Professional Documents

Culture Documents

Warning: Replacing The Main Chassis Batteries

Warning: Replacing The Main Chassis Batteries

Uploaded by

Adan ChanCopyright:

Available Formats

You might also like

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- 3 Phase Handbook ATS 1.1 Issue 3Document23 pages3 Phase Handbook ATS 1.1 Issue 3yorgo7002100% (2)

- vxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityDocument1 pagevxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityAlok PatilNo ratings yet

- User's Manual - Fuel Dispenser-EnGDocument123 pagesUser's Manual - Fuel Dispenser-EnGPabloNo ratings yet

- FAS8300 and FAS8700 - Replacing The Controller ModuleDocument21 pagesFAS8300 and FAS8700 - Replacing The Controller ModuleKhurram SaoodNo ratings yet

- Manual Deep Sea 520Document19 pagesManual Deep Sea 520MH..202367% (6)

- MSA2000 Controller ReplacementDocument4 pagesMSA2000 Controller ReplacementGeorge_TNTNo ratings yet

- Reemplazo Bateria TriconexDocument2 pagesReemplazo Bateria Triconexfergot2010No ratings yet

- MkII Connection Instructions Tadano AML M1 M2-TLDocument5 pagesMkII Connection Instructions Tadano AML M1 M2-TLImamFadiliNo ratings yet

- Challeger Testeo y AjusteDocument304 pagesChalleger Testeo y AjusteCarlos Irabedra100% (1)

- ROTHER SERVICE MANUAL cp130c Dcp330c Dcp540cnDocument383 pagesROTHER SERVICE MANUAL cp130c Dcp330c Dcp540cnelenoremail100% (1)

- What Is Meaning of Failsafe Systems - PLC, PLC Ladder, PLC Ebook, PLC ProgrammingDocument3 pagesWhat Is Meaning of Failsafe Systems - PLC, PLC Ladder, PLC Ebook, PLC ProgrammingSyed Hassan TariqNo ratings yet

- Autohelm 6000 Power Pilot Installation and Operating Handbook PDFDocument18 pagesAutohelm 6000 Power Pilot Installation and Operating Handbook PDFМилен НанковNo ratings yet

- Er-105-1-1 - Proflo No-Flow SwitchDocument10 pagesEr-105-1-1 - Proflo No-Flow SwitchJeff LNo ratings yet

- M0ST10N19-00 Installation Use and Maintenance Manual 1680093460102Document66 pagesM0ST10N19-00 Installation Use and Maintenance Manual 1680093460102Ira BilokonNo ratings yet

- Replacing The RealTime Clock Battery On A 32xxDocument10 pagesReplacing The RealTime Clock Battery On A 32xxPurushothama GnNo ratings yet

- Datavideo TLM-702 7" X 2 TFT LCD Monitors: Instruction ManualDocument9 pagesDatavideo TLM-702 7" X 2 TFT LCD Monitors: Instruction Manualangelo017No ratings yet

- Diagnosis and Testing Instrument Cluster: 2010 Dodge Grand Caravan 3.3L Eng SEDocument3 pagesDiagnosis and Testing Instrument Cluster: 2010 Dodge Grand Caravan 3.3L Eng SEMikeNo ratings yet

- Manual Control Temperatura WatlowDocument6 pagesManual Control Temperatura WatlowVladoussNo ratings yet

- Manual XTREME-1Document52 pagesManual XTREME-1ManojNo ratings yet

- Meridian GyrocompassDocument76 pagesMeridian GyrocompassRiddhi DasNo ratings yet

- Installation Viper 5101Document64 pagesInstallation Viper 5101bigdeshaNo ratings yet

- Instruction Manual: CDBR-BDocument14 pagesInstruction Manual: CDBR-BJeferson TadeuNo ratings yet

- Preface: Industrial Sewing Machine Digital AC Servo SystemDocument8 pagesPreface: Industrial Sewing Machine Digital AC Servo SystemJoão ArtilheiroNo ratings yet

- Amalgamador Promix ESP Pag.17-28 EspañolDocument84 pagesAmalgamador Promix ESP Pag.17-28 EspañolMarce CastroNo ratings yet

- Mpu 4 ManDocument44 pagesMpu 4 ManmagicchrisNo ratings yet

- Mirrowstic 3codeDocument16 pagesMirrowstic 3codeJesús EspinosaNo ratings yet

- 3500/44 Aeroderivative GT Vibration Monitor: Operation and Maintenance ManualDocument87 pages3500/44 Aeroderivative GT Vibration Monitor: Operation and Maintenance ManualDenis JimenezNo ratings yet

