Professional Documents

Culture Documents

Saudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 3-Jul-18 CP

Saudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 3-Jul-18 CP

Uploaded by

karthi51289Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 3-Jul-18 CP

Saudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 3-Jul-18 CP

Uploaded by

karthi51289Copyright:

Available Formats

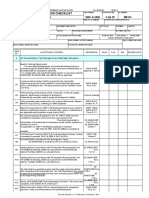

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.

00 30-Apr-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Cathodic Protection Testing for Marine Structures SATR-X-3206 3-Jul-18 CP-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

TEST PROCEDURE ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

A. Appropriate safety precautions must be followed when making electrical measurements:

Use properly insulated test lead clips and terminals to avoid contact with

unexpected hazardous voltages.

- Test clips should be attached one at a time each time a connection is

SAEP-332

A1 made.

Sec. 4 e

- A single hand should be used to make the connection, in a well balanced

body position, while the other hand should be free from resting on any

surface.

Use caution when long test leads (100 meters or longer) are extended

near overhead high voltage AC power lines, since hazardous voltages can

SAEP-332

A2 be induced into the test leads. Use rubber mats, rubber gloves, or both,

Sec. 4 f

when making measurements if induced AC potentials over 15 volts are

measured on pipelines near high voltage AC power lines.

Use caution when stringing test leads across streets, roads and other SAEP-332

A3

locations subject to vehicular traffic. Sec. 4

Use caution when making tests at electrical isolation devices. Appropriate

voltage detection instruments or voltmeters with insulated test leads SAEP-332

A3

should be used to determine if hazardous voltages exist before Sec. 4

proceeding with tests.

Personnel must be knowledgeable and qualified in electrical safety

SAEP-332

A4 precautions prior to installing, adjusting, repairing or removing impressed

Sec. 4

current protection equipment.

Testing should be avoided when thunderstorms are in the area. Remote

SAEP-332

A5 lightning strikes can create hazardous voltage surges that travel along the

Sec. 4

pipe under test.

B CP Test Equipment and Maintenance- Voltmeters, ammeters and Reference Electrodes

Ensure that the proper voltmeters and ammeters and suitable reference SAES-X-300

B1

electrodes was used for CP testing.SAEP-332, Section 7 Sec. 3.1

Check the meter batteries periodically to ensure they still function

SAES-X-300

B2 properly. Generally, they should be replaced every year. SAEP-332,

Sec. 3.1

Section 7

SAES-X-300

B3 Ensure that all meters was calibrated.SAEP-332, Section 7

Sec. 3.1

Ensure that high input impedance meters for structure-to-electrolyte

SAES-X-300

B4 potential measurements, especially in areas of high resistivity was used.

Sec. 3.1

Input impedance should be 20 megohms or greater.SAEP-332, Section 7

Saudi Aramco: Company General Use

Use a clamp-on-ammeter for the direct measurements of DC currents.

SAES-X-300

B5 Meters having current measuring capacity up to 200 amps and a variety of

Sec. 3.1

clamp sizes are preferred.SAEP-332, Section 7

Ensure that the copper-copper sulfate and silver-silver chloride reference SAES-X-300

B6

electrodes was properly maintained.SAEP-332, Section 7 Sec. 3.1

Check test leads of voltmeters used for structure-to-electrolyte

measurements periodically, for continuity and integrity. Repair or replace SAES-X-300

B7

faulty leads or connections before making measurements. SAEP-332, Sec. 3.1

Section 7

Testing and Commissioning should be completed by technicians with a

minimum of two years verifiable field experience and with a minimum

B8 SAEP-332, Sec. 6

industry certification level of NACE CP Level 2.

Minimum design life for the cathodic protection systems shall be 25 years

as follows:

a. Galvanic anodes only: 25 years (preferably for offshore pipelines and SAES-X-300

B9

non-electrified / non energized structures) and Sec. 6.3

b. Impressed current anodes: 25 years (preferably for electrified /

energized structures)

GALVANIC ANODE TESTING

C. TEST RESULTS

STRUCTURE TO POLARIZATION

GALVANIC ANODE

EQUIPMENT IDENTIFICATION TEST POINTS LOCATION ELECTROLYTE CURRENT REMARKS

TYPE (Amp)

POTENTIAL (mV)

Volt Meter

Brand: ______________

S/N: ______________

Calib. Date:___________

Ammeter

Brand: ______________

S/N: ______________

Calib. Date:___________

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Cathodic Protection Testing for Marine Structures SATR-X-3206 3-Jul-18 CP-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand TestingDocument10 pagesSaudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand Testingkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Syn Gto 52 RollerDocument1 pageSyn Gto 52 RollerSamsung Kzoom100% (1)

- Saudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 15-Jul-18 CPDocument3 pagesSaudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 15-Jul-18 CPSreni Excel MacrosNo ratings yet

- Saudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 24-Jul-18 CPDocument3 pagesSaudi Aramco Test Report: Cathodic Protection Testing For Marine Structures SATR-X-3206 24-Jul-18 CPnadeem shaikhNo ratings yet

- Saudi Aramco Test Report: External Tank Bottom Testing 24-Jul-18 CP-SATR-X-3204Document7 pagesSaudi Aramco Test Report: External Tank Bottom Testing 24-Jul-18 CP-SATR-X-3204nadeem shaikhNo ratings yet

- Saudi Aramco Test Report: External Tank Bottom Testing 3-Jul-18 CP-SATR-X-3204Document7 pagesSaudi Aramco Test Report: External Tank Bottom Testing 3-Jul-18 CP-SATR-X-3204karthi51289No ratings yet

- Saudi Aramco Test Report: Internal Tank Bottom Testing CP-SATR-X-3205Document8 pagesSaudi Aramco Test Report: Internal Tank Bottom Testing CP-SATR-X-3205Yehia FelifelNo ratings yet

- Saudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202Document7 pagesSaudi Aramco Test Report: DC Rectifier Testing 24-Jul-18 CP-SATR-X-3202nadeem shaikhNo ratings yet

- Saudi Aramco Test Report: External Tank Bottom Testing CP-SATR-X-3204Document8 pagesSaudi Aramco Test Report: External Tank Bottom Testing CP-SATR-X-3204Yehia FelifelNo ratings yet

- SATR-X-3203 Rev 7Document10 pagesSATR-X-3203 Rev 7Rohit BassNo ratings yet

- Saudi Aramco Test Report: DC Rectifier Testing CP-SATR-X-3202Document8 pagesSaudi Aramco Test Report: DC Rectifier Testing CP-SATR-X-3202Yehia FelifelNo ratings yet

- Saudi Aramco Test Report: Plant Potential Survey Testing 3-Jul-18 CP-SATR-X-3203Document10 pagesSaudi Aramco Test Report: Plant Potential Survey Testing 3-Jul-18 CP-SATR-X-3203karthi51289No ratings yet

- Saudi Aramco Test Report: DC Rectifier Testing 3-Jul-18 CP-SATR-X-3202Document7 pagesSaudi Aramco Test Report: DC Rectifier Testing 3-Jul-18 CP-SATR-X-3202karthi51289No ratings yet

- Saudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Document7 pagesSaudi Aramco Test Report: Internal Tank Bottom Testing 15-Jul-18 CP-SATR-X-3205Sreni Excel MacrosNo ratings yet

- Saudi Aramco Test Report: Plant Potential Survey Testing 24-Jul-18 CP-SATR-X-3203Document10 pagesSaudi Aramco Test Report: Plant Potential Survey Testing 24-Jul-18 CP-SATR-X-3203nadeem shaikhNo ratings yet

- Saudi Aramco Test Report: Internal Tank Bottom Testing 30-Oct-17 CP-SATR-X-3205Document8 pagesSaudi Aramco Test Report: Internal Tank Bottom Testing 30-Oct-17 CP-SATR-X-3205Tayyab AchakzaiNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 31-Mar-19 CPAwais NaeemNo ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 3-Jul-18 CPkarthi51289No ratings yet

- Saudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPDocument2 pagesSaudi Aramco Test Report: Galvanic CP Testing SATR-X-3101 24-Jul-18 CPnadeem shaikhNo ratings yet

- Saudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ElectDocument5 pagesSaudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 Electkarthi51289No ratings yet

- Satr-P-3218 Rev 3Document9 pagesSatr-P-3218 Rev 3Parag WadekarNo ratings yet

- Saudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 ElectDocument3 pagesSaudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test Report: DC Cable Holiday Testing 3-Jul-18 CP-SATR-X-3201Document3 pagesSaudi Aramco Test Report: DC Cable Holiday Testing 3-Jul-18 CP-SATR-X-3201karthi51289No ratings yet

- Satr-P-3219 Rev 3Document7 pagesSatr-P-3219 Rev 3Parag WadekarNo ratings yet

- Saudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Satr-P-3210 Rev 7 FinalDocument11 pagesSatr-P-3210 Rev 7 FinalzhangNo ratings yet

- Saudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116karthi51289No ratings yet

- Saudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test Report: UPS/DC Vented Ni-Cad Wet Cell, Jobsite Acceptance Test SATR-P-3102 ElectDocument7 pagesSaudi Aramco Test Report: UPS/DC Vented Ni-Cad Wet Cell, Jobsite Acceptance Test SATR-P-3102 ElectehteshamNo ratings yet

- Saudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingDocument9 pagesSaudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingehteshamNo ratings yet

- Satr-P-3220 Rev 3Document8 pagesSatr-P-3220 Rev 3Parag WadekarNo ratings yet

- Saudi Aramco Test Report: DC Cable Holiday Testing 24-Jul-18 CP-SATR-X-3201Document3 pagesSaudi Aramco Test Report: DC Cable Holiday Testing 24-Jul-18 CP-SATR-X-3201nadeem shaikhNo ratings yet

- Saudi Aramco Test Report: SATR-P-3117 3-Jul-18 Elect-DC Panelboards / CB'S, Pre-Commissioning & Functional TestingDocument6 pagesSaudi Aramco Test Report: SATR-P-3117 3-Jul-18 Elect-DC Panelboards / CB'S, Pre-Commissioning & Functional Testingkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument10 pagesSaudi Aramco Test Reportkarthi51289100% (1)

- Saudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116zhangNo ratings yet

- Saudi Aramco Test Report: SATR-P-3103 Elect-UPS/DC Vented Lead-Acid Wet Cell, Jobsite Acceptance TestDocument9 pagesSaudi Aramco Test Report: SATR-P-3103 Elect-UPS/DC Vented Lead-Acid Wet Cell, Jobsite Acceptance TestehteshamNo ratings yet

- Satr-P-3216 Rev 3Document4 pagesSatr-P-3216 Rev 3Parag WadekarNo ratings yet

- Saudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Document6 pagesSaudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Ma.socorro SaballaNo ratings yet

- Satr-P-3109 Rev 3Document13 pagesSatr-P-3109 Rev 3Parag WadekarNo ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Satr-P-3111 Rev 3Document3 pagesSatr-P-3111 Rev 3Parag WadekarNo ratings yet

- SATR-P-3417 Rev 7 FinalDocument6 pagesSATR-P-3417 Rev 7 FinalzhangNo ratings yet

- Satr-P-3206 LV Cable TerminationDocument5 pagesSatr-P-3206 LV Cable TerminationSurendren RNo ratings yet

- Saudi Aramco Test Report: SATR-P-3101 Elect-UPS/DC Electrochemical Battery, Storage and Preservation TestingDocument8 pagesSaudi Aramco Test Report: SATR-P-3101 Elect-UPS/DC Electrochemical Battery, Storage and Preservation TestingehteshamNo ratings yet

- A318 - A319 - A320 - A321 - ESPM - 01-Nov-2023 - 20-52-22-700-000-001 - Test For Short Circuit - Procedure (AIRBUS)Document7 pagesA318 - A319 - A320 - A321 - ESPM - 01-Nov-2023 - 20-52-22-700-000-001 - Test For Short Circuit - Procedure (AIRBUS)Dilshan PriyadharshanaNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: SATR-P-3205 30-Apr-13 Elect-Low Voltage Power and Control Cable, Termination Torque TestingDocument7 pagesSaudi Aramco Test Report: SATR-P-3205 30-Apr-13 Elect-Low Voltage Power and Control Cable, Termination Torque TestingzhangNo ratings yet

- SATR-P-3825 LV Panelboard - Pre-Energized TestingDocument4 pagesSATR-P-3825 LV Panelboard - Pre-Energized TestingheikelNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportMa.socorro SaballaNo ratings yet

- Saudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument12 pagesSaudi Aramco Test ReportehteshamNo ratings yet

- Satr-P-3208 Rev 8 FinalDocument7 pagesSatr-P-3208 Rev 8 FinalMohamed HaleemNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistmkalidas2006No ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistYehia FelifelNo ratings yet

- SAIC-W-2031 In-Process Welding Inspection of Hot TapDocument2 pagesSAIC-W-2031 In-Process Welding Inspection of Hot TapAnonymous S9qBDVkyNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- TWAD - Hdpe Certificate - 75231 Sudhakar 90mmDocument2 pagesTWAD - Hdpe Certificate - 75231 Sudhakar 90mmkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 InstDocument17 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 Instkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18Document5 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18karthi51289No ratings yet

