Professional Documents

Culture Documents

Slow Setting Bitumen Emulsion: Product Data Sheet

Slow Setting Bitumen Emulsion: Product Data Sheet

Uploaded by

mijanur rahmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Slow Setting Bitumen Emulsion: Product Data Sheet

Slow Setting Bitumen Emulsion: Product Data Sheet

Uploaded by

mijanur rahmanCopyright:

Available Formats

PRODUCT DATA SHEET

SLOW SETTING BITUMEN EMULSION

BITUMENA SS-1H (TACK COAT)

PACKING

BITUMENA SS-1h is an anionic asphalt emulsion

Bulk & 200 Kg. Drum.

which is recommended for use as an adhesion

promoter (tack-coat) between the two layers of

asphaltic concrete used in road construction.

STORAGE/SHELF LIFE

Store under normal warehouse conditions.

USES

Shelf life of the product is 12 months from the

date of manufacturing provided it is stored in

BITUMENA SS-1h is recommended for use as tack unopened factory packed drums.

coat between the two layers of asphaltic concrete

in road construction. CLEANING

STANDARD COMPLIANCE Tools may be cleaned with water as long as the

product is wet. Once dry, by mechanical

The product complies with the specification as per means only.

ASTM D 977 and AASHTO M140

TECHNICAL SERVICES

APPLICATION

Technical assistance and information is

For large projects, BITUMENA SS-1h is usually available by calling MENA ENERGY DMCC on

sprayed directly from the road tanker. The nozzle specific application.

size and speed of the tanker movement

determines the rate of spray. Usually the speed is

RECOMMENDED TEMPERATURES

adjusted in such a way that the spray rate remains

between 0.3 – 0.6 Kg/m2. The spray rate depends

TEMPERATURES MIN MAX

upon type of asphalt pavement

STORAGE 10⁰C 60⁰C

APPLICATION 10⁰C 55⁰C

DILUTION

Generally, the product is recommended for spray HEALTH AND SAFETY

with dilution with equal quantity of potable water

as per the project requirement or as Use normal safety precautions. Wear

recommended and accepted by the consultant. rubber hand gloves, safety shoes and safety

The water to be added to emulsion and not vice – goggles while using and handling the

versa. product. Avoid contact with skin and eyes.

In case of accidental contact with eyes,

wash with plenty of water and seek medical

treatment immediately.

PRODUCT DATA SHEET

SLOW SETTING BITUMEN EMULSION

BITUMENA SS-1H

TYPICAL PROPERTIES

CHARACTERISTICS TEST METHOD Unit MIN MAX

Saybolt Furol Viscosity @ 25⁰C ASTM D 88 Sec 20 100

Storage Stability Test, 24 hours ASTM D 6930 % - 1

Cement Mixing Test ASTM D 6935 % - 2

Sieve Test ASTM D6933 % - 0.1

Residue by Distillation ASTM D 6997 % 57

Test on residue from Distillation

Penetration @ 25⁰C (100gm) 5 sec. ASTM D 5 dmm 40 90

Ductility @ 25⁰C 5 cm/min ASTM D 113 cm 40

Solubility in Trichloroethylene ASTM D 2042 % 97.5

LEGAL NOTES: MENA ENERGY reserves the right to change or modify the data without prior notice. All reasonable care has been taken in compiling

the data that to the best of our knowledge and experience of the products when properly stored, handled and applied under normal conditions in

accordance with MENA ENERGY recommendations is accurate and true. All recommendations are made in good faith. No responsibility can be

accepted by us and no warranty is implied with regards to any recommendations made in this data sheet, since the conditions of actual use, method of

application and the labour involved are beyond our control.

MENA Energy DMCC, 34th Floor, Silver Tower, Jumeirah Lake Tower, Dubai, United Arab Emirates

Tel: +9714-435-3400 E-Mail: info@menaenergy.ae www.menaenergy.ae

TDS 105 Issued Date:01-01-2018

You might also like

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Microcontroller Based Digital Control - Dogan IbrahimDocument191 pagesMicrocontroller Based Digital Control - Dogan IbrahimMuuo WambuaNo ratings yet

- Fortress Square MallDocument5 pagesFortress Square MallUmair Hassan100% (3)

- Goldmix Iwa TdsDocument1 pageGoldmix Iwa TdsRafael Obusan IINo ratings yet

- Masterprotect 1813: Amine-Cured, Pitch Free EpoxyDocument2 pagesMasterprotect 1813: Amine-Cured, Pitch Free EpoxyGavriel Ng100% (1)

