Professional Documents

Culture Documents

Standard Specifications: Powered by

Standard Specifications: Powered by

Uploaded by

Augusto AraujoCopyright:

Available Formats

You might also like

- Boatowners Mechanical and Electrical Manual 4/EFrom EverandBoatowners Mechanical and Electrical Manual 4/ERating: 4.5 out of 5 stars4.5/5 (10)

- Boatowner's Mechanical and Electrical Manual: How to Maintain, Repair, and Improve Your Boat's Essential SystemsFrom EverandBoatowner's Mechanical and Electrical Manual: How to Maintain, Repair, and Improve Your Boat's Essential SystemsRating: 4.5 out of 5 stars4.5/5 (10)

- 4 Cylinder Tdi Engine 2 0 LTR 4 Valve Common Rail Generation IIDocument333 pages4 Cylinder Tdi Engine 2 0 LTR 4 Valve Common Rail Generation IIMilan Petrovic100% (3)

- Perkins 30 KVADocument4 pagesPerkins 30 KVAfirman harianjaNo ratings yet

- 1kz-Te Engine Sup. (Rm790e) PDFDocument284 pages1kz-Te Engine Sup. (Rm790e) PDFวัฒน์ ยอดแหลม100% (7)

- Rexroth A4VGDocument68 pagesRexroth A4VGÁgoston Imre50% (2)

- Ficha Técnica Engine Gas L7042GSI PDFDocument2 pagesFicha Técnica Engine Gas L7042GSI PDFCamilo Sanchez VanegasNo ratings yet

- Piston Check Valve: Installation, Operation & Maintenance ManualDocument12 pagesPiston Check Valve: Installation, Operation & Maintenance ManualJoseph Samir EshakNo ratings yet

- Nigeria's Gas and Gas-Liquid ReservesDocument31 pagesNigeria's Gas and Gas-Liquid ReservessiriuslotNo ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered bysaramagiNo ratings yet

- JP400Document2 pagesJP400Sirwan Mustafa (Albajalan)No ratings yet

- JP200 (1506)Document2 pagesJP200 (1506)Mohamed OsmanNo ratings yet

- JP12 5Document2 pagesJP12 5Ahmad KassemNo ratings yet

- Jp9 Lsac: Standard SpecificationsDocument2 pagesJp9 Lsac: Standard SpecificationssarahlawaNo ratings yet

- JP1000 (4008 30tag2)Document2 pagesJP1000 (4008 30tag2)aleenmalek2024No ratings yet

- JP150Document2 pagesJP150Maroun El-MansabNo ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered byወንዴ መካኒኩ ወንዴ አሰፉNo ratings yet

- Standard Specifications: Powered byDocument3 pagesStandard Specifications: Powered bysarahlawaNo ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered byKAMENo ratings yet

- JP1000Document2 pagesJP1000simeneh demelashNo ratings yet

- JL12 5Document2 pagesJL12 5Mohammad IsmailNo ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered byAhsan JavedNo ratings yet

- Standard Specifications: 1. EngineDocument2 pagesStandard Specifications: 1. EngineMaan MohammedNo ratings yet

- JP135 kVA TALDocument2 pagesJP135 kVA TALomarNo ratings yet

- Standard Specifications: 1. EngineDocument2 pagesStandard Specifications: 1. EngineMaan MohammedNo ratings yet

- SPS400TALDocument2 pagesSPS400TALbereketNo ratings yet

- JL17Document2 pagesJL17Mohammad IsmailNo ratings yet

- SPS350LSADocument2 pagesSPS350LSAbereketNo ratings yet

- Datasheet GrupoDocument2 pagesDatasheet GrupoRichard De La PeñaNo ratings yet

- DEPCO DC-501 1800rpm - 1622605917Document2 pagesDEPCO DC-501 1800rpm - 1622605917Gab MercadoNo ratings yet

- DC-850 60hzDocument2 pagesDC-850 60hzJunnie Alvin AgravanteNo ratings yet

- Depco Power Generator: Standard SpecificationsDocument2 pagesDepco Power Generator: Standard SpecificationsJohanna GironNo ratings yet

