Professional Documents

Culture Documents

4y - ENGINEce602 2 (131 140)

4y - ENGINEce602 2 (131 140)

Uploaded by

David Quispe0 ratings0% found this document useful (0 votes)

9 views10 pagesOriginal Title

4y_ENGINEce602-2[131-140]

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

9 views10 pages4y - ENGINEce602 2 (131 140)

4y - ENGINEce602 2 (131 140)

Uploaded by

David QuispeCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 10

56

WATER PUMP ASSY

REMOVAL

1. Coolant draining

(1) Open the engine hood

(2) Loosen tha radiator and engine drain

plugs to drain the coolant.

2. Fan shround removal (in torque converter

model)

3. Fan, fan pulley and V-belt removal

(1) Loosen ‘the alternator adjusting bolt

(2) Remove four set bolts, and remove the

fan, fan pulley and V-belt.

4, Radiator autlet hose disconnection

(1) Disconnect the radiator outlet hose

from the engine.

5. Water pump w/ thermostat removal

(1) Remove the union bolt for the water

outlet hose.

(2) Disconnect the water inlet hose from

the water pump.

(3) Remove four water pump set bolts, and

then remove the water pump and gasket,

6 Thermostat removal

(1) Remove two set bolts, and disconnect

the water inlet from the water pump

body.

(2), Romove the thermostat,

(3). Remove the water bypass flange.

Drain cook

Drain plug

Drain Cock and Plug Positions Kasea

KAISE9

KAus90

Flemoving the Water Pump wi Thermostat KAJS67

~129-

58

7. Water pump cover ASSY removal

(1), Remove five nuts, and remove the water

pump cover ASSY and gasket

INSPECTION

1. Water pump inspection

(1) Make sure that each part is not cracked

cor damages.

2. Water pump bearing inspection

(1) Make sure that the bearing rotates

smoothly without abnormal sound.

INSTALLATION

1. Water pump cover ASSY installation

(1) Position the water pump cover ASSY so

that the drain holes are placed up and

own,

(2) Fix the cover to the pump body with a

new gasket in-between by tightening

five set nuts.

Femoving the Purp Gover ASSY

exw!

CAL

5175

Ingtaling the Water Pump Cover

= 130 —

KAIS68

59

2

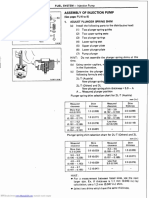

Water bypass flange installation

(1) Drive in the bypass flange to the water

ump inlet portion. The notch on the

flange shall face the inlet mounting bolt

hole direction.

Thermostat installation

(See page 55.)

Water pump installation

(1) Remove the old gasket adhered on the

water pump and cylinder block.

(2) Install the water pump witha new gasket

inbetween, and tighten four set bolts.

T= 1,85 kom

(3) Connect the water inlet hose to the

water pump.

(4) Install the water outlet pipe union bolt.

Radiator outlet hose instalation

Fan pulley, V-belt and fan installation.

Soe page 1-3 for V-belt adjustment

Coolant filing

(Seo page 5:5.)

Water leak check

Noten

Noten

Installing the Water Bypass Flange KAsSe2

Installing the Water Pump Cover KAIS6S

=131-

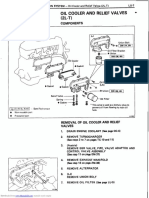

OIL PRESSURE INSPECTION

OIL FILTER ..

OIL PUMP........

LUBRICATION SYSTEM

Page

62

63

66

e2

OIL PRESSURE INSPECTION

1. Oil inspection

(1) Make sure that the engine oil does not

‘contain with coolant or gasoline.

(2) Check proper viscosity without exces

sive contamination,

(2) Check that the ail level is between F

{and L lines on the ol level gauge.

2. Oil pressure switch removal

3. Oil pressure gauge installation

4, Engine warm-up

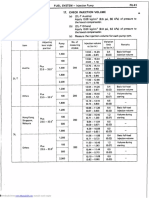

Standard:

Coolant temperature

75 — 85°C (167 ~ 185°F)

Hydraulic temperature

50°C oF more

5. Oil pressure measurement

Standard:

At idle speed 0.3 kglem? or more

(4.3 psi)

‘At 2000 rpm 2.0~ 4.5 kglom?

(28.4 ~ 64.0 psid

6. Oil pressure switch installation

T= 1.0 kom (7 fel)

Lv0300

Inspecting the Oi Pressure ‘Luc296

= 134

OIL FILTER

o4

ENGINE OIL FILTER

REPLACEMENT

1. Engine oil draining

(1), Remove the oil filer cap,

(2) Prepare a container for drained ol

(3) Remove the oil pan drain plug to drain

the engine ol

2. Oil filter removal

(1) Use the SST to remove the oil filter.

‘SST 09228-76005.71

(ST 09228-22020}

3. Oil filter installation

(1) Clean the ol filter mounting surface,

(2) Coat clean engine oil on the gasket of

the new oil filter.

