Professional Documents

Culture Documents

Eni North Africa BV WTP Nalue Hospital

Eni North Africa BV WTP Nalue Hospital

Uploaded by

Hedi Ben Mohamed0 ratings0% found this document useful (0 votes)

33 views3 pagesEni North Africa B.V. Libyan Branch is seeking qualified vendors to submit documentation for consideration to upgrade the wastewater treatment plant for Nalut General Hospital in Libya. The current plant is obsolete and unsafe. The project scope includes designing, constructing, and commissioning a new 250 cubic meter per day plant along with civil, electrical, and mechanical works. Vendors must have experience in similar projects and meet minimum technical and health, safety, and environmental requirements. Documentation must be submitted by December 1, 2020.

Original Description:

Eni north africa waster water plant

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEni North Africa B.V. Libyan Branch is seeking qualified vendors to submit documentation for consideration to upgrade the wastewater treatment plant for Nalut General Hospital in Libya. The current plant is obsolete and unsafe. The project scope includes designing, constructing, and commissioning a new 250 cubic meter per day plant along with civil, electrical, and mechanical works. Vendors must have experience in similar projects and meet minimum technical and health, safety, and environmental requirements. Documentation must be submitted by December 1, 2020.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

33 views3 pagesEni North Africa BV WTP Nalue Hospital

Eni North Africa BV WTP Nalue Hospital

Uploaded by

Hedi Ben MohamedEni North Africa B.V. Libyan Branch is seeking qualified vendors to submit documentation for consideration to upgrade the wastewater treatment plant for Nalut General Hospital in Libya. The current plant is obsolete and unsafe. The project scope includes designing, constructing, and commissioning a new 250 cubic meter per day plant along with civil, electrical, and mechanical works. Vendors must have experience in similar projects and meet minimum technical and health, safety, and environmental requirements. Documentation must be submitted by December 1, 2020.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

Eni North Africa B.V. Libyan Branch (ENI NA) ....

Wastewater Treatment Plant for Nalut General Hospital

Eni North Africa B.V. Libyan Branch (ENI NA) wishes to verify the availability

of reputable, interested and experienced vendors specialized in providing the

SERVICE/WORK relevant to the Supply and installation of Wastewater

Treatment Plant for Nalut General Hospital. The SERVICE/WORK to be

performed by vendor is described in the Scope of work here below.

As a result of EN INA evaluation in respect of above required services, only

qualified, specialized and experienced vendors will be registered within ENI NA

vendor list

Only qualified companies that have proven capability and recent experience of

supplying the required services will be considered for potential tenders for the

scope of service described above.

SCOPE OF WORK

Nalut General Hospital has an obsolete wastewater treatment plant (WWTP) that

not duly operational and considered unsafe to operate and maintain. Due to the

poor conditions of this WWTP, the hospital maintenance team has experienced

several environmental incidents resulting in many complaints of Nalut

Community against the air quality impact since April 2011.

Eni North Africa (ENA) in cooperation with National Oil Corporation (NOC),

under the framework of Memorandum of Understanding 2017 for Health &

Education development initiatives in Libya, decided to intervene in support of the

local communities, upgrading the Nalut General Hospital obsolete WWTP,

replacing it with a modern unit.

The scope of supply shall include for the following items, activities and constraints

within the boundary limits shown as defined in tender:

Site survey to check the existing wastewater package and identification of

components possible to be used within the new wastewater treatment

package.

Contractor to collect wastewater sample, perform water analysis, and

design the wastewater plant accordingly.

Design, construct, commissioning, start-up and handover to hospital of a

new WWTP with a capacity of 250 Cubic meters per day.

The Contractor must supply all equipment, material and resources that

might be required to ensure smooth run of the project in line with schedule.

Provide brand new equipment to be delivered with one year warranty.

Perform all civil works, including but not limited to engineering,

construction, painting excavation, new tanks construction, existing tanks

modification, waterproofing, reinforced concrete, qualified

manpower…etc

Perform all mechanical work including but not limited to engineering,

pumps, pipes, mixers, valves, installation, commissioning …etc .