- Depco Power Generator: Standard SpecificationsDocument2 pagesDepco Power Generator: Standard SpecificationsRichard De La PeñaNo ratings yet

- DC-35 1800RPMDocument2 pagesDC-35 1800RPMJunnie Alvin AgravanteNo ratings yet

- Fawde GS50FLD Spec - Faw - 40 KWDocument2 pagesFawde GS50FLD Spec - Faw - 40 KWomar bejaranoNo ratings yet

- Depco Power DPK-DB-100Document2 pagesDepco Power DPK-DB-100Johanna GironNo ratings yet

- JD250Document2 pagesJD250Shahzad Ali100% (1)

- Fawde Gs33fld Spec - Faw - 26 KWDocument2 pagesFawde Gs33fld Spec - Faw - 26 KWPaul Cabello SalazarNo ratings yet

- MODEL: SC330 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDocument4 pagesMODEL: SC330 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDefly GustiNo ratings yet

- STG FPT 65kvaDocument2 pagesSTG FPT 65kvamohamadNo ratings yet

- SC315 60HZ Cummins Generator STAMFORDDocument4 pagesSC315 60HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- Cummins 125 KVADocument4 pagesCummins 125 KVAZein Ardha101No ratings yet

- SD46.5 50HZ Deutz GeneratorDocument4 pagesSD46.5 50HZ Deutz GeneratorsunshinemachineryNo ratings yet

- MODEL: SC388 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDocument4 pagesMODEL: SC388 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDefly GustiNo ratings yet

- Weber - WPS 500Document4 pagesWeber - WPS 500Express Backup54No ratings yet

- STG Perkins 135kvaDocument2 pagesSTG Perkins 135kvaromeo ramirez100% (1)

- Weber WVS 250Document4 pagesWeber WVS 250Express Backup54No ratings yet

- C2500 50HZ Cummins Generator STAMFORDDocument4 pagesC2500 50HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- 250kw 50HZ Cummins Marine GeneratorDocument3 pages250kw 50HZ Cummins Marine GeneratorChen Caroline100% (1)

- Standard Specifications: Alternator OptionsDocument2 pagesStandard Specifications: Alternator Optionssimeneh demelashNo ratings yet

- AMD Series: Mold DehumidifierDocument2 pagesAMD Series: Mold DehumidifierNATHANNo ratings yet

- C3000 50HZ Cummins Generator STAMFORDDocument4 pagesC3000 50HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- Design Specifications: 3 Phase, Diesel GeneratorsDocument1 pageDesign Specifications: 3 Phase, Diesel GeneratorsBayuNo ratings yet

- Gfs-30kw 50hz Yangdong GeneratorDocument4 pagesGfs-30kw 50hz Yangdong GeneratorChen CarolineNo ratings yet

- 650kva Open SetDocument1 page650kva Open SetBayuNo ratings yet

- SC500 G5 50HZ Cummins Generator STAMFORDDocument4 pagesSC500 G5 50HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- SC475 Cummins GeneratorDocument4 pagesSC475 Cummins GeneratorChen CarolineNo ratings yet

- Weber - WBS 1250Document4 pagesWeber - WBS 1250Express Backup54No ratings yet

- SC33 50HZ Cummins GeneratorDocument4 pagesSC33 50HZ Cummins GeneratorChen CarolineNo ratings yet

- MANEJADORA 10000 CFM - SubmittalDocument13 pagesMANEJADORA 10000 CFM - SubmittalJulio JumboNo ratings yet

- 490 24,2 KWM at 1500 RPMDocument1 page490 24,2 KWM at 1500 RPMautokrautuvasNo ratings yet

- 3054CNA Fire Spec SheetDocument2 pages3054CNA Fire Spec SheetdfheardNo ratings yet

- SMI1650 50HZ CHINA Mitsubishi GeneratorDocument4 pagesSMI1650 50HZ CHINA Mitsubishi GeneratorsunshinemachineryNo ratings yet

