Professional Documents

Culture Documents

Welding Procedure Qualification: in According ASME IX

Welding Procedure Qualification: in According ASME IX

Uploaded by

Rochy GbCopyright:

Available Formats

You might also like

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Astm A193 - Nuts and BoltsDocument5 pagesAstm A193 - Nuts and BoltsgarrybieberNo ratings yet

- AMICON - Butterfly ValvesDocument16 pagesAMICON - Butterfly ValvesAnees OlasserilNo ratings yet

- Noble Metal AlloysDocument77 pagesNoble Metal AlloysVivek Choukse50% (2)

- Wps PQR PDFDocument35 pagesWps PQR PDFquality unifab83% (6)

- WPS 684 CS 012Document3 pagesWPS 684 CS 012siva8000100% (1)

- Assignment Answer WPS HK40Document4 pagesAssignment Answer WPS HK40RahulNo ratings yet

- Welding Procedure Specification (WPS) : JOINTS (QW-402)Document4 pagesWelding Procedure Specification (WPS) : JOINTS (QW-402)andresrojas25No ratings yet

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- 3-Actual Exams Last Edition (ASME IX)Document6 pages3-Actual Exams Last Edition (ASME IX)Hares SlalNo ratings yet

- Welding Procedure Specification: Backing MaterialDocument2 pagesWelding Procedure Specification: Backing MaterialDiki ArmandoNo ratings yet

- Qw-482 Welding Procedure Specification (WPS) : (Automatic, Manual, Machine or Semi-Auto)Document2 pagesQw-482 Welding Procedure Specification (WPS) : (Automatic, Manual, Machine or Semi-Auto)BalasahebNo ratings yet

- WPS 1-1-GT-SM-6 Rev. 0Document8 pagesWPS 1-1-GT-SM-6 Rev. 0Melby de la rosaNo ratings yet

- WPS Sitelca S002Document2 pagesWPS Sitelca S002kikokiko KarimNo ratings yet

- GCB WPS Tsila 012Document19 pagesGCB WPS Tsila 012AslaouiNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Document2 pagesWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin Romero100% (2)

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- O O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Document1 pageO O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Ali MoosaviNo ratings yet

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- First: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesDocument3 pagesFirst: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesAhmed AbdoNo ratings yet

- Ongc WPS 1 of 2Document4 pagesOngc WPS 1 of 2Kiran NikateNo ratings yet

- WPS Tsila 012Document2 pagesWPS Tsila 012AslaouiNo ratings yet

- 04 WPS Atp Asme 2012 (A312 304) (A312 310)Document6 pages04 WPS Atp Asme 2012 (A312 304) (A312 310)lailatul kodriNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- Procedimiento de Soldadura .Document2 pagesProcedimiento de Soldadura .luis m hueto castilloNo ratings yet

- PWPS 102Document2 pagesPWPS 102Cyril J PadiyathNo ratings yet

- Reliance Engineering Associates (P) Limited Welding Procedure SpecificationDocument1 pageReliance Engineering Associates (P) Limited Welding Procedure SpecificationdeepakNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- Wps PQR A3620 PDFDocument5 pagesWps PQR A3620 PDFHamid MansouriNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationHasan Ahmed100% (1)

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNo ratings yet

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- Form Qw-482 Suggested Format For Welding Procedure Specification (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document10 pagesForm Qw-482 Suggested Format For Welding Procedure Specification (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Prakash PatelNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- WPS SS316Document4 pagesWPS SS316Budi Setia RahmanNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- Wps Train 01 (AIDIL)Document2 pagesWps Train 01 (AIDIL)aidil30No ratings yet

- Wps 22Document2 pagesWps 22Avishek GuptaNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Qw-482 Welding Procedure SpecificationDocument2 pagesQw-482 Welding Procedure SpecificationAmanSharmaNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli Moosavi100% (1)

- 1108-DES-005 Rev02Document1 page1108-DES-005 Rev02Omar TocmoNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- (Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMDocument2 pages(Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMpraveesh qc2023No ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Anup SirDocument22 pagesAnup SirFAIQNo ratings yet