Perform all electrical works including but not limited to engineering,

control panels, cables, cable trays, installation, commissioning …etc.

Perform all instrumentation works including but not limited to

engineering, instruments, PLC, HMI, junction boxes, installation,

commissioning …etc.

Provide any further material needed during the project activity

Prepare all preliminary and detailed engineering, schedules of quantities

and materials and all drawings and maps such as civil, electrical and

mechanical and others if needed, including the final structural drawings of

the water collection tank, feeder lines, connecting lines to the existing

pumping station .

Train 5 technicians on the operation and maintenance activities of the

wastewater treatment plant.

Provide the spare parts for two years preventive maintenance according to

Operation & Maintenance Manual to grant normal operability of the

WWTP.

Procurement and installation of CCTV equipment around the existing

fence and the system of cameras & equipment should be placed in the

housekeeper room.

Other minor refurbishment works for the ancillaries

Maintenance of the main water pipeline network, by purchasing and

installing a new copper pipeline with the same existed sizes and dimensions

TECHNICAL MINIMUM REQUIREMENTS

Contractor shall provide the following minimum technical requirements:

Previous documented experiences in similar projects

Availability of machinery and equipment

Qualified man power

HSE MINIMUM REQUIREMENTS

Contractor shall provide the following minimum HSE requirements:

Compliance with local/national regulations regarding environmental

protection, safety, health and welfare/insurance issues

HSE policy and objectives;

Occupational Health and Safety Management: Details of its Safety

Management structure and reporting system;

Environmental Management: Evidence of how it intends to manage the

environmental aspects of the contracts and relevant environmental

procedures applied to the Contract activities;

A record of hazards/impacts in the workplace related to the general

activities associated with the CONTRACT, inclusive of Subcontractor

activities.

Planning of activities required for the identification, assessment and

management of the significant HSE risks associated with the work;

Evidences about the: Firefighting arrangements, First Aid arrangements,

Lifting Equipment lists and certificates

Organization Chart focusing on HSE roles and responsibilities (including

CONTRACTOR’s key resources) and showing the name, title and contacts

of its HSE representatives;

Emergency response management, covering but not limited to: medical

evacuation, road traffic accidents, oil/chemical spills, man/vehicle lost,

offshore incidents…;

HSE training plan;

A HSE audit and inspection plan/schedule;

HSE reporting process;

Fitness to Work Certificate of contractor and sub-contractor personnel;

Certification of all Critical Machinery and Equipment’s (cranes, forklifts,

power generators, etc.);

Comply with all PTW requirements for all jobs to be done within the

COMPANY’s premises;

Standard PPEs for all contractors and sub-contractors employees;

Equipment Maintenance records.

This enquiry shall not be considered an invitation to bid and therefore it does not

represent or constitute any promise, obligation or commitment of any kind on the

part of ENI NA, to enter into any agreement or arrangement with you or with any

company participating in this pre-enquiry.

Consequently, all data and information provided by you shall not be construed as

a commitment on the part of ENI NA, to enter into any agreement or arrangement

with you, nor shall they entitle your company to claim any indemnity from ENI

NA.

All data and information provided pursuant to this enquiry will be treated as

strictly confidential and will not be disclosed or communicated to non-authorized

persons or companies except

ENI NA.

If interested and without any obligation on our part, you are kindly requested to

Submit the whole documentation requested above.

Documentation shall be saved in Acrobat “.pdf” format and sent by email to:

Important Note:should your Company not providing the above required specific

Services, you are kindly requested to not apply for this pre-qualification process.

The closing date for the submission of the above mentioned documentation is fixed

to 1st December 2020 at noon (Libyan time), or earlier.