- D051 330Document20 pagesD051 330Rodriguez JohannNo ratings yet

- Sonachron Dwa-S Manual - DwasDocument28 pagesSonachron Dwa-S Manual - DwasexampleuserNo ratings yet

- Triconex Technical Application Note #54Document5 pagesTriconex Technical Application Note #54thiyagu05.infosysNo ratings yet

- X130 SVC Eng 091225Document92 pagesX130 SVC Eng 091225oiramlopesNo ratings yet

- Manual Inversor OFF GridDocument28 pagesManual Inversor OFF GridCalvin CrispimNo ratings yet

- Grundfosliterature 5768738Document36 pagesGrundfosliterature 5768738warmaster81No ratings yet

- Avital 5303 InstallationDocument64 pagesAvital 5303 Installationtou3600% (1)

- CHAPTER 16 Relé Alstom PortuguesDocument10 pagesCHAPTER 16 Relé Alstom Portuguestalys sartoriNo ratings yet

- EN FANOXTD GUIDE SIA OCEFSecondaryDist SIAB000B0010AA R03Document32 pagesEN FANOXTD GUIDE SIA OCEFSecondaryDist SIAB000B0010AA R03cosme pereiraNo ratings yet

- Smartonline Singlephase 10kvaDocument74 pagesSmartonline Singlephase 10kvaMagdiel Omar Zavala GutierrezNo ratings yet

- Model 4111 Installation Guide: © 2009 Directed Electronics, Vista, CA N4111L 2009-07Document52 pagesModel 4111 Installation Guide: © 2009 Directed Electronics, Vista, CA N4111L 2009-07Geovani RuizNo ratings yet

- Fault Finding Immobiliser: N.T. 3532A Xb0XDocument19 pagesFault Finding Immobiliser: N.T. 3532A Xb0Xsantia6768No ratings yet

- Gen ATSDocument42 pagesGen ATSM Rashid AshrafNo ratings yet

- Manual UPSDocument96 pagesManual UPSLarita89No ratings yet

- Schneider Altivar 31 ProgrammingDocument84 pagesSchneider Altivar 31 ProgrammingluckamaralNo ratings yet

- Parker SSD 650 Series User ManualDocument70 pagesParker SSD 650 Series User ManuallivanelNo ratings yet

- Libra-Ul-R: Quadro Comando Control Panel Centrale de Commande Cuadro de MandosDocument13 pagesLibra-Ul-R: Quadro Comando Control Panel Centrale de Commande Cuadro de MandosSumit SabaleNo ratings yet

- HP MSA P2000 G3 Modular Smart Array Controller Module Replacement InstructionsDocument4 pagesHP MSA P2000 G3 Modular Smart Array Controller Module Replacement InstructionsharryNo ratings yet

- Crio-9012 9014 Operating InstructionsDocument20 pagesCrio-9012 9014 Operating InstructionskalovireNo ratings yet

- Altivar 31 ManualDocument94 pagesAltivar 31 ManualYesid GómezNo ratings yet

- Altivar 31: Variable Speed Drives For Asynchronous MotorsDocument77 pagesAltivar 31: Variable Speed Drives For Asynchronous MotorsPepoNo ratings yet

- Acer Al1521 SM (ET)Document50 pagesAcer Al1521 SM (ET)zack9mm2003No ratings yet

- Mvi56 Mnetc User ManualDocument153 pagesMvi56 Mnetc User Manual19860103No ratings yet

- 03-0202 WH1 OperationDocument13 pages03-0202 WH1 Operationmao limingNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Steamshovel Press Issue 04Document60 pagesSteamshovel Press Issue 04liondog1No ratings yet

- Module 2 - Assessment ActivitiesDocument3 pagesModule 2 - Assessment Activitiesaj dumpNo ratings yet

- English For Nursing Topic 12 Reinforcing A Dietary ProgramDocument6 pagesEnglish For Nursing Topic 12 Reinforcing A Dietary ProgramEha Huwaida HayatiNo ratings yet

- Bartleby The ScrivenerDocument58 pagesBartleby The ScrivenerMrEvidenceLove100% (1)

- Mathematics: Quarter 3 - Module 5: Independent & Dependent EventsDocument19 pagesMathematics: Quarter 3 - Module 5: Independent & Dependent EventsAlexis Jon NaingueNo ratings yet