- Metal Cas MCQDocument25 pagesMetal Cas MCQKanhaiyaPrasadNo ratings yet

- CreepDocument26 pagesCreepOsu AmpawanonNo ratings yet

- FQA Registry PDFDocument116 pagesFQA Registry PDFsattar12345No ratings yet

- Astm e 1019 - 03 Leco CS NoDocument21 pagesAstm e 1019 - 03 Leco CS NoPYDNo ratings yet

- c71500 PDFDocument1 pagec71500 PDFArtish PadaiyaNo ratings yet

- Astm F 13608Document4 pagesAstm F 13608Riesma TasomaraNo ratings yet

- Astm A450Document10 pagesAstm A450Đoàn Thoại Đông TriềuNo ratings yet

- Is 817 For Welding QalificationDocument59 pagesIs 817 For Welding QalificationRathnakrajaNo ratings yet

- Aluminium Diecasting MaterialDocument2 pagesAluminium Diecasting MaterialzainudinNo ratings yet

- Tig Welding MinDocument31 pagesTig Welding MinStefan O. CatalinNo ratings yet

- Electroslag Casting Guide Vane The Three Gorges Hydraulic China Heart - Electroslag Casting GuideDocument2 pagesElectroslag Casting Guide Vane The Three Gorges Hydraulic China Heart - Electroslag Casting GuideHickeyLowery54No ratings yet

- About Dissimilar MetalsDocument1 pageAbout Dissimilar MetalsIsabel Christina Gonzalez MoralesNo ratings yet

- Satisfactory Work Sheet - OdsDocument8 pagesSatisfactory Work Sheet - OdsIgnorant MassNo ratings yet

- GHGFHDocument4 pagesGHGFHasfaruk2556No ratings yet

- HW8 Solution KeyDocument3 pagesHW8 Solution KeyHerlina PebrianiNo ratings yet

- 9 2 2Document2 pages9 2 2123No ratings yet

- Metal Injection Molding Material PropertiesDocument12 pagesMetal Injection Molding Material Propertiesdbfreelancer1195No ratings yet

- s4273447 Mphil ThesisDocument205 pagess4273447 Mphil ThesispmarteeneNo ratings yet

- Dimensions N Weights Pipes N TubesDocument6 pagesDimensions N Weights Pipes N TubesRahul SinghNo ratings yet

- Asme SB 381 & Astm B 381Document1 pageAsme SB 381 & Astm B 381jung-57No ratings yet

- IOZ PaintingDocument3 pagesIOZ PaintingDhinesh ThanappanNo ratings yet

- 1.0 Fundamentals of CastingDocument43 pages1.0 Fundamentals of CastingLoo Tong ShianNo ratings yet

- Examples and Answers-The Science and Engineering of MaterialsDocument6 pagesExamples and Answers-The Science and Engineering of MaterialschutiyaNo ratings yet

- AJIYA-Structural Product Purlin PDFDocument4 pagesAJIYA-Structural Product Purlin PDFKartegan ElavarasuNo ratings yet

- Chem181 m2 Experiment5 AbapoDocument9 pagesChem181 m2 Experiment5 AbapoRyan Angelo AbapoNo ratings yet

- Lukas KatalogDocument31 pagesLukas KatalogJosko SpehNo ratings yet

Welding Procedure Qualification: in According ASME IX

Welding Procedure Qualification: in According ASME IX

Uploaded by

Rochy GbOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Qualification: in According ASME IX

Welding Procedure Qualification: in According ASME IX

Uploaded by

Rochy GbCopyright:

Available Formats

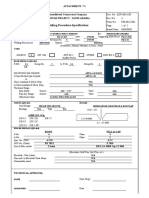

WELDING PROCEDURE

QUALIFICATION 0

WPS Nr. 21UT-1-.370.3 REV.

W P S Date 27/11/2019

in according ASME IX Supporting PQR 04A/2006

Welding Process(es) 1 GTAW 2 SMAW 3 --

Type(s) 1 MANUAL 2 MANUAL 3 --

(Manual, Automatic, Semi-Automatic)

JOINTS (QW-402)

DETAILS

75°

n.

O.D.

Tk.