- Mafco - Cutback Medium Curing Mc-70: Production DescriptionDocument2 pagesMafco - Cutback Medium Curing Mc-70: Production Descriptionvelmurug_balaNo ratings yet

- Mea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaDocument2 pagesMea Polybit Tds Polybit Polygrout Ey 3000 PH en MeaMuhammad hussainNo ratings yet

- Goldmix SP 321: High Range Water Reducing SuperplasticiserDocument1 pageGoldmix SP 321: High Range Water Reducing SuperplasticiserRafael Obusan IINo ratings yet

- 06.19.2022 Mafco-Rapid Curing RC-50Document2 pages06.19.2022 Mafco-Rapid Curing RC-50Pangky AbasoloNo ratings yet

- Technical Details of Bonding ChemicalsDocument18 pagesTechnical Details of Bonding ChemicalsSangeet KarnaNo ratings yet

- Goldmix p108 TdsDocument1 pageGoldmix p108 TdsRafael Obusan IINo ratings yet

- Cement Properties and CharacteristicsDocument2 pagesCement Properties and CharacteristicsAnonymous XVEucVMsENo ratings yet

- Humiseal 1R32 Conformal Coating English TdsDocument2 pagesHumiseal 1R32 Conformal Coating English TdsLee HitchensNo ratings yet

- Fluidmatic Syn T668: Key DataDocument2 pagesFluidmatic Syn T668: Key Datazac.mechanicalNo ratings yet

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- HYGROSMART-PU-CEMENT-3K - v24 - 230925 - 150128Document5 pagesHYGROSMART-PU-CEMENT-3K - v24 - 230925 - 150128Ahmed DebchiNo ratings yet

- EMULSION TECHNICAL DATA SHEET (7 Revised 1212)Document1 pageEMULSION TECHNICAL DATA SHEET (7 Revised 1212)kabiru isahNo ratings yet

- En - Silcoset 151 TDS - 1Document1 pageEn - Silcoset 151 TDS - 1Андрей МошкинNo ratings yet

- Humiseal 1B31 English TdsDocument2 pagesHumiseal 1B31 English TdsLee HitchensNo ratings yet

- Humiseal 1A33 Conformal Coating English TdsDocument2 pagesHumiseal 1A33 Conformal Coating English TdsLee HitchensNo ratings yet

- Aquasmart Bitumen Emulsion-V2.0Document2 pagesAquasmart Bitumen Emulsion-V2.0Rubul AliNo ratings yet

- Molykote D 321R - BrochureDocument2 pagesMolykote D 321R - Brochuretaufik perdanaNo ratings yet

- General: Ultra UTTO Is Manufactured From Premium Quality Hydro-Treated Base Oils, Which Contain Lower LevelsDocument2 pagesGeneral: Ultra UTTO Is Manufactured From Premium Quality Hydro-Treated Base Oils, Which Contain Lower LevelsPaul GuillaumeNo ratings yet

- Rubia SX 30Document2 pagesRubia SX 30Renato FerreiraNo ratings yet

- 1eshacoat6s enDocument2 pages1eshacoat6s enAhmed TahsinNo ratings yet

- TOTAL QUARTZ 5000 SN 10W-40: Key DataDocument2 pagesTOTAL QUARTZ 5000 SN 10W-40: Key DataAdnanNo ratings yet

- Masterinject 1315 TdsDocument2 pagesMasterinject 1315 TdsMoatz HamedNo ratings yet

- Ceramic-Polymer 232 Spray Version - Ds - PDSDocument3 pagesCeramic-Polymer 232 Spray Version - Ds - PDSANIBALLOPEZVEGANo ratings yet

- TDS - Total - Rubia Fleet HD 100 10W 30 40 50 - TRV - 202011 - enDocument2 pagesTDS - Total - Rubia Fleet HD 100 10W 30 40 50 - TRV - 202011 - enAdnanNo ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Masterseal NP 472 (Brisk)Document2 pagesMasterseal NP 472 (Brisk)MumtazNo ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- Scotchkote: Fusion-Bonded Epoxy Coating 206N LGDocument1 pageScotchkote: Fusion-Bonded Epoxy Coating 206N LGSohail TisekarNo ratings yet

