Professional Documents

Culture Documents

HILO Takes The Guesswork Out of Setting Adjustable Ring Gages

HILO Takes The Guesswork Out of Setting Adjustable Ring Gages

Uploaded by

Mariangel Rodríguez GómezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HILO Takes The Guesswork Out of Setting Adjustable Ring Gages

HILO Takes The Guesswork Out of Setting Adjustable Ring Gages

Uploaded by

Mariangel Rodríguez GómezCopyright:

Available Formats

HILO™ Takes The Guesswork Out

Of Setting Adjustable Ring Gages

Most times, you have to rely on an individual’s sense of “good feel”, “good fit”, or amount of “shake”, to set an

adjustable ring gage with a truncated setting plug gage. And sometimes the accuracy of human judgement is highly

debatable…especially if you’re looking at hundreds of rejected parts.

A HILO setting plug gage provides optimum ring gage accuracy, without subjective human judgements for “fit”,

“feel”, or “shake”. It only relies on an inspector to turn it into the thread ring, and then helps the inspector make

foolproof adjustments. Here’s how:

First, the adjustable ring is set so it can be threaded onto the LO pitch diameter. The second, or HI pitch diameter

portion indicates that the setting is too high if the ring gage can be threaded on to it more than 1½ turns. The setting is

correct when the adjustable ring gage can be threaded only onto the LO pitch diameter portion, but not more than 1½

turns on the HI. It’s that simple!

HILO Prolongs Ring Gage Life

How many gages has your company scrapped or sent to be reconditioned because the “feel”, “fit”, or “shake” wasn’t

right? HILO set plugs can tell you without a doubt when flanks are excessively worn, or too much “bellmouthing” has

affected the accuracy of your gage. Plus, since HILO plugs are designed for the full use of the pitch diameter tolerance,

you can often discover additional tolerances in thread rings that couldn’t be found with conventional set plug gages.

More Than Just a Setting Plug

HILO is the only plug gage available with the HI and LO portions ground and lapped with identical lead and angles.

That means you can use a HILO plug gage to perform positive and dependable wear checks on solid ring gages too.

HILO Thread Setting Gages For Standard and Special Threads

HILO master setting plug gages are designed to precisely size and check minimum and maximum tolerances of

adjustable and solid type threaded ring gages. They’re also ideal for checking flanks and angles for wear, and to

determine excessive “bell mouthing”. Each gage is engraved to indicate: size, threads per inch, thread type, and

minimum pitch diameter limit for quick identification.

For Highly Accurate Adjustable Ring Gage Settings

HILO set plugs take the guesswork out of setting high and low tolerances on adjustable thread ring gages. These

unique setting plugs are designed with two different thread pitch diameters. The front portion is the low tolerance

limit, and the back portion is the high tolerance limit. By adjusting the ring gage so it will thread onto the front portion

without threading more than 1½ turns onto the back portion, a precise setting is achieved.

Worn Flank Checks

The back portion, or high limit end of each HILO gage has the outside diameter of the thread truncated in accordance

with ANSI/ASME B1.2, latest edition. It automatically furnishes a check on worn flanks similar to, but more exacting

than, standard truncated setting plug gages.

Angle Checks

In addition, HILO setting plugs can also provide a precise angle check on ring gages because of the high limit pitch

diameter, and the low outside diameter on the back portion of the plug. Any worn flanks or angles will be indicated

when the ring gage fits snugly on the low pitch diameter portion, and enters the high pitch diameter portion more than

1½ turns.

“Bellmouthing” Inspection

The amount of excessive ring gage “bell mouthing” can be determined by the number of turns required for the high

pitch diameter portion to enter the ring. If the high portion does not enter the ring, the ring is within tolerance.

Solid Ring Gage Checks

Since the HILO setting plug has the low and high limit portions ground and lapped with identical leads and angles, the

low and high limits on solid gages can be easily and accurately checked. The HILO plug design provides a completely

positive and dependable wear check, and allows for full utilization of the pitch diameter tolerance inside the ring in

accordance with ANSI/ASME B1.2, latest edition.

Manufacturing Standards

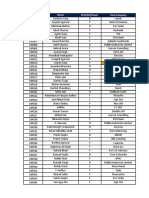

Material…………………………………………………………………………....High Speed Steel

Up to 1 ½” Diameter

LO Pitch Diameter Tolerance

(Minimum Ring Pitch Diameter Tolerance)…………………………………………..…± 0.00005”

HI Pitch Diameter Tolerance

(Maximum Ring Pitch Diameter Tolerance)………………………………………………+ 0.0001”

Lead & Angles…………………………………………..………………………….….W Tolerance

Major Diameter Back Portion (HI)……………………………....Truncated per ANSI/ASME B1.2

Class X, Standard Truncation

Major Diameter Back Portion (LO)………………………………………………Full Form Class X

Straightness & Taper………………………………………….... ANSI/ASME B1.2, Latest Edition

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- John Deere 5520 Tractor Operator's Manual PDFDocument16 pagesJohn Deere 5520 Tractor Operator's Manual PDFfkskefmmseNo ratings yet

- Tower DesignDocument15 pagesTower DesignKushan Dhanushka Nanayakkara100% (2)

- CDR-EL-1109 - CDR Sample ElectricalDocument1 pageCDR-EL-1109 - CDR Sample ElectricalCDR Download100% (1)

- ABS Coolant Proof Digimatic Indicator - Mitutoyo America CorporationDocument6 pagesABS Coolant Proof Digimatic Indicator - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- ROUNDTEST RA-2100 SERIES - Mitutoyo America CorporationDocument12 pagesROUNDTEST RA-2100 SERIES - Mitutoyo America CorporationMariangel Rodríguez Gómez100% (1)