- Cummins 80 KVADocument4 pagesCummins 80 KVAcv.rapipratamaNo ratings yet

- SD80 50HZ Deutz GeneratorDocument4 pagesSD80 50HZ Deutz GeneratorsunshinemachineryNo ratings yet

- Sdo625 50hz Doosan GeneratorDocument4 pagesSdo625 50hz Doosan GeneratorsunshinemachineryNo ratings yet

- 6.1.5 - Well Control Worksheet & Pump DataDocument4 pages6.1.5 - Well Control Worksheet & Pump DatadagingoNo ratings yet

- Clio Bobine 4242ADocument7 pagesClio Bobine 4242APaul Bridges50% (2)

- PC3000 6 PDFDocument8 pagesPC3000 6 PDFDavyda VedaNo ratings yet

- NDV Supervisory Trades SyllabusDocument151 pagesNDV Supervisory Trades SyllabustulasiraoNo ratings yet

- Tango 125 Owner ManualDocument36 pagesTango 125 Owner ManualARTURO ALONSO GRACIANo ratings yet

- Final Report of Inplant Training ReviewDocument12 pagesFinal Report of Inplant Training Reviewbalakvit100% (2)

- Somar Integra Executive Summary.r2Document3 pagesSomar Integra Executive Summary.r2vanessa_corneliaNo ratings yet

- 7 CNH Round One Technical SessionsDocument35 pages7 CNH Round One Technical SessionsMónica AquinoNo ratings yet

- Ic EnginesDocument85 pagesIc Enginessupertpm127No ratings yet

- Manual Motor Perkins PDFDocument8 pagesManual Motor Perkins PDFRobertoSoares0% (1)

- Lureye SDMO T22KDocument4 pagesLureye SDMO T22KLuis Leiva Sanchez100% (1)

- Introduction To VR HCR by GS Caltex Corporation PDFDocument26 pagesIntroduction To VR HCR by GS Caltex Corporation PDFRey100% (2)

- Equipment List and Type - Engine and Part of Accommodation Exhaust FanDocument30 pagesEquipment List and Type - Engine and Part of Accommodation Exhaust FanAli Ferhat BoyrazNo ratings yet

- Periodic MaintenanceDocument58 pagesPeriodic MaintenanceSergioNo ratings yet

- Engine Repair Fundamentals Self Study PDFDocument94 pagesEngine Repair Fundamentals Self Study PDFduongbk24 luu quang duong100% (1)

- Analysis Oil Hand Book For Motor PDFDocument106 pagesAnalysis Oil Hand Book For Motor PDFDonald VasquezNo ratings yet

- Bull Gear InstallationDocument9 pagesBull Gear InstallationKikin HermantoNo ratings yet

- Lesson Plan TaiDocument4 pagesLesson Plan TaiKen Ubit Nurul SNo ratings yet

- Application of Technology ForDocument27 pagesApplication of Technology ForHotib PerwiraNo ratings yet

- Compressor QuestionDocument3 pagesCompressor QuestionnellaiNo ratings yet

- Supply Chain For A Petroleum Industry Refinery Downstream-Dissertation AcDocument78 pagesSupply Chain For A Petroleum Industry Refinery Downstream-Dissertation AcHeisenberg100% (4)

- Compression Ratio Effects On Performance, Efficiency, Emissions and Combustion in A Carbureted and PFI Small EngineDocument16 pagesCompression Ratio Effects On Performance, Efficiency, Emissions and Combustion in A Carbureted and PFI Small EngineAbdurahman MuhammadNo ratings yet

- Ian Palmer HTDocument33 pagesIan Palmer HTtassili17No ratings yet

- Seminar On GDI (Gasoline Direct Injection) 97-03 FinalDocument12 pagesSeminar On GDI (Gasoline Direct Injection) 97-03 FinalHarshadNaik75% (4)

Standard Specifications: Powered by

Standard Specifications: Powered by

Uploaded by

Augusto AraujoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Specifications: Powered by

Standard Specifications: Powered by

Uploaded by

Augusto AraujoCopyright:

Available Formats

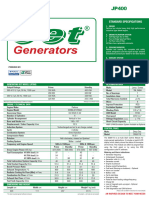

JP250

STANDARD SPECIFICATIONS

1. ENGINE

Perkins four stroke heavy duty high performance

industrial type diesel engine.