You might also like

- Project Quality Plan: ContentDocument25 pagesProject Quality Plan: ContentAbd Rahim57% (7)

- Low-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionFrom EverandLow-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionRating: 5 out of 5 stars5/5 (1)

- Scope of Work For Commissioning and PrecommissioningDocument19 pagesScope of Work For Commissioning and PrecommissioningSaravanan Paramasivam100% (5)

- Work Method Rehabilitation of Water Storage Tank-Shell R.A PDFDocument4 pagesWork Method Rehabilitation of Water Storage Tank-Shell R.A PDFIziyon Harrison OsalobohNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Radar Plotting SheetDocument1 pageRadar Plotting SheetCl dubeyNo ratings yet

- Consultant Service For EPC ContractDocument10 pagesConsultant Service For EPC Contractjaberbahari100% (1)

- Contracts, Biddings and Tender:Rule of ThumbFrom EverandContracts, Biddings and Tender:Rule of ThumbRating: 5 out of 5 stars5/5 (1)

- Rubber Burn Test SpecsDocument1 pageRubber Burn Test SpecsTushar BagdeNo ratings yet

- A Brief History of The Vikings - Jonathan ClementsDocument1,459 pagesA Brief History of The Vikings - Jonathan ClementsRodrigo Hky100% (2)

- Mahmoud Fathallah Abdelmotaleb Mansour: Career SummaryDocument4 pagesMahmoud Fathallah Abdelmotaleb Mansour: Career SummaryHatem HusseinNo ratings yet

- Mohammad Abu-Radi ResumeDocument4 pagesMohammad Abu-Radi ResumeMohammad Abu-RadiNo ratings yet

- Mechanical Eng 2 3Document4 pagesMechanical Eng 2 3RifatNo ratings yet

- STP SPecifiucationsDocument186 pagesSTP SPecifiucationsAnonymous d6tUk8QZNo ratings yet

- 12 OperationAndMaintenance319to328Document10 pages12 OperationAndMaintenance319to328gaurangagola1991No ratings yet

- Volume III - O&MDocument25 pagesVolume III - O&MStephen Rajkumar JayakumarNo ratings yet

- TOR For EM Engineer South 20240206Document6 pagesTOR For EM Engineer South 20240206wondeambaw036No ratings yet

- Huawei DC Mep+Equipment Boq Ph1a 20210421Document91 pagesHuawei DC Mep+Equipment Boq Ph1a 20210421Sergio Solar melendezNo ratings yet

- Contractor HSE Management Procedure: Attachment 1 - Enec Standard Hse Requirements For ContractorsDocument2 pagesContractor HSE Management Procedure: Attachment 1 - Enec Standard Hse Requirements For ContractorsEMP KFMNo ratings yet

- IFB EPRU 001 2015 Technical Specification Part1Document71 pagesIFB EPRU 001 2015 Technical Specification Part1Cristopher JavidoNo ratings yet

- Areo ToluDocument9 pagesAreo ToluAreo Tolulope ANo ratings yet

- Specification - (5-2-2-3) Sludge Incineration SystemDocument8 pagesSpecification - (5-2-2-3) Sludge Incineration SystemAmir ShahzadNo ratings yet

- Abu Dhabi Equine Rev001Document70 pagesAbu Dhabi Equine Rev001mahmoudNo ratings yet

- 9 ScopeOfWorks130to150Document21 pages9 ScopeOfWorks130to150gaurangagola1991No ratings yet

- Gail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFDocument612 pagesGail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFChirag ShahNo ratings yet

- Volume II Sow (A) PipelineDocument114 pagesVolume II Sow (A) PipelineVeena Nagesh100% (1)

- Gottumukkala HemanthDocument11 pagesGottumukkala HemanthShankker KumarNo ratings yet

- 742 Method Statement 2011Document20 pages742 Method Statement 2011kikokiko KarimNo ratings yet

- Sow TCP DST SWT 2023 - 2025 R0Document45 pagesSow TCP DST SWT 2023 - 2025 R0Marc LefrancqNo ratings yet

- PRFRM spcfctn-OnM CLG TwrsDocument21 pagesPRFRM spcfctn-OnM CLG TwrsimsayaaNo ratings yet