- Memoria Proyecto Informativo de Alcantarillado Domiciliario Miguel CorralDocument7 pagesMemoria Proyecto Informativo de Alcantarillado Domiciliario Miguel CorralCarlos MoralesNo ratings yet

- Form LRA 42Document3 pagesForm LRA 42Godfrey ochieng modiNo ratings yet

- Earth and Lice Science Quarter 2 BrochureDocument2 pagesEarth and Lice Science Quarter 2 BrochureCamille NavorNo ratings yet

- Muslim BotanistsDocument34 pagesMuslim BotanistsbilkaweNo ratings yet

- Internship Report On GPDocument45 pagesInternship Report On GPpavel2051No ratings yet

- Problem StatementDocument15 pagesProblem Statementcabamaro100% (3)

- Introduction To Awadh Architecture: Submitted By: Utkarsh Agarwal Pratibha Verma Ankit Shukla Sunaina BansalDocument7 pagesIntroduction To Awadh Architecture: Submitted By: Utkarsh Agarwal Pratibha Verma Ankit Shukla Sunaina BansalMahak Gupta100% (1)

- Spice Hub - Values NewDocument17 pagesSpice Hub - Values NewJohn ShrinksNo ratings yet

- BFI E BrochureADocument6 pagesBFI E BrochureAAnuj JainNo ratings yet

- Tellabs Inspire Magazine - Five Steps To A Smart Mobile InternetDocument2 pagesTellabs Inspire Magazine - Five Steps To A Smart Mobile InternetTellabsNo ratings yet

- Post Event Report WritingDocument6 pagesPost Event Report WritingMansi PatelNo ratings yet

- Lataif, Exert Tafseer by Al QushayriDocument16 pagesLataif, Exert Tafseer by Al Qushayrimadanuodad100% (1)

- Power Point Presentation About Modalds of Obligations.Document9 pagesPower Point Presentation About Modalds of Obligations.Sebastian Orjuela HerediaNo ratings yet

- Create BAPI TutorialDocument28 pagesCreate BAPI TutorialRoberto Trejos GonzalezNo ratings yet

- Guaranty and Suretyship CasesDocument82 pagesGuaranty and Suretyship Cases001nooneNo ratings yet

- Steering System (Notes On Tom)Document8 pagesSteering System (Notes On Tom)Vaibhav Vithoba Naik100% (1)

- Matter Wars Pure Substance Vs Mixture by A. D. Barcelon PDFDocument5 pagesMatter Wars Pure Substance Vs Mixture by A. D. Barcelon PDFjonna mae ranzaNo ratings yet

- Ip Talks Presentation - Keaune ReevesDocument2 pagesIp Talks Presentation - Keaune Reeveskarina talledoNo ratings yet

- Kakhisong Church A2-ModelDocument1 pageKakhisong Church A2-ModelanzaniNo ratings yet

- Jersey Documentation 1.0.3 User GuideDocument35 pagesJersey Documentation 1.0.3 User Guidenaresh921No ratings yet

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDocument11 pagesRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (2)

- Article 2013 Legume Perspectives 1-45-46Document53 pagesArticle 2013 Legume Perspectives 1-45-46kondwanigift0101No ratings yet

- Final Defense in PR2Document53 pagesFinal Defense in PR2Friza ann marie NiduazaNo ratings yet

- To-Do List FormulaDocument1 pageTo-Do List FormulaPre MANo ratings yet

Warning: Replacing The Main Chassis Batteries

Warning: Replacing The Main Chassis Batteries

Uploaded by

Adan ChanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Warning: Replacing The Main Chassis Batteries

Warning: Replacing The Main Chassis Batteries

Uploaded by

Adan ChanCopyright:

Available Formats

236 Chapter 3 Installation and Maintenance

For assistance with load devices that might be sensitive to such glitches, please contact the

Global Customer Support (GCS) center.

Procedure

1 From TriStation 1131, disable OVD on all or on specific Digital Output Modules. For

instructions, see the TriStation 1131 Developers Guide for the version of TriStation being

used.

2 Log the date when OVD was disabled so that you can re-enable the OVDs for 10 minutes

every three months. If this is not possible due to process concerns, do one of the

following:

Replace the module, while it is online, with one that has been operated without the

OVDs disabled.

Reserve a slot in a chassis as an OVD test slot and rotate modules through the OVD

test slot every three months.