2. ENGINE FILTRATION SYSTEM

• Cartridge type dry air filter.

• Cartridge type fuel filter.

• Full flow lube oil filter.

• Water filter.

All filters have replaceable elements.

3. COOLING RADIATOR

Radiator and cooling fan, complete with safety

guards, designed to cool the engine at high ambient

temperatures (consult your dealer for de-ration factors)

4. EXHAUST SYSTEM

Heavy duty Industrial Exhaust Silencer

Silencer noise reduction level 12 (dB)

Maximum allowable back pressure 10 (kPa)

POWERED BY:

5. CIRCUIT BREAKER TYPE

ABB 3 pole MCCB. (4 pole is optional)

(contd.)

Generating Set pictured may include optional accessories

ALTERNATOR DATA

GENERATING SET MODEL (JP250) Make Leroy Somer

Output Ratings Prime Standby Model LSA46.2L6

400 V, 3 ph, 50 Hz, 1500 rpm 250 KVA 275 KVA No. of bearings 1

200 KW 220 KW Insulation class H

Ratings at 0.8 Power Factor Total Harmonic Content <2.5%

ENGINE / TECHNICAL DATA Wires 12

Engine Make Perkins Ingress Protection IP23

Engine Model 1506A-E88TAG3 Excitation System SHUNT

Governing Type Electronic Winding Pitch 2/3 (n° 6)

Number of Cylinders 6 AVR Model R250

Cylinder Arrangement Vertical in line Overspeed 2250 mn-1

Bore and Stroke mm 112 x 149 Voltage Regulation (steady) ± 0.5%

Displacement / Cubic Capacity litres 8.8 Short Circuit Capacity -

Induction System Turbocharged, air to air charge cooled AREP & PMG Excitation System Available as Optional.

Cycle 4 stroke

CONTROL PANEL

Combustion System Direct Injection

Make Deep Sea

Compression Ratio 16.1:1

Model DSE6110

Rotation Anti-clockwise, viewed on flywheel

The DSE6110 is an Auto Start Control Module for

Cooling System Water - cooled

single genset applications. It includes a backlit LCD

Frequency and Engine Speed 50Hz & 1500rpm display which clearly shows the status of the engine

Prime Standby all the times. This module can either be programmed

Gross Engine Power kW 236 258 using the front panel or by using the DSE

Fuel Consumption @ 50% load L/hr 28.9 - configuration suite PC software.

@ 75% load L/hr 41.6 - Metering and Alarm indications:

• Generator frequency

@ 100% load L/hr 55.5 60.7

• Underspeed, Overspeed

Total Lubrication System Capacity litres 41 41 • Generator volts (L-L, L-N)

Total Coolant Capacity litres 29.6 29.6 • Generator current

Boost Pressure Ratio 2.8 3.0 • Engine oil pressure

• Engine coolant temperature

Exhaust Temperature: °C 537 558

• Fuel level (Warning or shutdown) - Optional

Radiator Cooling Air Flow (Min): m3/sec 6.16 6.16 • Hours run counter

Combustion Air Flow: m3/min 14.1 15.0 • Battery volts

Exhaust Gas Flow: m3/min 37.5 40.4 • Fail to start/stop

• Emergency stop

Fuel Tank Capacity: litres 360 360 • Failed to reach loading voltage/frequency

• Charge fail

DIMENSIONS AND WEIGHT • Loss of magnetic pick-up signal - Optional

Length cm Width cm Height cm Weight* kg (wet) • Low DC voltage

• CAN diagnostics and CAN fail/error

290 99 183 2252 (Please refer to DSE6110 brochure for more details)

* For skid mounted genset without enclosure wet weight = with lube oil and coolant AN INSPIRED DESIGN TO MEET YOUR NEEDS

JP250

AN INSPIRED DESIGN TO MEET YOUR NEEDS

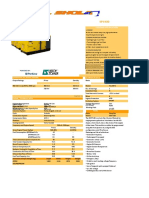

STANDARD SPECIFICATIONS

6. FUEL SYSTEM

On Generating Sets up to 700 KVA, the baseframe

design is incorporated with an integral fuel tank with

a capacity of approx. 8 hours running at Full Load.