- Sample Specification For Procurement of Operation and Maintenance Services For Fresh Water Cooling TowersDocument19 pagesSample Specification For Procurement of Operation and Maintenance Services For Fresh Water Cooling TowersSimon LawNo ratings yet

- Construction Management BriefDocument8 pagesConstruction Management Briefsaravananr04No ratings yet

- Technicalspecification 7Document87 pagesTechnicalspecification 7anuragtiwari762No ratings yet

- 54-GENERAL Section - 1 - 57Document4 pages54-GENERAL Section - 1 - 57高欣东No ratings yet

- Electrical SupervisorDocument13 pagesElectrical SupervisorMarilyn PantorillaNo ratings yet

- CV Julius T P SilalahiDocument8 pagesCV Julius T P SilalahinabaratNo ratings yet

- Final TOR Owners EngineerDocument15 pagesFinal TOR Owners EngineerTriono SyakbaniNo ratings yet

- ECC ConditionsDocument4 pagesECC ConditionsMarlon AllecerNo ratings yet

- Method Statement - Site EstablishmentDocument4 pagesMethod Statement - Site EstablishmentaceNo ratings yet

- Tensile Test, Torsion Test: Conceptual EngineeringDocument7 pagesTensile Test, Torsion Test: Conceptual EngineeringMeryL AngNo ratings yet

- PTT Public Company Limited Ratchaburi World Cogeneration Company LimitedDocument49 pagesPTT Public Company Limited Ratchaburi World Cogeneration Company LimitedzhangjieNo ratings yet

- Annex A PHC Jet A1 Rev2Document30 pagesAnnex A PHC Jet A1 Rev2Chisom IkengwuNo ratings yet

- B ME Utilities and Existing Services V10Document10 pagesB ME Utilities and Existing Services V10Zaimi ZamaludinNo ratings yet

- Majid CVDocument7 pagesMajid CVAbdul Ahad LoneNo ratings yet

- Exhibit B - Scope of WorksDocument3 pagesExhibit B - Scope of WorksAhmet EpozhanNo ratings yet

- E & I Tender WorkDocument9 pagesE & I Tender Workmanojjuvali100% (1)

- Scope of Service - Senior Metering EngineerDocument2 pagesScope of Service - Senior Metering EngineerOtuagaNo ratings yet

- Oxygen Plant Repair - Project Management ConsultancyDocument6 pagesOxygen Plant Repair - Project Management ConsultancyOlatunji AjoseNo ratings yet

- A04 SOW - Boiler and Hot Water Heater ReplacementDocument10 pagesA04 SOW - Boiler and Hot Water Heater Replacementkikokiko KarimNo ratings yet

- Contact No: 00 91 85477 69130: Arjun KannambathDocument10 pagesContact No: 00 91 85477 69130: Arjun KannambathShankker KumarNo ratings yet

- Sai Kumar - CVDocument4 pagesSai Kumar - CVsai kumar GoduguNo ratings yet

- Indian Gen Const SpecsDocument154 pagesIndian Gen Const SpecsjungzkiNo ratings yet

- Pipeline Construction Specification (Pcs-01) Sp-1208Document80 pagesPipeline Construction Specification (Pcs-01) Sp-1208samkarthik47100% (1)

- Building Engineering DesignDocument3 pagesBuilding Engineering DesignTambilung MekarjayaNo ratings yet

- BOQDocument73 pagesBOQBhanuka samarakoonNo ratings yet

- MD Yusuf HvacDocument4 pagesMD Yusuf HvacMOHAMMED YUSUFNo ratings yet

- Specification of BuildingDocument168 pagesSpecification of BuildingroshanNo ratings yet

- Client: Method Statement For Construction of Civil WorksDocument17 pagesClient: Method Statement For Construction of Civil WorksAzharudin ZoechnyNo ratings yet

- STO (Repairs & Service) - Feb2015Document2 pagesSTO (Repairs & Service) - Feb2015666667No ratings yet

