Professional Documents

Culture Documents

5.4 ESW and EGW Processes: AWS D1.1/D1.1M:2015 Clause 5. Fabrication

5.4 ESW and EGW Processes: AWS D1.1/D1.1M:2015 Clause 5. Fabrication

Uploaded by

Rohit KambleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5.4 ESW and EGW Processes: AWS D1.1/D1.1M:2015 Clause 5. Fabrication

5.4 ESW and EGW Processes: AWS D1.1/D1.1M:2015 Clause 5. Fabrication

Uploaded by

Rohit KambleCopyright:

Available Formats

AWS D1.1/D1.1M:2015 CLAUSE 5.

FABRICATION

a minimum temperature of 500°F [260°C] for one hour A5.18 or AWS A5.28 and AWS A5.30, Specification for

before use. Flux shall be placed in the dispensing system Consumable Inserts, as applicable.

immediately upon opening a package, or if used from an

opened package, the top one inch shall be discarded.

Flux that has been wet shall not be used.

5.3.3.3 Flux Reclamation. SAW flux that has not 5.4 ESW and EGW Processes

been melted during the welding operation may be reused

after recovery by vacuuming, catch pans, sweeping, or 5.4.1 Process Limitations. The ESW and EGW pro-

other means. The welding fabricator shall have a system cesses shall be restricted to use of Table 3.1, Group I, II,

for collecting unmelted flux, adding new flux, and weld- and III steels, except that ESW and EGW of ASTM

ing with the mixture of these two, such that the flux com- A710 shall not be permitted.

position and particle size distribution at the weld puddle

are relatively constant. 5.4.2 Condition of Electrodes and Guide Tubes. Elec-

trodes and consumable guide tubes shall be dry, clean,

5.3.3.4 Crushed Slag. Crushed slag may be used and in suitable condition for use.

provided it has its own marking, using the crusher’s

name and trade designation. In addition, each dry batch 5.4.3 Condition of Flux. Flux used for ESW shall be

or dry blend (lot) of flux, as defined in AWS A5.01, dry and free of contamination from dirt, mill scale, or

Filler Metal Procurement Guidelines, shall be tested in other foreign material. All flux shall be purchased in

conformance with Schedule I of AWS A5.01 and classi- packages that can be stored, under normal conditions, for

fied by the Contractor or crusher per AWS A5.17 or at least six months without such storage affecting its

A5.23, as applicable. welding characteristics or weld properties. Flux from

packages damaged in transit or in handling shall be dis-

5.3.4 GMAW/FCAW Electrodes. The electrodes for carded or shall be dried at a minimum temperature of

GMAW or FCAW shall conform to the requirements of 250°F [120°C] for one hour before use. Flux that has

the following: been wet shall not be used.

(1) AWS A5.18/A5.18M, Specification for Carbon 5.4.4 Weld Starts and Stops. Welds shall be started in

Steel Electrodes and Rods for Gas Shielded Arc Welding; such a manner as to allow sufficient heat buildup for

complete fusion of the weld metal to the groove faces of

(2) AWS A5.20/A5.20M, Specification for Carbon the joint. Welds which have been stopped at any point in

Steel Electrodes for Flux Cored Arc Welding; the weld joint for a sufficient amount of time for the slag

or weld pool to begin to solidify may be restarted and

(3) AWS A5.28/A5.28M, Specification for Low-

completed, provided the completed weld is examined by

Alloy Steel Electrodes and Rods for Gas Shielded Arc

UT for a minimum of 6 in [150 mm] on either side of the

Welding;

restart and, unless prohibited by joint geometry, also

(4) AWS A5.29/A5.29M, Specification for Low- confirmed by RT. All such restart locations shall be re-

Alloy Steel Electrodes for Flux Cored Arc Welding; or corded and reported to the Engineer.

(5) AWS A5.36/A5.36M, Specification for Carbon 5.4.5 Preheating. Because of the high-heat input char-

and Low-Alloy Steel Flux Cored Electrodes for Flux acteristic of these processes, preheating is not normally

Cored Arc Welding and Metal Cored Electrodes for Gas required. However, no welding shall be performed when

Metal Arc Welding. the temperature of the base metal at the point of welding

is below 32°F [0°C].