- Taller de Ingles Ciclo VDocument3 pagesTaller de Ingles Ciclo VDayan Mauricio Lopez SNo ratings yet

- Name: Date: Animal Adaptations Test: Multiple Choice: Read All Questions and Answers. Select The BestDocument5 pagesName: Date: Animal Adaptations Test: Multiple Choice: Read All Questions and Answers. Select The Bestapi-532490346No ratings yet

- SST PRACTICE WORKSHEET-Grade 5Document4 pagesSST PRACTICE WORKSHEET-Grade 5rameshdorage12No ratings yet

- Dual-Band Panel Dual Polarized Antenna: Product Data Sheet For APX15G0-15D2-1Document4 pagesDual-Band Panel Dual Polarized Antenna: Product Data Sheet For APX15G0-15D2-1AlexeySPSNo ratings yet

- Attachment 7 (Geology Survey Form)Document11 pagesAttachment 7 (Geology Survey Form)Rhea CelzoNo ratings yet

- 2 - 03. Horas LuasDocument29 pages2 - 03. Horas LuasMohd Suffian YusoffNo ratings yet

- Ocean's Impact On Climate Activity Worksheet: Part OneDocument6 pagesOcean's Impact On Climate Activity Worksheet: Part OneColtonTvNo ratings yet

- Wind Load CalculationsDocument1 pageWind Load CalculationsPrayas SubediNo ratings yet

- Fast Recovery Diodes - Reverse Recovery Behaviour and Dynamic AvalancheDocument6 pagesFast Recovery Diodes - Reverse Recovery Behaviour and Dynamic AvalancheAna CicadaNo ratings yet

- A Review of Agricultural Drought Assessment With Remote Sensing Data: Methods, Issues, Challenges and OpportunitiesDocument14 pagesA Review of Agricultural Drought Assessment With Remote Sensing Data: Methods, Issues, Challenges and Opportunitiesاسامة نعمة جبارNo ratings yet

- General CirculationDocument63 pagesGeneral CirculationAdam Yustin AmanullahNo ratings yet

- JGB 6 4 65Document12 pagesJGB 6 4 65rohitNo ratings yet

- Venus - WikipediaDocument176 pagesVenus - WikipediaGOWTHAM NEMANINo ratings yet

- 5.0 Hydrology and Hydraulic Analyses 5Document181 pages5.0 Hydrology and Hydraulic Analyses 5Victor De los ReyesNo ratings yet

- Heat Stress ChartDocument3 pagesHeat Stress ChartCAP History Library100% (1)

- Solution: Excess Rain, inDocument2 pagesSolution: Excess Rain, inteshNo ratings yet

- Review of Permeable Pavement Systems in Malaysia ConditionsDocument10 pagesReview of Permeable Pavement Systems in Malaysia ConditionsEkki GustiNo ratings yet

- A Storm Is Brewing...Document2 pagesA Storm Is Brewing...María José SaldiviaNo ratings yet

- 英语口语关于天气Document31 pages英语口语关于天气SZE HANG MOUNo ratings yet

- Lecture4 - Fluvial Processes and LandformsDocument70 pagesLecture4 - Fluvial Processes and LandformsAniket KannoujiyaNo ratings yet

- S - 2.a Measurement of Distance, Angles, BearingsDocument13 pagesS - 2.a Measurement of Distance, Angles, BearingsqetNo ratings yet

- 8-3-Effects of Volcanic EruptionsDocument18 pages8-3-Effects of Volcanic EruptionsVijay KumarNo ratings yet

- CellMax Spec - CMA - BDHH - 6521 - E0-6 - A1Document1 pageCellMax Spec - CMA - BDHH - 6521 - E0-6 - A1mzamfirNo ratings yet

- Write A Story Beginning WithDocument2 pagesWrite A Story Beginning WithQiao XinNo ratings yet

- Nitrogen - Syngas 2017 London Pré-Conference WorkshopDocument8 pagesNitrogen - Syngas 2017 London Pré-Conference WorkshopRAMESHWAR VEDACHALAMNo ratings yet

- Oriental Abrasives Porbandar Electrical Safety Assessment ReportDocument48 pagesOriental Abrasives Porbandar Electrical Safety Assessment Reportbhavesh shettyNo ratings yet

- Emergency OpsDocument14 pagesEmergency OpsJomy JohnNo ratings yet

- Volcanic Hazards: Lava FlowDocument31 pagesVolcanic Hazards: Lava FlowMark ArceNo ratings yet

- Pyrenometer PDFDocument76 pagesPyrenometer PDFDhopesor hazarikaNo ratings yet