- PDS22 - MegaAdd LA - CCMAPDS04Ver50723Document2 pagesPDS22 - MegaAdd LA - CCMAPDS04Ver50723Alfred BulayaNo ratings yet

- Folheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01Document2 pagesFolheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01marcosNo ratings yet

- Masterseal 588: Description Packaging and ColorsDocument2 pagesMasterseal 588: Description Packaging and ColorsmariaNo ratings yet

- EpdmDocument2 pagesEpdmParashuram ChauhanNo ratings yet

- Hyperdesmo Polyurea 2K HCDocument3 pagesHyperdesmo Polyurea 2K HCmeena nachiyarNo ratings yet

- Mastermatrix SDC 100 TdsDocument3 pagesMastermatrix SDC 100 TdsGibaPeNo ratings yet

- Hyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane SealantDocument2 pagesHyperseal - Expert 60Fc: One Component Fast Curing, High Hardness, Chemical Resistant Polyurethane Sealantsasikumar durairajanNo ratings yet

- Dermaprimer: Product DescriptionDocument2 pagesDermaprimer: Product DescriptionSaud NawabNo ratings yet

- Hyspin Awv 32Document2 pagesHyspin Awv 32carmaNo ratings yet

- Tds CA 1000 Mastinox PPGDocument2 pagesTds CA 1000 Mastinox PPGAstari Putri NuarisaNo ratings yet

- Multiplant 10W30Document2 pagesMultiplant 10W30carmaNo ratings yet

- Aquasmart Hybrid PDFDocument3 pagesAquasmart Hybrid PDFmeena nachiyarNo ratings yet

- BitugardDocument2 pagesBitugardAhmad SamyNo ratings yet

- VT-201 All Purpose Sealant: Low Modulus Acetoxy Silicone SealantDocument2 pagesVT-201 All Purpose Sealant: Low Modulus Acetoxy Silicone SealantENGINEER MONIRUJJAMANNo ratings yet

- iKOTE AC 40 (DEC-2023) V1.3Document2 pagesiKOTE AC 40 (DEC-2023) V1.3nguyen hoang AnhNo ratings yet

- PETRONAS Syntium 800 10W-40 - Final - v2Document2 pagesPETRONAS Syntium 800 10W-40 - Final - v2rizal rizalNo ratings yet

- Alumanation-301 TDSDocument2 pagesAlumanation-301 TDSm.shaheerNo ratings yet

- Transmission Axle 7 80w 90 TDS v180903Document2 pagesTransmission Axle 7 80w 90 TDS v180903William RobertoNo ratings yet

- En - Silcoset 158 TDS - 1Document1 pageEn - Silcoset 158 TDS - 1Андрей МошкинNo ratings yet

- TOTAL QUARTZ 7000 SN 15W-50: Key DataDocument2 pagesTOTAL QUARTZ 7000 SN 15W-50: Key DataDouimni AyoubNo ratings yet

- Ultrasynt Atox 32 10785 Fds SP Es 6.0Document2 pagesUltrasynt Atox 32 10785 Fds SP Es 6.0Iker BasqueadventureNo ratings yet

- Aircol SN RangeDocument2 pagesAircol SN RangecarmaNo ratings yet

- Basf Masterglenium Sky 920 Tds PDFDocument4 pagesBasf Masterglenium Sky 920 Tds PDFvikasNo ratings yet

- TDS Total Rubia Fleet HD 300 15W40 enDocument2 pagesTDS Total Rubia Fleet HD 300 15W40 enthe anhNo ratings yet

- Intertherm 972: Product DescriptionDocument4 pagesIntertherm 972: Product DescriptionRohit RathiNo ratings yet

- Rubber Binder-M20-V2.0 0Document2 pagesRubber Binder-M20-V2.0 0recep kablanNo ratings yet

- Weberrep 360 FFR-KSA 01Document2 pagesWeberrep 360 FFR-KSA 01moizm53No ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Concrete Material: 5.1 GeneralDocument21 pagesConcrete Material: 5.1 Generalmijanur rahmanNo ratings yet

- Methodology For PBTDocument7 pagesMethodology For PBTmijanur rahmanNo ratings yet

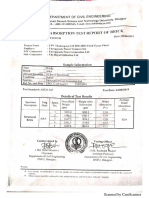

- 1x115 MW HFD FIRED POWER PLANT PROJECT Thakurgaon MS PC Pile2Document11 pages1x115 MW HFD FIRED POWER PLANT PROJECT Thakurgaon MS PC Pile2mijanur rahmanNo ratings yet