5.3.5 GTAW

5.4.6 Repairs. Welds having discontinuities prohibited

5.3.5.1 Tungsten Electrodes. Welding current shall by Clause 6, Part C or Clause 9, Part F shall be repaired

be compatible with the diameter and type or classi- as allowed by 5.25 utilizing a qualified welding process,

fication of electrode. Tungsten electrodes shall be in or the entire weld shall be removed and replaced.

conformance with AWS A5.12, Specification for Tung-

sten and Tungsten Alloy Electrodes for Arc Welding and 5.4.7 Weathering Steel Requirements. For ESW and

Cutting. EGW of exposed, bare, unpainted applications of ASTM

A588 steel requiring weld metal with atmospheric corro-

5.3.5.2 Filler Metal. The filler metal shall conform sion resistance and coloring characteristics similar to that

to all the requirements of the latest edition of AWS of the base metal, the electrode-flux combination shall be

167

You might also like

- Asme Section II A Sa-351 Sa-351mDocument8 pagesAsme Section II A Sa-351 Sa-351mAnonymous GhPzn1x100% (1)

- D1 3scopeDocument4 pagesD1 3scopeayub82No ratings yet

- Astm A403 Standard PDFDocument12 pagesAstm A403 Standard PDFHugo Marcelo Valdivia AguileraNo ratings yet

- ASME II A 1 (2015) .PDF ExtractDocument7 pagesASME II A 1 (2015) .PDF ExtractPedro Montes Marin100% (1)

- Zinc Alloys EncyclopediaDocument10 pagesZinc Alloys EncyclopediavkmsNo ratings yet

- Specification For Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature ServiceDocument21 pagesSpecification For Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature Servicecesar jaramilloNo ratings yet

- Astm A351Document5 pagesAstm A351Srinivasan KrishnamoorthyNo ratings yet

- Specification For Forgeo or Rolleo Alloy Ano Stainless Steel Pipe Flanges, Forgeo Fittings, Ano Valves Ano Parts For High-Temperature ServiceDocument18 pagesSpecification For Forgeo or Rolleo Alloy Ano Stainless Steel Pipe Flanges, Forgeo Fittings, Ano Valves Ano Parts For High-Temperature Serviceedisson_barreraNo ratings yet

- Astm A351-14Document5 pagesAstm A351-14Marcel Dandaro100% (3)

- Fabrication: 5.1 Scope 5.3 Welding Consumables and Electrode RequirementsDocument1 pageFabrication: 5.1 Scope 5.3 Welding Consumables and Electrode RequirementsRohit KambleNo ratings yet

- Specification For Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature ServiceDocument22 pagesSpecification For Forged or Rolled Alloy-Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature Servicedaniel pacheco do nascimento PachecoNo ratings yet

- Sa-182 Forgings PDFDocument17 pagesSa-182 Forgings PDFSalmanNo ratings yet

- Specification For Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature ServiceDocument19 pagesSpecification For Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature Servicekranthi kumarNo ratings yet

- Guidance On The Welding of Weathering SteelsDocument0 pagesGuidance On The Welding of Weathering Steelsinfinity_178No ratings yet

- CF 8 MDocument1 pageCF 8 Mbarani_g3939No ratings yet

- TS 16448 - Structural Field Welding - 201407071322217372Document19 pagesTS 16448 - Structural Field Welding - 201407071322217372mayNo ratings yet

- (UOP) Fabrication of PipingDocument5 pages(UOP) Fabrication of Pipingchandirandelhi100% (1)

- Alloy Steel Forgings For Pressure and High-Temperature PartsDocument8 pagesAlloy Steel Forgings For Pressure and High-Temperature PartsDarwin Darmawan100% (1)

- Astm A351Document5 pagesAstm A351pepelefuuNo ratings yet

- A351A351MDocument5 pagesA351A351MWanderlan Rodrigues da Silva100% (1)

- ASME NOTES - Part29Document1 pageASME NOTES - Part29Head copperNo ratings yet

- GTAW_SEPL_2020-21Document24 pagesGTAW_SEPL_2020-21Kunal ParikhNo ratings yet

- Recom. de Soldadura XARDocument4 pagesRecom. de Soldadura XARelias667No ratings yet

- Specification For Welded Large Diameter Austenitic Steel Pipe For Corrosive or High-Temperature ServiceDocument8 pagesSpecification For Welded Large Diameter Austenitic Steel Pipe For Corrosive or High-Temperature Serviceedisson_barreraNo ratings yet

- 1.1.5 WPSDocument15 pages1.1.5 WPSDominic Apollo RoblesNo ratings yet

- Astm A351Document5 pagesAstm A351Iksan MustofaNo ratings yet

- A351a351m-14 10877Document5 pagesA351a351m-14 10877Lalit PatelNo ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- Asme Section II A Sa-358 Sa-358mDocument10 pagesAsme Section II A Sa-358 Sa-358mAnonymous GhPzn1xNo ratings yet

- BRIDGE Steel Welding GuideDocument2 pagesBRIDGE Steel Welding GuideANTONYLEONo ratings yet

- Flux-Cored Arc Welding: A. Process PrinciplesDocument3 pagesFlux-Cored Arc Welding: A. Process Principlessn200709No ratings yet