2,0 1

1,5

Joint Design BUTT JOINT; SINGLE V GROOVE (SEE DETAIL).

Backing NO FOR FIRST PASS ; YES FOR FILLING PASS.

Backing Material (Type) WELD METAL

Metal x

Nonfusing Metal

Non Metallic

Other

BASE METALS (QW-403) ( 1 )

P - Nr. : 8 Group : 1 To P - Nr. : 8 Group : 1

OR

Specification Type : A312 Grade : Tp.316L To Specification Type : SA 312 Grade : Tp.316L

OR A 182 F316L / A 403WP316L

Chem. Analysis : - And Mech. Property : -

To Chem. Analysis : - And Mech. Property : -

BASE METAL: THICKNESS / DIAMETER RANGE :

Thickness Range : Groove : (3,73mm)0,147"(9,27mm)0,365" And Fillet : All

Pipe Diam. Range : Groove : (21,3mm)½" (273,0mm)10" And Fillet : All

Other : NONE.

FILLER METALS (QW-404) ( 1 )

1 2÷n 3

SFA Specification Nr. : SFA 5.9 SFA 5.4 --

AWS Class Nr. : ER 308-L E 308L-16 --

F-Nr. : 6 5 --

A-Nr. : 8 8 --

Size of Filler Metals : 2,40 mm 2,50 - 3,25 mm --

Deposited W. Metal Thk. Range Groove : up to 2,5 mm up to 6,77 --

Deposited W. Metal Thk. Range Fillet : N.A. N.A. --

Electrode / Flux : N.A. N.A. --

Flux Trade Name : N.A. N.A. --

Consumable Insert : N.A. N.A. --

Other : Trade Name Tigrod 308L or similar OK 308L-16 or similar --

Manufacturer ESAB Saldature or similar ESAB Saldature or similar --

(1)

= Each base metal / filler metal combination should be recorded individually. Page 1 of 3

FILE: WPS-21UT-193703rev0 - SCHEDA: WPS_1_3

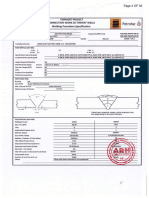

WELDING PROCEDURE

QUALIFICATION 0

WPS Nr. 21UT-1-.370.3 REV.

W P S Date 27/11/2019

in according ASME IX Supporting PQR 04A/2006

POSITION (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position of Groove : ALL Temperature : NONE.

Weld Progrssion (Uphill, Downhill) : Uphill. Time : N.A.

Position of Fillet : N.A. Other : NONE.

PREHEAT (QW-406) GAS (QW-408) % Composition

Gas(es) (Mixture) Flow Rate

Preheat Temperature Min. : if Te 5°C Tp 50° C Shielding (1) Argon 99,998 10 ÷ 12 l/min.

Interpass Temperature Max. : 150°C. Trailing N.A. N.A. N.A.

Preheat Maintenance : NONE Backing Nitrogen 100 14 ÷ 16 l/min.

ELECTRICAL CHARACTERISTICS (QW-409)

Weld Layer(s) Process Filler Metal Current Volts Range (V) Travel Speed Heat Input

Class Diameter (mm) Type / Polarity Amps Range (A) Ran. (mm/min.) (KJ/mm)

1 GTAW ER 308L 2,4 D.C. / E.N. 70÷80 11÷12 40÷45 1,03÷1,44

2÷n SMAW E 308L-16 2,50 D.C. - E.P. 70÷80 23 ÷ 24 160÷170 0,57÷0,72

3÷n SMAW E 308L-16 3,25 D.C. - E.P. 90÷100 24 ÷ 26 125÷144 0,90÷1,25

Tungsten Electode Size and Type : 2,40 mm SFA 5.12 EWCe-2.

Mode of Metal Transfer for FCAW : N.A.

TECNIQUE (QW-410)

String or Weave Bead : String and weave.

Orifice or Gas Cup Size : 5/16".

Initial and Interpass Cleaning : Brushing and grinding.

Method of Back Gouging : NONE.

Oscillation : N.A.

Contact Tube to Work Distance : N.A.

Multiple or Single P. (x side) : Multiple.