(3) Lightly screw in the oil filter by and

Until the gasket is brought into contact

with the filter bracket

(4) Use the SST for further tightening by

3/4 turn

‘SST 09228-76005-71

(SST 08228-22020)

KAIST

Installing the Ol iter (1)

Installing the Oi Filter (2)

= 136 —

‘Lv0006,0007

a

(1) Install the oil drain plug with the new

gasket in between,

Caution

Clean the mounting surface.

Fillo)

Total capacity (when oll and filter

are replaced): 4.08 (1.1 US gal)

Oil pan capacity (when only oil is

replaced): 3.28 (0.8 US gal)

(3) Install the oil filler cap,

0 level and leak inspection

(1) Pull out the dipstick and check the oil

level

Start the engine and check that no oil is

leaking

(3) Check that the oil level is between F

‘and L marks on the oil level gauge,

Inspecting the Engine Ol! Level

Kasai

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Descubre Como Reparar Modulos Automotrices en 8 Pasos-12-14Document3 pagesDescubre Como Reparar Modulos Automotrices en 8 Pasos-12-14David QuispeNo ratings yet

- Descubre Como Reparar Modulos Automotrices en 8 Pasos-9-12Document4 pagesDescubre Como Reparar Modulos Automotrices en 8 Pasos-9-12David QuispeNo ratings yet

- !3imzy: Oil Cooler and Relief ValvesDocument6 pages!3imzy: Oil Cooler and Relief ValvesDavid QuispeNo ratings yet

- Atmega16 (L) : Table 106. Pin Name Mapping (Continued)Document6 pagesAtmega16 (L) : Table 106. Pin Name Mapping (Continued)David QuispeNo ratings yet

- Peaae 1 5Document5 pagesPeaae 1 5David QuispeNo ratings yet

- Troubleshooting: Downloaded From Manuals Search EngineDocument6 pagesTroubleshooting: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Atmega16 (L) : Programming The EepromDocument6 pagesAtmega16 (L) : Programming The EepromDavid QuispeNo ratings yet

- Starting System: Differ From The Above Listed ManualDocument6 pagesStarting System: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Descubre Como Reparar Modulos Automotrices en 8 Pasos-6-9Document4 pagesDescubre Como Reparar Modulos Automotrices en 8 Pasos-6-9David QuispeNo ratings yet

- Datasheet (3) (254-284) - 1-5Document5 pagesDatasheet (3) (254-284) - 1-5David QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- 2L-T W/ Hac: Downloaded From Manuals Search EngineDocument6 pages2L-T W/ Hac: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Inspection and Repair of Crankshaft: Crank Journal DiameterDocument6 pagesInspection and Repair of Crankshaft: Crank Journal DiameterDavid QuispeNo ratings yet

- Is As: &sleeve PlugDocument6 pagesIs As: &sleeve PlugDavid QuispeNo ratings yet

- Fuel System FU-31 2. Pre-Set Full Load Injection VolumeDocument6 pagesFuel System FU-31 2. Pre-Set Full Load Injection VolumeDavid QuispeNo ratings yet

- I Removal of TurbochargerDocument6 pagesI Removal of TurbochargerDavid QuispeNo ratings yet

- Installation of Injection Pump: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Injection Pump: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Fuel System FU-11 11. Remove Governor Cover: Downloaded From Manuals Search EngineDocument6 pagesFuel System FU-11 11. Remove Governor Cover: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Downloaded From Manuals Search EngineDocument6 pagesDownloaded From Manuals Search EngineDavid QuispeNo ratings yet

- System: Differ From The Above Listed ManualDocument6 pagesSystem: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- Volkswagen Pointer Con Distribuidor y Sistema DIS (01 10) PDFDocument10 pagesVolkswagen Pointer Con Distribuidor y Sistema DIS (01 10) PDFDavid QuispeNo ratings yet

- Assembly of Injection Pump: FU-16 Fuel SystemDocument6 pagesAssembly of Injection Pump: FU-16 Fuel SystemDavid QuispeNo ratings yet

- Components: Downloaded From Manuals Search EngineDocument6 pagesComponents: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Intake Venturi System (LN 2L-T: Only)Document11 pagesIntake Venturi System (LN 2L-T: Only)David QuispeNo ratings yet

- Troubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDocument6 pagesTroubleshooting: Insufficient Acceleration, Lack of Power or Excessive Fuel ConsumptionDavid QuispeNo ratings yet

- Excessive Exhaust S M O K E: Downloaded From Manuals Search EngineDocument11 pagesExcessive Exhaust S M O K E: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXDocument11 pagesAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeNo ratings yet

- Volkswagen Pointer Con Distribuidor y Sistema DIS (21 30)Document10 pagesVolkswagen Pointer Con Distribuidor y Sistema DIS (21 30)David QuispeNo ratings yet

- Universidad San Francisco de Quito-Usfq: Colegio de Ciencias e IngenieríasDocument10 pagesUniversidad San Francisco de Quito-Usfq: Colegio de Ciencias e IngenieríasDavid QuispeNo ratings yet