- Soldadura de Hierro ColadoDocument10 pagesSoldadura de Hierro ColadoclnNo ratings yet

- Cast Steel HandBookDocument93 pagesCast Steel HandBookAlexa Harper100% (1)

- Steel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesDocument93 pagesSteel Casting Handbook Supplement 8 - High Alloy Data Sheets - Corrosion SeriesjosemiguelzuNo ratings yet

- A 182Document20 pagesA 182Thomas100% (1)

- Welding of Ferritic CreepDocument3 pagesWelding of Ferritic CreepMuhammed SulfeekNo ratings yet

- Castings, Austenitic, For Pressure-Containing PartsDocument5 pagesCastings, Austenitic, For Pressure-Containing PartsالGINIRAL FREE FIRENo ratings yet

- A234A234M-15 Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature Service PDFDocument9 pagesA234A234M-15 Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature Service PDFRony YudaNo ratings yet

- Metal Characteristics Part 2Document48 pagesMetal Characteristics Part 2Ali RayyaNo ratings yet

- Exotic Metal Base Metal & Filler GuideDocument1 pageExotic Metal Base Metal & Filler GuideJuan RodriguezNo ratings yet

- Sa 409Document10 pagesSa 409ismaelarchilacastilloNo ratings yet

- 26 Astm A928Document7 pages26 Astm A928FYNo ratings yet

- ASTM A182 - 2009aDocument18 pagesASTM A182 - 2009aLeonardo R. GonçalvesNo ratings yet

- AT Weld New ManualDocument21 pagesAT Weld New ManualsoupNo ratings yet

- A New Low-Melting-Point Aluminum BrazeDocument8 pagesA New Low-Melting-Point Aluminum BrazeA K SinghNo ratings yet

- IRS S-93-96 (A) (Amd. 1)Document41 pagesIRS S-93-96 (A) (Amd. 1)vineet.navrang7882No ratings yet

- Astm A439-83-2004Document6 pagesAstm A439-83-2004NadhiraNo ratings yet

- Clad Metal WeldingDocument6 pagesClad Metal WeldinggoguluNo ratings yet

- Manual Soldadura en CampoDocument32 pagesManual Soldadura en Campoll vvNo ratings yet

- AISC 13th - Material GradesDocument5 pagesAISC 13th - Material GradesUpadrasta HarishNo ratings yet

- Astm A335 PDFDocument11 pagesAstm A335 PDFJACILDO SOARES CAVALCANTE100% (1)

- How To Weld 254 SMODocument12 pagesHow To Weld 254 SMOsateesh chand100% (7)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingFrom EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNo ratings yet

- 91symp11 2Document1 page91symp11 2Rohit KambleNo ratings yet

- Aws D1.1 D1.1M-2010 - SDocument1 pageAws D1.1 D1.1M-2010 - SRohit KambleNo ratings yet

- 91symp11 1Document1 page91symp11 1Rohit KambleNo ratings yet

- 91symp11 3Document1 page91symp11 3Rohit KambleNo ratings yet

- Penguard Primer: Technical DataDocument4 pagesPenguard Primer: Technical DataRohit KambleNo ratings yet

- Aws d1.1 d1.1m-2010 - Structural Welding Code-Steel-18Document1 pageAws d1.1 d1.1m-2010 - Structural Welding Code-Steel-18Rohit KambleNo ratings yet

- Return Trip RedBus Ticket - TQ3K22800244Document3 pagesReturn Trip RedBus Ticket - TQ3K22800244Rohit KambleNo ratings yet

- OffshoreDocument225 pagesOffshoreRohit KambleNo ratings yet

- Aws d1.1 d1.1m-2010 - Structural Welding Code-Steel-15Document1 pageAws d1.1 d1.1m-2010 - Structural Welding Code-Steel-15Rohit KambleNo ratings yet

- Aws D1.1 D1.1M-2010 - Structural Welding Code-Steel-1Document1 pageAws D1.1 D1.1M-2010 - Structural Welding Code-Steel-1Rohit Kamble0% (1)

- Aws D1.1 D1.1M-2010 - Structural Welding Code-Steel-17Document1 pageAws D1.1 D1.1M-2010 - Structural Welding Code-Steel-17Rohit KambleNo ratings yet

- 46606-1-Application Format Chartered Engineer CertificateDocument1 page46606-1-Application Format Chartered Engineer CertificateRohit KambleNo ratings yet

- 9607 BRO 0005 06 Corporate Brochure SCREEN1Document12 pages9607 BRO 0005 06 Corporate Brochure SCREEN1Rohit KambleNo ratings yet

- Work Breakdown StructureDocument6 pagesWork Breakdown StructureRohit KambleNo ratings yet

