDocument46 pagesHitachi Air-Cooled Chiller PDFJeffrey Chua60% (5)

- Fineness of Hydraulic Cement by The 45 - M (No. 325) Sieve: Standard Test Method ForDocument3 pagesFineness of Hydraulic Cement by The 45 - M (No. 325) Sieve: Standard Test Method ForHamed HamidpourNo ratings yet

- EbooksHouse Super Earth Encyclopedia - DKDocument210 pagesEbooksHouse Super Earth Encyclopedia - DKRaj100% (6)

- Overview of Functions and Operations BSPDocument2 pagesOverview of Functions and Operations BSPKarla GalvezNo ratings yet

- Maptek I-Site Studio Geotechnical ModuleDocument4 pagesMaptek I-Site Studio Geotechnical ModulekennycasillaNo ratings yet

- Espec Environmental Stress ChamberDocument24 pagesEspec Environmental Stress Chamberck_peyNo ratings yet

- Heat Pumps Co2Document8 pagesHeat Pumps Co2Domagoj VulinNo ratings yet

- Tx7 Series Thermostatic Expansion Valves en Us 1733664Document2 pagesTx7 Series Thermostatic Expansion Valves en Us 1733664Brian ByengaboNo ratings yet

- Tx7 Series Thermostatic Expansion Valves en Us 1733664Document2 pagesTx7 Series Thermostatic Expansion Valves en Us 1733664Jak JoniNo ratings yet

- Matushima Servicemanual UkDocument30 pagesMatushima Servicemanual Ukgeorge dimopoulosNo ratings yet

- CAJA FULLER - ENFRIADOR CAJA - ACEITE - Eaton - Oilcoolers - HeatexchangersDocument2 pagesCAJA FULLER - ENFRIADOR CAJA - ACEITE - Eaton - Oilcoolers - HeatexchangersWERNER SILVA ALVAREZNo ratings yet

- The Design and Performance Analysis of Refrigeration System Using R12 and R134A RefrigerantDocument19 pagesThe Design and Performance Analysis of Refrigeration System Using R12 and R134A Refrigerantjerico castilloNo ratings yet

- E No.04-01Document14 pagesE No.04-01Erdinc Senman0% (1)

- Copeland 4re2-200a-Tsk-800 Article 1377777674228 en SsDocument1 pageCopeland 4re2-200a-Tsk-800 Article 1377777674228 en SsGhulam HussainNo ratings yet

- #081 Danfoss AntoineAbboud v1 PDFDocument20 pages#081 Danfoss AntoineAbboud v1 PDFSyed Ali KhanNo ratings yet

- Danfoss Compressors r600 BrochureDocument6 pagesDanfoss Compressors r600 BrochureSyed Noman Ahmed100% (6)

- HGX34e R407C GBDocument8 pagesHGX34e R407C GBRodrigo GonçalvesNo ratings yet

- Hisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgDocument34 pagesHisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgRajesh SoniNo ratings yet

- Refcomp SRC-S&134-S For AC SeriesDocument51 pagesRefcomp SRC-S&134-S For AC SeriesajajsainNo ratings yet

- ZF48K4E-TW7 - ResumoDocument1 pageZF48K4E-TW7 - ResumoBruno MonteiroNo ratings yet

- Danfoss CompresorHermetico MP-MLDocument34 pagesDanfoss CompresorHermetico MP-MLOswaldo GomezNo ratings yet

- LHGH EvaporadoresDocument12 pagesLHGH EvaporadoresluismozoNo ratings yet

- Ar A Prova de ExplosãoDocument2 pagesAr A Prova de ExplosãoMailthon Ritter GilNo ratings yet

- Product Information Packet: Model AHP-150FFDocument8 pagesProduct Information Packet: Model AHP-150FFhalcon ceroNo ratings yet

- Technical Service Manual: Rooftop PackageDocument100 pagesTechnical Service Manual: Rooftop PackagelinoNo ratings yet

- V-800 Series: The Most Powerful Vehicle-Powered Solution For Medium and Large Truck ApplicationsDocument4 pagesV-800 Series: The Most Powerful Vehicle-Powered Solution For Medium and Large Truck ApplicationsYonathan TafeseworkNo ratings yet

- Dry Vacuum Pump (LR/HR/UR Series) : FeaturesDocument4 pagesDry Vacuum Pump (LR/HR/UR Series) : FeaturesHảo UlvacNo ratings yet

- Na16643a H 4000 TPLDocument17 pagesNa16643a H 4000 TPLMiroslav LuladžićNo ratings yet

- Compresores DanfossDocument2 pagesCompresores DanfossrocagomezaNo ratings yet

- Evap. KeeprideDocument44 pagesEvap. KeeprideAbdiel Kadir Martinez MendozaNo ratings yet

- RTHB 215-450: Helirotor Compressor Liquid Chillers 620 To 1370 KWDocument1 pageRTHB 215-450: Helirotor Compressor Liquid Chillers 620 To 1370 KWMohamed MohamedNo ratings yet