For information on OVD enabling, see Enabling Disabled Output Voter Diagnostics on

page 238.

Replacing the Main Chassis Batteries

This procedure explains how to replace the Main Processor memory backup batteries in a high-

density Tricon system. The batteries are located on the Main Chassis next to the I/O bus

connectors. If no power is being supplied to the Main Chassis, these batteries can maintain the

Main Processors memory contents for a cumulative period of six months.

WARNING

UNINTENDED EQUIPMENT OPERATION

Replace a battery with only the same or equivalent type. Dispose of used lithium batteries according to

local, applicable regulations. Waste management companies can provide assistance.

Failure to follow these instructions can result in death, serious injury, environmental damage, or

equipment damage.

Each battery has a shelf life of 8-10 years. For batteries that are installed in a system, Schneider

Electric recommends replacing the batteries every 5-7 years, or after 6 months of cumulative use,

whichever comes first.

Schneider Electric recommends replacing the batteries during offline maintenance periods;

however, they can be replaced while the system is online. Schneider Electric recommends that

you follow your applicable plant maintenance procedures to replace batteries in an online

system.

For specifications and part numbers, see Appendix D, Recommended Replacement Parts.

Planning and Installation Guide for Tricon 11.5 Systems

Implementation and Maintenance 237

In low-density Tricon systems, the Main Processor memory backup batteries are in the Main

Chassis Power Modules. Refer to the applicable version of the Planning and Installation Guide

for Tricon Systems for a replacement procedure.

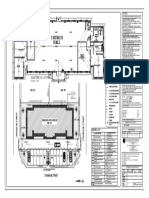

Figure 90 Battery Location and Access Cover

Procedure

1 Before starting, ensure you have a screwdriver.

2 Remove the battery access cover by squeezing the left side of the cover with your hand

to detach the small locking tab.

3 Noting the orientation of the batteries, remove each one with your hand. If necessary,

use a screwdriver to detach each battery from its position, then remove with your hand.

4 Insert the replacement batteries in the same orientation as the originalswith the

positive terminal facing the top of the chassis. Snap each battery firmly in place.

Planning and Installation Guide for Tricon 11.5 Systems

238 Chapter 3 Installation and Maintenance

5 Replace the battery access cover by:

Inserting the large locking tab under the right edge of the battery cut-out.

Squeezing the left side of the battery access cover with your hand and inserting the

small locking tab into the left edge of the battery cut-out.

Pressing the cover firmly to ensure it is locked in place.

Enabling Disabled Output Voter Diagnostics

This procedure explains how to enable disabled Output Voter Diagnostics (OVD) used by

Digital Output Modules. In some systems, these diagnostics can cause glitches that affect the

controlled process. If OVD has been disabled, it should be enabled periodically.

This action provides 100 percent failure detection for all components, particularly those that

remain in a single state for long periods of time. For example, if an output is always On, OVD

cannot determine if faults are present that would prevent the output from being turned Off.

WARNING

UNINTENDED EQUIPMENT OPERATION

Disabling the Output Voter Diagnostics is not recommended; however, if it is required due to process

interference concerns, it can be done if, and only if you follow the proof-test interval identified in the

specification table for your DO module.

Failure to follow these instructions can result in death, serious injury, environmental damage, or

equipment damage.

Procedure

1 Ensure the controlled process is shut down. (Do not stop the control program from

running.)

2 In TriStation 1131, go to the Controller Panel > Commands menu and enable the

disabled OVD modules.

3 Leave OVD enabled for a minimum of 10 minutes to verify the stability of the modules.

4 If required, disable OVD.

Planning and Installation Guide for Tricon 11.5 Systems

Implementation and Maintenance 239

Toggling Field I/O Points

To help allow complete fault-detection coverage of the digital circuitry in the modules listed in

Table 80, perform the following procedures.

Toggling Field I/O Points on DI Modules

1 Use TriStation 1131 to disable the field points.

2 Force the input to each point from outside the safety system, and leave each point in this

state for several minutes.

3 Use TriStation 1131 to re-enable the disabled field points.

Toggling Field I/O Points on DO Modules

1 Use TriStation 1131 to disable the field points, and then force the field points from

their normal operational state to the opposite state.

2 Leave each point in the opposite state for several minutes.

3 Use TriStation 1131 to re-enable the disabled field points.

Toggle the field points at least as frequently as the Minimum Toggle Rate identified in the

specifications for the module.