Multiple or Single Electrodes : Single.

Travel Speed (Range) : See electrical characteristics

Peening : NO.

Other : NO.

Page 2 of 3

FILE: WPS-21UT-193703rev0 - SCHEDA: WPS_2_3

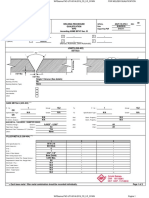

WPS-21UT-193703rev0

WELDING PROCEDURE

QUALIFICATION 0

WPS Nr. 21UT-1-.370.3 REV.

W P S Date 27/11/2019

in according ASME IX Supporting PQR 04A/2006

Layer Diam. Process

1 2,4 GTAW

2÷n 2,5 SMAW

Xmin = the lesser of

1,4T or the thinkness

of the hub

The lesser of T or

6 mm (1/4 in.)

SLIP ON FLANGE Xmin

PIPE

1 2,4 GTAW

2÷n 2,5 SMAW

1 2,4 GTAW

2÷n 2,5 SMAW

1 2,4 GTAW

2÷n 2,5 SMAW

1÷n 2,5 SMAW

Page 3 of 3

You might also like

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Astm A193 - Nuts and BoltsDocument5 pagesAstm A193 - Nuts and BoltsgarrybieberNo ratings yet

- AMICON - Butterfly ValvesDocument16 pagesAMICON - Butterfly ValvesAnees OlasserilNo ratings yet

- Noble Metal AlloysDocument77 pagesNoble Metal AlloysVivek Choukse50% (2)

- Wps PQR PDFDocument35 pagesWps PQR PDFquality unifab83% (6)

- WPS 684 CS 012Document3 pagesWPS 684 CS 012siva8000100% (1)

- Assignment Answer WPS HK40Document4 pagesAssignment Answer WPS HK40RahulNo ratings yet

- Welding Procedure Specification (WPS) : JOINTS (QW-402)Document4 pagesWelding Procedure Specification (WPS) : JOINTS (QW-402)andresrojas25No ratings yet

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- 3-Actual Exams Last Edition (ASME IX)Document6 pages3-Actual Exams Last Edition (ASME IX)Hares SlalNo ratings yet

- Welding Procedure Specification: Backing MaterialDocument2 pagesWelding Procedure Specification: Backing MaterialDiki ArmandoNo ratings yet

- Qw-482 Welding Procedure Specification (WPS) : (Automatic, Manual, Machine or Semi-Auto)Document2 pagesQw-482 Welding Procedure Specification (WPS) : (Automatic, Manual, Machine or Semi-Auto)BalasahebNo ratings yet

- WPS 1-1-GT-SM-6 Rev. 0Document8 pagesWPS 1-1-GT-SM-6 Rev. 0Melby de la rosaNo ratings yet

- WPS Sitelca S002Document2 pagesWPS Sitelca S002kikokiko KarimNo ratings yet

- GCB WPS Tsila 012Document19 pagesGCB WPS Tsila 012AslaouiNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Document2 pagesWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin Romero100% (2)

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- O O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Document1 pageO O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Ali MoosaviNo ratings yet

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- First: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesDocument3 pagesFirst: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesAhmed AbdoNo ratings yet

- Ongc WPS 1 of 2Document4 pagesOngc WPS 1 of 2Kiran NikateNo ratings yet

- WPS Tsila 012Document2 pagesWPS Tsila 012AslaouiNo ratings yet

- 04 WPS Atp Asme 2012 (A312 304) (A312 310)Document6 pages04 WPS Atp Asme 2012 (A312 304) (A312 310)lailatul kodriNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- Procedimiento de Soldadura .Document2 pagesProcedimiento de Soldadura .luis m hueto castilloNo ratings yet

- PWPS 102Document2 pagesPWPS 102Cyril J PadiyathNo ratings yet

- Reliance Engineering Associates (P) Limited Welding Procedure SpecificationDocument1 pageReliance Engineering Associates (P) Limited Welding Procedure SpecificationdeepakNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- Wps PQR A3620 PDFDocument5 pagesWps PQR A3620 PDFHamid MansouriNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationHasan Ahmed100% (1)