The tank is supplied complete with fill cap breather,

fuel feed and return lines to the Engine and drain

plug.

7. ALTERNATOR

7.1 INSULATION SYSTEM

• The insulation system is Class H.

• All windings are impregnated in either a triple dip

thermosetting liquid, oil and acid resisting polyester

varnish or vacuum pressure impregnated with a

special polyester resin.

• Heavy coat of antitracking varnish additional

protection against moisture or condensation.

7.2 AUTOMATIC VOLTAGE REGULATOR (AVR)

The fully sealed Automatic Voltage Regulator

maintains the Voltage Regulation at ±0.5%. Nominal

adjustment by means of a trim pot incorporated on

the AVR.

7.3 MOTOR STARTING

Generating Set pictured may include optional accessories An overload capacity equivalent to 300% of the Full

Load impedance at zero Power Factor can be

sustained for 10 seconds, when AREP or PMG option

RATINGS DEFINITION is fitted.

Prime Power 8. MOUNTING ARRANGEMENT

These ratings are applicable for supplying continuous electrical power (at variable load) in lieu of 8.1 BASE FRAME

commercially purchased power. 10% overload power is available for 1 hour in 12 hours continuous The complete Generating Set is mounted as a whole

operation. on a heavy duty fabricated steel Baseframe.

Standby Power 8.2 COUPLING

These ratings are applicable for supplying continuous electrical power (at variable load) in the event of a The Engine and Alternator are directly coupled by

utility power failure. No overload is permitted on these ratings. means of an SAE flange. The Engine flywheel is

flexibly coupled to the Alternator rotor.

STANDARD REFERENCE CONDITIONS 8.3 ANTI-VIBRATION MOUNTING PADS

Anti-Vibration pads are affixed between the Engine /

Output ratings are presented at 25°C air inlet temperature, barometric pressure 100 kPa, relative humidity Alternator feet and the Baseframe thus ensuring

30%. This generating set is designed to operate at high ambient temperatures (up to 55°C), humidity (up to complete vibration isolation of the rotating assembly.

99%) and higher altitudes. De-ration may apply, please consult your dealer for specific site ratings.

8.4 SAFETY GUARDS

Some of the specifications are not standard on all Genset models. The Fan & Fan Drive along with the Battery Charging

Alternator are Safety Guard protected for personnel

AVAILABLE OPTIONS & ACCESSORIES protection.

We offer a range of optional features and accessories to tailor our generating sets to meet your power needs. 9. FACTORY TESTS

• The Generating set is load tested before dispatch

OPTIONS ACCESSORIES • All protective devices control functions and site

• A variety of generating set control and synchronizing panels • Genuine spare parts load conditions are simulated. The generator and it’s

systems are checked before dispatch.

• Additional protection alarms and shutdowns • Load banks

• Water fuel seperator • Auxiliary fuel tanks 10. EQUIPMENT FINISHING

• Water jacket heater • Manual & automatic transfer All mild steel components are fully degreased and

painted with powder coated paint to ensure

• Battery charger switches

maximum scuff resistance and durability.

11. DOCUMENTATIONS

Operation & Maintenance manual, Circuit wiring

diagrams and Commissioning / Fault Finding instruction

Distributed and Serviced by: leaflets are accompanied with the Generator.

12. QUALITY STANDARDS

The equipment meets the following standards:

BS4999, BS5000, BS5514 IEC 60034, VDE0530,

NEMA MG 1.22 and ISO 8528.

For further information on all of the standard and optional features accompanying this product please

13. WARRANTY

contact your local dealer or visit www.JubailiBros.com All of the Generating Sets are covered under a

warranty policy for a period of 12 months. Warranty

of the equipment is in line with manufacturers

warranty terms & conditions.