- Project Management For Procurement Management ModuleFrom EverandProject Management For Procurement Management ModuleNo ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Advanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3From EverandAdvanced Plumbing Techniques: A Comprehensive Guide to Tackling Complex Projects for the DIY Enthusiast: Homeowner Plumbing Help, #3No ratings yet

- Hazardous Area Hazardous Area ClassificaDocument106 pagesHazardous Area Hazardous Area ClassificaHedi Ben MohamedNo ratings yet

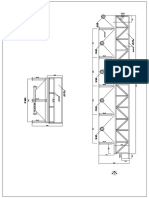

- Section Aa Section BB Fire Fighting TankDocument1 pageSection Aa Section BB Fire Fighting TankHedi Ben MohamedNo ratings yet

- Oisd GDN 178Document21 pagesOisd GDN 178Hedi Ben MohamedNo ratings yet

- Butterfly Valve K4 PVC-U - PP - PVDF Actuator ERDocument6 pagesButterfly Valve K4 PVC-U - PP - PVDF Actuator ERHedi Ben MohamedNo ratings yet

- Product Technical CatalogueDocument4 pagesProduct Technical CatalogueHedi Ben MohamedNo ratings yet

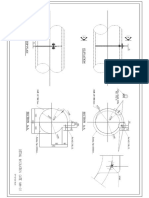

- Decanteur Ver1Document1 pageDecanteur Ver1Hedi Ben MohamedNo ratings yet

- Detail Isolating Gate Mh-01Document1 pageDetail Isolating Gate Mh-01Hedi Ben MohamedNo ratings yet

- Case Study - Fire Incident On MV of SPMDocument4 pagesCase Study - Fire Incident On MV of SPMHedi Ben MohamedNo ratings yet

- Amine Plant Troubleshooting and OptimizaDocument26 pagesAmine Plant Troubleshooting and OptimizaHedi Ben MohamedNo ratings yet

- Tank Pics-Filament Wound TanksDocument3 pagesTank Pics-Filament Wound TanksHedi Ben MohamedNo ratings yet

- FG Od en V2.0Document2 pagesFG Od en V2.0Hedi Ben MohamedNo ratings yet

- Multimedia Filter and Activated Carbon Filter Pilot Test StudyDocument10 pagesMultimedia Filter and Activated Carbon Filter Pilot Test StudyHedi Ben MohamedNo ratings yet

- Biological Odour Control System Specification - R1Document24 pagesBiological Odour Control System Specification - R1Hedi Ben MohamedNo ratings yet

- Decanteur Ver1Document1 pageDecanteur Ver1Hedi Ben MohamedNo ratings yet

- 9434-Sfe - Sequential Functional ExtractionDocument3 pages9434-Sfe - Sequential Functional ExtractionHedi Ben MohamedNo ratings yet

- Cross VentilationDocument1 pageCross VentilationHedi Ben MohamedNo ratings yet

- Remember: Always Call The Fire Department First: How Do Fire Extinguishers Work?Document2 pagesRemember: Always Call The Fire Department First: How Do Fire Extinguishers Work?Hedi Ben MohamedNo ratings yet

- Centrifugal Pumps - Engineering LibraryDocument9 pagesCentrifugal Pumps - Engineering LibraryHedi Ben MohamedNo ratings yet

- Fire Zone LayoutDocument1 pageFire Zone LayoutHedi Ben MohamedNo ratings yet

- Luxembourg Hydrant Design - EJet - Jet Fuel Engineering ConsultancyDocument3 pagesLuxembourg Hydrant Design - EJet - Jet Fuel Engineering ConsultancyHedi Ben MohamedNo ratings yet

- Purification of BiogasDocument15 pagesPurification of BiogasHedi Ben MohamedNo ratings yet

- Chapter 1: Shed Basics: PurposeDocument4 pagesChapter 1: Shed Basics: PurposeHedi Ben MohamedNo ratings yet

- Engineering Graphics NotesDocument115 pagesEngineering Graphics NotesThulasi Ram100% (1)