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNo ratings yet

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- Form Qw-482 Suggested Format For Welding Procedure Specification (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document10 pagesForm Qw-482 Suggested Format For Welding Procedure Specification (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Prakash PatelNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- WPS SS316Document4 pagesWPS SS316Budi Setia RahmanNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- Wps Train 01 (AIDIL)Document2 pagesWps Train 01 (AIDIL)aidil30No ratings yet

- Wps 22Document2 pagesWps 22Avishek GuptaNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Qw-482 Welding Procedure SpecificationDocument2 pagesQw-482 Welding Procedure SpecificationAmanSharmaNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli Moosavi100% (1)

- 1108-DES-005 Rev02Document1 page1108-DES-005 Rev02Omar TocmoNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- (Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMDocument2 pages(Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMpraveesh qc2023No ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Anup SirDocument22 pagesAnup SirFAIQNo ratings yet

- Metal Cas MCQDocument25 pagesMetal Cas MCQKanhaiyaPrasadNo ratings yet

- CreepDocument26 pagesCreepOsu AmpawanonNo ratings yet

- FQA Registry PDFDocument116 pagesFQA Registry PDFsattar12345No ratings yet

- Astm e 1019 - 03 Leco CS NoDocument21 pagesAstm e 1019 - 03 Leco CS NoPYDNo ratings yet

- c71500 PDFDocument1 pagec71500 PDFArtish PadaiyaNo ratings yet

- Astm F 13608Document4 pagesAstm F 13608Riesma TasomaraNo ratings yet

- Astm A450Document10 pagesAstm A450Đoàn Thoại Đông TriềuNo ratings yet

- Is 817 For Welding QalificationDocument59 pagesIs 817 For Welding QalificationRathnakrajaNo ratings yet

- Aluminium Diecasting MaterialDocument2 pagesAluminium Diecasting MaterialzainudinNo ratings yet

- Tig Welding MinDocument31 pagesTig Welding MinStefan O. CatalinNo ratings yet

- Electroslag Casting Guide Vane The Three Gorges Hydraulic China Heart - Electroslag Casting GuideDocument2 pagesElectroslag Casting Guide Vane The Three Gorges Hydraulic China Heart - Electroslag Casting GuideHickeyLowery54No ratings yet

- About Dissimilar MetalsDocument1 pageAbout Dissimilar MetalsIsabel Christina Gonzalez MoralesNo ratings yet

- Satisfactory Work Sheet - OdsDocument8 pagesSatisfactory Work Sheet - OdsIgnorant MassNo ratings yet

- GHGFHDocument4 pagesGHGFHasfaruk2556No ratings yet

- HW8 Solution KeyDocument3 pagesHW8 Solution KeyHerlina PebrianiNo ratings yet

- 9 2 2Document2 pages9 2 2123No ratings yet

- Metal Injection Molding Material PropertiesDocument12 pagesMetal Injection Molding Material Propertiesdbfreelancer1195No ratings yet

- s4273447 Mphil ThesisDocument205 pagess4273447 Mphil ThesispmarteeneNo ratings yet

- Dimensions N Weights Pipes N TubesDocument6 pagesDimensions N Weights Pipes N TubesRahul SinghNo ratings yet

- Asme SB 381 & Astm B 381Document1 pageAsme SB 381 & Astm B 381jung-57No ratings yet

- IOZ PaintingDocument3 pagesIOZ PaintingDhinesh ThanappanNo ratings yet

- 1.0 Fundamentals of CastingDocument43 pages1.0 Fundamentals of CastingLoo Tong ShianNo ratings yet

- Examples and Answers-The Science and Engineering of MaterialsDocument6 pagesExamples and Answers-The Science and Engineering of MaterialschutiyaNo ratings yet

- AJIYA-Structural Product Purlin PDFDocument4 pagesAJIYA-Structural Product Purlin PDFKartegan ElavarasuNo ratings yet

- Chem181 m2 Experiment5 AbapoDocument9 pagesChem181 m2 Experiment5 AbapoRyan Angelo AbapoNo ratings yet

- Lukas KatalogDocument31 pagesLukas KatalogJosko SpehNo ratings yet