Ideally, this type of testing is performed with the controlled process offline.

For instructions on how to toggle field points, see Disabling Points and Forcing Points in

the TriStation 1131 Developers Guide.

Table 80 DI Modules and DO Modules that Require Field Points to be Toggled

Model Description

3501E/T 115 VAC/VDC Digital Input

3502E 48 VAC/VDC Digital Input, normally off points only

3503E 24 VAC/VDC Digital Input, normally off points only

3505E 24 VDC Digital Input, normally off points only

3601E/T 115 VAC Digital Output

Verifying Spare Modules

The Tricon controller automatically tests all modules installed in the system. The only action

needed to check the integrity of a spare module is to periodically install it in an online system.

Spare I/O modules should be installed as hot-spare modules because the controller

automatically shifts control between the active and hot-spare modules.

Control between active and hot-spare modules changes as follows:

Periodically, approximately once an hour

After a system power outage

After an MP re-education

Planning and Installation Guide for Tricon 11.5 Systems

You might also like

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- 3 Phase Handbook ATS 1.1 Issue 3Document23 pages3 Phase Handbook ATS 1.1 Issue 3yorgo7002100% (2)

- vxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityDocument1 pagevxBjICCrQ7eQYyAgq0O3cg - Debit Credit Rules ActivityAlok PatilNo ratings yet

- User's Manual - Fuel Dispenser-EnGDocument123 pagesUser's Manual - Fuel Dispenser-EnGPabloNo ratings yet

- FAS8300 and FAS8700 - Replacing The Controller ModuleDocument21 pagesFAS8300 and FAS8700 - Replacing The Controller ModuleKhurram SaoodNo ratings yet

- Manual Deep Sea 520Document19 pagesManual Deep Sea 520MH..202367% (6)

- MSA2000 Controller ReplacementDocument4 pagesMSA2000 Controller ReplacementGeorge_TNTNo ratings yet

- Reemplazo Bateria TriconexDocument2 pagesReemplazo Bateria Triconexfergot2010No ratings yet

- MkII Connection Instructions Tadano AML M1 M2-TLDocument5 pagesMkII Connection Instructions Tadano AML M1 M2-TLImamFadiliNo ratings yet

- Challeger Testeo y AjusteDocument304 pagesChalleger Testeo y AjusteCarlos Irabedra100% (1)

- ROTHER SERVICE MANUAL cp130c Dcp330c Dcp540cnDocument383 pagesROTHER SERVICE MANUAL cp130c Dcp330c Dcp540cnelenoremail100% (1)

- What Is Meaning of Failsafe Systems - PLC, PLC Ladder, PLC Ebook, PLC ProgrammingDocument3 pagesWhat Is Meaning of Failsafe Systems - PLC, PLC Ladder, PLC Ebook, PLC ProgrammingSyed Hassan TariqNo ratings yet

- Autohelm 6000 Power Pilot Installation and Operating Handbook PDFDocument18 pagesAutohelm 6000 Power Pilot Installation and Operating Handbook PDFМилен НанковNo ratings yet

- Er-105-1-1 - Proflo No-Flow SwitchDocument10 pagesEr-105-1-1 - Proflo No-Flow SwitchJeff LNo ratings yet

- M0ST10N19-00 Installation Use and Maintenance Manual 1680093460102Document66 pagesM0ST10N19-00 Installation Use and Maintenance Manual 1680093460102Ira BilokonNo ratings yet

- Replacing The RealTime Clock Battery On A 32xxDocument10 pagesReplacing The RealTime Clock Battery On A 32xxPurushothama GnNo ratings yet

- Datavideo TLM-702 7" X 2 TFT LCD Monitors: Instruction ManualDocument9 pagesDatavideo TLM-702 7" X 2 TFT LCD Monitors: Instruction Manualangelo017No ratings yet

- Diagnosis and Testing Instrument Cluster: 2010 Dodge Grand Caravan 3.3L Eng SEDocument3 pagesDiagnosis and Testing Instrument Cluster: 2010 Dodge Grand Caravan 3.3L Eng SEMikeNo ratings yet

- Manual Control Temperatura WatlowDocument6 pagesManual Control Temperatura WatlowVladoussNo ratings yet

- Manual XTREME-1Document52 pagesManual XTREME-1ManojNo ratings yet

- Meridian GyrocompassDocument76 pagesMeridian GyrocompassRiddhi DasNo ratings yet