- Brick Test ReportDocument3 pagesBrick Test Reportmijanur rahman100% (1)

- Supply Chain Management: Junaid Jamshaid (J.)Document18 pagesSupply Chain Management: Junaid Jamshaid (J.)Mansoor ZainNo ratings yet

- Added Scenes For - Tattered FatesDocument19 pagesAdded Scenes For - Tattered FatesRadosław KwiecińskiNo ratings yet

- 5WG1527 1AB41 Siemens PDFDocument2 pages5WG1527 1AB41 Siemens PDFsamim_khNo ratings yet

- Manual Instr AnalysetteDocument63 pagesManual Instr AnalysettemarialuncanNo ratings yet

- Sunsigns NetDocument3 pagesSunsigns NetChester KuhlNo ratings yet

- 2021 Book SustainableLandManagementInAEuDocument344 pages2021 Book SustainableLandManagementInAEuEdson Ricardo Amaya SilvaNo ratings yet

- Cognitive Approaches To TranslationDocument10 pagesCognitive Approaches To TranslationKhali74No ratings yet

- FMT DFX WorkbookDocument25 pagesFMT DFX WorkbookSaurav SinghNo ratings yet

- HVAC Designing Drafting Estimation & InstallationDocument3 pagesHVAC Designing Drafting Estimation & Installationnoha azamali50% (2)

- ROCK Fill Specifiation & StandardsDocument17 pagesROCK Fill Specifiation & StandardsibrahimNo ratings yet

- Lesson Notes For Atoms and MoleculesDocument3 pagesLesson Notes For Atoms and MoleculesQurrat Ul AinNo ratings yet

- A LatheDocument3 pagesA LatheDReena JoyceNo ratings yet

- Per. Dev. Week 2Document21 pagesPer. Dev. Week 2Mi ChellNo ratings yet

- Davenport Blumenberg On HistoryDocument75 pagesDavenport Blumenberg On HistoryWillem OuweltjesNo ratings yet

- Form 0NE PDFDocument3 pagesForm 0NE PDFAlphonsius WongNo ratings yet

- Light Mild Brown Girl in Glasses Sales Brochuryye (Yyyyyyyyyyyy1)Document2 pagesLight Mild Brown Girl in Glasses Sales Brochuryye (Yyyyyyyyyyyy1)Althea KimNo ratings yet

- FRIGOMILK G9 From 2.000 LT To 30.000 LTDocument2 pagesFRIGOMILK G9 From 2.000 LT To 30.000 LTJorge PontonNo ratings yet

- Handicraft Production LMDocument82 pagesHandicraft Production LMmjcNo ratings yet

- Torr and Li 1993 Gravitoelectric-Electric CouplingDocument13 pagesTorr and Li 1993 Gravitoelectric-Electric Couplingjmulder1No ratings yet

- Ix-Biology - Target Paper 2024 - Homelander GroupDocument3 pagesIx-Biology - Target Paper 2024 - Homelander GroupTaroobaNo ratings yet

- Plum Concrete WallsDocument4 pagesPlum Concrete WallsnileshNo ratings yet

- Computational Fluid Dynamics Prof. Dr. Suman Chakraborty Department of Mechanical Engineering Indian Institute of Technology, KharagpurDocument18 pagesComputational Fluid Dynamics Prof. Dr. Suman Chakraborty Department of Mechanical Engineering Indian Institute of Technology, Kharagpurk krishna chaitanyaNo ratings yet

- Ground Floor Plan: Nitin SidhpuraDocument14 pagesGround Floor Plan: Nitin SidhpuraRam PatelNo ratings yet

- Analysis of Tennyson's Poem EagleDocument3 pagesAnalysis of Tennyson's Poem EagleRohana C. Fernando92% (13)

- Foundation LoadDocument2 pagesFoundation LoadmathuNo ratings yet

- Neptune in Pisces - Quietly Working To Destroy FearDocument3 pagesNeptune in Pisces - Quietly Working To Destroy FearReiki MasterNo ratings yet

- Ralph Menikoff and Thomas D Sewell - Constituent Properties of HMX Needed For Mesoscale SimulationsDocument23 pagesRalph Menikoff and Thomas D Sewell - Constituent Properties of HMX Needed For Mesoscale SimulationsKommissar1981No ratings yet

- Boxer Bm100Document69 pagesBoxer Bm100sanjika luckruwan100% (1)