- T-Series Mid-Size Outdoor: T29 T43 T50 T53Document18 pagesT-Series Mid-Size Outdoor: T29 T43 T50 T53MarioNo ratings yet

- FP - A.1 - HK Electric - Safety in Design and Installation of Heat Recovery Steam GeneratorDocument10 pagesFP - A.1 - HK Electric - Safety in Design and Installation of Heat Recovery Steam GeneratorJohnNo ratings yet

- Optyma™Pack Just Mount, Connect Pipingand PlugDocument10 pagesOptyma™Pack Just Mount, Connect Pipingand PlugNikolas ChionasNo ratings yet

- KSB RioRioZDocument32 pagesKSB RioRioZSrdjanNo ratings yet

- Telca TAF-50D-02ADocument5 pagesTelca TAF-50D-02AmeNo ratings yet

- Solahart Domestic Heat Pump - Sample CatalogueDocument2 pagesSolahart Domestic Heat Pump - Sample CatalogueManju NaikNo ratings yet

- Data Sheet: HEF40193B MSIDocument10 pagesData Sheet: HEF40193B MSIPedroZevallosNo ratings yet

- Heat Exchangers, Suction Heaters & Heating Coils: HEAT EXCHANGER Product DescriptionDocument6 pagesHeat Exchangers, Suction Heaters & Heating Coils: HEAT EXCHANGER Product DescriptionhamedpdmsNo ratings yet

- ZR16 M3e TWD 551Document1 pageZR16 M3e TWD 551Nazim VladimNo ratings yet

- 7 2011DS-4 WDocument8 pages7 2011DS-4 WMaria DazaNo ratings yet

- Catalogo KeepriteDocument44 pagesCatalogo KeepriteMiguel JulianNo ratings yet

- Manual de Ingenieria: (50Hz/R410A)Document51 pagesManual de Ingenieria: (50Hz/R410A)Edu Lopez GarciaNo ratings yet

- Keeprite Refrigeration KMPDocument36 pagesKeeprite Refrigeration KMPVíctor HugoNo ratings yet

- On Industrial Training in Bhel HaridwarDocument38 pagesOn Industrial Training in Bhel HaridwarYogesh SurveNo ratings yet

- MOVA CN BW EngDocument1 pageMOVA CN BW Engfopoku2k2No ratings yet

- Tecumseh Competitive Cross RefDocument80 pagesTecumseh Competitive Cross RefLoana Sofia Millan Carrera82% (11)

- Embaraco Compressor GesamtlisteDocument16 pagesEmbaraco Compressor Gesamtlisteأبو زينب المهندسNo ratings yet

- PTZ 781 Rev 0Document8 pagesPTZ 781 Rev 0ElianMNo ratings yet

- Agn013 CDocument10 pagesAgn013 Cmohsen_cumminsNo ratings yet

- Manual Rooftop On-OffDocument73 pagesManual Rooftop On-OffGerman CiclonNo ratings yet

- ExHeat - HRF Flanged Industrial Immersion HeatersDocument2 pagesExHeat - HRF Flanged Industrial Immersion HeatersVictor PomboNo ratings yet

- R290 Propane: AJ AE HG VTCDocument16 pagesR290 Propane: AJ AE HG VTCengmec12188No ratings yet

- Evaporadoras 3HpDocument44 pagesEvaporadoras 3HpAlexis PradoNo ratings yet

- Rtad Heat Recovery CatalogDocument48 pagesRtad Heat Recovery Catalogaidoudi walidNo ratings yet

- Defense Cooling and Compressed Air Carts 3Document2 pagesDefense Cooling and Compressed Air Carts 3ravi1111vermaNo ratings yet

- Power Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryFrom EverandPower Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Heating Equipment World Summary: Market Values & Financials by CountryFrom EverandHeating Equipment World Summary: Market Values & Financials by CountryNo ratings yet

- Loi CCO - SARL 1 PDFDocument1 pageLoi CCO - SARL 1 PDFHamed HamidpourNo ratings yet

- Thermogravimetric Analysis (TGA) Methodology of Calculating TheDocument15 pagesThermogravimetric Analysis (TGA) Methodology of Calculating TheHamed HamidpourNo ratings yet

- Technique of Sample Preparation (1) - 1 PDFDocument7 pagesTechnique of Sample Preparation (1) - 1 PDFHamed HamidpourNo ratings yet

- C1872 − 18ε2Document7 pagesC1872 − 18ε2Hamed HamidpourNo ratings yet

- Estimation of Hydration Degree of Blended Cements With The Help of K-ValuesDocument13 pagesEstimation of Hydration Degree of Blended Cements With The Help of K-ValuesHamed HamidpourNo ratings yet

- Mineralogical Evolution of Cement Pastes at Early Ages BasedDocument8 pagesMineralogical Evolution of Cement Pastes at Early Ages BasedHamed HamidpourNo ratings yet