JET Generators are assembled All information in this document is substantially correct (check warranty statement for more details, as it may vary for different countries)

in facilities certified to ISO 9001 at time of printing and may be altered subsequently.

ISO 9001: 2008

In line with continuous product development, we reserve the

FM 56710 right to change specifications without notice.

0410/2016

You might also like

- Boatowners Mechanical and Electrical Manual 4/EFrom EverandBoatowners Mechanical and Electrical Manual 4/ERating: 4.5 out of 5 stars4.5/5 (10)

- Boatowner's Mechanical and Electrical Manual: How to Maintain, Repair, and Improve Your Boat's Essential SystemsFrom EverandBoatowner's Mechanical and Electrical Manual: How to Maintain, Repair, and Improve Your Boat's Essential SystemsRating: 4.5 out of 5 stars4.5/5 (10)

- 4 Cylinder Tdi Engine 2 0 LTR 4 Valve Common Rail Generation IIDocument333 pages4 Cylinder Tdi Engine 2 0 LTR 4 Valve Common Rail Generation IIMilan Petrovic100% (3)

- Perkins 30 KVADocument4 pagesPerkins 30 KVAfirman harianjaNo ratings yet

- 1kz-Te Engine Sup. (Rm790e) PDFDocument284 pages1kz-Te Engine Sup. (Rm790e) PDFวัฒน์ ยอดแหลม100% (7)

- Rexroth A4VGDocument68 pagesRexroth A4VGÁgoston Imre50% (2)

- Ficha Técnica Engine Gas L7042GSI PDFDocument2 pagesFicha Técnica Engine Gas L7042GSI PDFCamilo Sanchez VanegasNo ratings yet

- Piston Check Valve: Installation, Operation & Maintenance ManualDocument12 pagesPiston Check Valve: Installation, Operation & Maintenance ManualJoseph Samir EshakNo ratings yet

- Nigeria's Gas and Gas-Liquid ReservesDocument31 pagesNigeria's Gas and Gas-Liquid ReservessiriuslotNo ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered bysaramagiNo ratings yet

- JP400Document2 pagesJP400Sirwan Mustafa (Albajalan)No ratings yet

- JP200 (1506)Document2 pagesJP200 (1506)Mohamed OsmanNo ratings yet

- JP12 5Document2 pagesJP12 5Ahmad KassemNo ratings yet

- Jp9 Lsac: Standard SpecificationsDocument2 pagesJp9 Lsac: Standard SpecificationssarahlawaNo ratings yet

- JP1000 (4008 30tag2)Document2 pagesJP1000 (4008 30tag2)aleenmalek2024No ratings yet

- JP150Document2 pagesJP150Maroun El-MansabNo ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered byወንዴ መካኒኩ ወንዴ አሰፉNo ratings yet

- Standard Specifications: Powered byDocument3 pagesStandard Specifications: Powered bysarahlawaNo ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered byKAMENo ratings yet

- JP1000Document2 pagesJP1000simeneh demelashNo ratings yet

- JL12 5Document2 pagesJL12 5Mohammad IsmailNo ratings yet

- Standard Specifications: Powered byDocument2 pagesStandard Specifications: Powered byAhsan JavedNo ratings yet

- Standard Specifications: 1. EngineDocument2 pagesStandard Specifications: 1. EngineMaan MohammedNo ratings yet

- JP135 kVA TALDocument2 pagesJP135 kVA TALomarNo ratings yet

- Standard Specifications: 1. EngineDocument2 pagesStandard Specifications: 1. EngineMaan MohammedNo ratings yet

- SPS400TALDocument2 pagesSPS400TALbereketNo ratings yet

- JL17Document2 pagesJL17Mohammad IsmailNo ratings yet

- SPS350LSADocument2 pagesSPS350LSAbereketNo ratings yet

- Datasheet GrupoDocument2 pagesDatasheet GrupoRichard De La PeñaNo ratings yet

- DEPCO DC-501 1800rpm - 1622605917Document2 pagesDEPCO DC-501 1800rpm - 1622605917Gab MercadoNo ratings yet