- CNC Vision Measuring System - Precision Tool DistributorsDocument24 pagesCNC Vision Measuring System - Precision Tool DistributorsMariangel Rodríguez GómezNo ratings yet

- QV APex SeRieS - Mitutoyo America CorporationDocument19 pagesQV APex SeRieS - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- Mitutoyo New Products Guide - Mitutoyo America CorporationDocument20 pagesMitutoyo New Products Guide - Mitutoyo America CorporationMariangel Rodríguez GómezNo ratings yet

- BX-1000 BXG-1000 Operation Manual0 PDFDocument36 pagesBX-1000 BXG-1000 Operation Manual0 PDFMariangel Rodríguez GómezNo ratings yet

- TF-CA CALPAK New DRODocument16 pagesTF-CA CALPAK New DROMariangel Rodríguez GómezNo ratings yet

- TF-LG3 LG5003Document12 pagesTF-LG3 LG5003Mariangel Rodríguez GómezNo ratings yet

- Case Study - 5Q Group 2Document5 pagesCase Study - 5Q Group 2ZulkifliyJamil100% (3)

- Key, Scripts BIG STEP TOEIC 3 - Actual Test 3 - EFIS EnglishDocument7 pagesKey, Scripts BIG STEP TOEIC 3 - Actual Test 3 - EFIS EnglishThao NguyenNo ratings yet

- THE PAPACY AND THE CRUSADERS IN THE EAST, 1100-1160 by John Gordon RoweDocument618 pagesTHE PAPACY AND THE CRUSADERS IN THE EAST, 1100-1160 by John Gordon RoweVasilis AchillesNo ratings yet

- A Detailed Study On Loss Processes in Solar CellsDocument11 pagesA Detailed Study On Loss Processes in Solar CellsFernando DiasNo ratings yet

- 1 - Introduction To Accountign - Icap - Questions and Answers PDFDocument202 pages1 - Introduction To Accountign - Icap - Questions and Answers PDFM.Abdullah MBIT100% (1)

- Menz Issue 1Document40 pagesMenz Issue 1Dan Moore100% (2)

- 12 Essentials of A Dynamic Disciple - Sermon SeriesDocument3 pages12 Essentials of A Dynamic Disciple - Sermon SeriesMarla MagatNo ratings yet

- Aluminum Welding GuideDocument8 pagesAluminum Welding Guideharish3742No ratings yet

- Oworin Meji Falokun Fatumbi Awo Ifa World PerspectiveDocument13 pagesOworin Meji Falokun Fatumbi Awo Ifa World PerspectiveLevy Braunstein100% (1)

- Grade: 10E ROOM: 212 Homeroom Adviser: John Paolo FernandezDocument1 pageGrade: 10E ROOM: 212 Homeroom Adviser: John Paolo FernandezRangga NarindraNo ratings yet

- Roles and Characteristics of Problem Solving in The Mathematics Curriculum: A ReviewDocument19 pagesRoles and Characteristics of Problem Solving in The Mathematics Curriculum: A ReviewSarahNo ratings yet

- CDP Proposal KavarattiDocument11 pagesCDP Proposal KavarattiShivansh Singh GautamNo ratings yet

- Huawei Transmission Configuring The Built-In WDM ServiceDocument5 pagesHuawei Transmission Configuring The Built-In WDM ServiceElizabeth RichNo ratings yet

- Pembumian 110705103913 Phpapp02Document33 pagesPembumian 110705103913 Phpapp02Noor Syazwani Md SharifNo ratings yet

- Configuration Guide - User Access (V600R003C00 - 02) PDFDocument186 pagesConfiguration Guide - User Access (V600R003C00 - 02) PDFdarket_masterNo ratings yet

- MC DonaldDocument65 pagesMC DonaldNeha MishraaNo ratings yet

- Vmware Vsphere - Pricing White Paper PDFDocument12 pagesVmware Vsphere - Pricing White Paper PDFsabeelshakirNo ratings yet

- Callo Trinidad V EstebanDocument13 pagesCallo Trinidad V EstebanIvan Montealegre ConchasNo ratings yet

- TUYEN CHON DE THI HOC SINH GIỎI 8 PHẠM THỦY HƯƠNGDocument70 pagesTUYEN CHON DE THI HOC SINH GIỎI 8 PHẠM THỦY HƯƠNGTrang Lê HuyềnNo ratings yet

- BS en 01256-1996Document12 pagesBS en 01256-1996Mustafa Ersin EkremNo ratings yet

- Business Environment ProjectDocument19 pagesBusiness Environment Projectaditi100% (1)

- Definition of Research, Characteristics of Research, Research Process and Functions of Research Definition of ResearchDocument2 pagesDefinition of Research, Characteristics of Research, Research Process and Functions of Research Definition of ResearchNinda SNo ratings yet

- Roll No. Name PPO/PPI/Finals Final CompanyDocument48 pagesRoll No. Name PPO/PPI/Finals Final CompanyYash AgarwalNo ratings yet

- Spotify Royalties CalcDocument50 pagesSpotify Royalties Calcalex100% (1)

- Da Vinci Surgical System Power PointDocument23 pagesDa Vinci Surgical System Power PointJaed CaraigNo ratings yet

- Iris Marion Youngs Critique of The Rawlsian Theory of Justice 1Document19 pagesIris Marion Youngs Critique of The Rawlsian Theory of Justice 1AlenNo ratings yet