- Transient Modelling of A Rotary-Kiln Pyrolyser: A. Traverso, R. Bertone and A.F. MassardoDocument13 pagesTransient Modelling of A Rotary-Kiln Pyrolyser: A. Traverso, R. Bertone and A.F. MassardoHamed HamidpourNo ratings yet

- Cement Presentation 190524154235Document139 pagesCement Presentation 190524154235Hamed Hamidpour100% (1)

- Manufacturing Ordinary Portland Cement: Presented by AglaiaDocument18 pagesManufacturing Ordinary Portland Cement: Presented by AglaiaHamed HamidpourNo ratings yet

- A Facile and e Cient Synthesis of Highly Functionalised 3,3 - Dispiropyrrolidine-And 3,3 - Dispiropyrrolizidine Bisoxindoles Via (3+2) CycloadditionDocument5 pagesA Facile and e Cient Synthesis of Highly Functionalised 3,3 - Dispiropyrrolidine-And 3,3 - Dispiropyrrolizidine Bisoxindoles Via (3+2) CycloadditionHamed HamidpourNo ratings yet

- Derudwru/&Kdpehu) Xuqdfh&:) : Hqhudo, QirupdwlrqDocument2 pagesDerudwru/&Kdpehu) Xuqdfh&:) : Hqhudo, QirupdwlrqHamed HamidpourNo ratings yet

- B. Sigmatropic RearrangementsDocument10 pagesB. Sigmatropic RearrangementsHamed HamidpourNo ratings yet

- هندبوک جیبی بکائیانDocument92 pagesهندبوک جیبی بکائیانHamed HamidpourNo ratings yet

- Dispersion PollutantsDocument18 pagesDispersion PollutantsAmira GogoantaNo ratings yet

- A 304 - 11 Aceros Tipo HDocument48 pagesA 304 - 11 Aceros Tipo Halucard375No ratings yet

- Hughes2007 PDFDocument21 pagesHughes2007 PDFThiago CancianNo ratings yet

- NDRRMC UPDATE Re SitreDocument31 pagesNDRRMC UPDATE Re SitreQuiapo ChurchNo ratings yet

- Adina ModelisationDocument240 pagesAdina ModelisationSafia SoufiNo ratings yet

- Discuss Vision StatementDocument4 pagesDiscuss Vision StatementAKINDE DAMILOLANo ratings yet

- Klystron TubeDocument21 pagesKlystron TubeRavi Kapatel100% (1)

- Industrial PaintingDocument312 pagesIndustrial Paintingyoners1691No ratings yet

- PG Prospectus 2022Document20 pagesPG Prospectus 2022Harshit AmbeshNo ratings yet

- Product CatalogDocument30 pagesProduct CatalogVeri Ambar SariNo ratings yet

- DC/DC Converters: FeaturesDocument3 pagesDC/DC Converters: FeaturesPustinjak SaharicNo ratings yet

- Hazardous AreasDocument118 pagesHazardous AreaskamalNo ratings yet

- PosterDocument1 pagePosterSaad Ullah100% (2)

- SLE MCQDocument9 pagesSLE MCQAsif NewazNo ratings yet

- Q& A Operation Management CaseDocument4 pagesQ& A Operation Management CaseAbdullah Al MunirNo ratings yet

- SOLUTION VECTOR ANALYSIS BY S M YUSUF PDF - Are You Looking For Solution VectorDocument6 pagesSOLUTION VECTOR ANALYSIS BY S M YUSUF PDF - Are You Looking For Solution VectorZara Malik67% (3)

- A202Document3 pagesA202Edisson CordovaNo ratings yet

- Kotamovol2no5 WardialamsyahDocument27 pagesKotamovol2no5 WardialamsyahRo'onspadoSiiTorusNo ratings yet

- EC6304-Electronic Circuits-I PDFDocument11 pagesEC6304-Electronic Circuits-I PDFShinu PaulNo ratings yet

- FibromaDocument3 pagesFibromaAsiyath HNo ratings yet

- Lab Report 1Document5 pagesLab Report 1jvelezdanielaNo ratings yet

- Orthognathic Surgery Types and Indications: Mousa Ibrahim MousaDocument42 pagesOrthognathic Surgery Types and Indications: Mousa Ibrahim MousahashimalarwliaNo ratings yet

- Germany Import ExportDocument12 pagesGermany Import Exporttariquekhan143No ratings yet

- QA SNT Amdt 1Document2 pagesQA SNT Amdt 1raj2404No ratings yet

- Earthquake Resistance BuildingDocument62 pagesEarthquake Resistance BuildingTGODA_13No ratings yet

- Secondary 6 FCE ExamPack SEVENDocument3 pagesSecondary 6 FCE ExamPack SEVENamtenistaNo ratings yet

- A Christmas Carol Revision GuideDocument11 pagesA Christmas Carol Revision Guidehedy 해디No ratings yet