- Installation Viper 5101Document64 pagesInstallation Viper 5101bigdeshaNo ratings yet

- Instruction Manual: CDBR-BDocument14 pagesInstruction Manual: CDBR-BJeferson TadeuNo ratings yet

- Preface: Industrial Sewing Machine Digital AC Servo SystemDocument8 pagesPreface: Industrial Sewing Machine Digital AC Servo SystemJoão ArtilheiroNo ratings yet

- Amalgamador Promix ESP Pag.17-28 EspañolDocument84 pagesAmalgamador Promix ESP Pag.17-28 EspañolMarce CastroNo ratings yet

- Mpu 4 ManDocument44 pagesMpu 4 ManmagicchrisNo ratings yet

- Mirrowstic 3codeDocument16 pagesMirrowstic 3codeJesús EspinosaNo ratings yet

- 3500/44 Aeroderivative GT Vibration Monitor: Operation and Maintenance ManualDocument87 pages3500/44 Aeroderivative GT Vibration Monitor: Operation and Maintenance ManualDenis JimenezNo ratings yet

- D051 330Document20 pagesD051 330Rodriguez JohannNo ratings yet

- Sonachron Dwa-S Manual - DwasDocument28 pagesSonachron Dwa-S Manual - DwasexampleuserNo ratings yet

- Triconex Technical Application Note #54Document5 pagesTriconex Technical Application Note #54thiyagu05.infosysNo ratings yet

- X130 SVC Eng 091225Document92 pagesX130 SVC Eng 091225oiramlopesNo ratings yet

- Manual Inversor OFF GridDocument28 pagesManual Inversor OFF GridCalvin CrispimNo ratings yet

- Grundfosliterature 5768738Document36 pagesGrundfosliterature 5768738warmaster81No ratings yet

- Avital 5303 InstallationDocument64 pagesAvital 5303 Installationtou3600% (1)

- CHAPTER 16 Relé Alstom PortuguesDocument10 pagesCHAPTER 16 Relé Alstom Portuguestalys sartoriNo ratings yet

- EN FANOXTD GUIDE SIA OCEFSecondaryDist SIAB000B0010AA R03Document32 pagesEN FANOXTD GUIDE SIA OCEFSecondaryDist SIAB000B0010AA R03cosme pereiraNo ratings yet

- Smartonline Singlephase 10kvaDocument74 pagesSmartonline Singlephase 10kvaMagdiel Omar Zavala GutierrezNo ratings yet

- Model 4111 Installation Guide: © 2009 Directed Electronics, Vista, CA N4111L 2009-07Document52 pagesModel 4111 Installation Guide: © 2009 Directed Electronics, Vista, CA N4111L 2009-07Geovani RuizNo ratings yet

- Fault Finding Immobiliser: N.T. 3532A Xb0XDocument19 pagesFault Finding Immobiliser: N.T. 3532A Xb0Xsantia6768No ratings yet

- Gen ATSDocument42 pagesGen ATSM Rashid AshrafNo ratings yet

- Manual UPSDocument96 pagesManual UPSLarita89No ratings yet

- Schneider Altivar 31 ProgrammingDocument84 pagesSchneider Altivar 31 ProgrammingluckamaralNo ratings yet

- Parker SSD 650 Series User ManualDocument70 pagesParker SSD 650 Series User ManuallivanelNo ratings yet

- Libra-Ul-R: Quadro Comando Control Panel Centrale de Commande Cuadro de MandosDocument13 pagesLibra-Ul-R: Quadro Comando Control Panel Centrale de Commande Cuadro de MandosSumit SabaleNo ratings yet

- HP MSA P2000 G3 Modular Smart Array Controller Module Replacement InstructionsDocument4 pagesHP MSA P2000 G3 Modular Smart Array Controller Module Replacement InstructionsharryNo ratings yet

- Crio-9012 9014 Operating InstructionsDocument20 pagesCrio-9012 9014 Operating InstructionskalovireNo ratings yet

- Altivar 31 ManualDocument94 pagesAltivar 31 ManualYesid GómezNo ratings yet

- Altivar 31: Variable Speed Drives For Asynchronous MotorsDocument77 pagesAltivar 31: Variable Speed Drives For Asynchronous MotorsPepoNo ratings yet

- Acer Al1521 SM (ET)Document50 pagesAcer Al1521 SM (ET)zack9mm2003No ratings yet