- DC-850 60hzDocument2 pagesDC-850 60hzJunnie Alvin AgravanteNo ratings yet

- Depco Power Generator: Standard SpecificationsDocument2 pagesDepco Power Generator: Standard SpecificationsJohanna GironNo ratings yet

- Depco Power Generator: Standard SpecificationsDocument2 pagesDepco Power Generator: Standard SpecificationsRichard De La PeñaNo ratings yet

- DC-35 1800RPMDocument2 pagesDC-35 1800RPMJunnie Alvin AgravanteNo ratings yet

- Fawde GS50FLD Spec - Faw - 40 KWDocument2 pagesFawde GS50FLD Spec - Faw - 40 KWomar bejaranoNo ratings yet

- Depco Power DPK-DB-100Document2 pagesDepco Power DPK-DB-100Johanna GironNo ratings yet

- JD250Document2 pagesJD250Shahzad Ali100% (1)

- Fawde Gs33fld Spec - Faw - 26 KWDocument2 pagesFawde Gs33fld Spec - Faw - 26 KWPaul Cabello SalazarNo ratings yet

- MODEL: SC330 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDocument4 pagesMODEL: SC330 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDefly GustiNo ratings yet

- STG FPT 65kvaDocument2 pagesSTG FPT 65kvamohamadNo ratings yet

- SC315 60HZ Cummins Generator STAMFORDDocument4 pagesSC315 60HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- Cummins 125 KVADocument4 pagesCummins 125 KVAZein Ardha101No ratings yet

- SD46.5 50HZ Deutz GeneratorDocument4 pagesSD46.5 50HZ Deutz GeneratorsunshinemachineryNo ratings yet

- MODEL: SC388 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDocument4 pagesMODEL: SC388 Industrial Range Powered by Cummins: Diesel Generating Set 400/230 V - 50 HZ - 3phaseDefly GustiNo ratings yet

- Weber - WPS 500Document4 pagesWeber - WPS 500Express Backup54No ratings yet

- STG Perkins 135kvaDocument2 pagesSTG Perkins 135kvaromeo ramirez100% (1)

- Weber WVS 250Document4 pagesWeber WVS 250Express Backup54No ratings yet

- C2500 50HZ Cummins Generator STAMFORDDocument4 pagesC2500 50HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- 250kw 50HZ Cummins Marine GeneratorDocument3 pages250kw 50HZ Cummins Marine GeneratorChen Caroline100% (1)

- Standard Specifications: Alternator OptionsDocument2 pagesStandard Specifications: Alternator Optionssimeneh demelashNo ratings yet

- AMD Series: Mold DehumidifierDocument2 pagesAMD Series: Mold DehumidifierNATHANNo ratings yet

- C3000 50HZ Cummins Generator STAMFORDDocument4 pagesC3000 50HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- Design Specifications: 3 Phase, Diesel GeneratorsDocument1 pageDesign Specifications: 3 Phase, Diesel GeneratorsBayuNo ratings yet

- Gfs-30kw 50hz Yangdong GeneratorDocument4 pagesGfs-30kw 50hz Yangdong GeneratorChen CarolineNo ratings yet

- 650kva Open SetDocument1 page650kva Open SetBayuNo ratings yet

- SC500 G5 50HZ Cummins Generator STAMFORDDocument4 pagesSC500 G5 50HZ Cummins Generator STAMFORDChen CarolineNo ratings yet

- SC475 Cummins GeneratorDocument4 pagesSC475 Cummins GeneratorChen CarolineNo ratings yet

- Weber - WBS 1250Document4 pagesWeber - WBS 1250Express Backup54No ratings yet

- SC33 50HZ Cummins GeneratorDocument4 pagesSC33 50HZ Cummins GeneratorChen CarolineNo ratings yet

- MANEJADORA 10000 CFM - SubmittalDocument13 pagesMANEJADORA 10000 CFM - SubmittalJulio JumboNo ratings yet

- 490 24,2 KWM at 1500 RPMDocument1 page490 24,2 KWM at 1500 RPMautokrautuvasNo ratings yet

- 3054CNA Fire Spec SheetDocument2 pages3054CNA Fire Spec SheetdfheardNo ratings yet