- Procedure Qualification Record - Page 1 of 2Document3 pagesProcedure Qualification Record - Page 1 of 2Rohit KambleNo ratings yet

- TYP TYP: Sideshell Angles Marked in Red 200 100 16Document1 pageTYP TYP: Sideshell Angles Marked in Red 200 100 16Rohit KambleNo ratings yet

- Status of COVID-19 Vaccines Within WHO EUL/PQ Evaluation ProcessDocument2 pagesStatus of COVID-19 Vaccines Within WHO EUL/PQ Evaluation ProcessRohit KambleNo ratings yet

- Onshore Weighing Procedure: Project Name: Tapti Decommissioning ProjectDocument32 pagesOnshore Weighing Procedure: Project Name: Tapti Decommissioning ProjectRohit KambleNo ratings yet

- Maraging Steel: Sandeep NairDocument20 pagesMaraging Steel: Sandeep NairVysakh VasudevanNo ratings yet

- 07545-Foam RoofingDocument4 pages07545-Foam RoofingEfz EfzNo ratings yet

- 05 Ex Control Stations-2016 IngDocument14 pages05 Ex Control Stations-2016 IngSivagurunathan SpNo ratings yet

- 2010 SEAOC Convention ProceedingsDocument9 pages2010 SEAOC Convention ProceedingsPE EngNo ratings yet

- Wastewater LayoutDocument1 pageWastewater LayoutUsha CastagneNo ratings yet

- Content of ReportDocument52 pagesContent of ReportZaim AdliNo ratings yet

- TIG Gas RodsDocument6 pagesTIG Gas RodsSankar KrishnanNo ratings yet

- Glass MaterialsDocument9 pagesGlass MaterialsFrenz ValdezNo ratings yet

- Concrete Products Plant ProposalDocument8 pagesConcrete Products Plant ProposalFady AntonNo ratings yet

- Furniture QuotationDocument3 pagesFurniture QuotationRaphael ArchNo ratings yet

- Leporello Aluminium Casting Alloys RHEINFELDEN ALLOYS 2018Document10 pagesLeporello Aluminium Casting Alloys RHEINFELDEN ALLOYS 2018luisA1923No ratings yet

- SP7000M00W15 000 ADocument10 pagesSP7000M00W15 000 APedro Casimiro GámizNo ratings yet

- Clear LiteDocument2 pagesClear LitemanojNo ratings yet

- Secar71 PDFDocument2 pagesSecar71 PDFashtaxNo ratings yet

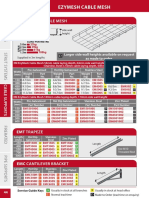

- EzyMesh and Accessories DataSheetDocument2 pagesEzyMesh and Accessories DataSheet30101985No ratings yet

- Bill of Quantity: Item Description Uni T Quantity Price Per Unit Total CostDocument4 pagesBill of Quantity: Item Description Uni T Quantity Price Per Unit Total CostAnil AbduNo ratings yet

- WINSTRIP Brochure ENG PDFDocument4 pagesWINSTRIP Brochure ENG PDFsriatul2006No ratings yet

- Gas Well Casing and Tubing Data PDFDocument2 pagesGas Well Casing and Tubing Data PDFAlexandru AndreiNo ratings yet

- Abstract of ASTM F568M 1996Document12 pagesAbstract of ASTM F568M 1996Jesse ChenNo ratings yet

- Mahagama Private Industrial Training Institute, At:-Amarpur, Po: - Mahagama, PS: - Mahagama, Dist: - Godda, Pin: - 814154, JharkhandDocument1 pageMahagama Private Industrial Training Institute, At:-Amarpur, Po: - Mahagama, PS: - Mahagama, Dist: - Godda, Pin: - 814154, JharkhandAchintya MohnishNo ratings yet

- Suncor: Technical Standard No - FB-L-521 3Document11 pagesSuncor: Technical Standard No - FB-L-521 3rezzdezzNo ratings yet

- Welding Procedures (Overview)Document11 pagesWelding Procedures (Overview)Luis LugoNo ratings yet

- Series LF860 Specification SheetDocument2 pagesSeries LF860 Specification SheetFEBCONo ratings yet

- BoqDocument7 pagesBoqManuel CassarNo ratings yet

- Specification Sheet: West-Com Part WYP Paige Part 32WYPWESTDocument2 pagesSpecification Sheet: West-Com Part WYP Paige Part 32WYPWESTAnonymous XYAPaxjbYNo ratings yet

- Technical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesDocument117 pagesTechnical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesJankoNo ratings yet

- Table of ContentsDocument4 pagesTable of Contentsbella gurlzNo ratings yet

- Vessel Spec SheetDocument1 pageVessel Spec SheetricardoNo ratings yet