- Mvi56 Mnetc User ManualDocument153 pagesMvi56 Mnetc User Manual19860103No ratings yet

- 03-0202 WH1 OperationDocument13 pages03-0202 WH1 Operationmao limingNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Steamshovel Press Issue 04Document60 pagesSteamshovel Press Issue 04liondog1No ratings yet

- Module 2 - Assessment ActivitiesDocument3 pagesModule 2 - Assessment Activitiesaj dumpNo ratings yet

- English For Nursing Topic 12 Reinforcing A Dietary ProgramDocument6 pagesEnglish For Nursing Topic 12 Reinforcing A Dietary ProgramEha Huwaida HayatiNo ratings yet

- Bartleby The ScrivenerDocument58 pagesBartleby The ScrivenerMrEvidenceLove100% (1)

- Mathematics: Quarter 3 - Module 5: Independent & Dependent EventsDocument19 pagesMathematics: Quarter 3 - Module 5: Independent & Dependent EventsAlexis Jon NaingueNo ratings yet

- Memoria Proyecto Informativo de Alcantarillado Domiciliario Miguel CorralDocument7 pagesMemoria Proyecto Informativo de Alcantarillado Domiciliario Miguel CorralCarlos MoralesNo ratings yet

- Form LRA 42Document3 pagesForm LRA 42Godfrey ochieng modiNo ratings yet

- Earth and Lice Science Quarter 2 BrochureDocument2 pagesEarth and Lice Science Quarter 2 BrochureCamille NavorNo ratings yet

- Muslim BotanistsDocument34 pagesMuslim BotanistsbilkaweNo ratings yet

- Internship Report On GPDocument45 pagesInternship Report On GPpavel2051No ratings yet

- Problem StatementDocument15 pagesProblem Statementcabamaro100% (3)

- Introduction To Awadh Architecture: Submitted By: Utkarsh Agarwal Pratibha Verma Ankit Shukla Sunaina BansalDocument7 pagesIntroduction To Awadh Architecture: Submitted By: Utkarsh Agarwal Pratibha Verma Ankit Shukla Sunaina BansalMahak Gupta100% (1)

- Spice Hub - Values NewDocument17 pagesSpice Hub - Values NewJohn ShrinksNo ratings yet

- BFI E BrochureADocument6 pagesBFI E BrochureAAnuj JainNo ratings yet

- Tellabs Inspire Magazine - Five Steps To A Smart Mobile InternetDocument2 pagesTellabs Inspire Magazine - Five Steps To A Smart Mobile InternetTellabsNo ratings yet

- Post Event Report WritingDocument6 pagesPost Event Report WritingMansi PatelNo ratings yet

- Lataif, Exert Tafseer by Al QushayriDocument16 pagesLataif, Exert Tafseer by Al Qushayrimadanuodad100% (1)

- Power Point Presentation About Modalds of Obligations.Document9 pagesPower Point Presentation About Modalds of Obligations.Sebastian Orjuela HerediaNo ratings yet

- Create BAPI TutorialDocument28 pagesCreate BAPI TutorialRoberto Trejos GonzalezNo ratings yet

- Guaranty and Suretyship CasesDocument82 pagesGuaranty and Suretyship Cases001nooneNo ratings yet

- Steering System (Notes On Tom)Document8 pagesSteering System (Notes On Tom)Vaibhav Vithoba Naik100% (1)

- Matter Wars Pure Substance Vs Mixture by A. D. Barcelon PDFDocument5 pagesMatter Wars Pure Substance Vs Mixture by A. D. Barcelon PDFjonna mae ranzaNo ratings yet

- Ip Talks Presentation - Keaune ReevesDocument2 pagesIp Talks Presentation - Keaune Reeveskarina talledoNo ratings yet

- Kakhisong Church A2-ModelDocument1 pageKakhisong Church A2-ModelanzaniNo ratings yet

- Jersey Documentation 1.0.3 User GuideDocument35 pagesJersey Documentation 1.0.3 User Guidenaresh921No ratings yet

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDocument11 pagesRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (2)

- Article 2013 Legume Perspectives 1-45-46Document53 pagesArticle 2013 Legume Perspectives 1-45-46kondwanigift0101No ratings yet

- Final Defense in PR2Document53 pagesFinal Defense in PR2Friza ann marie NiduazaNo ratings yet

- To-Do List FormulaDocument1 pageTo-Do List FormulaPre MANo ratings yet