- SMI1650 50HZ CHINA Mitsubishi GeneratorDocument4 pagesSMI1650 50HZ CHINA Mitsubishi GeneratorsunshinemachineryNo ratings yet

- Cummins 80 KVADocument4 pagesCummins 80 KVAcv.rapipratamaNo ratings yet

- SD80 50HZ Deutz GeneratorDocument4 pagesSD80 50HZ Deutz GeneratorsunshinemachineryNo ratings yet

- Sdo625 50hz Doosan GeneratorDocument4 pagesSdo625 50hz Doosan GeneratorsunshinemachineryNo ratings yet

- 6.1.5 - Well Control Worksheet & Pump DataDocument4 pages6.1.5 - Well Control Worksheet & Pump DatadagingoNo ratings yet

- Clio Bobine 4242ADocument7 pagesClio Bobine 4242APaul Bridges50% (2)

- PC3000 6 PDFDocument8 pagesPC3000 6 PDFDavyda VedaNo ratings yet

- NDV Supervisory Trades SyllabusDocument151 pagesNDV Supervisory Trades SyllabustulasiraoNo ratings yet

- Tango 125 Owner ManualDocument36 pagesTango 125 Owner ManualARTURO ALONSO GRACIANo ratings yet

- Final Report of Inplant Training ReviewDocument12 pagesFinal Report of Inplant Training Reviewbalakvit100% (2)

- Somar Integra Executive Summary.r2Document3 pagesSomar Integra Executive Summary.r2vanessa_corneliaNo ratings yet

- 7 CNH Round One Technical SessionsDocument35 pages7 CNH Round One Technical SessionsMónica AquinoNo ratings yet

- Ic EnginesDocument85 pagesIc Enginessupertpm127No ratings yet

- Manual Motor Perkins PDFDocument8 pagesManual Motor Perkins PDFRobertoSoares0% (1)

- Lureye SDMO T22KDocument4 pagesLureye SDMO T22KLuis Leiva Sanchez100% (1)

- Introduction To VR HCR by GS Caltex Corporation PDFDocument26 pagesIntroduction To VR HCR by GS Caltex Corporation PDFRey100% (2)

- Equipment List and Type - Engine and Part of Accommodation Exhaust FanDocument30 pagesEquipment List and Type - Engine and Part of Accommodation Exhaust FanAli Ferhat BoyrazNo ratings yet

- Periodic MaintenanceDocument58 pagesPeriodic MaintenanceSergioNo ratings yet

- Engine Repair Fundamentals Self Study PDFDocument94 pagesEngine Repair Fundamentals Self Study PDFduongbk24 luu quang duong100% (1)

- Analysis Oil Hand Book For Motor PDFDocument106 pagesAnalysis Oil Hand Book For Motor PDFDonald VasquezNo ratings yet

- Bull Gear InstallationDocument9 pagesBull Gear InstallationKikin HermantoNo ratings yet

- Lesson Plan TaiDocument4 pagesLesson Plan TaiKen Ubit Nurul SNo ratings yet

- Application of Technology ForDocument27 pagesApplication of Technology ForHotib PerwiraNo ratings yet

- Compressor QuestionDocument3 pagesCompressor QuestionnellaiNo ratings yet

- Supply Chain For A Petroleum Industry Refinery Downstream-Dissertation AcDocument78 pagesSupply Chain For A Petroleum Industry Refinery Downstream-Dissertation AcHeisenberg100% (4)

- Compression Ratio Effects On Performance, Efficiency, Emissions and Combustion in A Carbureted and PFI Small EngineDocument16 pagesCompression Ratio Effects On Performance, Efficiency, Emissions and Combustion in A Carbureted and PFI Small EngineAbdurahman MuhammadNo ratings yet

- Ian Palmer HTDocument33 pagesIan Palmer HTtassili17No ratings yet

- Seminar On GDI (Gasoline Direct Injection) 97-03 FinalDocument12 pagesSeminar On GDI (Gasoline Direct Injection) 97-03 FinalHarshadNaik75% (4)