- Microcontroller Based Speech To Text Translation SystemDocument6 pagesMicrocontroller Based Speech To Text Translation SystemJay Prakash MandalNo ratings yet

- Travel Tourism in Bangladesh: A Study On Regent Tours & TravelDocument72 pagesTravel Tourism in Bangladesh: A Study On Regent Tours & TravelNahidNo ratings yet

- Aquion Battery Technology - 1216Document18 pagesAquion Battery Technology - 1216sinnlosNo ratings yet

- Fliqlo - Mobile AppDocument1 pageFliqlo - Mobile AppJon BaerNo ratings yet

- Are Urbanization, Industrialization and CO2 Emissions Cointegrated?Document30 pagesAre Urbanization, Industrialization and CO2 Emissions Cointegrated?doctshNo ratings yet

- Test Report CMI, 200 Amp 35kV Class "Tuf-Ex-Well II" Bushing WellDocument8 pagesTest Report CMI, 200 Amp 35kV Class "Tuf-Ex-Well II" Bushing WellCristobal BohorquezNo ratings yet

- XPR 300 Manual HyperthermDocument106 pagesXPR 300 Manual HyperthermDawitt BadilloNo ratings yet

- Academic Reading TestDocument14 pagesAcademic Reading Testjade kamboj0% (1)

- Pizzi 1993Document8 pagesPizzi 1993jgNo ratings yet

- Smoke Alarm User's Guide: For Model: PI2010Document16 pagesSmoke Alarm User's Guide: For Model: PI2010goawayNo ratings yet

- Exhaust Gas Recirculation (EGR)Document18 pagesExhaust Gas Recirculation (EGR)Srinath Pai100% (1)

- The Prince of Evolution - Lee Alan DugatkinDocument68 pagesThe Prince of Evolution - Lee Alan DugatkinDjordje78No ratings yet

- Elphos Erald: Police Chief Clarifies Child's ID Kit UsageDocument10 pagesElphos Erald: Police Chief Clarifies Child's ID Kit UsageThe Delphos HeraldNo ratings yet

- IEE Checklist InstructionsDocument20 pagesIEE Checklist InstructionsBalaji_Rajaman_2280No ratings yet

- Fil-Chin Engineering: To: Limketkai Attn: Mr. Eduard Oh Re: Heat ExchangerDocument6 pagesFil-Chin Engineering: To: Limketkai Attn: Mr. Eduard Oh Re: Heat ExchangerKeith Henrich M. ChuaNo ratings yet

- CCDS Parent Letter - Letter For Student-Contact To CaseDocument1 pageCCDS Parent Letter - Letter For Student-Contact To CaseActionNewsJaxNo ratings yet

- Project Proposal: Energy Efficient Building or Zero Energy BuildingDocument4 pagesProject Proposal: Energy Efficient Building or Zero Energy BuildingAdnanKhanNo ratings yet

- GSB PDFDocument4 pagesGSB PDFsachin sNo ratings yet

- IGNITE CIB 24 February 2024Document4 pagesIGNITE CIB 24 February 2024jigarNo ratings yet

- Serial Adder Mealy Modelling ProgramDocument22 pagesSerial Adder Mealy Modelling ProgrambcemailidNo ratings yet

- Lab ManualDocument41 pagesLab Manualprojectapply2023No ratings yet

- Asus T12C (X51C) Motherboard Schematic DiagramDocument94 pagesAsus T12C (X51C) Motherboard Schematic DiagramYblis100% (1)

- Soal Bahasa Inggris Kelas Xii Semua JurusanDocument13 pagesSoal Bahasa Inggris Kelas Xii Semua Jurusaneka sanjayaNo ratings yet

- English FinalDocument71 pagesEnglish FinalKhadeeja MarjanNo ratings yet

- Sherlock Holmes Script - Dialogue TranscriptDocument83 pagesSherlock Holmes Script - Dialogue TranscriptLocustaNo ratings yet

- c1Document7 pagesc1Ingrid Garcia de JaureguiNo ratings yet